Liquid fuel furnace

A liquid fuel and fuel technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of high cost, weak firepower, complex overall structure, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

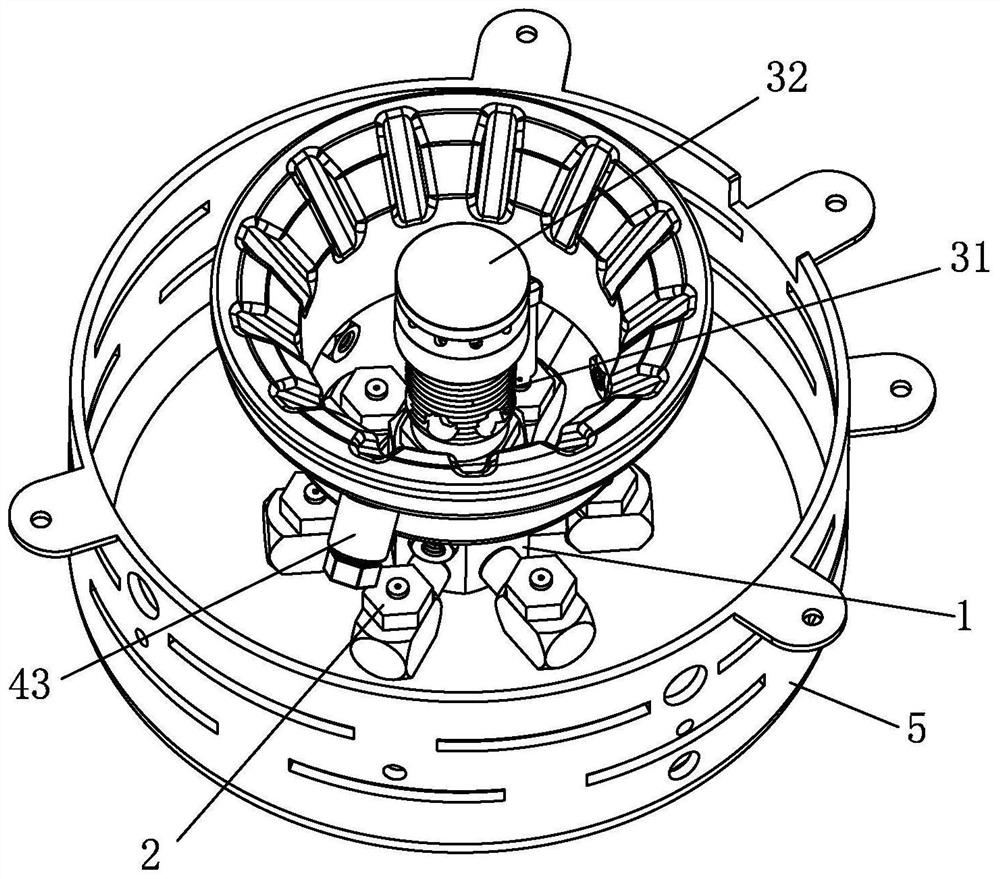

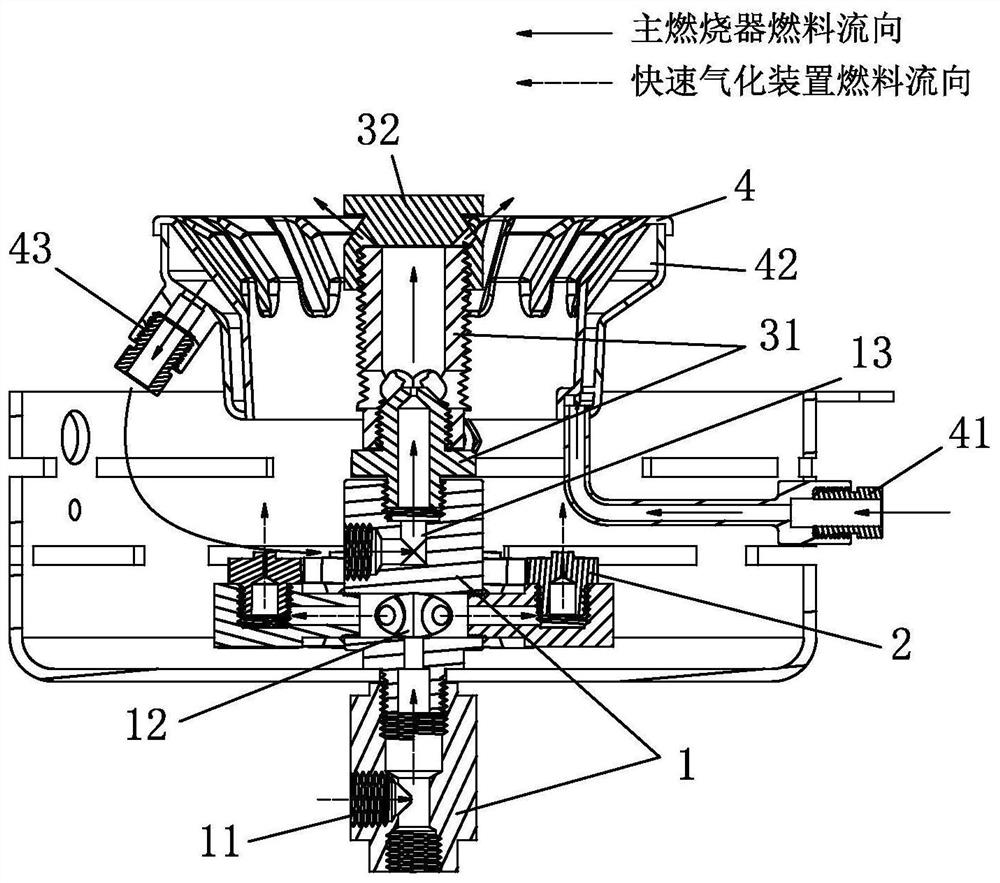

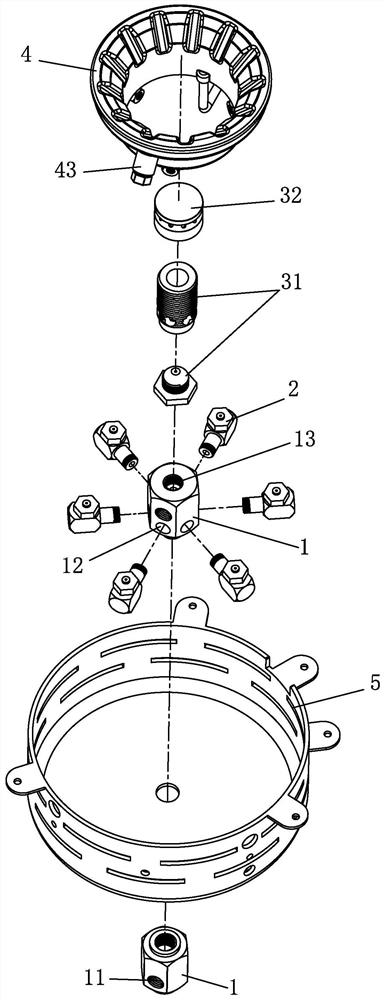

[0027] see Figure 1-Figure 6 , the liquid fuel furnace, the main burner, gasification ring 4 and rapid gasification device, the rapid gasification device includes through the main body 1, several atomization combustion nozzles 2, specifically, the present embodiment preferably six atomization Combustion nozzle 2, the main body 1 is located below the main burner, the main body 1 is provided with a main body fuel inlet 11 and a main body fuel distribution channel 12, and the main body fuel inlet 11, the main body fuel distribution channel 12, and the atomizing combustion nozzle 2 are sequentially connected The atomization combustion nozzle 2 is radially distributed on the periphery of the main body 1, the atomization combustion nozzle 2 is provided with a nozzle opening, and the nozzle opening is from bottom to top towards the gasification ring 4, and the nozzle opening gradually changes from its ejection direction Small, so that the sprayed liquid fuel can be atomized naturall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com