Patents

Literature

35results about How to "Improve enhanced performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

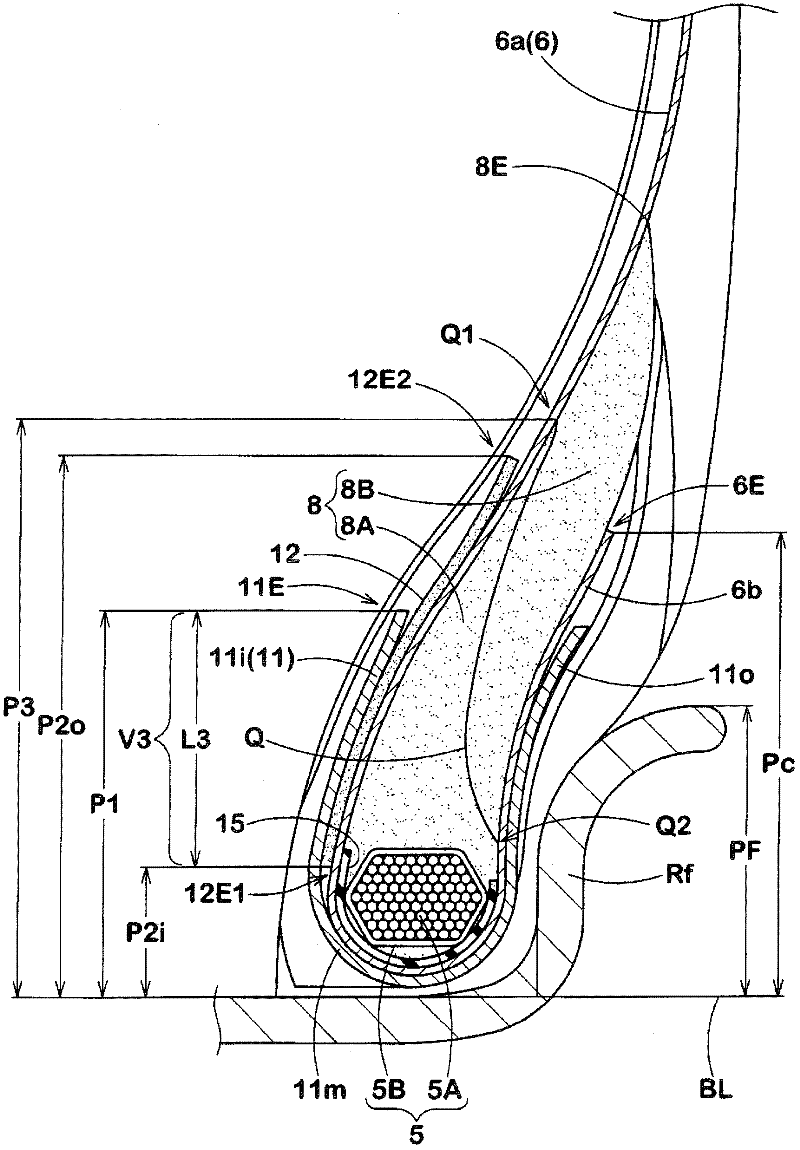

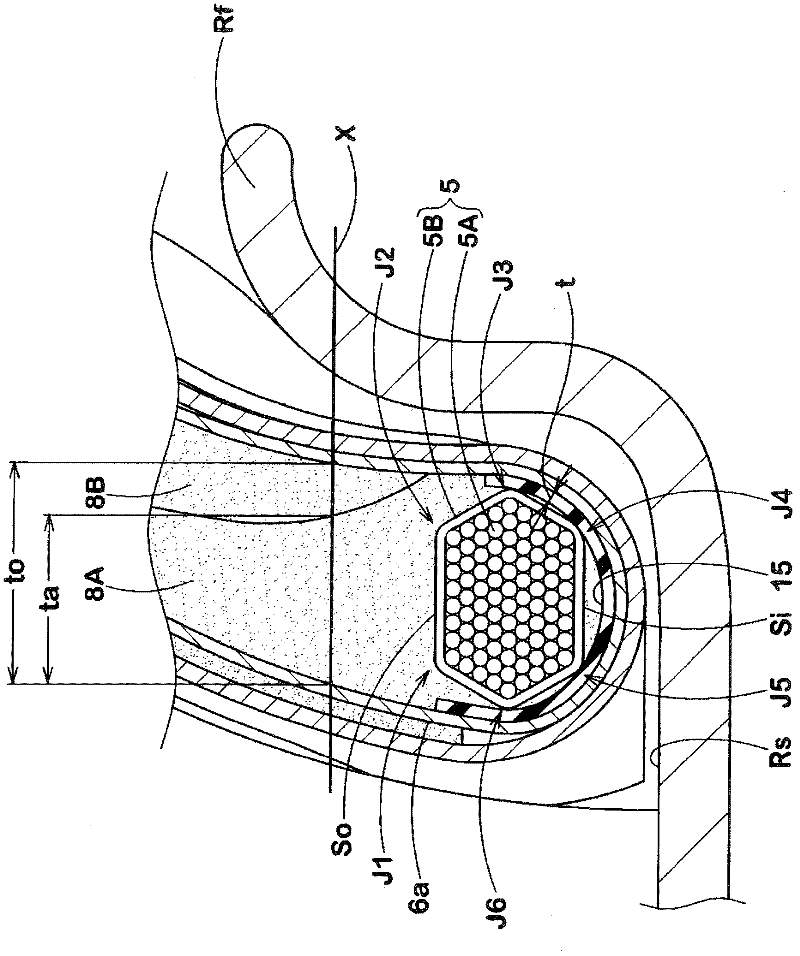

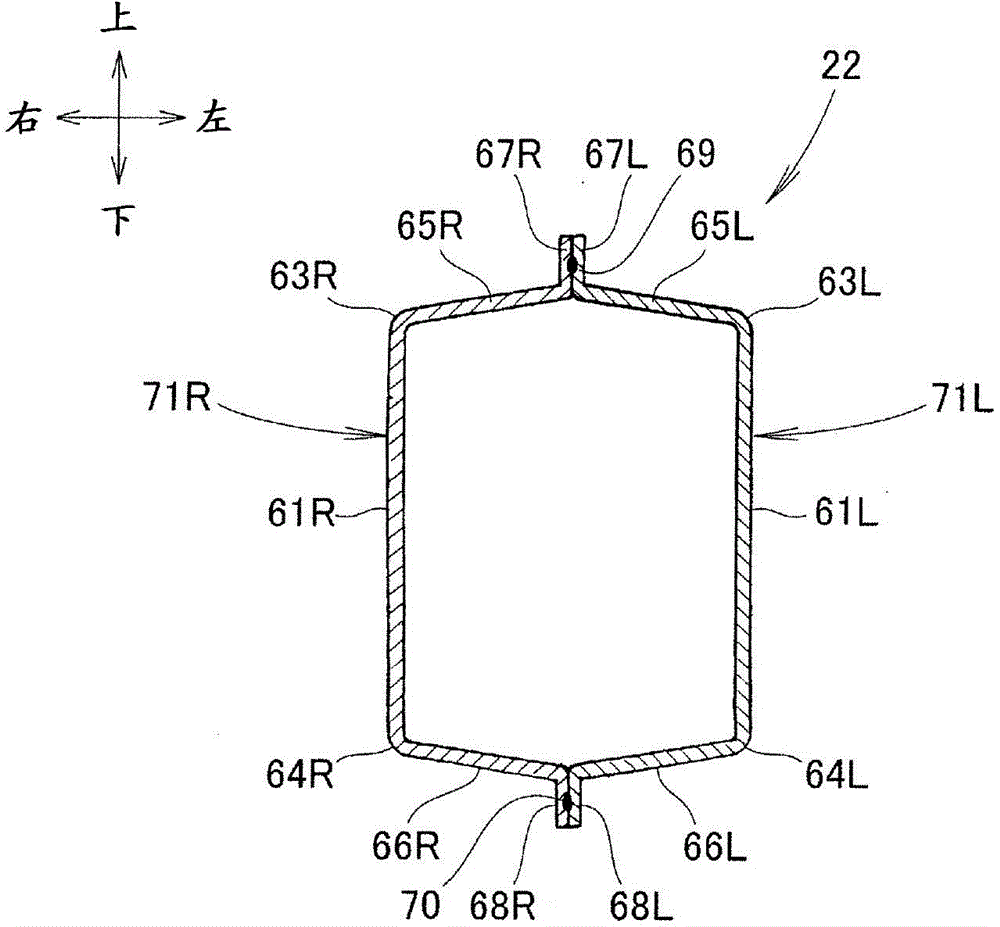

Non-pneumatic tire, and its manufacturing method

InactiveCN101668646AEnsure deflectionEasy to transformNon-inflatable tyresEngineeringMechanical engineering

Owner:TOYO TIRE & RUBBER CO LTD

Truck tire

The truck tire of the invention allows the endurance of an ordianry tire not to be damaged and helps to improve the wearing resistance. A tire bead is provided with a first tire bead reinforcing cord layer, a second tire bead reinforcing cord layer and an anti-wearing rubber layer. The first tire bead reinforcing cord layer is U-shaped for connecting an internal portion and an external portion via a bottom portion, wherein the internal portion is arranged along the internal side of the cord main body of a tire body, and the external portion is arranged along the external side of the cord returning portion of the tire body. From an internal end clamped between the internal portion and the cord main body, the second tire bead reinforcing cord layer extends toward an radial external side beyond the internal portion along the cord main body. The anti-wearing rubber layer comprises a rubber sheet which is 0.5-1.5mm in thickness, has a complex modulus of 6.0-10.0MPa, and is arranged between a tire body cord and a tire bead core along the tire body cord. The difference between the height of the external end of the second tire bead reinforcing cord layer and the height of the external end of the cord returning portion is 5-25mm. The difference between the height of the external end of the internal portion and the height of the internal end of the second tire bead reinforcing cord layer is 10-40mm.

