A zonal turning and drying equipment for plastic granules after cleaning

A technology for plastic granules and drying equipment, which is applied in drying, dryers, lighting and heating equipment, etc., and can solve the problem of uneven drying of granules, uneven drying of plastic granules, and difficulty in drying the bottom of the drying equipment. Dry effect and other issues, to achieve the effect of easy and uniform removal, easy air circulation, and expanded range of activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

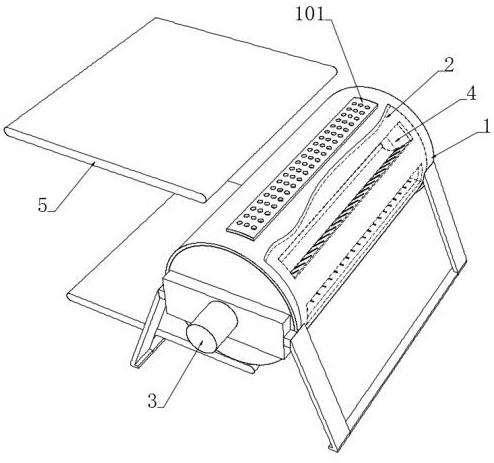

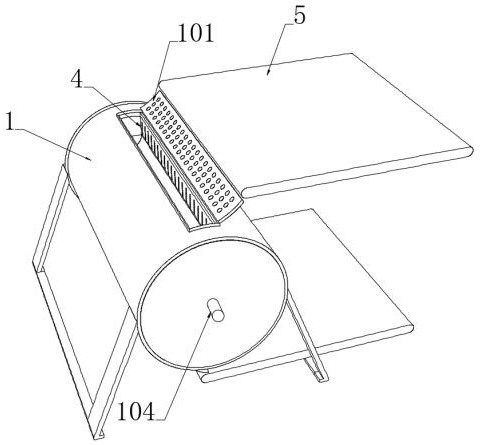

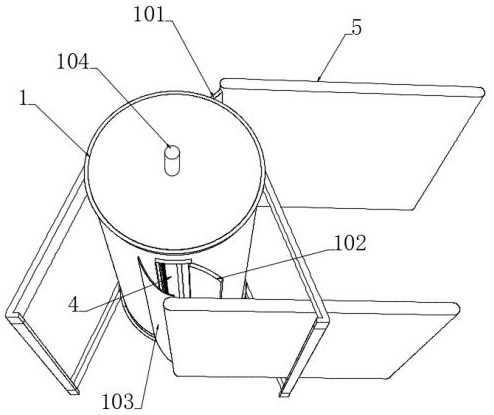

Embodiment 1

[0046] see Figure 1-5 , a partitioned turning and drying equipment for plastic particles after cleaning, including an inner rotating cylinder 2 and an outer positioning cylinder 1 which are sleeved with internal and external activities, and a motor for driving the inner rotating cylinder 2 is installed on the outer wall of one end of the outer positioning cylinder 1 3. The end of the outer positioning cylinder 1 away from the motor 3 is provided with an air intake pipe 104, and the outer wall of the inner rotating cylinder 2 is provided with a plurality of hollow cavities, and each hollow cavity is fixedly equipped with a drying bucket 4, and the drying bucket 4 includes mutual The connected positioning bucket 401 and the deformation bucket 402 have a plurality of drainage holes 4011 on the walls of the left and right ends of the positioning bucket 401. The end extends to the inner side of the inner rotating cylinder 2, and the upper and lower ends of the outer positioning cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com