Pipe penetrating machine

A technology for pipe threading machines and work pieces, which is applied in the field of pipe threading machines, can solve time-consuming and labor-intensive problems, and achieve the effects of time-consuming and labor-intensive, stable transmission, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

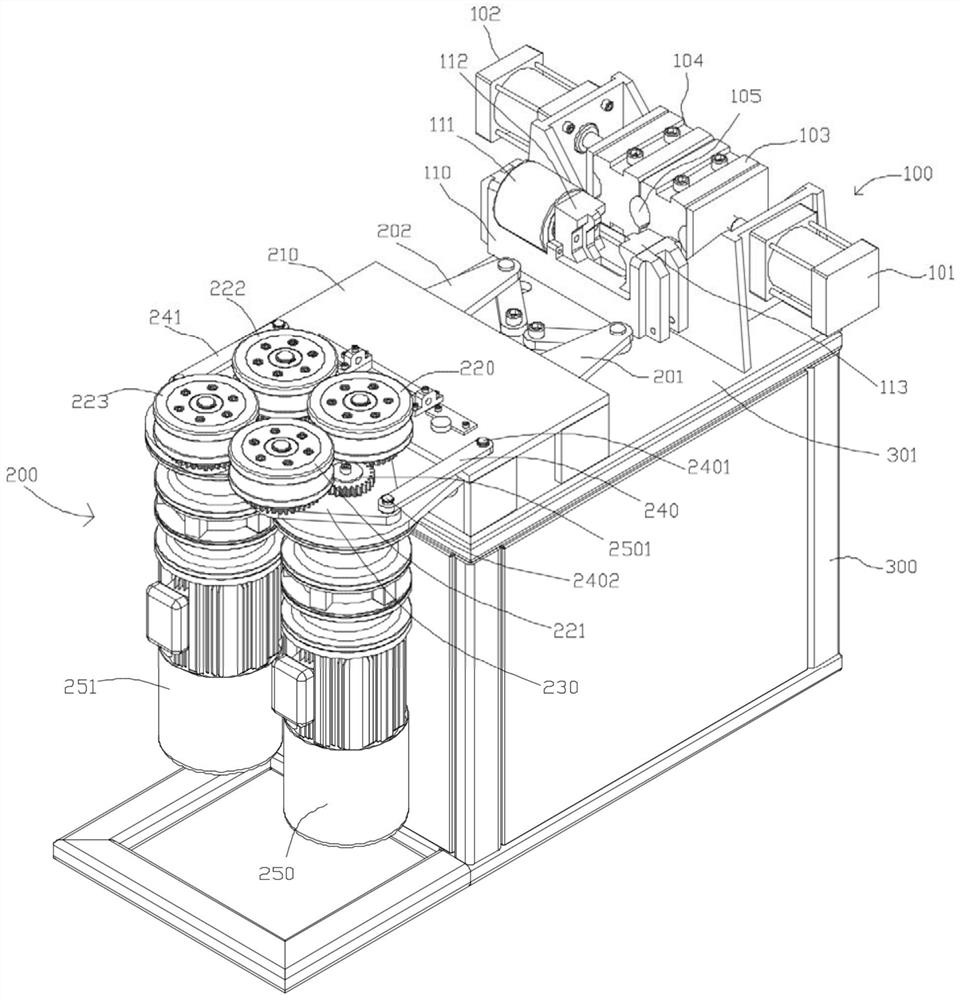

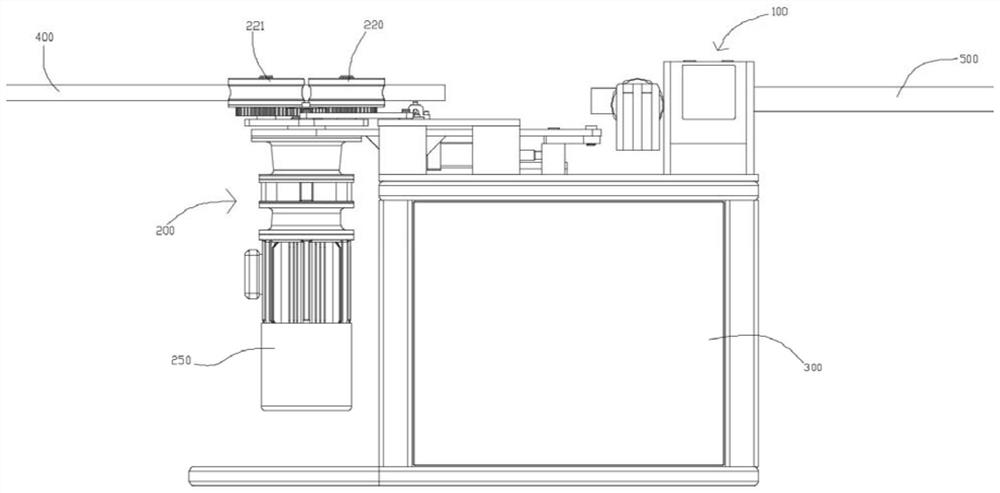

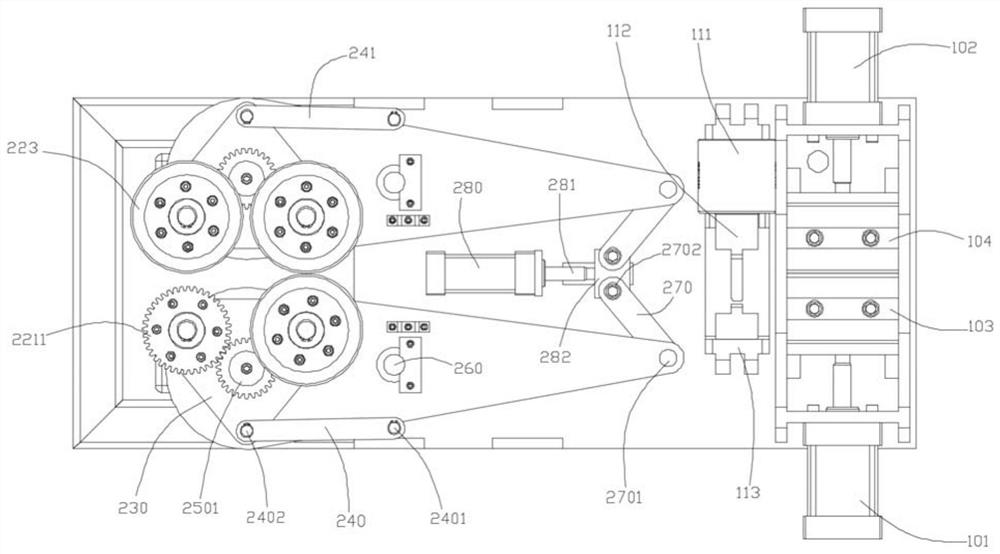

[0035] A pipe threading machine has a bracket 300 and an assembly surface 301 arranged on the upper end surface of the bracket 300, a clamping unit 200 is provided at one end of the assembly surface 301, and a drive unit 100 is provided at the other end, wherein the drive unit includes two A symmetrically arranged drive assembly and a set of adjustment assemblies.

[0036] The two drive components are identical and symmetrical structures, specifically, as follows:

[0037] It includes a first drive assembly and a second drive assembly, the first drive assembly includes a first motor 250, and is connected to two drive wheels at the output end, which are drive wheel one 220 and drive wheel two 221; The second driving assembly includes a second motor 251, and is connected to two driving wheels at the output end, which are respectively driving wheel three 222 and driving wheel four 223; due to the symmetrical structure and the use of the same parts, the following will focus on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap