Telescopic redirection device of conveying line

A technology of conveying line and telescopic machine, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problem of unfavorable information identification and storage efficiency, low efficiency of bin sorting and conveying, and high cost of use. problems, to improve the efficiency of information identification and storage and outbound operations, improve the efficiency and availability of sorting operations, and simplify the control device and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

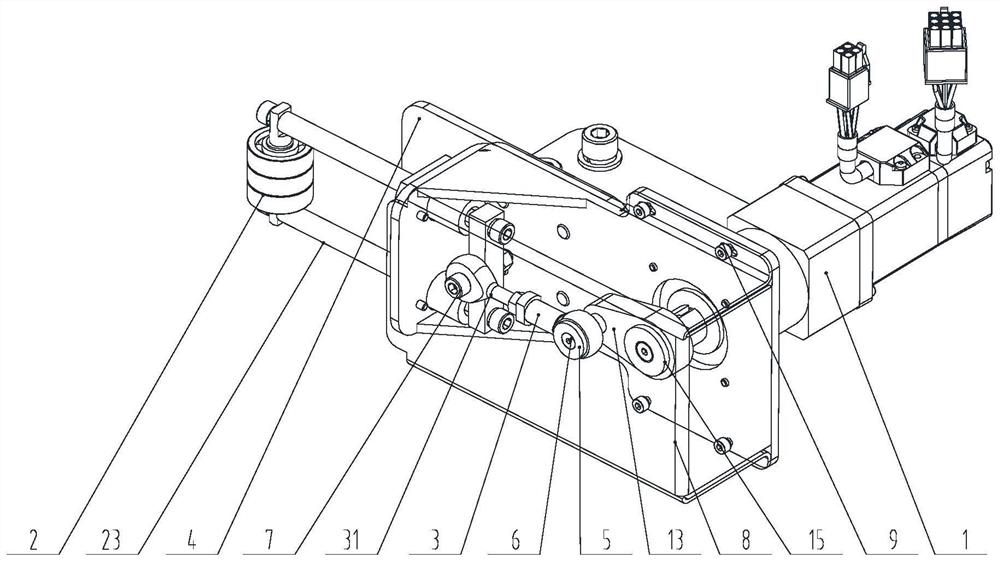

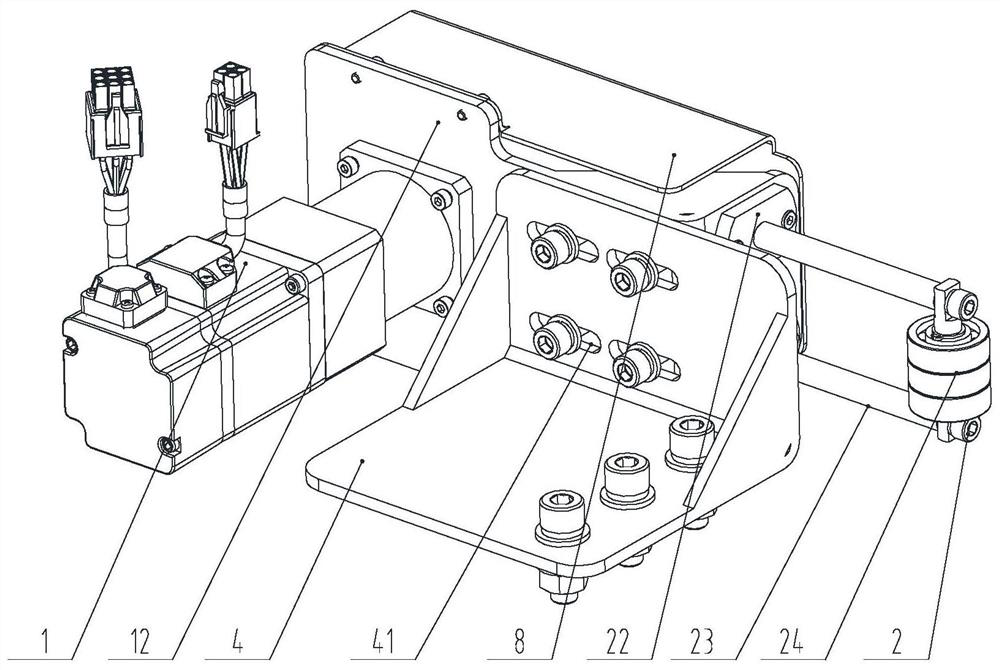

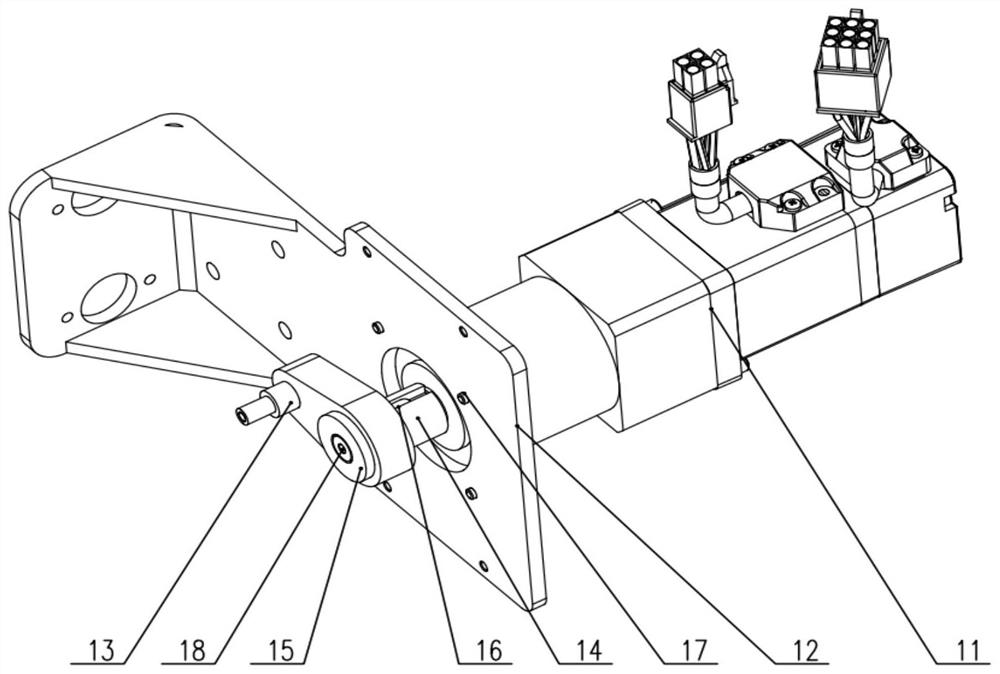

[0027] Embodiment 1, as shown in Figure 1 to Figure 8 As shown, the conveying line telescopic redirecting device 100 described in the present application is applied to implement the horizontal flipping of the material box 400 during the conveying process, so as to realize the online 90° redirecting operation.

[0028] The conveying line telescoping and diverting device 100 is integrally installed and connected to the side of the conveying device. In this embodiment, the conveying device is an inclined-drum side-by-side machine 200, and it can also be other types of conveying devices such as belt conveyors.

[0029] As shown in FIG. 1 , the conveying line telescopic redirection device 100 includes a fuselage connection adjustment plate 4 installed and connected to the side of the inclined roller edge machine 200, and a driving traction plate connected to the fuselage connection adjustment plate 4 respectively. The component 1 and the telescopic sliding component 2 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com