Novel reinforcing structure for automobile longitudinal beam

A technology for automobile longitudinal beams and reinforced structures, which is applied in the field of automobile parts, can solve the problems of reducing production efficiency, inconvenience, and increasing production costs, and achieve the effects of improving reinforcement effects, reducing production costs, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

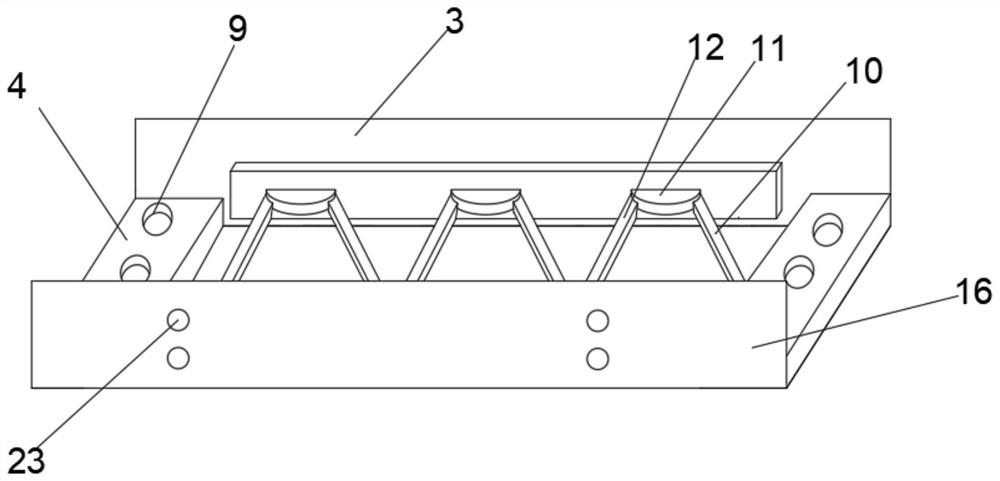

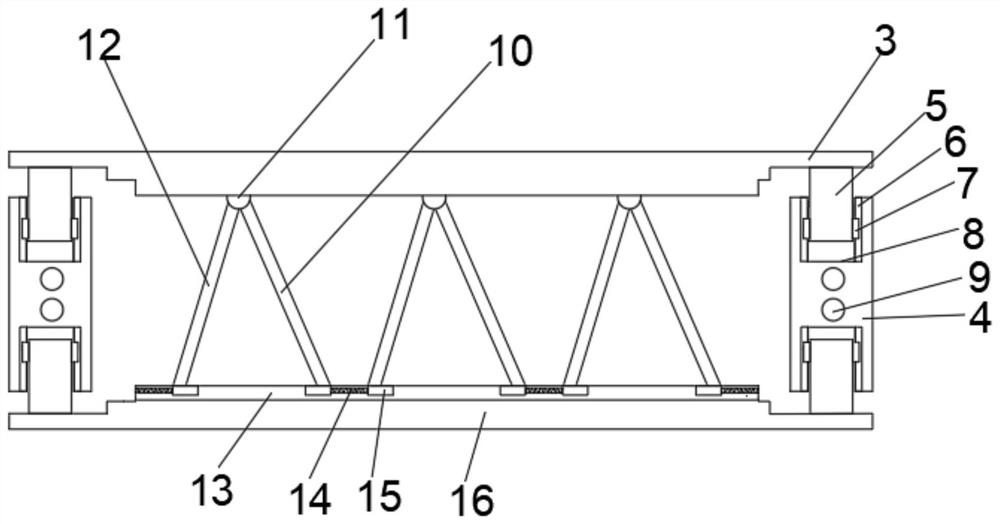

[0028] The number of the first rotating shafts 11 is three groups, and the three groups of the first rotating shafts 11 are evenly distributed on one side of the first mounting plate 3, and the second mounting plate 16 is opened on the side close to the first mounting plate 3 The second chute 13, the inner wall of the second chute 13 is slidably connected with the second slider 15, the number of the second slider 15 is six groups, and the six groups of the second slider 15 are evenly distributed on the second On the inner wall of the two chute 13, a spring 14 is arranged between each group of the second sliding blocks 15, and a first connecting rod 10 and a second connecting rod 12 are arranged on the outer wall of the first rotating shaft 11. The bottoms of the connecting rod 10 and the second connecting rod 12 are fixedly connected with the second sliding block 15, and the second sliding block 15 corresponds to the first connecting rod 10 and the second connecting rod 12. Wh...

Embodiment 2

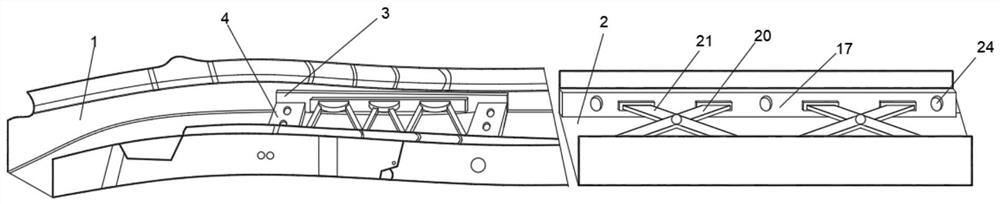

[0030]The inner wall of the rear section 2 of the longitudinal beam of the vehicle is provided with a third mounting plate 17, the number of the third mounting plates 17 is two groups, and the third mounting plates 17 of the two groups are symmetrically distributed on the rear section 2 of the longitudinal beam of the vehicle. On the inner wall, the sides of the third mounting plates 17 of the two groups are provided with draw-in slots 18, the number of the draw-in slots 18 is eight groups, and the eight sets of draw-in slots 18 are evenly distributed in the two groups of the third mounting plates. On the three mounting plates 17, the inner wall of the draw-in groove 18 is provided with a block 19, the surface of the third mounting plate 17 is hinged with a first movable rod 20, and the surface of another group of the third mounting plate 17 is hinged with The second movable rod 21, a second rotating shaft 22 is arranged between the first movable rod 20 and the second movable r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com