Owner:SUMITOMO RUBBER IND LTD

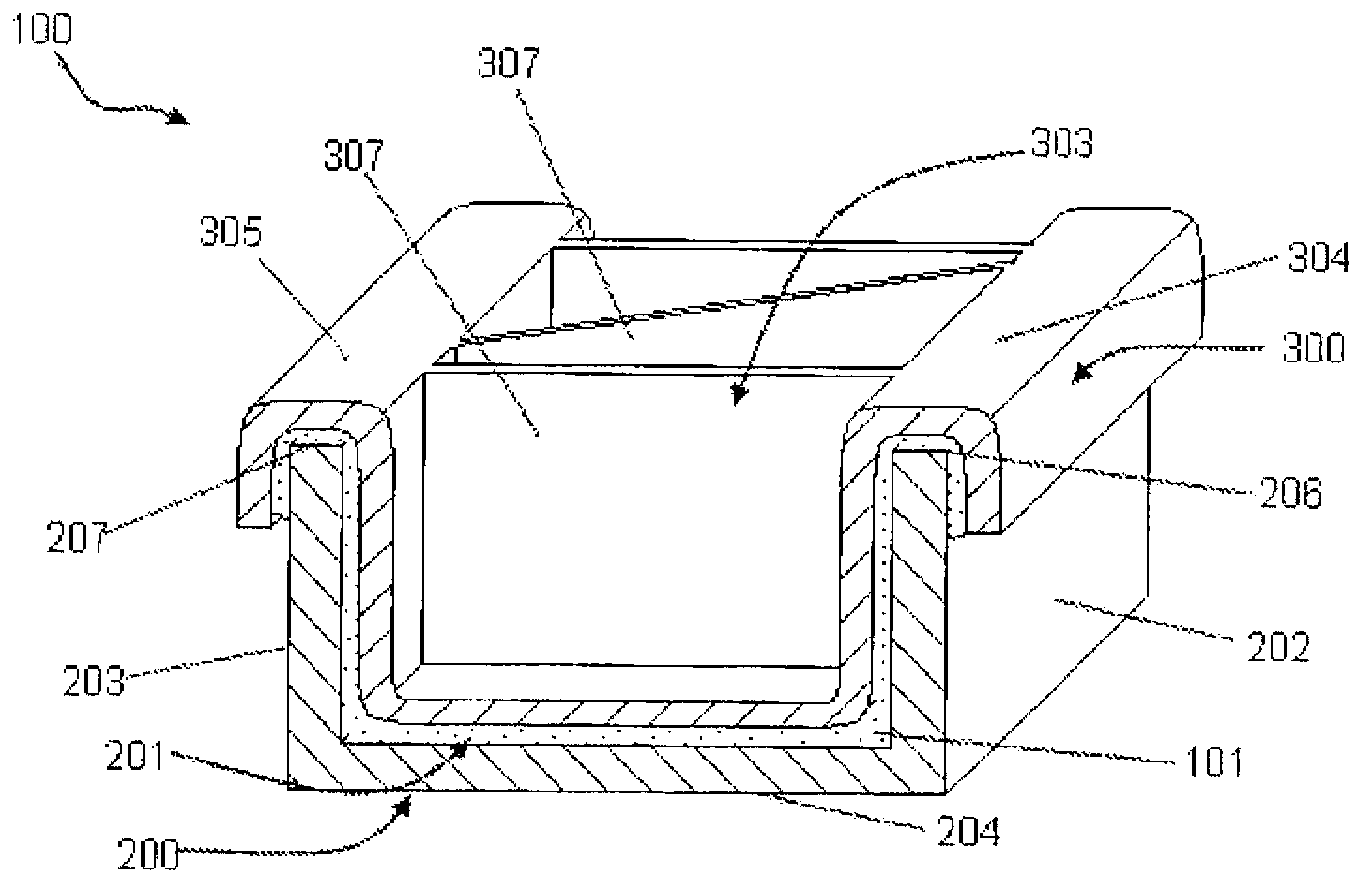

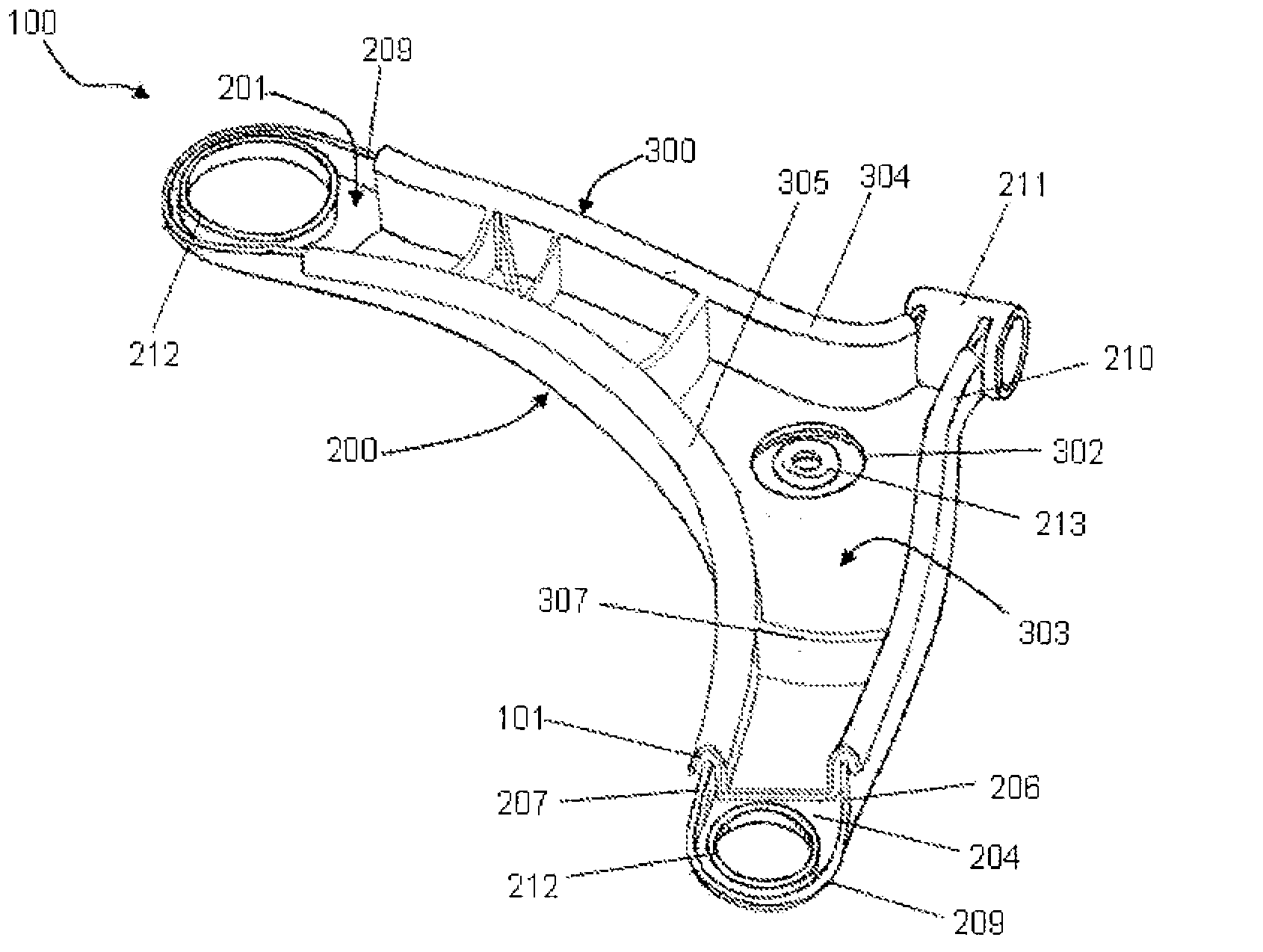

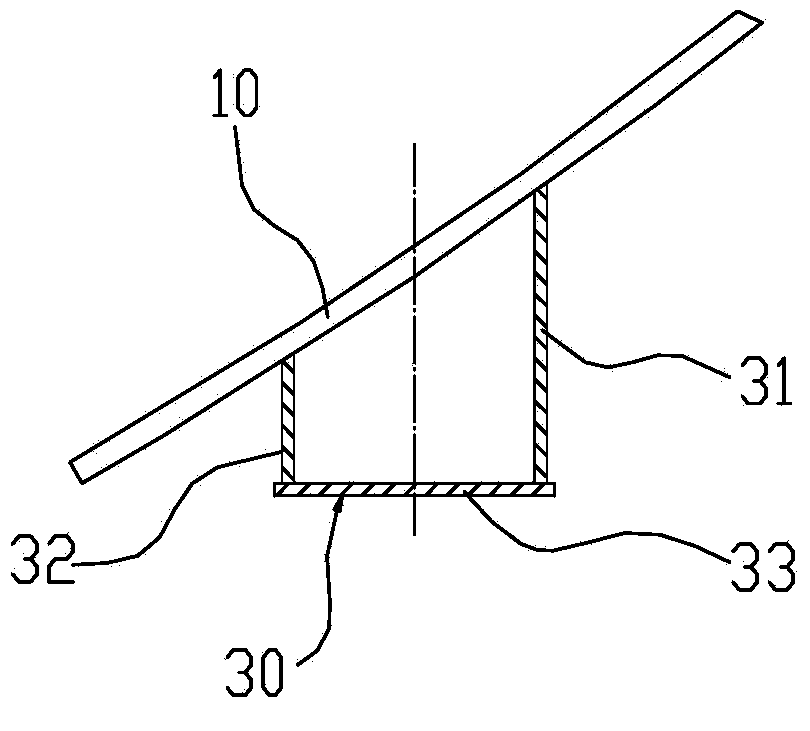

Composite component

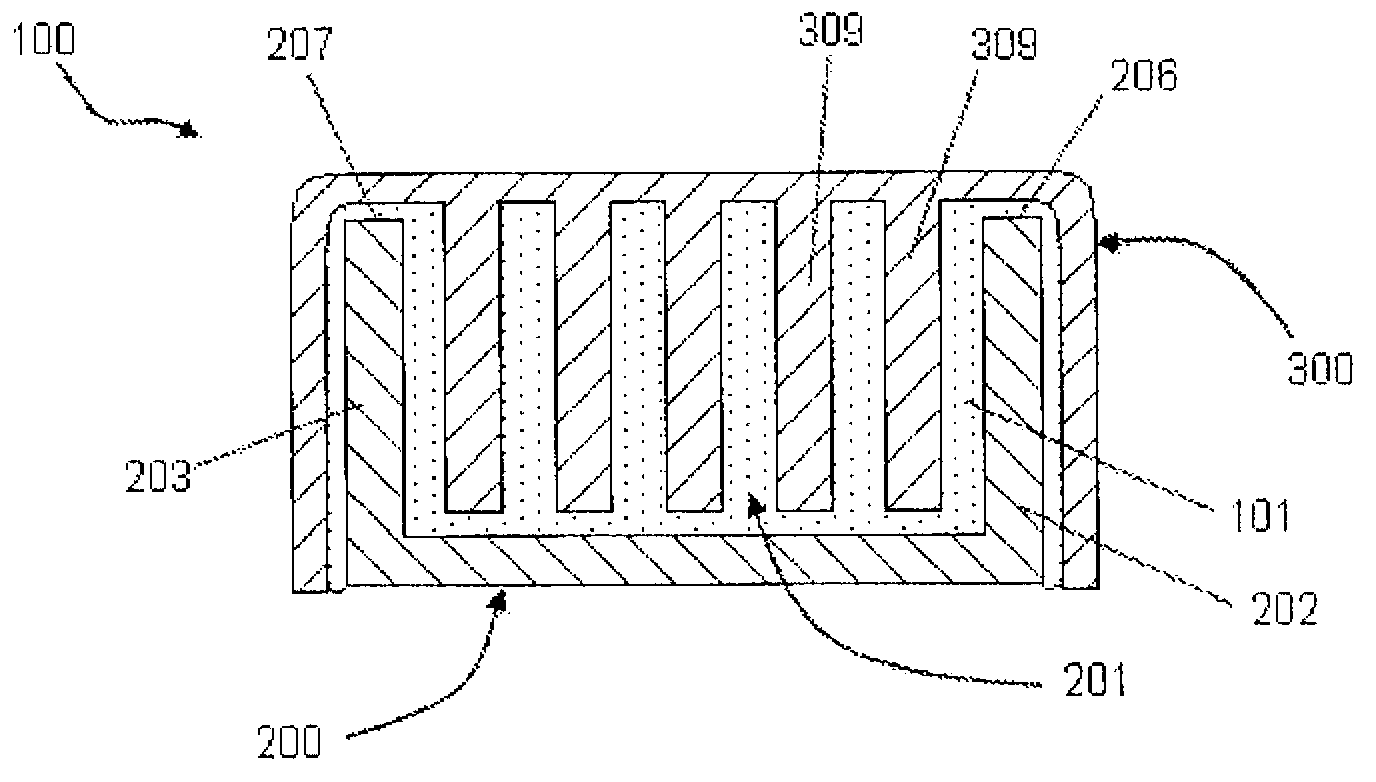

InactiveCN102741113AImprove enhanced performanceSuperstructure subunitsPivoted suspension armsFree edgeEngineering

The invention relates to a composite component (100) comprising a shell (200) that surrounds at least some areas of a chamber (201) and comprising a structural component (300) for reinforcing the shell (200). The structural component (300) is spaced from a wall (202, 203, 204) of the shell (200) at least in some areas, said wall determining the chamber (201), and a structural material (101) is provided at least along some areas between the wall (202, 203, 204) of the shell (200) and the structural component (300). The shell (200) has at least one free edge (206, 207), and the structural component (300) extends over at least some areas of the free edge (206, 207) of the shell (200).

