Unit energy consumption performance evaluation method for customized design machine tool

An evaluation method and a technology for unit energy consumption, applied in the direction of comprehensive factory control, program control, energy industry, etc., which can solve the problems of changing machine tool processing requirements and not considering the operation and processing characteristics of customized machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

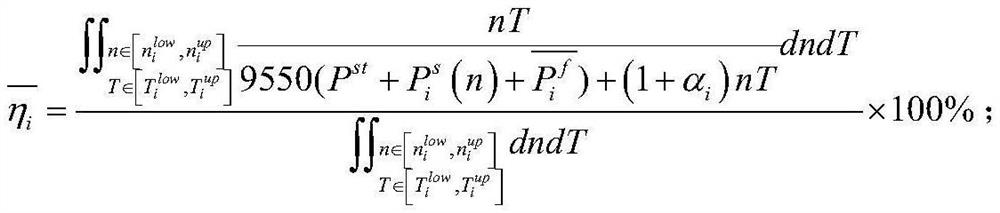

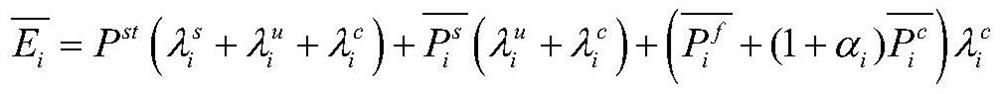

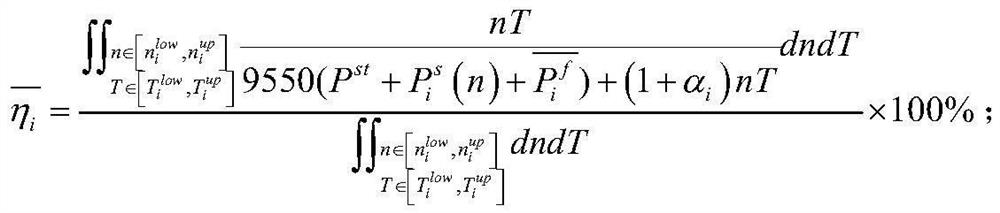

[0030] A method for evaluating the unit energy consumption performance of a custom-designed machine tool, comprising the following steps:

[0031] Obtain the basic functional data of the machine tool under test, including the rated spindle speed n r , the maximum spindle speed n m and spindle rated torque T r ; This specific embodiment obtains the parameter n according to the instruction manual of the machine tool to be evaluated r , n m , T r is the rated torque of the spindle, which can also be obtained by measurement.

[0032] Transform the processing requirements of different workpieces into different customized working conditions: finishing working condition FM, semi-finishing working condition SfM and rough machining working condition RM.

[0033] Predict the probability ρ of the machine tool to be tested under each customized working condition according to the customized working condition requirements i , and i∈[FM,SfM,RM].

[0034] According to the processing re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com