Permanent extrusion type pipe joint crimping tool

A technology for crimping tools and pipe joints, which is applied in the field of permanent extrusion pipe joint crimping tools to achieve the effect of easy use and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

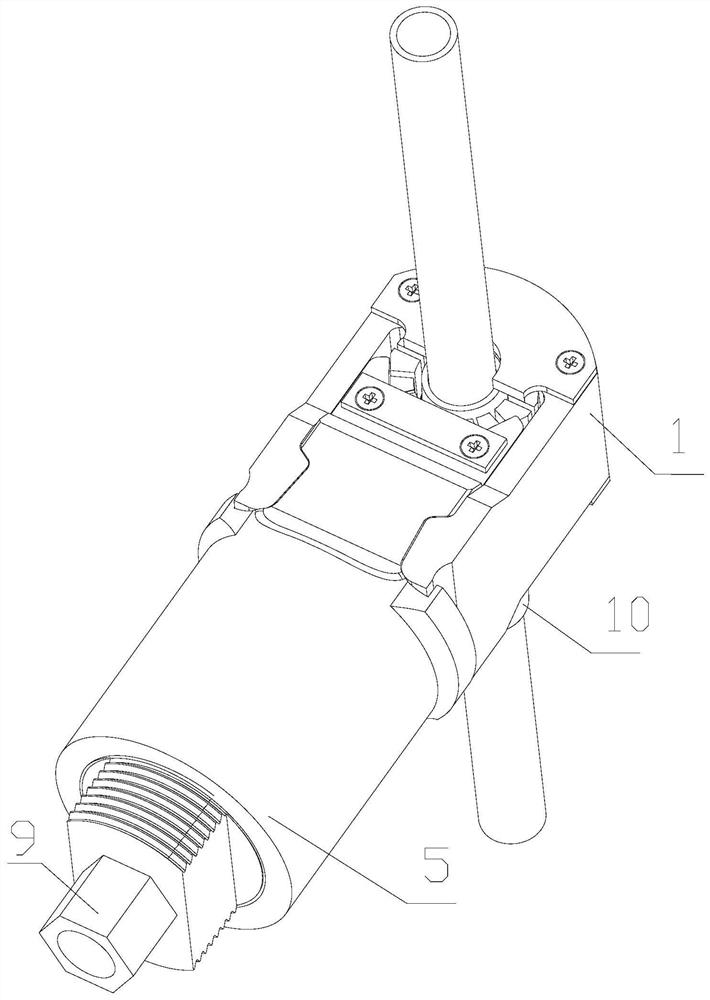

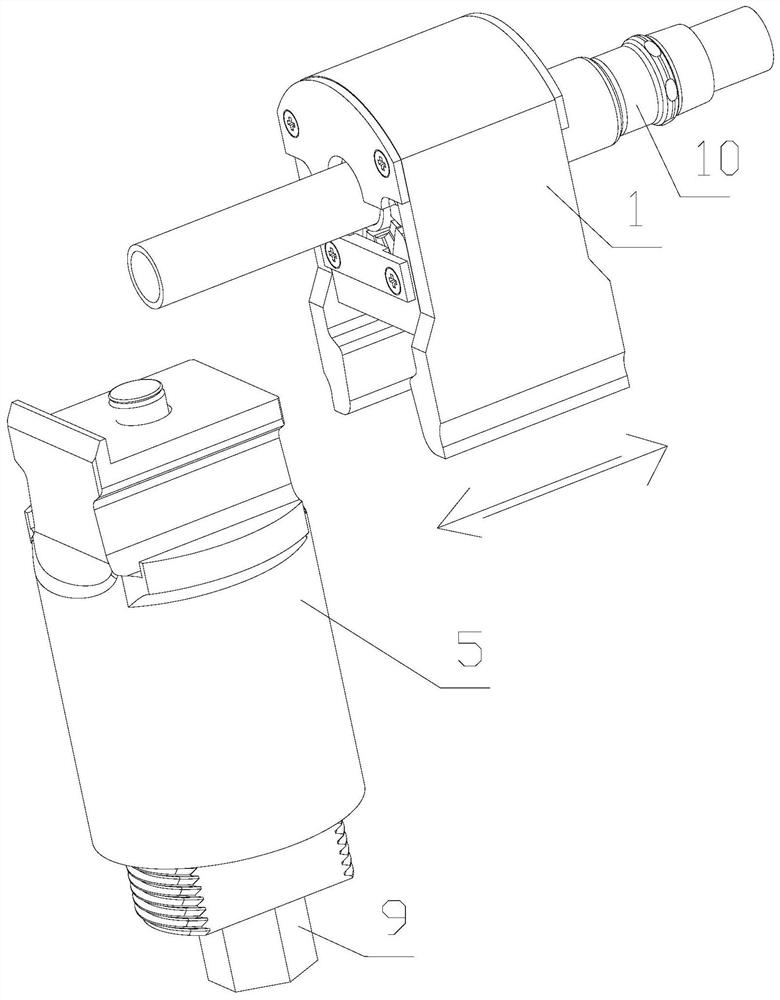

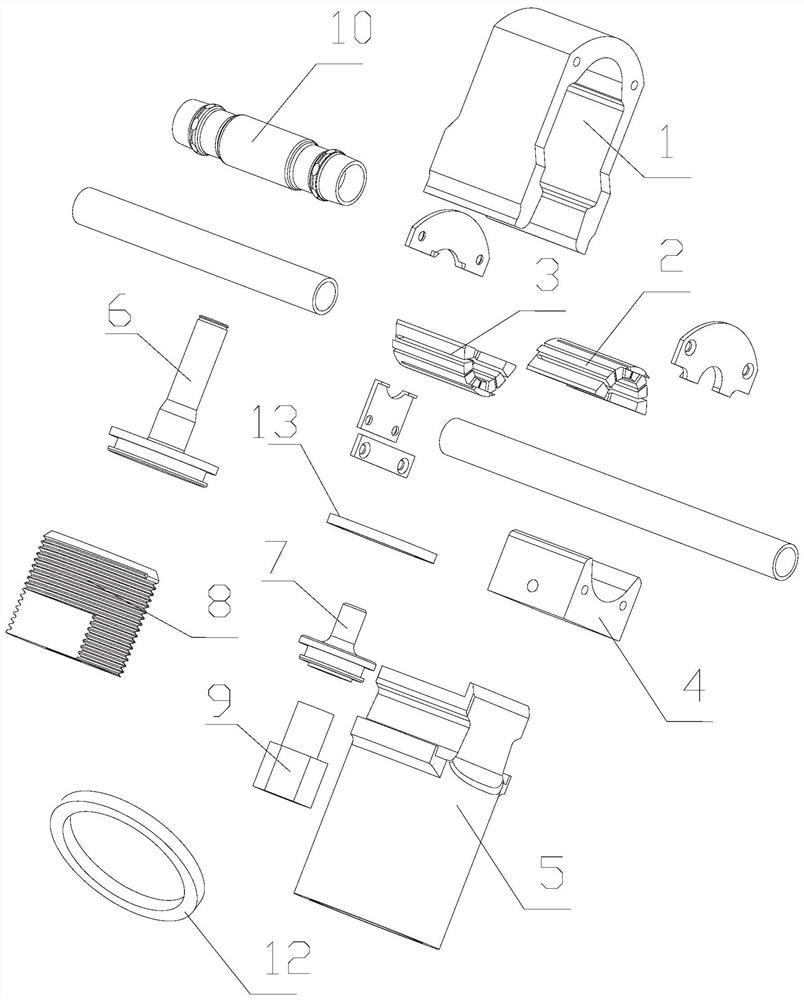

[0023] Referring to the accompanying drawings, a permanent extrusion type pipe joint crimping tool disclosed by the present invention includes an oil cylinder and a crimping head, the oil cylinder is connected with a manual hydraulic pump or an electric pump, and the crimping head is After the bit groove slides in, the oil cylinder is buckled and connected with the crimping head, and the power provided by the manual hydraulic pump or electric pump is given to the oil cylinder, and the oil cylinder pushes the crimping head to extrude the pipe joint to deform the pipe joint to form a connection. The unit of the size of the crimping part of the crimping head is set to the metric unit.

[0024] The crimping head includes a jacket 1, an upper mandrel 2, a lower mandrel 3, and a slider 4, wherein the upper mandrel 2 and the lower mandrel 3 are arranged togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com