Owner:HENKEL KGAA

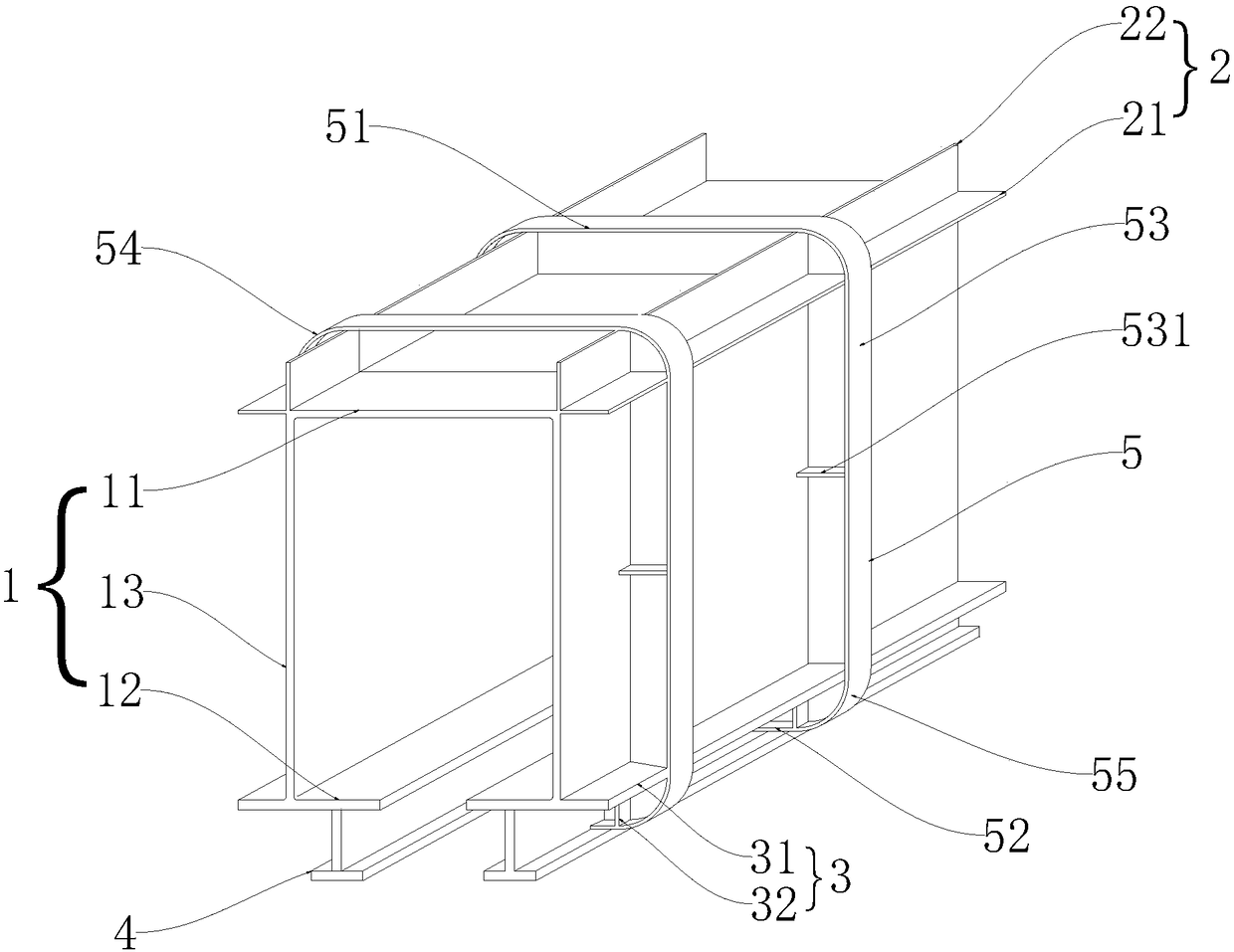

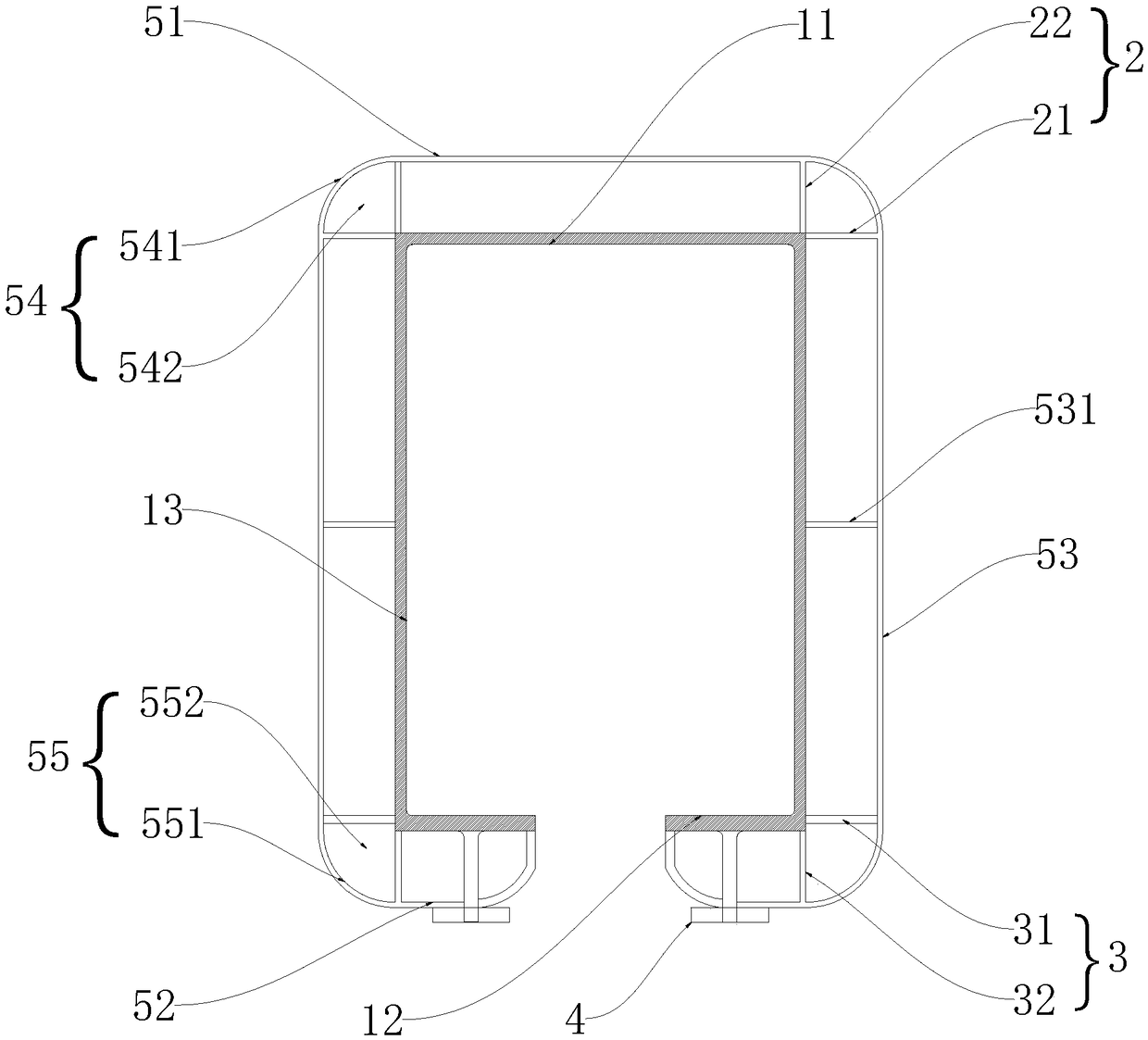

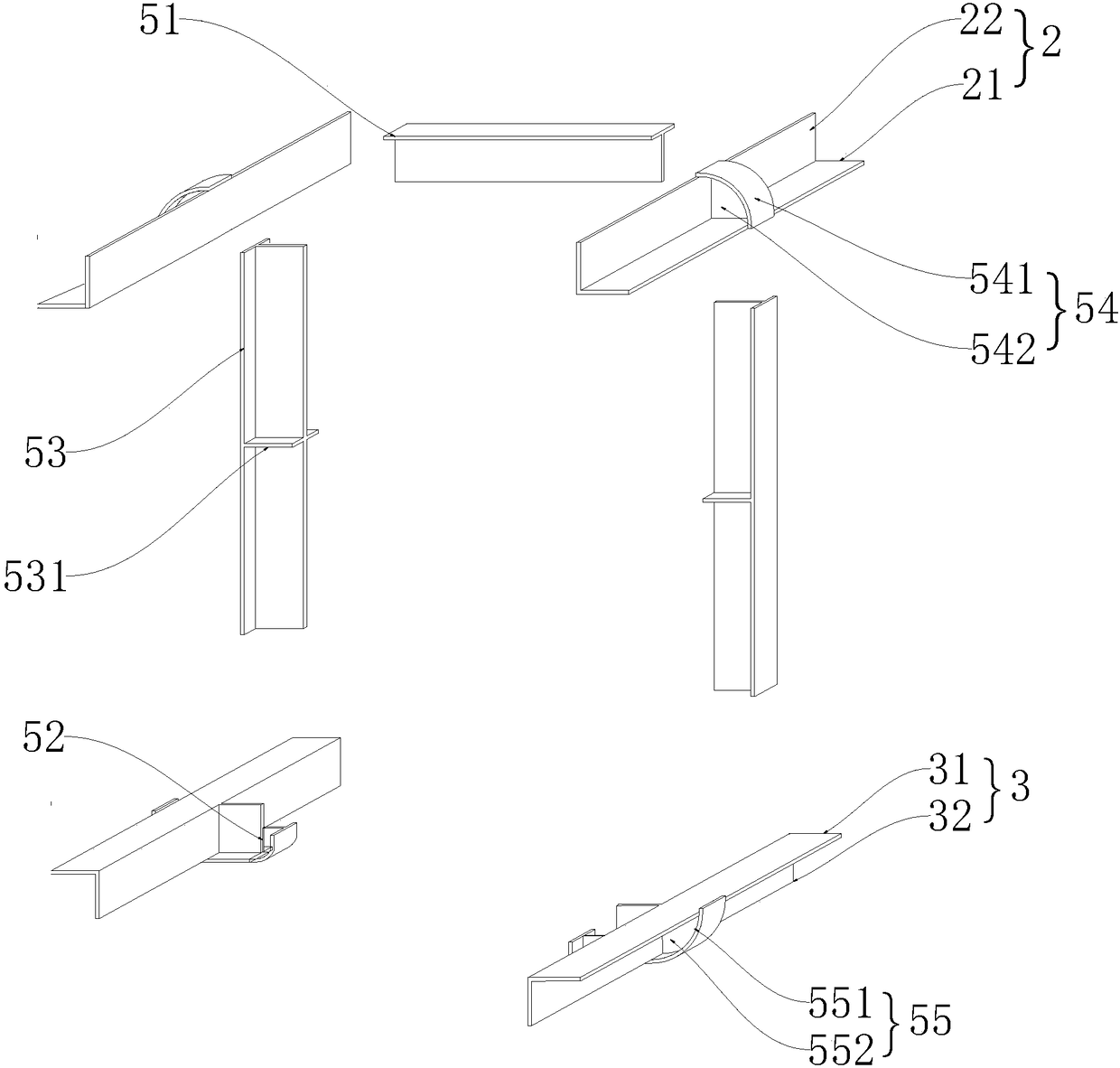

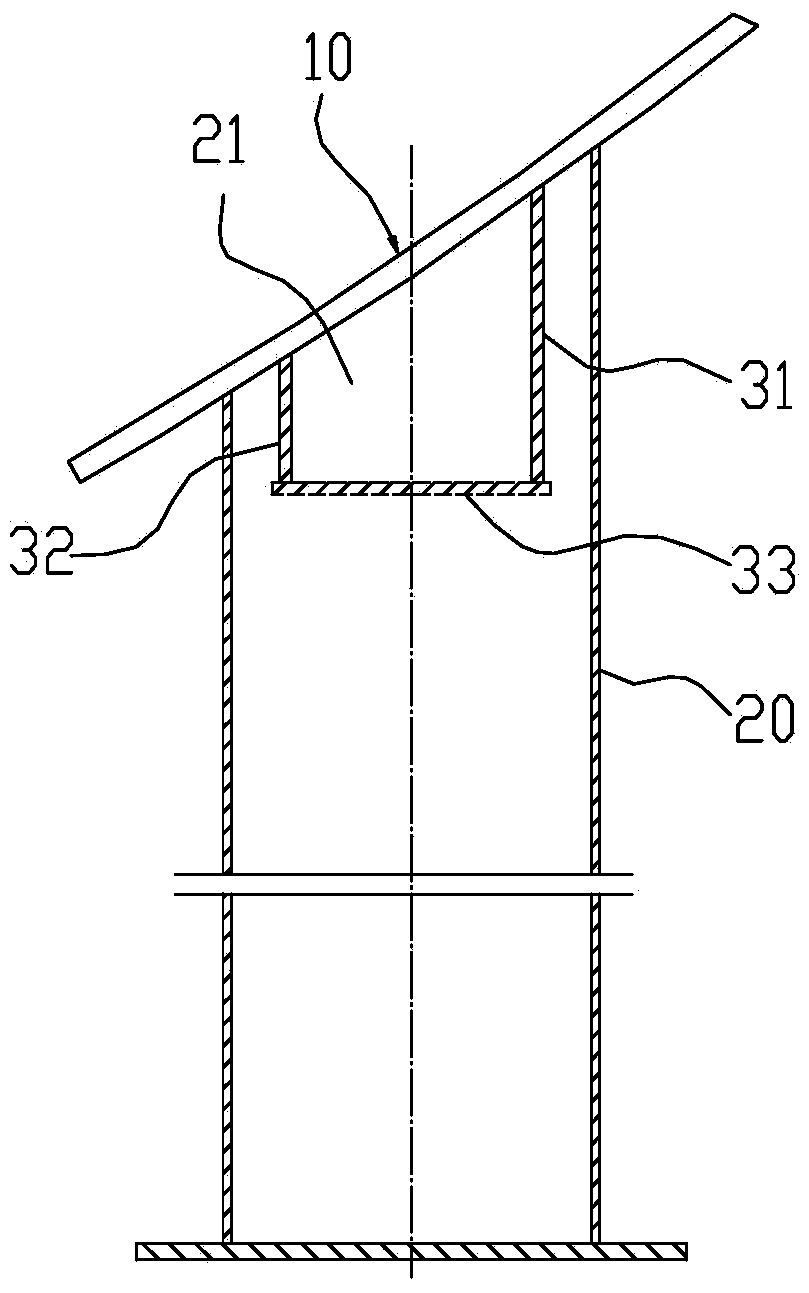

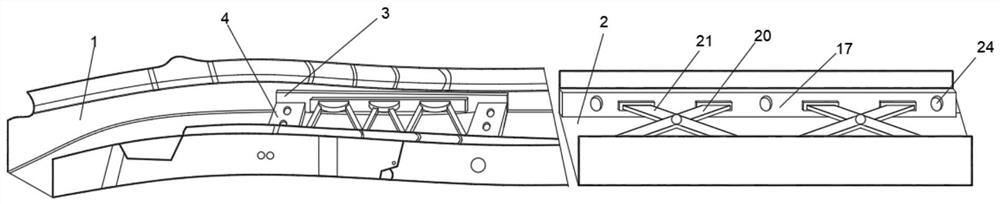

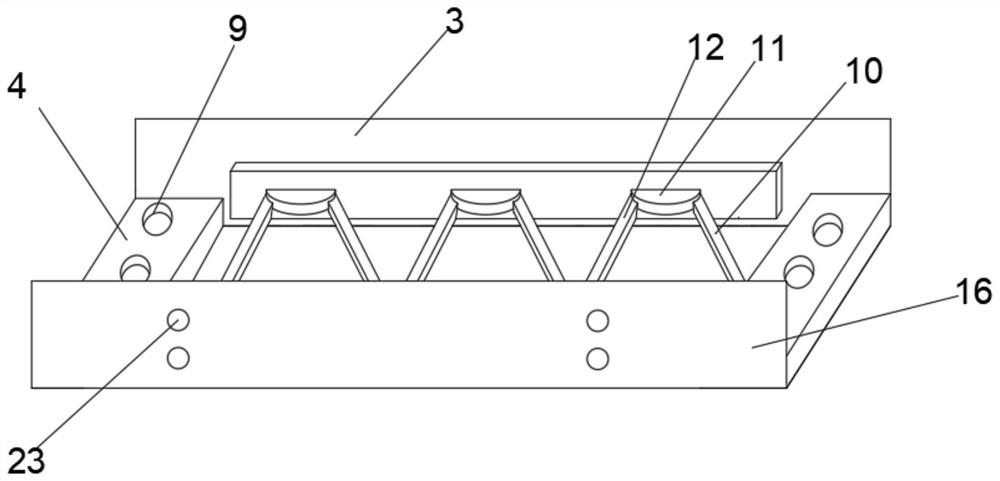

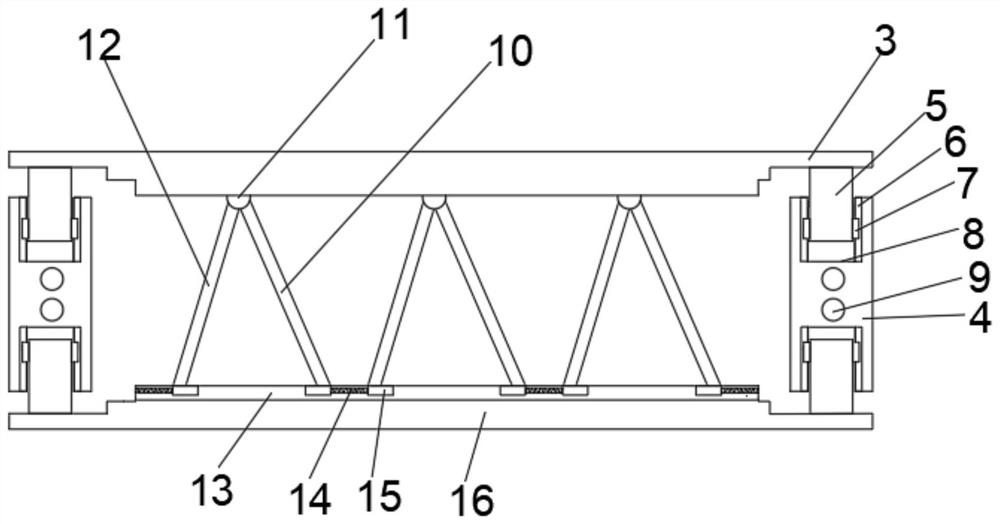

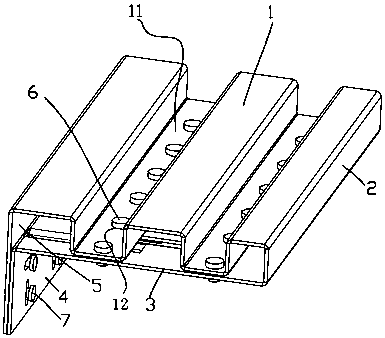

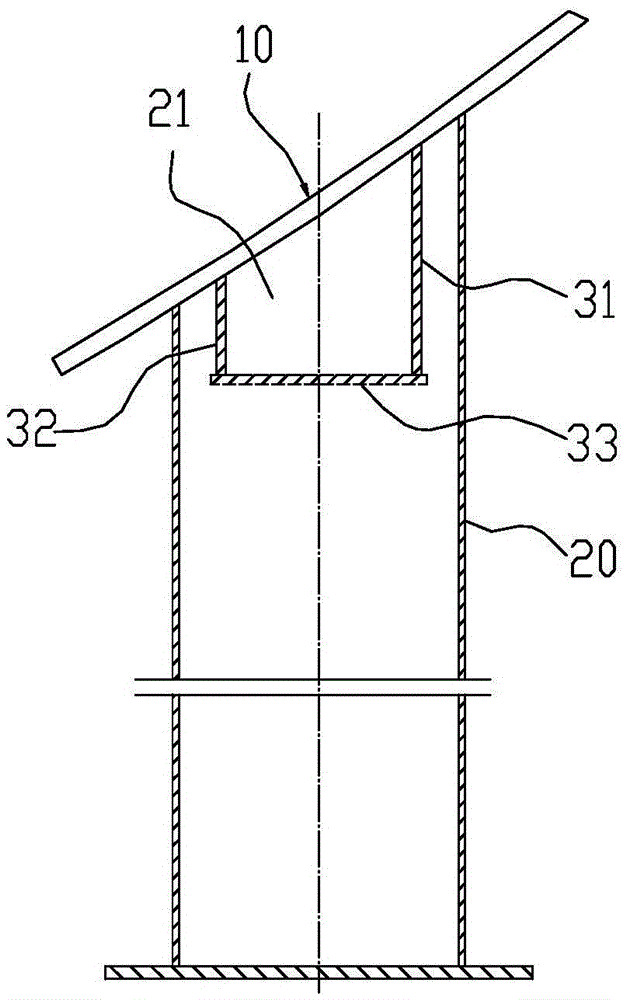

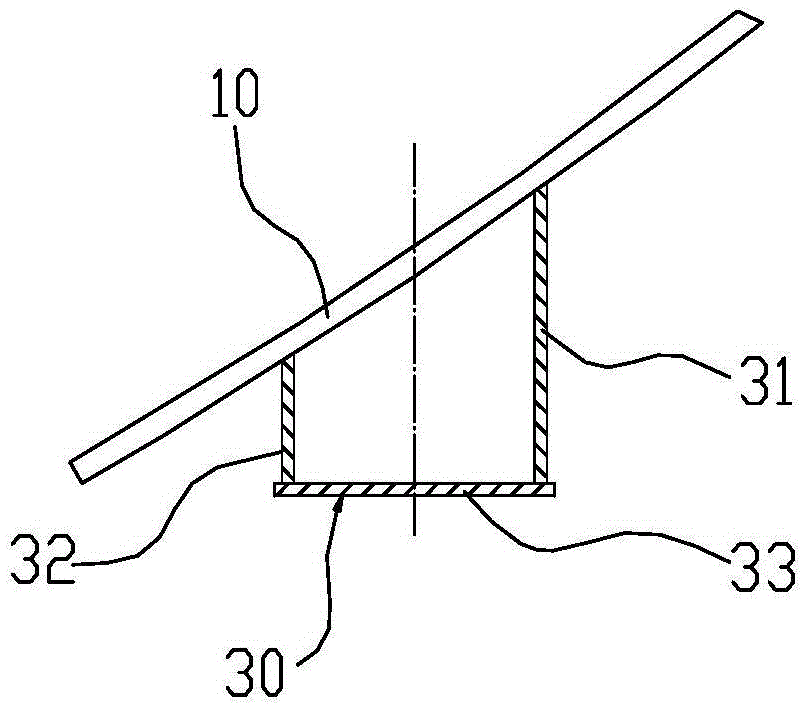

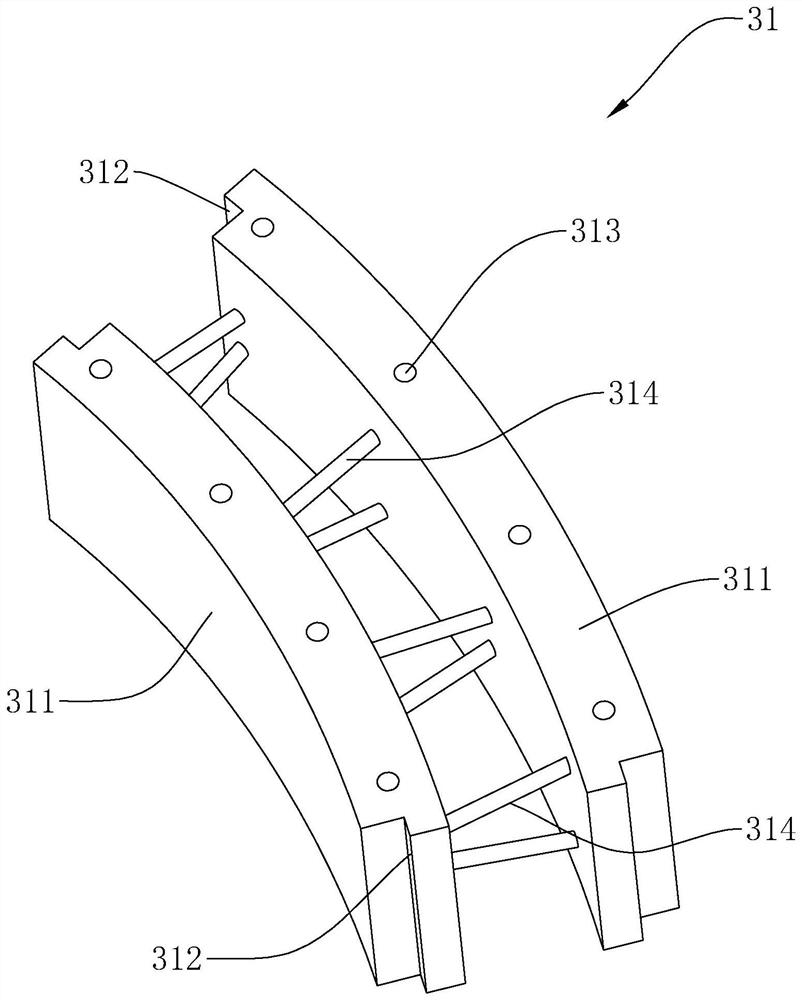

Rail beam used for aerial rail traffic system and aerial rail traffic system

PendingCN108442191AImprove flexural strengthHigh strengthRailway tracksRail trafficUltimate tensile strength

The invention relates to the technical field of aerial rail trains and particularly provides a rail beam used for an aerial rail traffic system and the aerial rail traffic system to solve the problemthat the strength reinforcement effect of rail beams is unsatisfactory. In order to achieve the purpose above, the rail beam used for the aerial rail traffic system includes a first reinforcement assembly and a second reinforcement assembly, wherein the first reinforcement assembly is arranged in the length direction of the rail beam to enhance the bending strength of the rail beam in the verticaldirection, and the second reinforcement assembly is arranged in the circumferential direction of the rail beam to enhance the bending strength of the rail beam in the horizontal direction. Accordingto the rail beam, by means of the first reinforcement assembly, the bending strength of the rail beam in the vertical direction is enhanced; by means of the second reinforcement assembly, the bendingstrength of the rail beam in the horizontal direction is enhanced; deformation of the rail beam is effectively inhibited, the situation that the rail beam is bent, deformed and even broken due to poorstrength is avoided, the service life of the rail beam is prolonged, and the cost of the aerial rail traffic system is reduced.

