Wire binding structure and wire binding method for hybrid rail car

A vehicle-used, wire-tying technology, applied in the connection/disconnection of connection devices, electrical components, circuits, etc., to achieve good promotion and application value, solve crimping problems, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

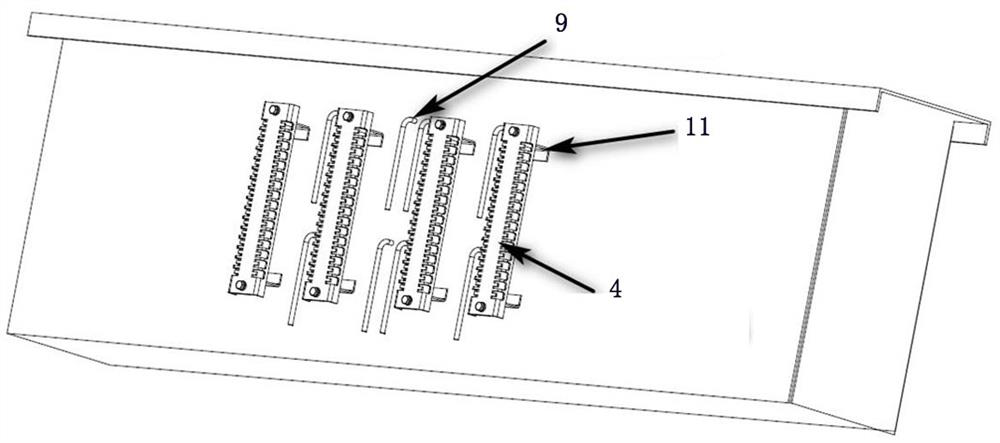

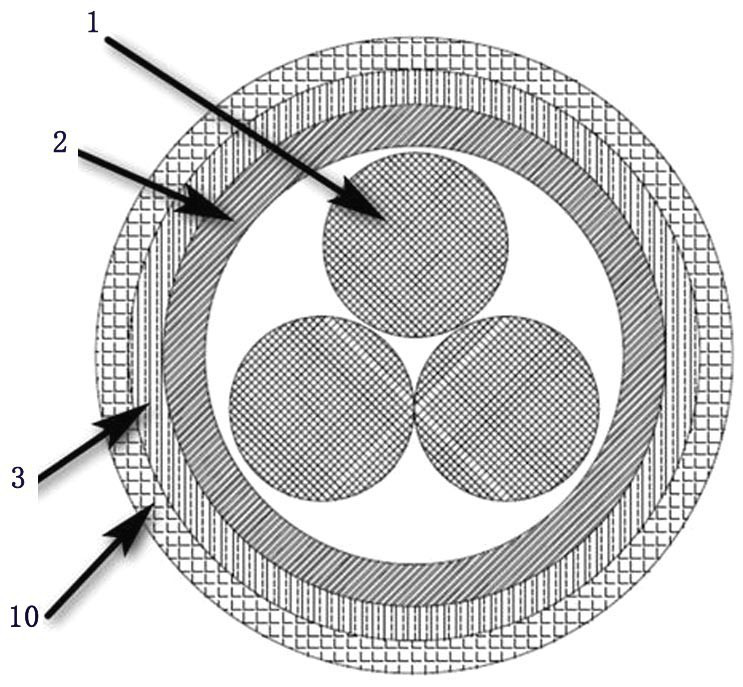

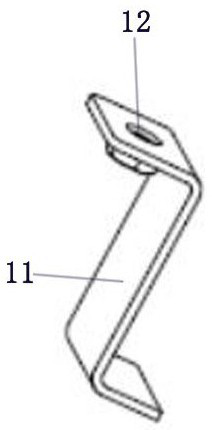

[0016] A cable tie structure for a hybrid rail car, including a connector and a cable frame; the connector includes a conductive sleeve 2 for crimping the multi-strand cable 1 after the branch line, and a conductive sleeve fixed to the conductive sleeve 2 during use. The insulating sleeve 3; the cable tie frame includes a strip-shaped channel steel 4 composed of vertical plates on both sides and a top plate in the middle, and a plurality of one-to-one corresponding first threading plates are respectively opened on the vertical plates on both sides of the channel steel 4 Holes 5 and the second threading hole 6 (one side vertical plate of channel steel 4 has a plurality of first threading holes 5, and the other side vertical plate of channel steel 4 has a plurality of second threading holes 6, The first threading hole 5 corresponds to the second threading hole 6), when in use, the connector passes through the first threading hole 5 and the second threading hole 6 in sequence, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com