Owner:中建空列(北京)工程设计研究院有限公司

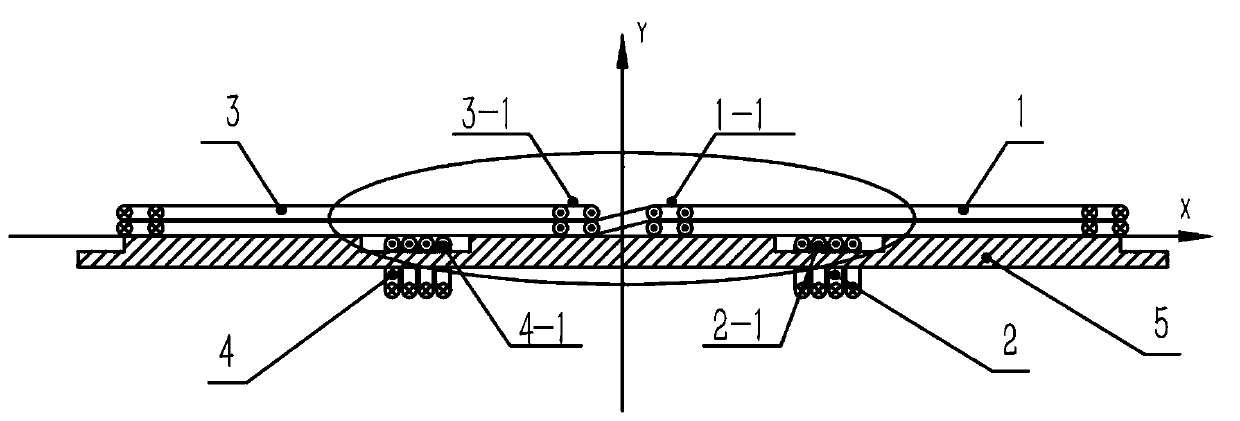

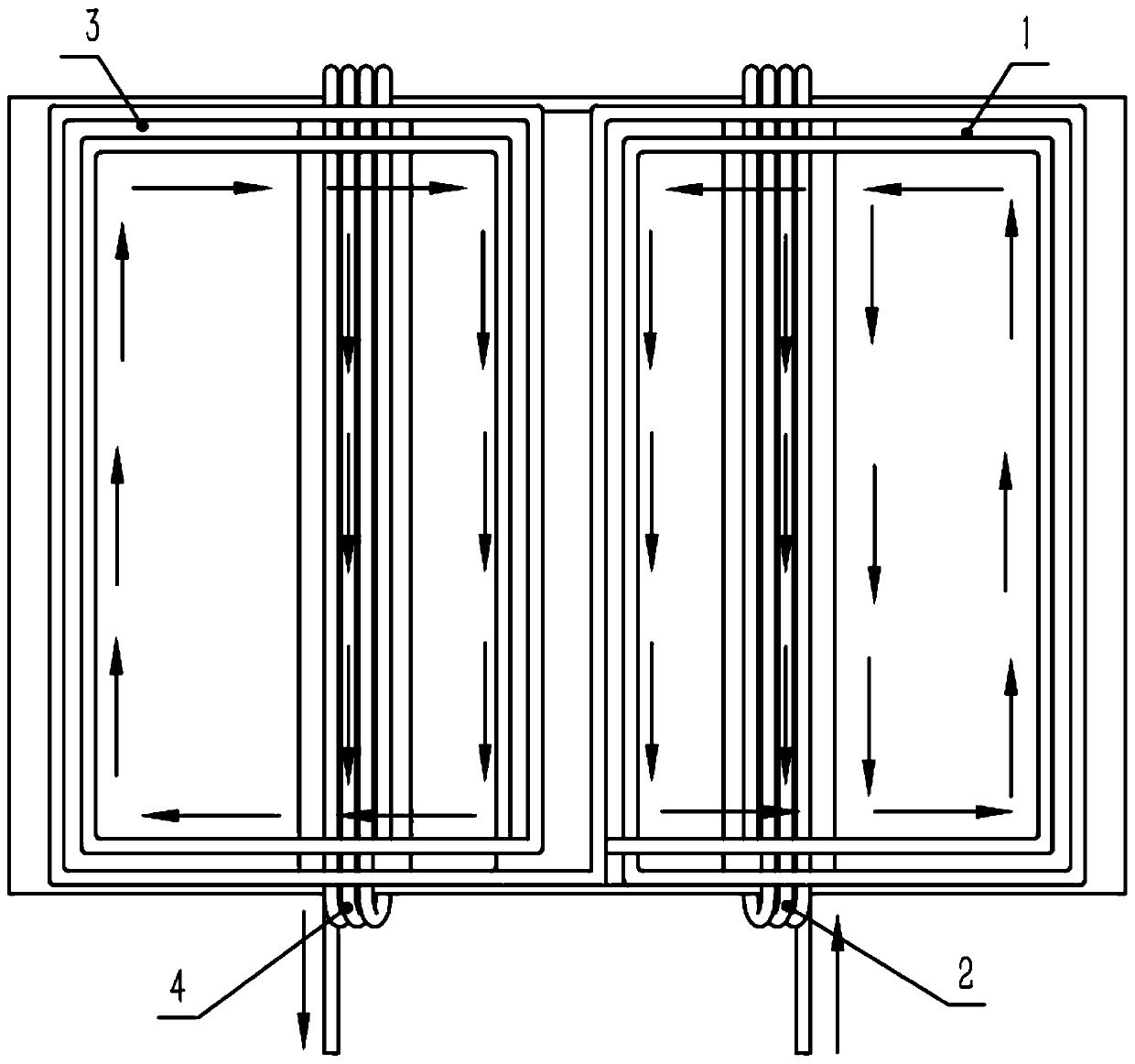

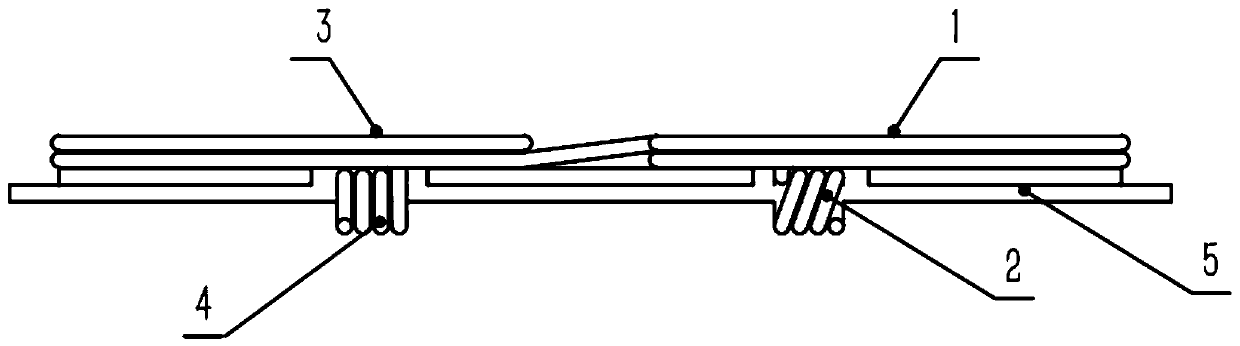

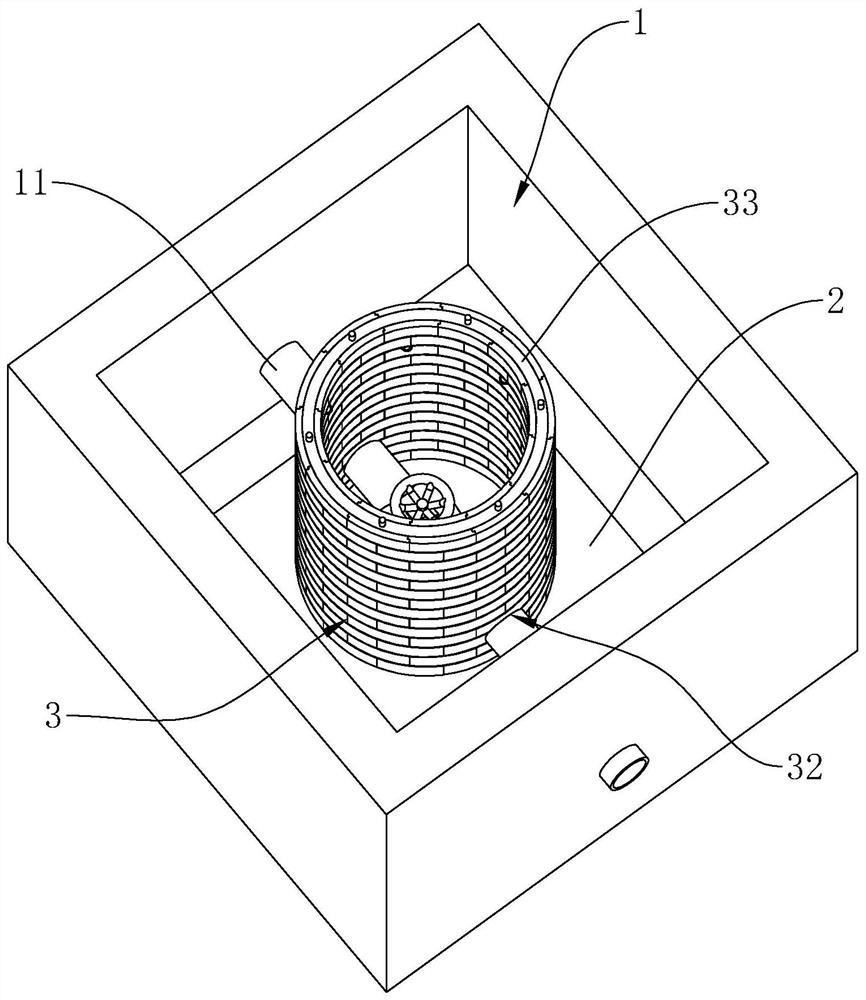

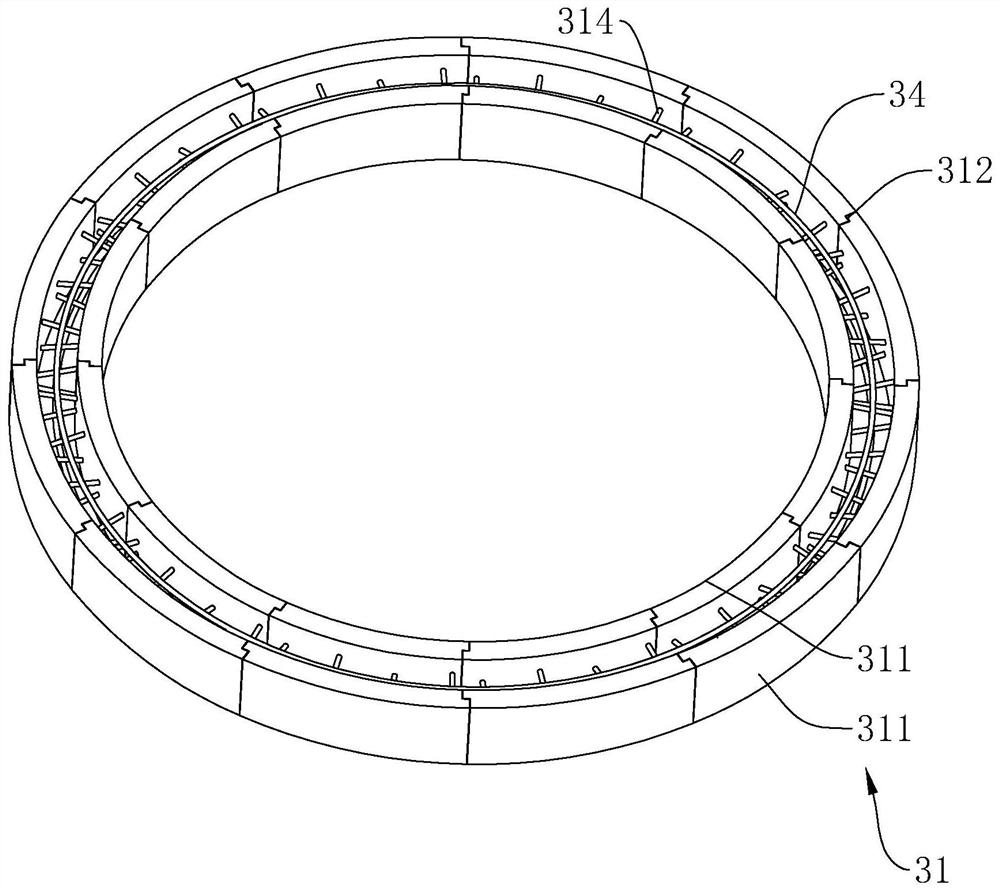

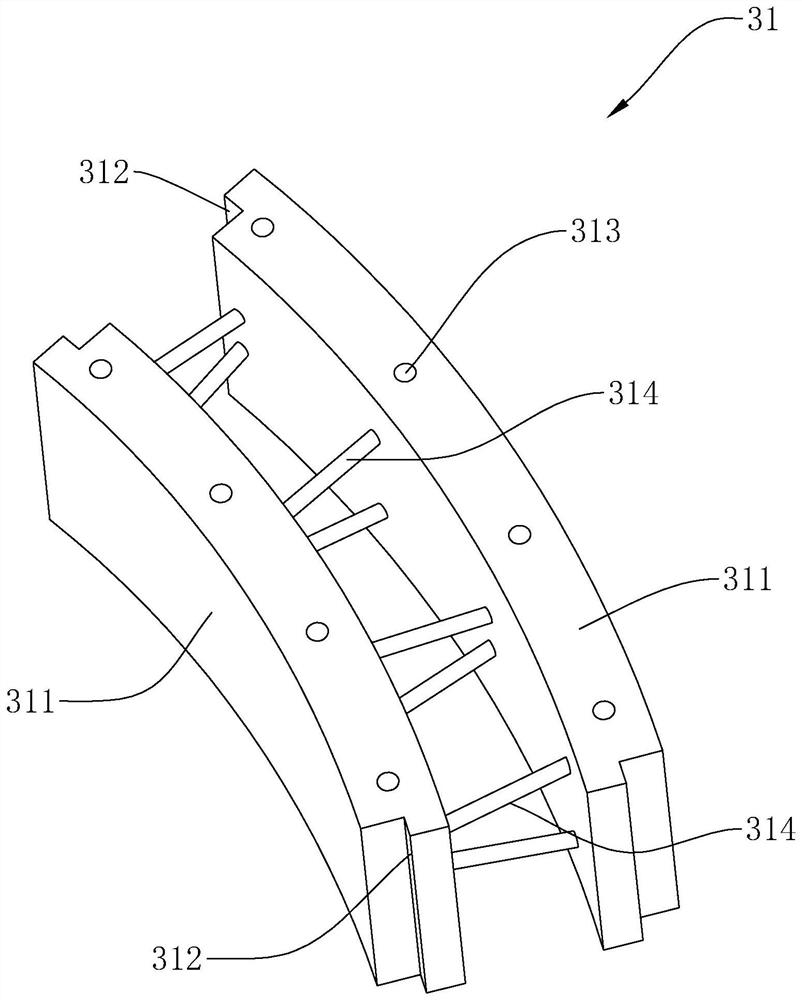

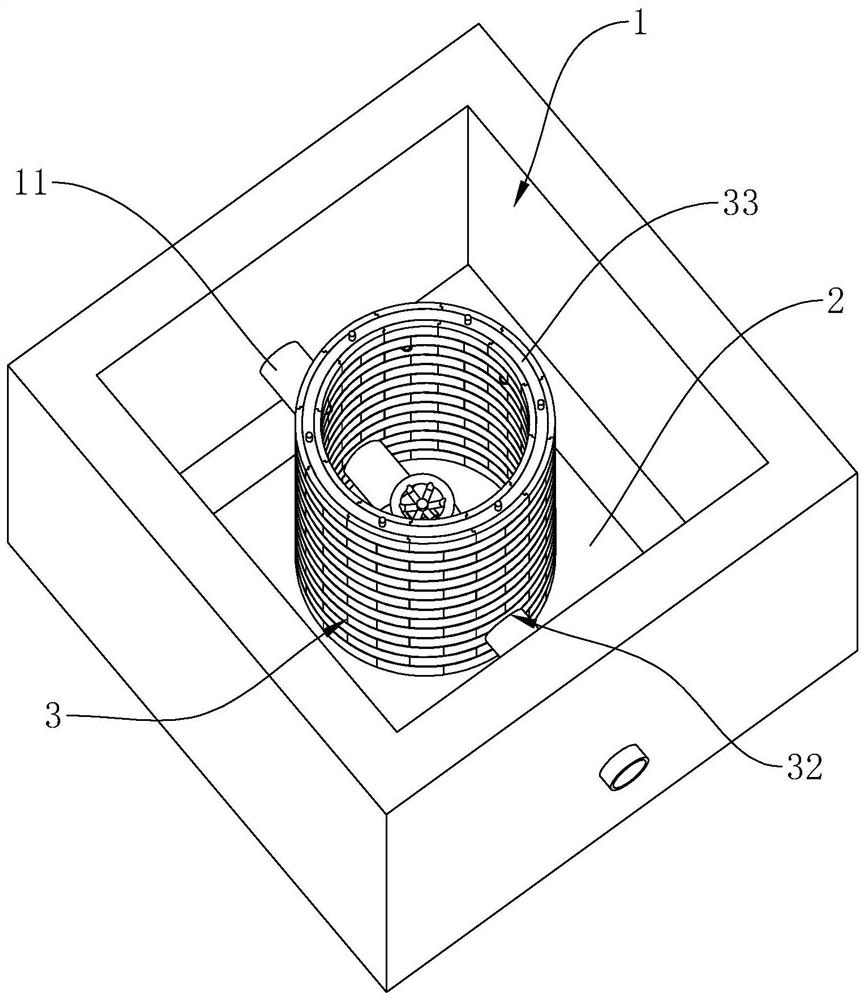

Wireless charging coil

PendingCN110189897AImprove practicalityEnhanced magnetic fieldTransformersCircuit arrangementsCircular loopEngineering

The invention relates to a wireless charging coil, and belongs to the technical field of wireless charging. The wireless charging coil comprises an excitation layer and coil annular loops wound by thesame insulating wire, wherein the coil annular loops includes a first coil annular loop and a second coil annular loop, the first coil annular loop is arranged on the upper end face of the excitationlayer, and the plane where the first coil annular loop is located is parallel to the excitation layer; and the second coil annular loop is arranged around the upper and lower end faces and two side surfaces of the excitation layer. The two coil annular loops are designed by using the same insulating wire, so that the magnetic field generated by the wireless charging coil after being electrified is enabled to be strengthened. Compared with the wireless charging coil in which the same insulating wire only forms one coil annular loop in the prior art, the excitation effect is enhanced, and the wireless charging efficiency and the practicability of the charging coil are improved.

Owner:XJ POWER CO LTD +1

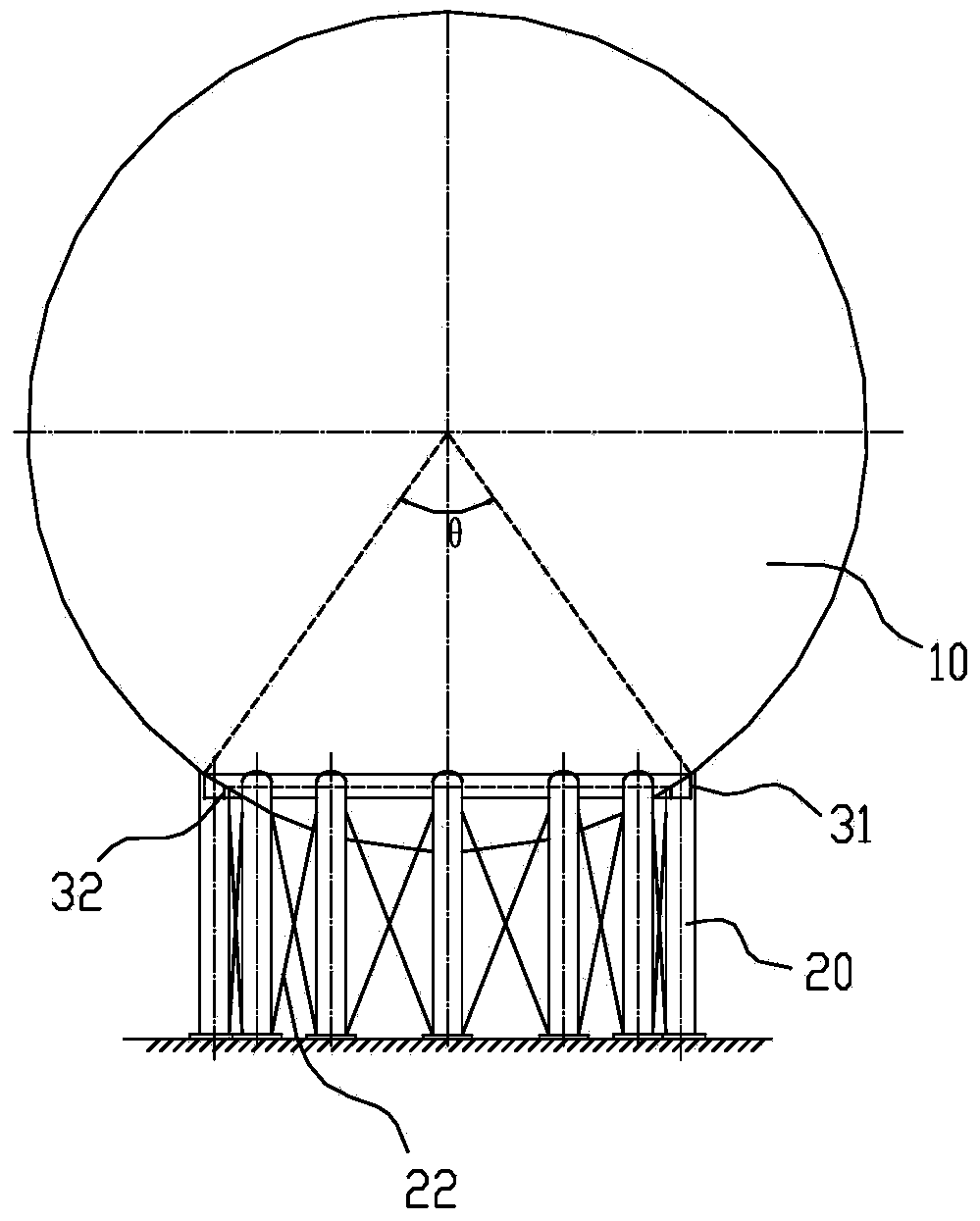

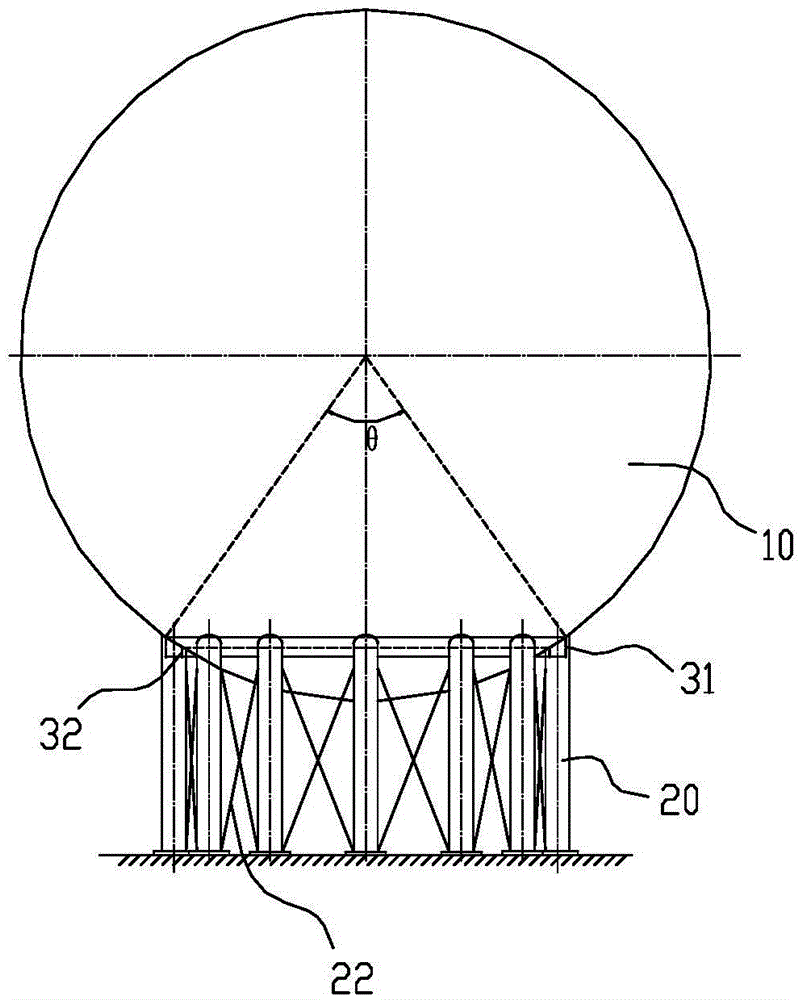

Spherical tank supporting structure

ActiveCN104110576AEnhanced resistance to horizontal loadsEven by forceContainer filling methodsContainer discharging methodsLoad resistanceMaterial consumption

The invention discloses a spherical tank supporting structure. The spherical tank supporting structure comprises a plurality of supporting pillars of a spherical tank, one end of the supporting pillars close to the spherical tank, that is the upper end of the spherical tank is connected with the tank wall in the lower temperature zone of the spherical tank, and the supporting structure also comprises a supporting ring matched with the supporting pillars to support the spherical tank. The structure is used for solving the problems of difficult welding, large material consumption and poor performances of equatorial tangent supporting pillar structures in the prior art, and the supporting pillars in the invention are shorter than the supporting pillars in the equatorial tangent supporting structures, so the material is saved, the cost is reduced, and the overall horizontal load resistance of the spherical tank is enhanced; and the supporting ring is arranged in the connection of the supporting pillars and the spherical tank, so the contact area of the spherical tank and the supporting structure is enlarged, thereby the whole force bearing of the spherical tank is uniform, the spherical tank has a good stability, and the resistance to horizontal earthquake load, wind load and other outside force loads of the spherical tank is improved.

Owner:HEFEI GENERAL MACHINERY RES INST

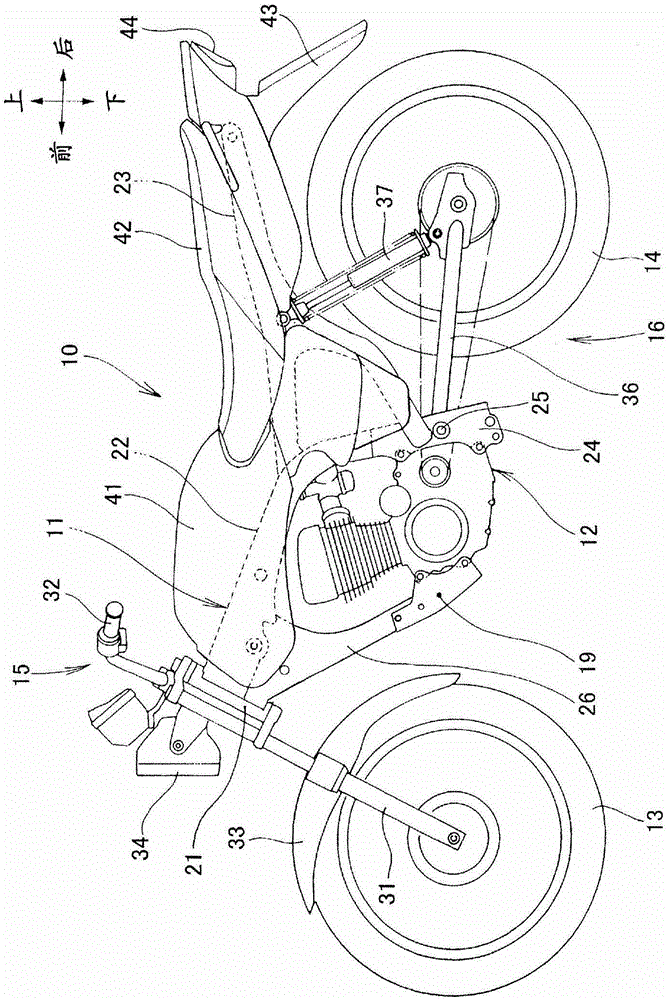

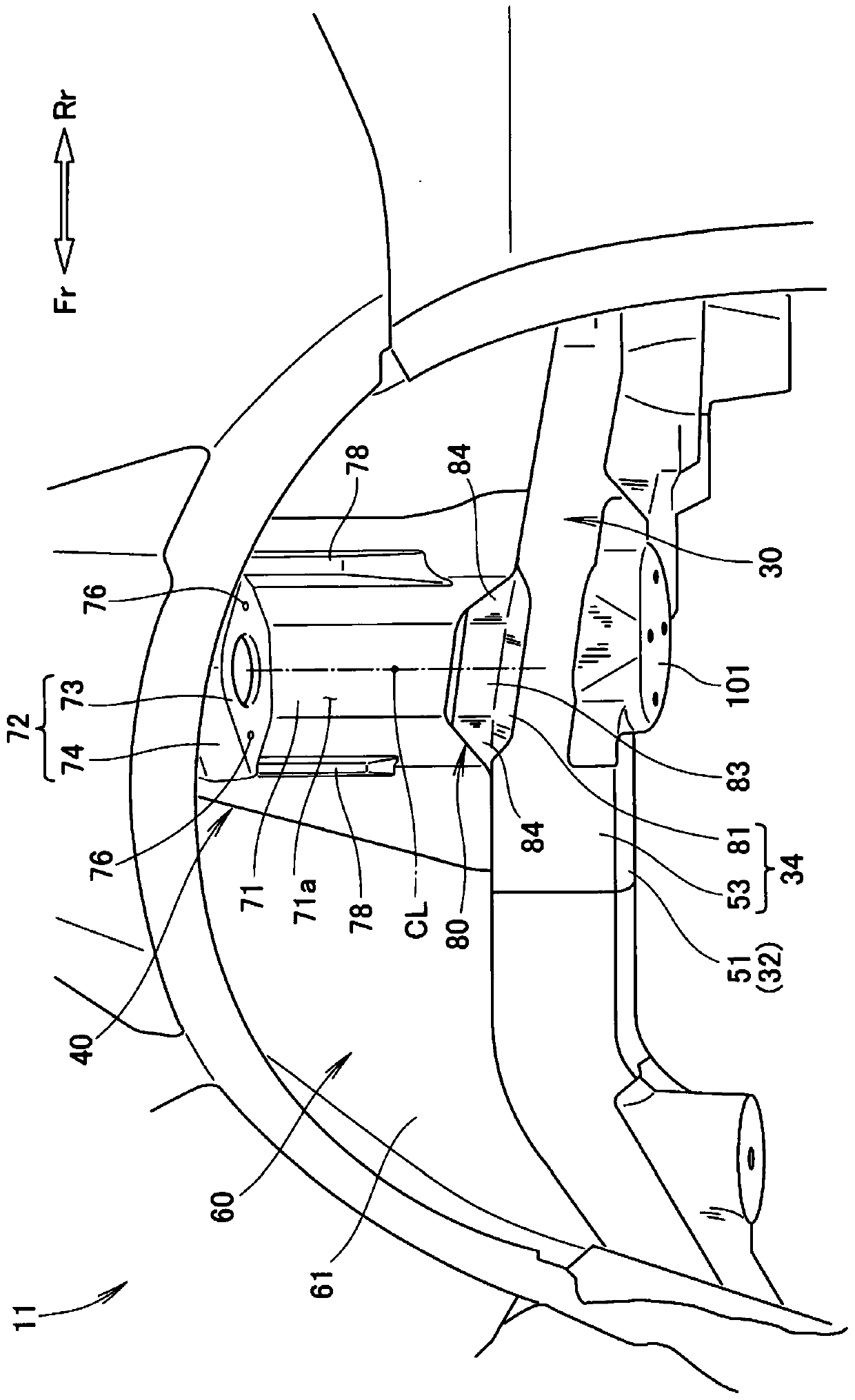

Body frame of a two-wheeled motorcycle

Owner:HONDA MOTOR CO LTD

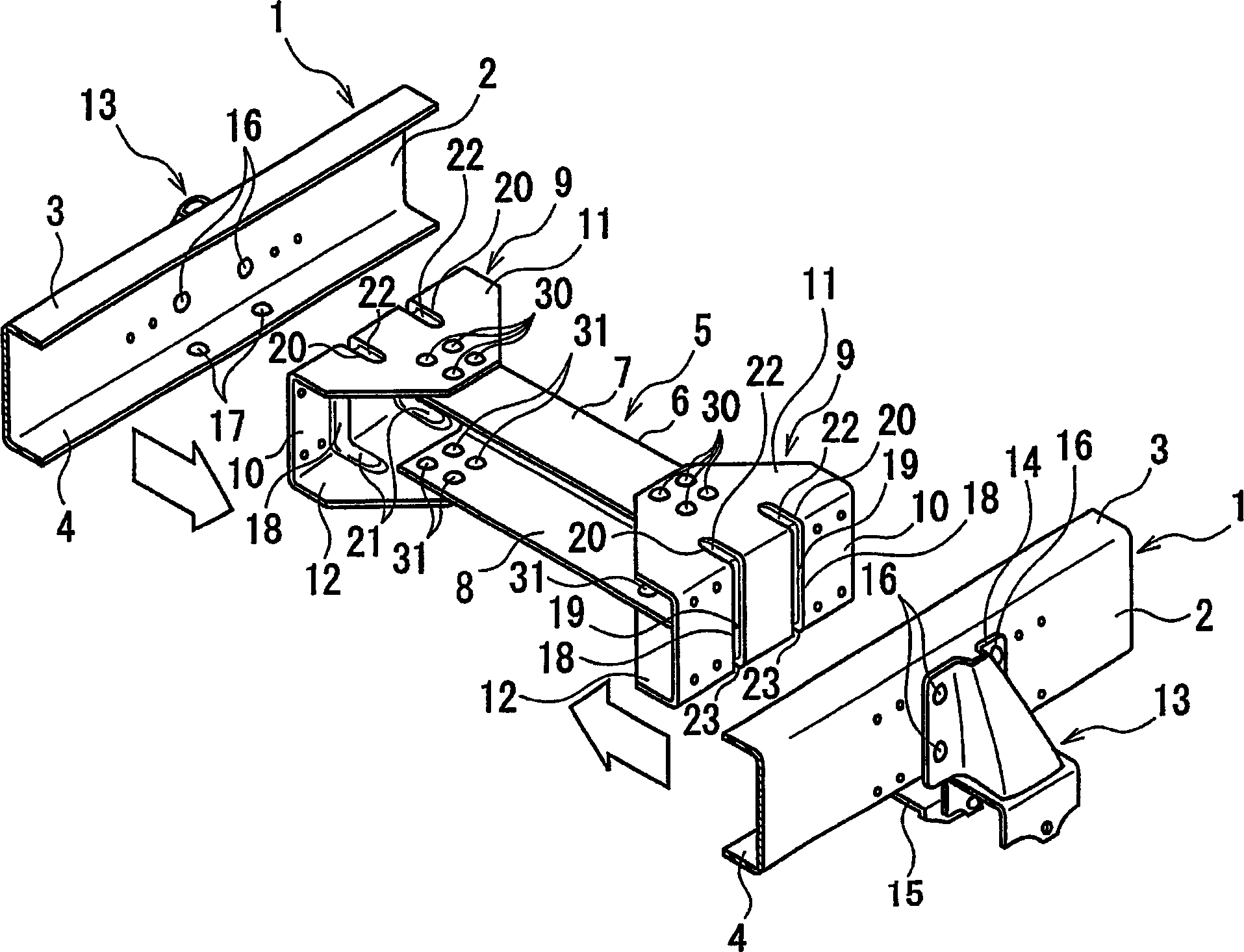

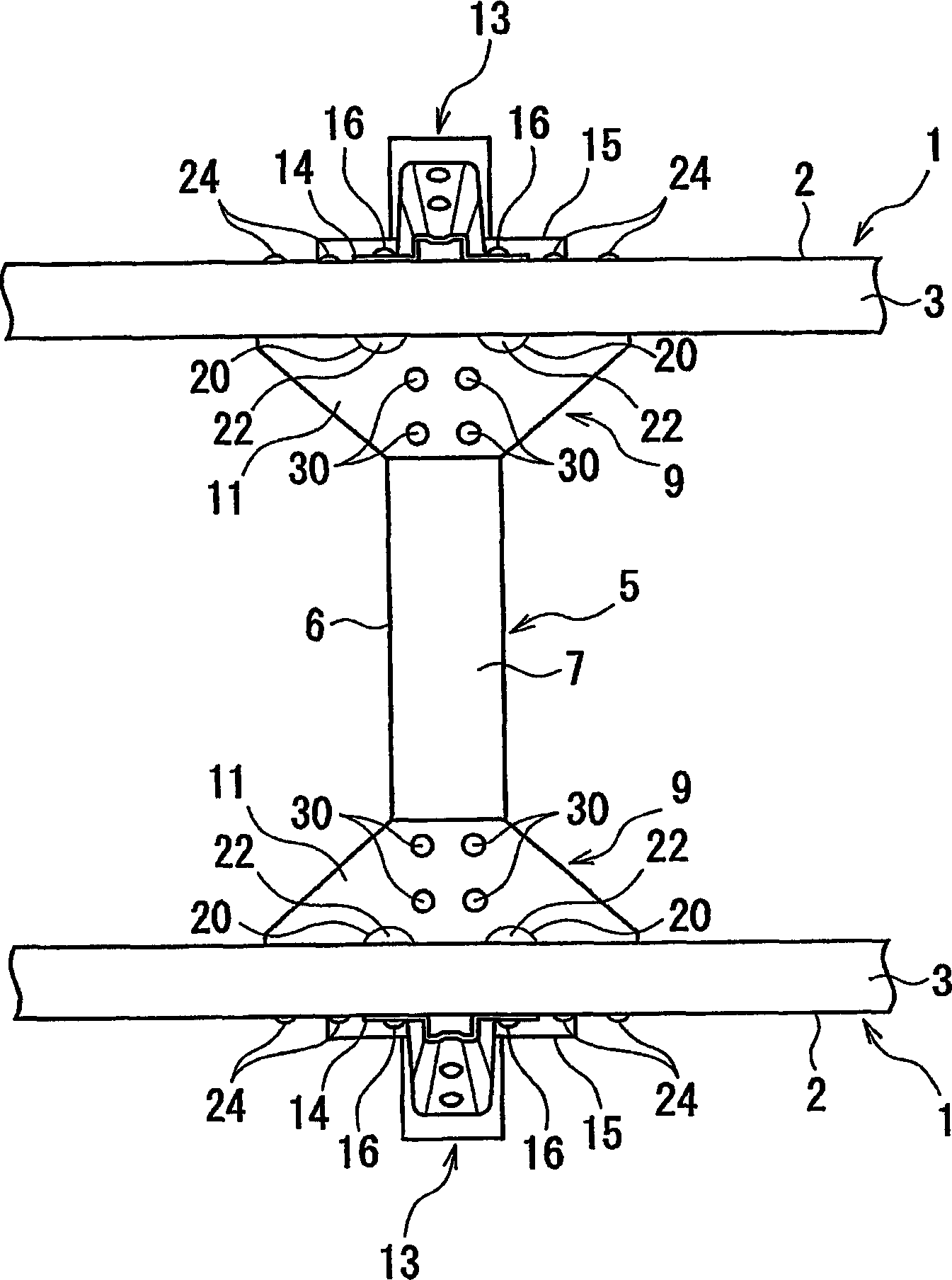

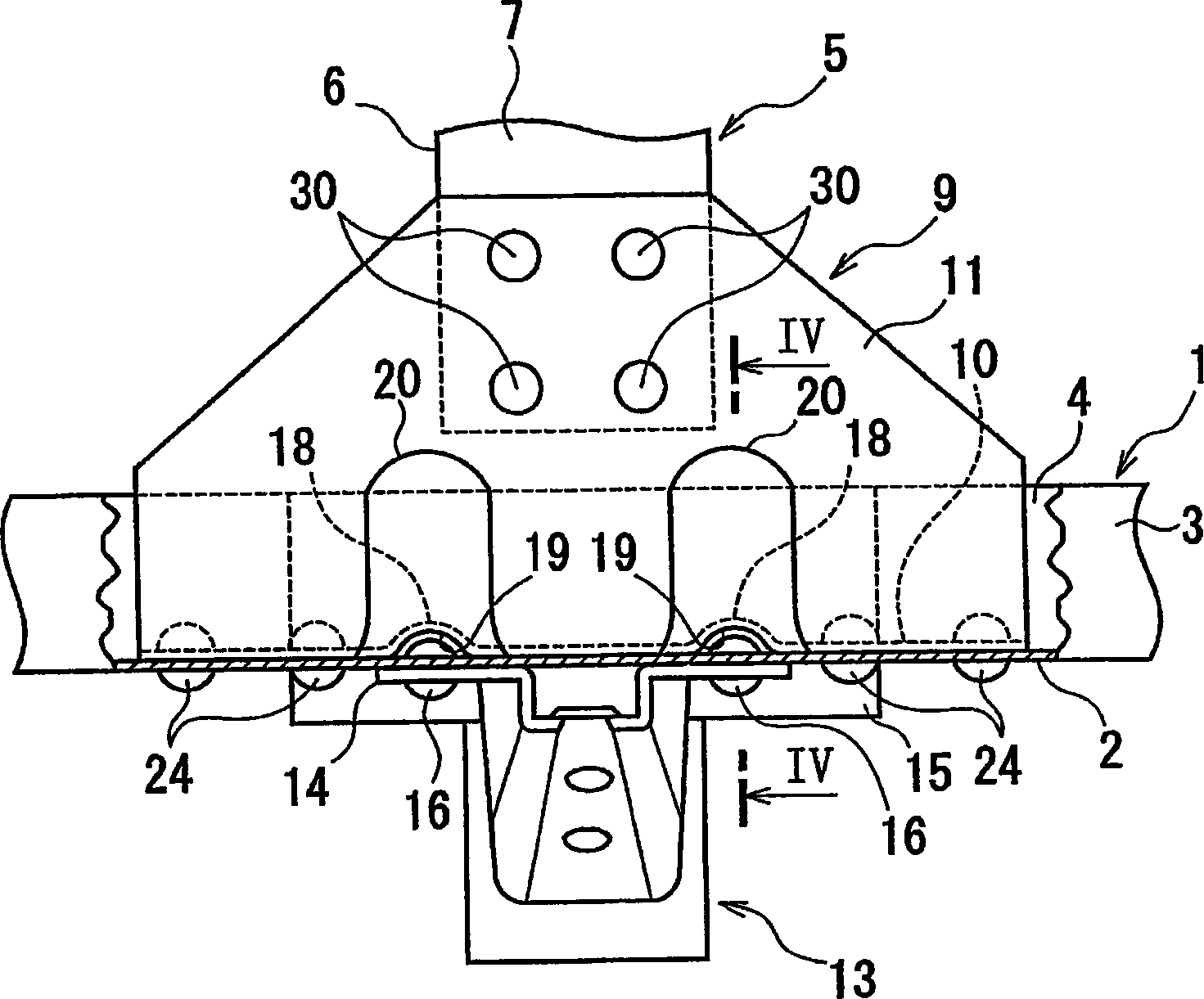

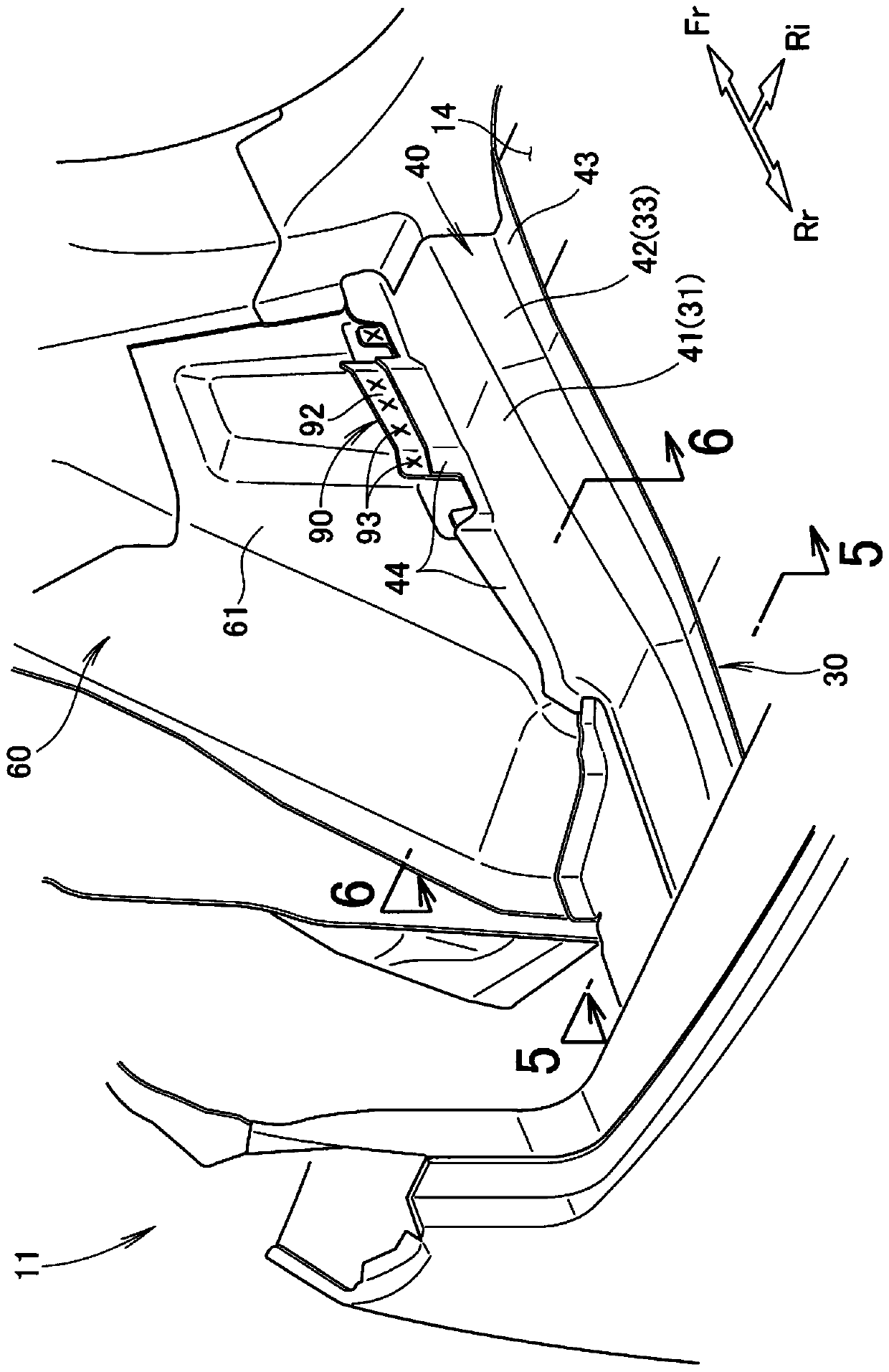

Connection structure of side member to cross member

InactiveCN1638997AIncrease stiffnessImprove enhanced performanceUnderstructuresSuperstructure subunitsClassical mechanicsRivet

A gusset connecting the lateral end of the cross bar to the side plate, comprises vertical plate and upper and lower lateral plates. Ribs formed in the vertical plate, form recesses in its lateral outer surface to fit the rivets used for fixing leaf spring bracket to lateral outer surface of vertical wall of side plate, so as to fix the vertical plate to the lateral inner surface of the vertical wall in surface contact state.

Owner:ISUZU MOTORS LTD

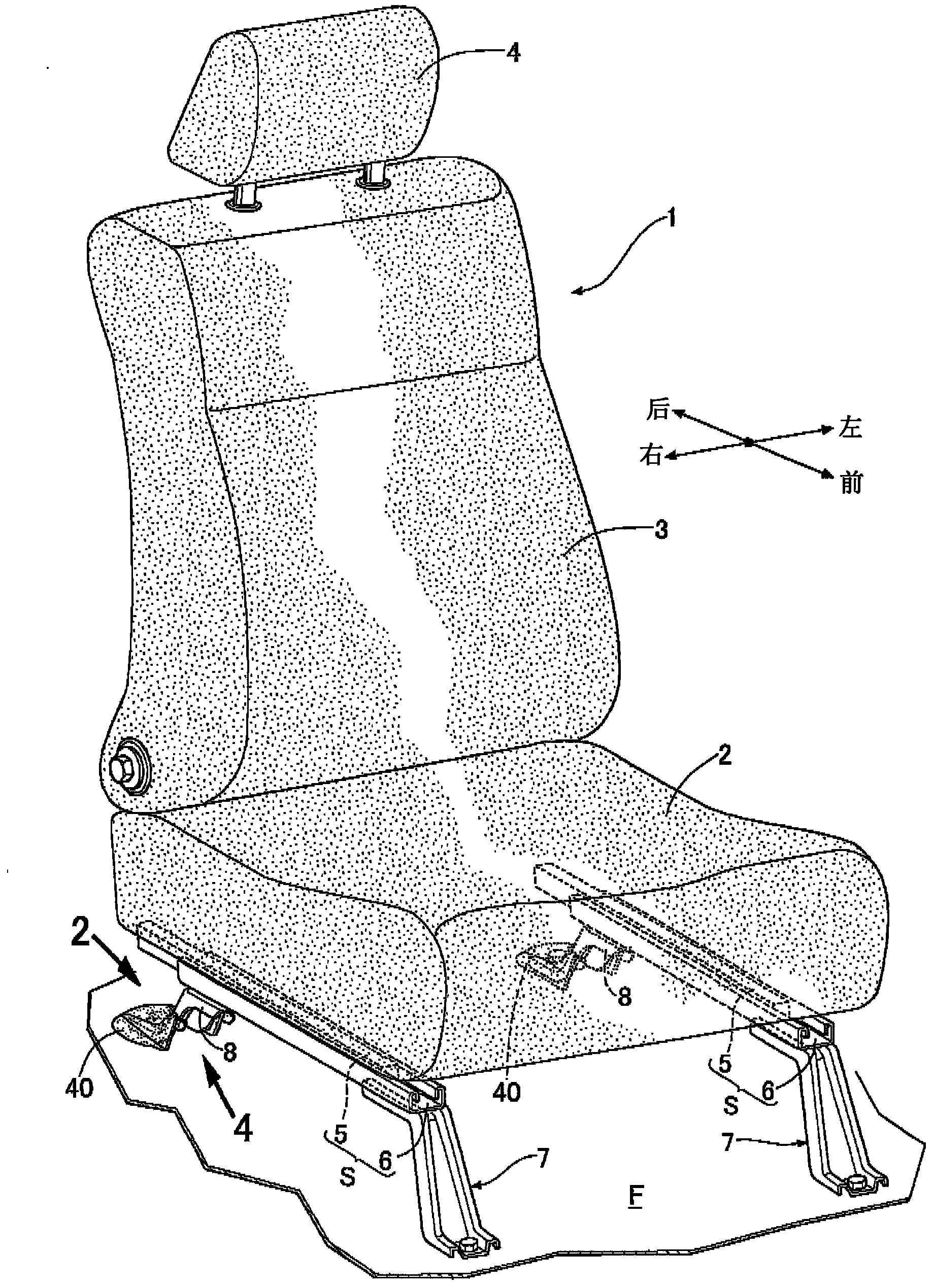

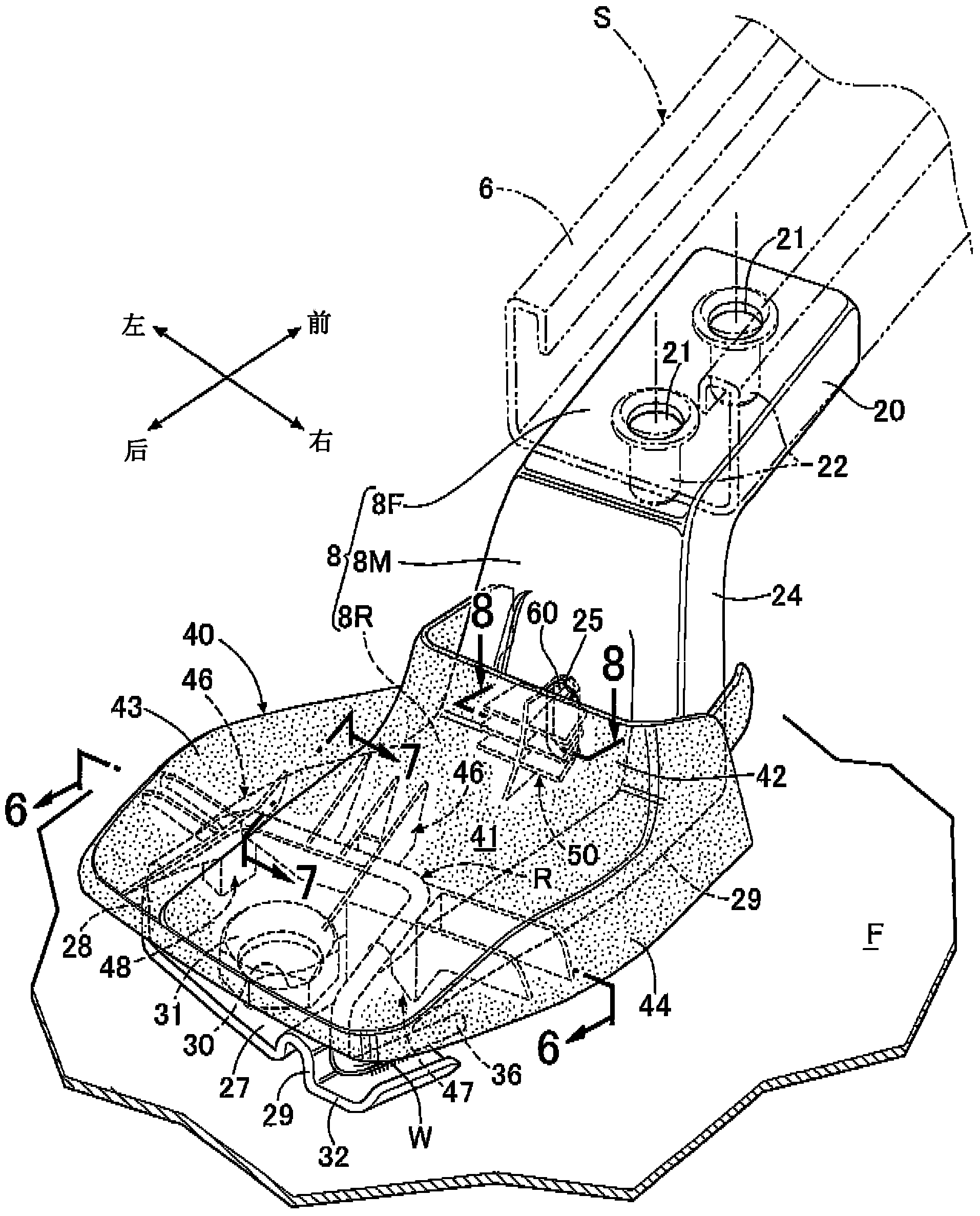

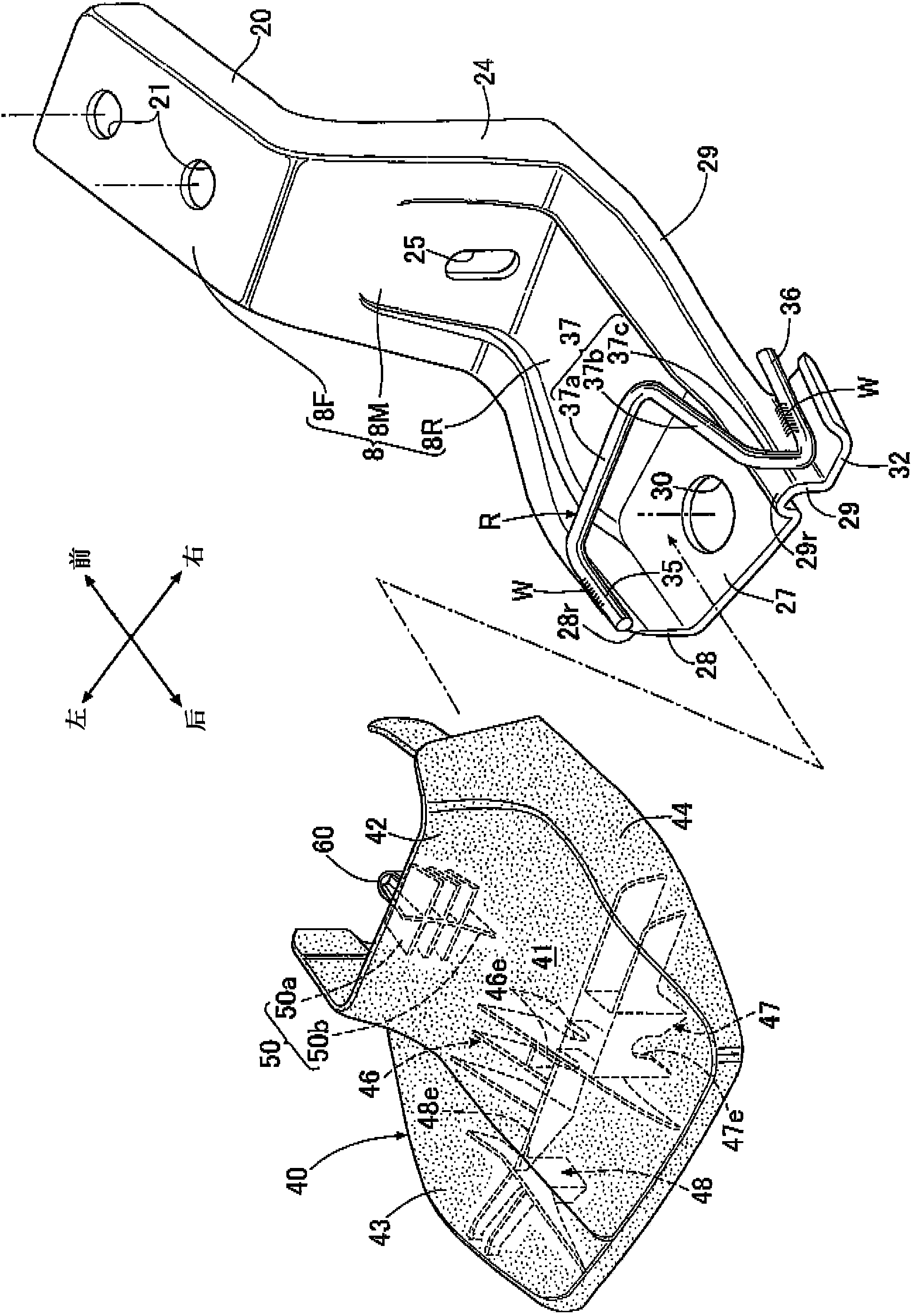

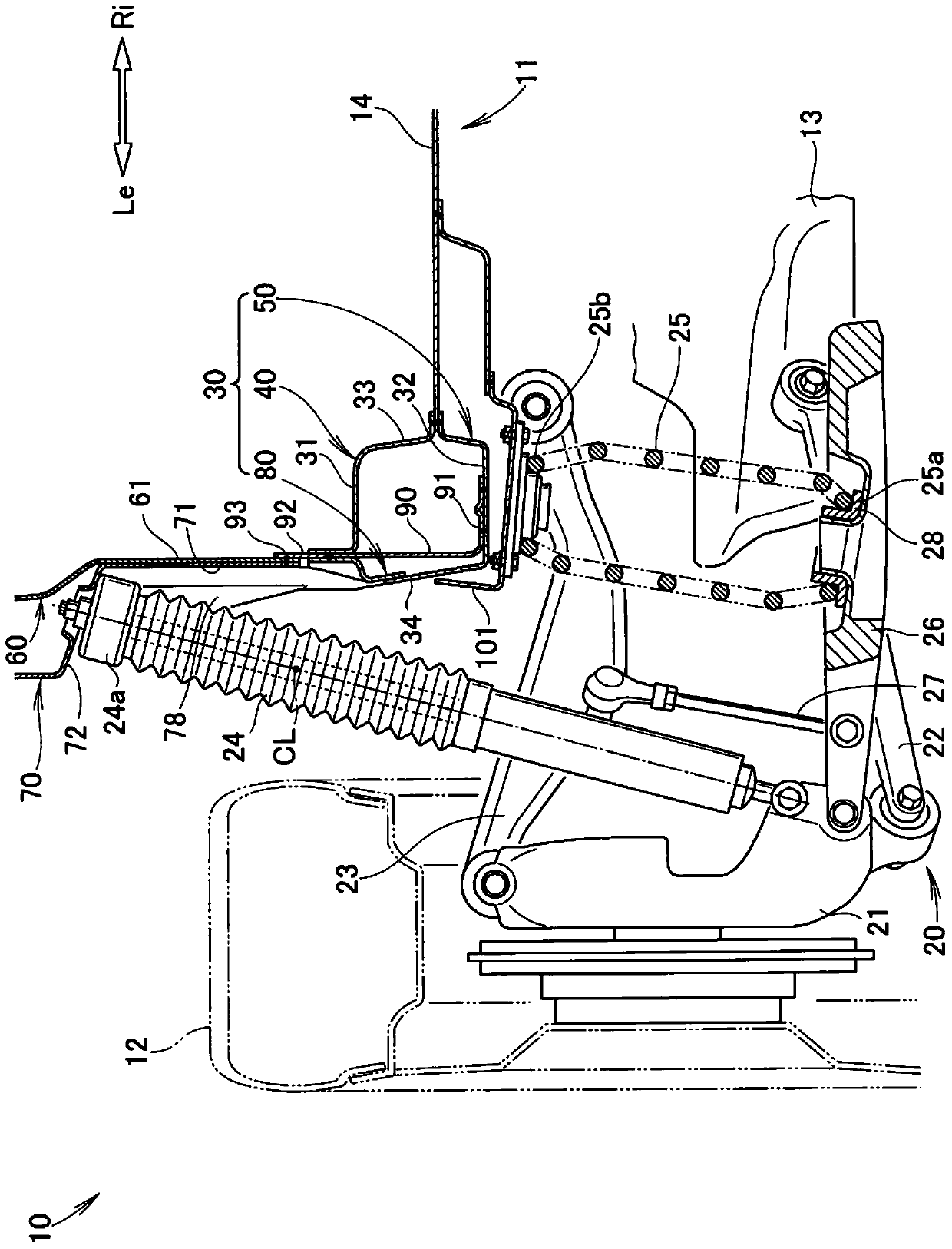

Vehicle seat supporting device

ActiveCN104139715AImprove enhanced performanceDoes not interfere with fixed operationSeat framesMovable seatsEngineering

Owner:TS TECH CO LTD +1

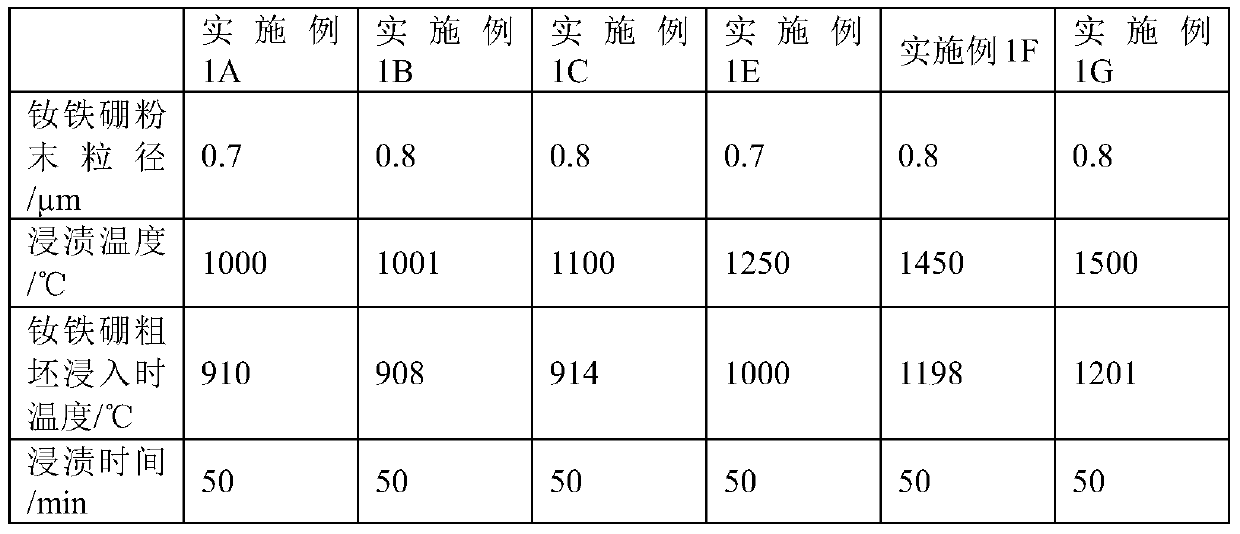

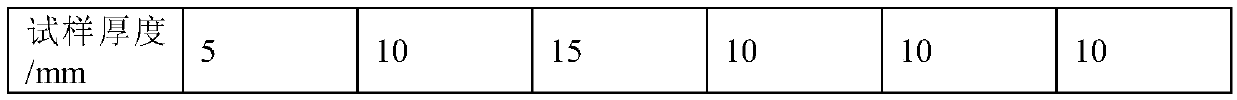

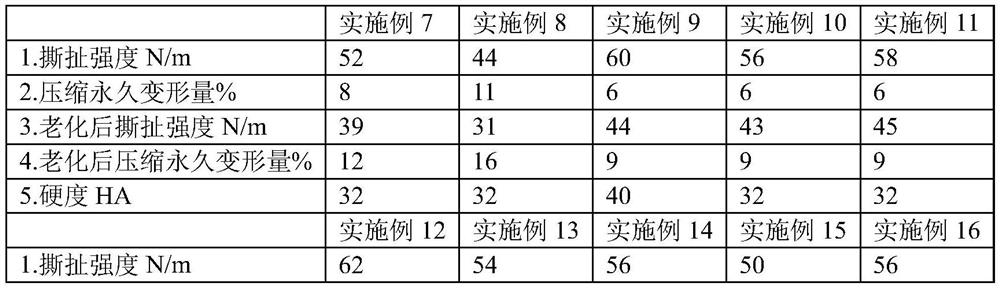

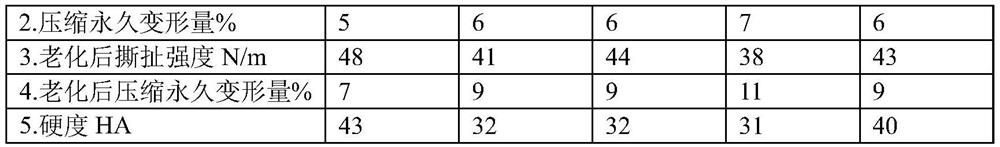

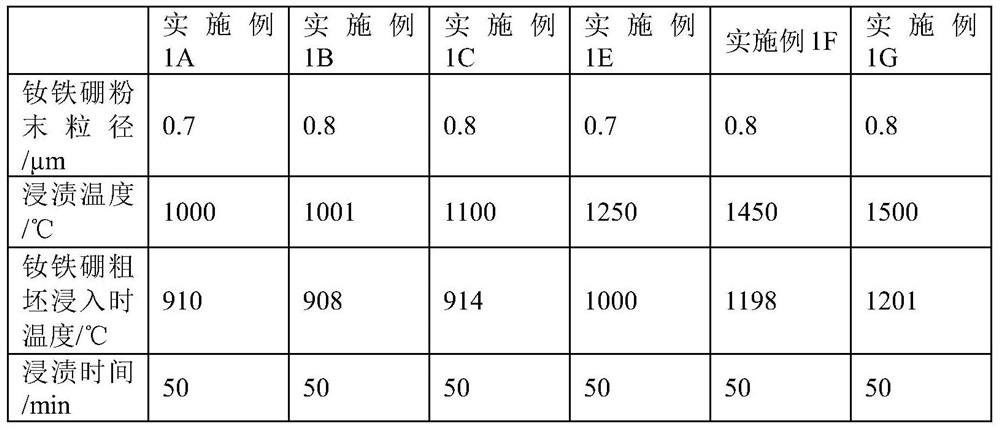

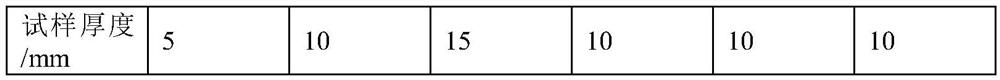

Preparation method of grain boundary diffusion heavy rare earth neodymium iron boron magnet and neodymium iron boron magnet

ActiveCN109935462AEnhance internal bondingReduce collapseInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSolid solution

The invention relates to a neodymium iron boron magnet and discloses a preparation method of a grain boundary diffusion heavy rare earth neodymium iron boron magnet and a neodymium iron boron magnet.The neodymium iron boron powders are pressed into a neodymium iron boron rough blank, and then are immersed in a heavy rare earth source molten mass. The heavy rare earth source molten mass proactively permeates the neodymium iron boron rough blank. The solid solution and permeation are generated between the heavy rare earth source molten mass and the neodymium iron boron rough blank so as to fillgaps and defects in the neodymium iron boron rough blank. Further, heavy rare earth elements are subjected to grain boundary diffusion in the neodymium iron boron magnet, to improve the grain boundary diffusion efficiency of the heavy rare earth elements, so that the grain boundary diffusion heavy rare earth element process becomes feasible for strengthening the coercive force of the neodymium iron boron magnet with large thickness, and a neodymium iron boron magnet having a thickness greater than 5 mm and a coercive force enhancement effect higher than that of the existing grain boundary diffusion heavy rare earth element process is obtained.

Owner:宁波雄海稀土速凝技术有限公司

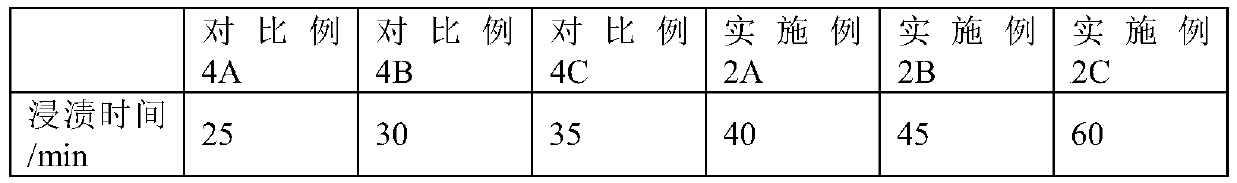

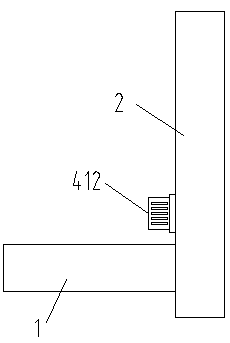

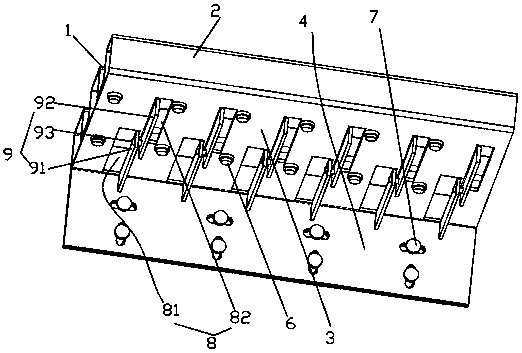

Small tremie grouting machine for tunnel construction

ActiveCN111577335AEasy to removeAvoid bendingUnderground chambersTunnel liningTremieArchitectural engineering

The invention discloses a small tremie grouting machine for tunnel construction. The small tremie grouting machine comprises a cantilever, a supporting disc is fixedly connected to one end of the cantilever, and a plurality of grouting devices are arranged on the supporting disc; the grouting devices comprise sliding blocks, a plurality of sliding grooves are formed in the side, away from the cantilever, of the supporting disc, the sliding blocks are slidably connected with the sliding grooves in one-to-one correspondence, a supporting box is fixedly connected to the sliding blocks, an extending hole is formed in one end of the supporting box, an injection pipe is slidably connected into the extending hole, a storage pipe is fixedly connected to the outer side of the supporting box, a piston plate is slidably connected into the storage pipe, a pushing rod is fixedly connected to one side of the piston plate, the pushing rod extends to the outer part of the storage pipe, a conveying pipe is fixedly connected to the other end of the storage pipe, and the other end of the conveying pipe communicates with the injection pipe and is fixedly connected with the injection pipe. According tothe small tremie grouting machine, a grouting hole is grouted by the injection pipe, and meanwhile retracting is conducted, so that the grouting hole can be fully filled with cement slurry, and the foundation strengthening effect is improved.

Owner:山东美固德新材料有限公司

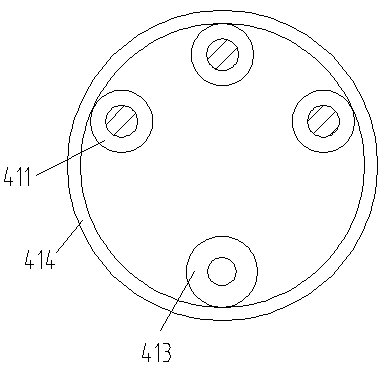

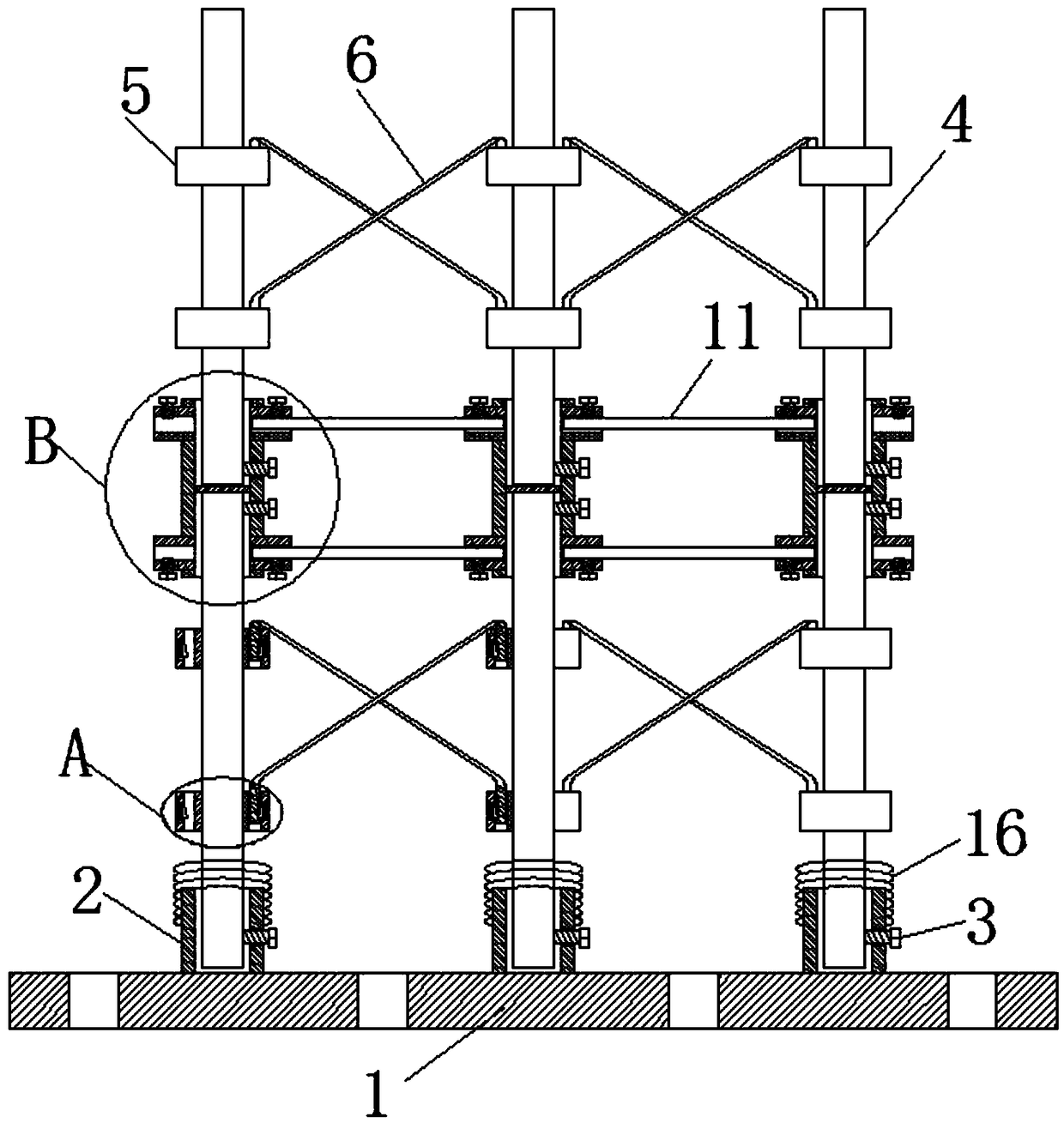

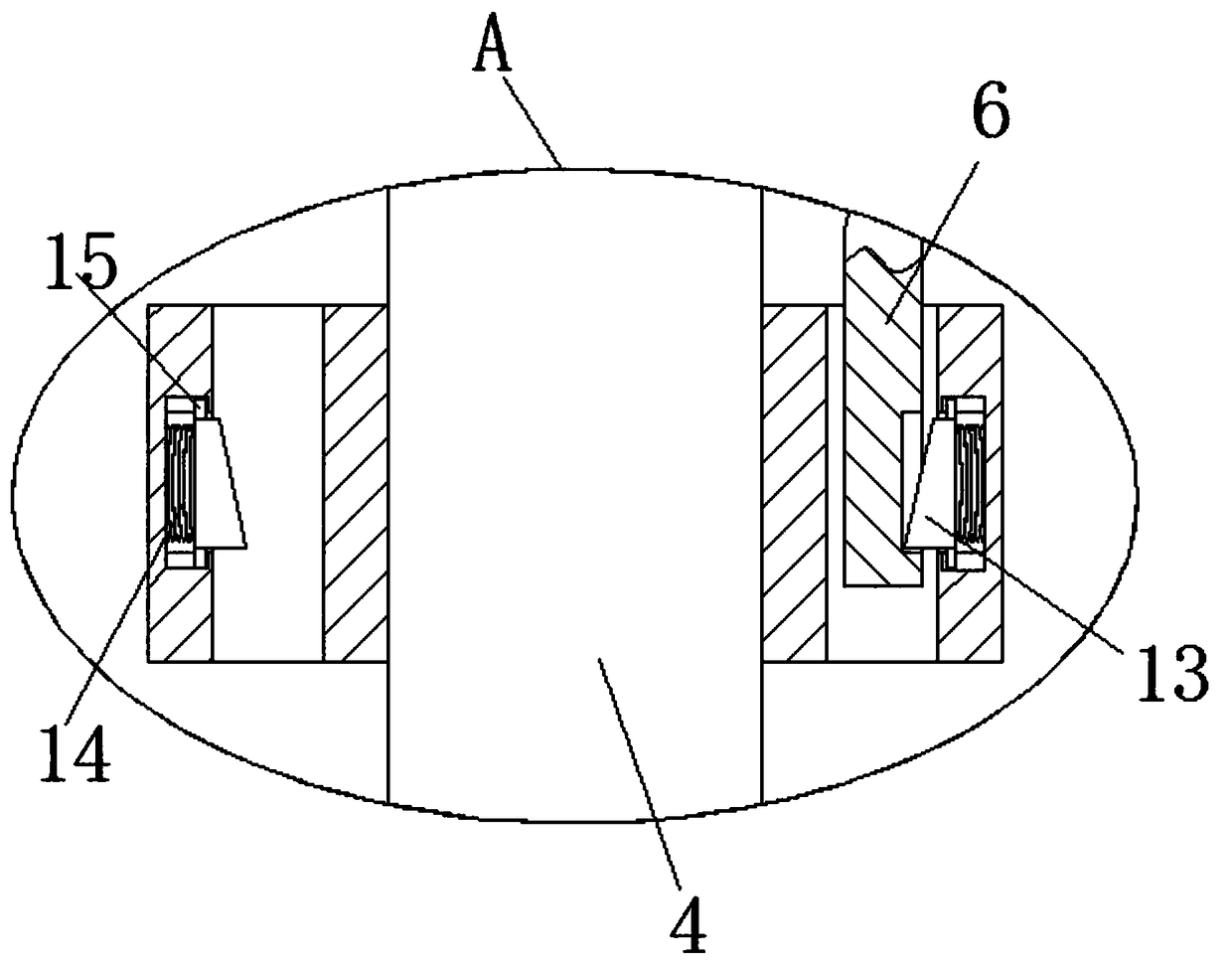

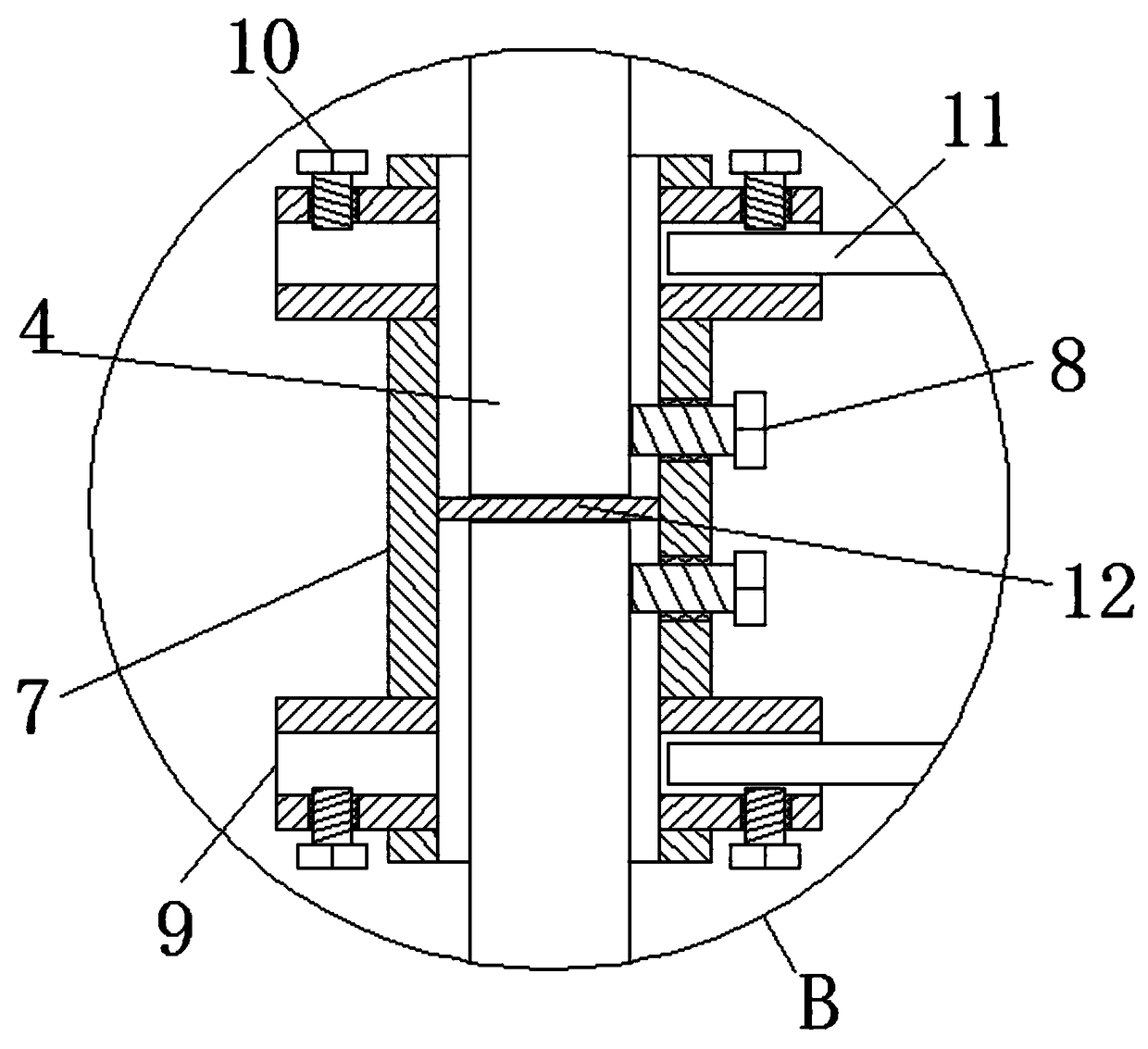

Internal force reinforcement device for pillar structure

InactiveCN104718331AImprove enhanced performanceImproved ease of construction and maintenance management and disassemblyStrutsPillarsEngineeringWrap around

The present invention relates to an internal force reinforcement device for a pillar structure, including: a plurality of inner reinforcement plates that wrap around a circumferential surface of the pillar; at least one pair of outer reinforcement plates that are coupled to each other to wrap around an outer wall of the pillar so as to be separated from the inner reinforcement plates; and a pressure control member that is arranged on the outer reinforcement plate to put pressure or release pressure on the inner reinforcement plate to or from the pillar side. In this manner, the internal force reinforcement performance of the pillar structure is improved and at the same time, convenience in terms of construction, maintenance and repair, and disassembly is significantly improved.

Owner:INDUSRTY ACADEMIC COOPERATION FOUND CHOSUN UNIV

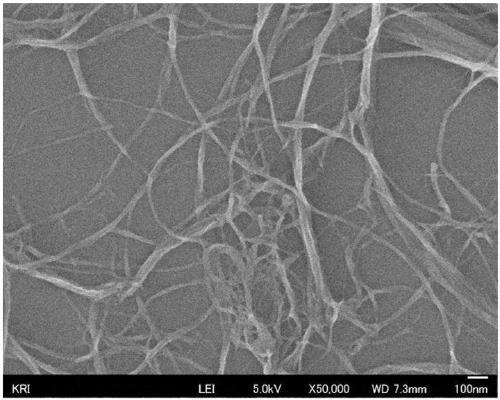

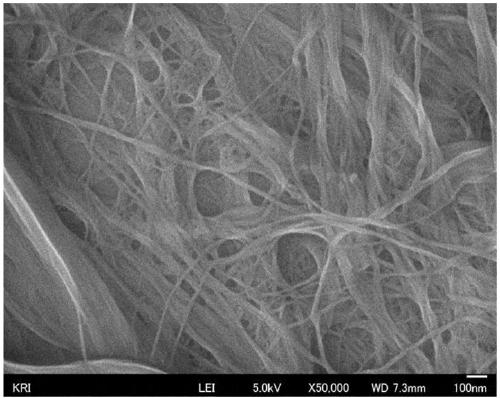

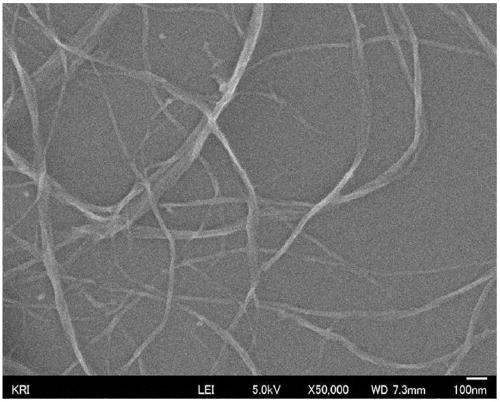

Method for producing cellulose fine fiber

InactiveCN109642397AAvoid damageHigh affinityPulp properties modificationPretreatment with acid reacting compoundsPolymer scienceMechanical fragmentation

Provided is a method for producing a cellulose fine fiber that has a nano size and high crystallinity and rarely undergoes the damage of a fiber shape, by impregnating cellulose with a formic acid-containing fiberizing solution and then fiberizing the cellulose, without requiring vigorous mechanical fragmentation of the cellulose. Also provided is a method for producing a surface-modified cellulose fine fiber in which the cellulose is modified. The method for producing a cellulose fine fiber according to the present invention involves impregnating cellulose with a fiberizing solution, i.e., formic acid, a formic acid-rich aqueous solution or a solution of formic acid or a formic acid-rich aqueous solution in an aprotic solvent having a number of donors of 26 or more and then fiberizing thecellulose. The method for producing a surface-modified cellulose fine fiber according to the present invention is characterized in that the fiberizing solution further contains a modification reaction agent and the method involves impregnating cellulose with the fiberizing solution and then modifying the microfibril surface of the cellulose while fiberizing the cellulose.

Owner:FUTAMURA CHEM

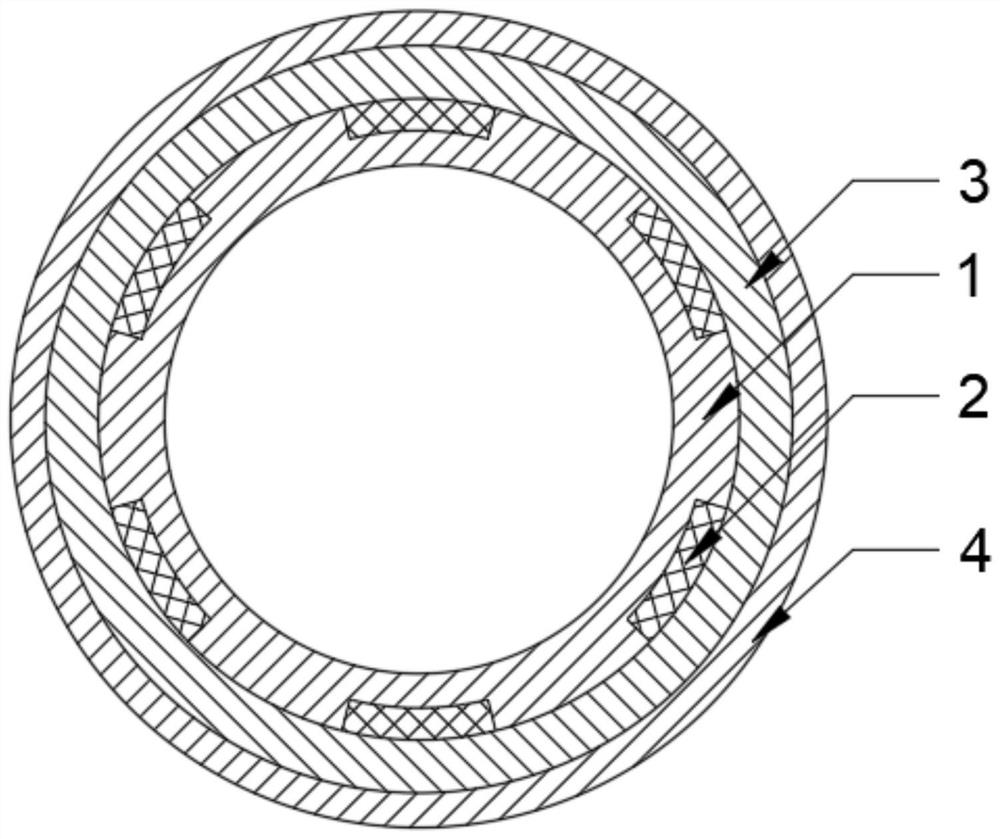

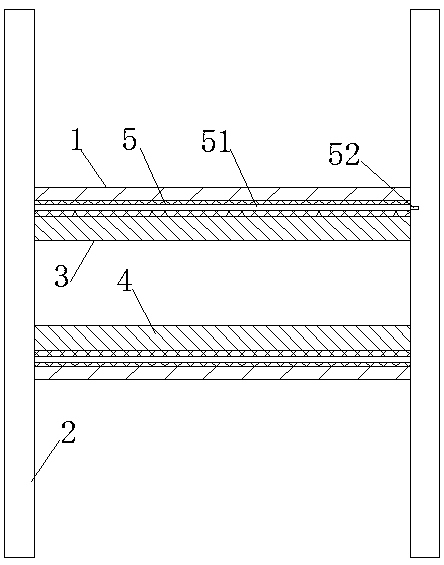

High-strength corrosion-resistant polyethylene composite pipe

The invention discloses a high-strength corrosion-resistant polyethylene composite pipe. The high-strength corrosion-resistant polyethylene composite pipe comprises an inner-layer pipe, a middle reinforcing layer, a plurality of reinforcing rings and an outer-layer pipe, wherein the inner-layer pipe is made of a polyethylene material; the middle reinforcing layer is made of a high-strength aluminum alloy and comprises a plurality of reinforcing strips attached to the outer surface of the inner-layer pipe; the reinforcing rings are arranged on the outer surface of the middle reinforcing layer at intervals and are fixed to the reinforcing strips of the middle reinforcing layer in a welded mode; the reinforcing strips are made of a high-strength aluminum alloy; and the outer-layer pipe is made of the polyethylene material and covers the outer surfaces of the middle reinforcing layer, the inner-layer pipe and the reinforcing rings. The middle reinforcing rings and the reinforcing strips are wrapped through the inner-layer pipe and the outer-layer pipe, the overall strength of the pipe can be enhanced through the middle reinforcing rings and the reinforcing strips, and therefore the polyethylene composite pipe has the advantages of high strength and corrosion resistance and can be suitable for places with the requirements for strength and corrosion resistance.

Owner:江西爱森德实业有限公司

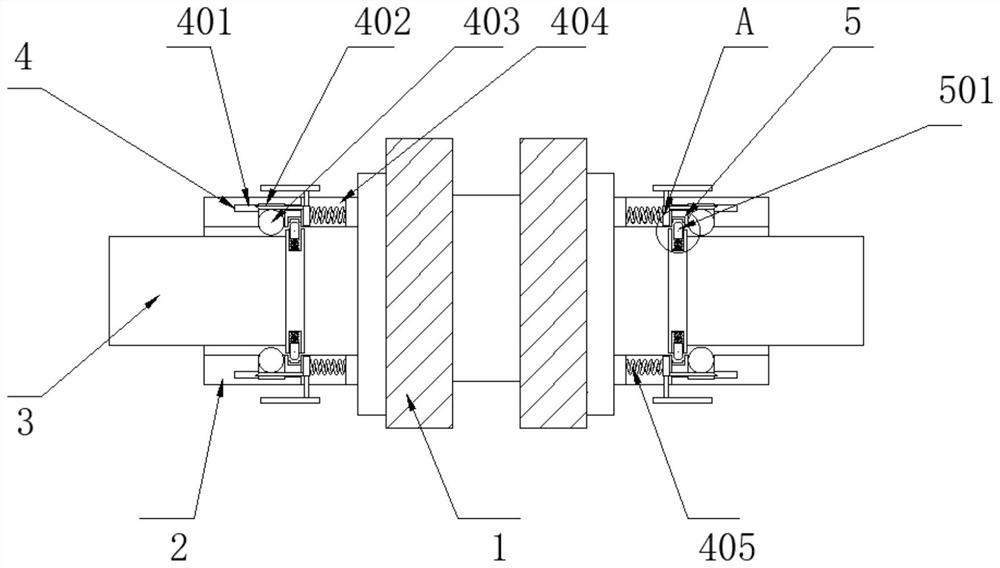

Pipeline compensation joint convenient and rapid to butt joint

The invention discloses a pipeline compensation joint convenient and rapid in butt joint. The pipeline compensation joint comprises a joint main body and connectors, the connectors are arranged on the two sides of the joint main body, an external pipeline is arranged on one side of each connector, and splicing structures are arranged at the two ends in each connector; and each splicing structure comprises a limiting groove, a moving groove, a ball, a through groove, a telescopic spring, a supporting block, a push plate and a limiting block, the through groove is formed in the two ends of the interior of the connector, the telescopic spring is arranged in the through groove, and the supporting block is fixed to one side of the telescopic spring. A sealing structure is arranged in the middle of the interior of the connector, when the external pipeline moves in the connector, a sealing block is squeezed to contract towards one side, when the external pipeline moves to a sealing groove, a reset spring pushes the sealing block to be inserted into a sealing gasket according to the elastic characteristic of the reset spring, and therefore sealing is completed, and the sealing effect is improved.

Owner:HUHANG TECH GRP CO LTD

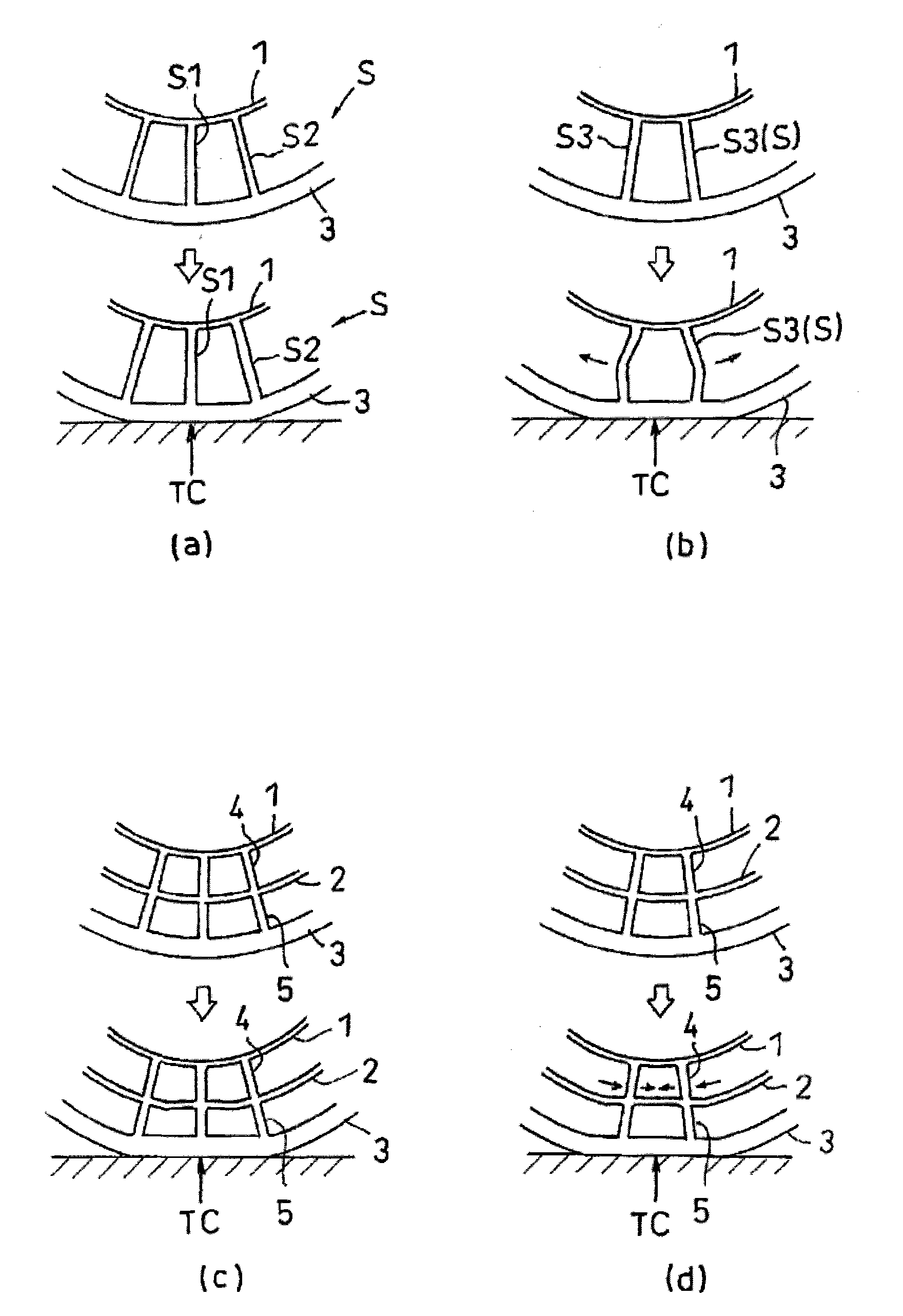

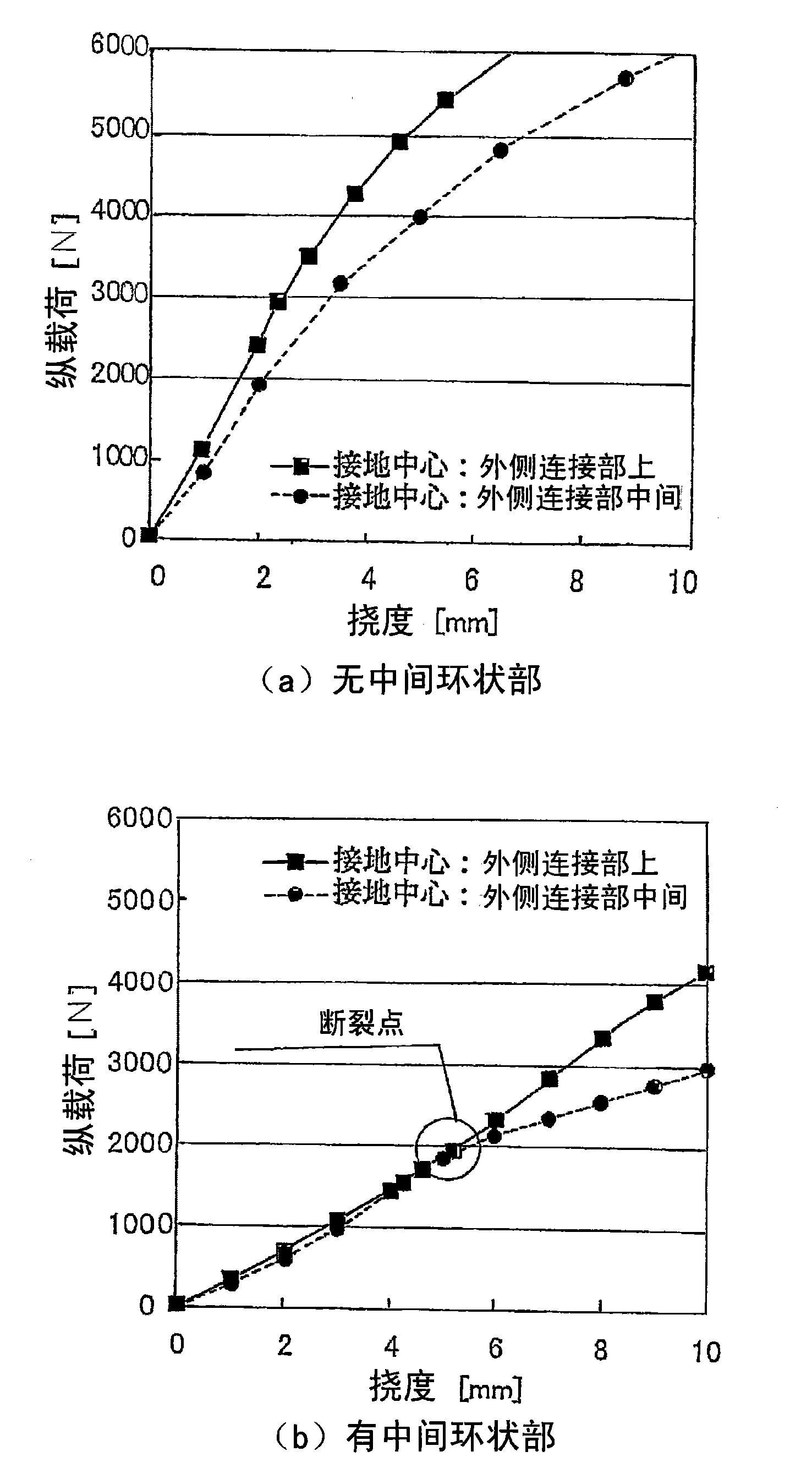

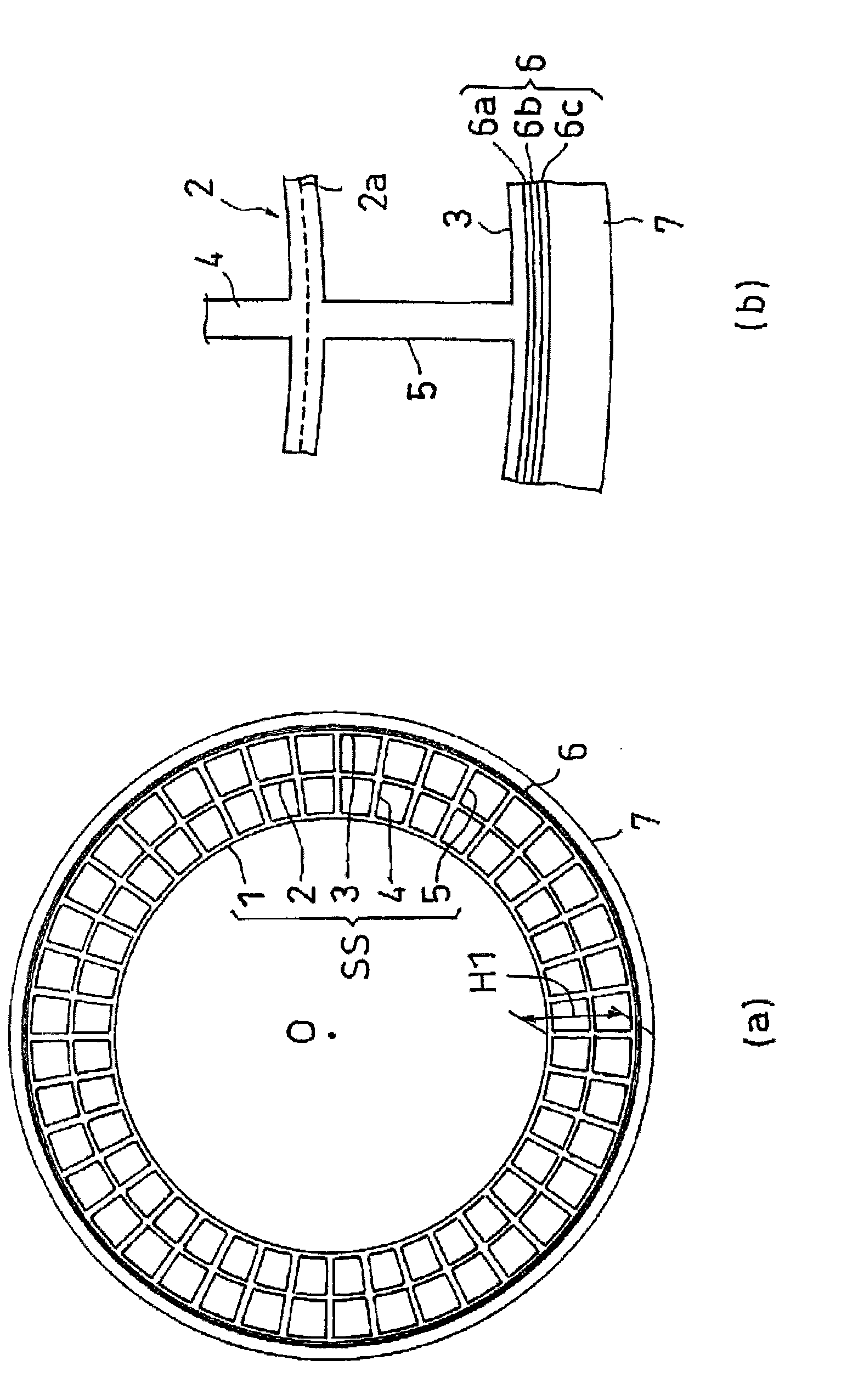

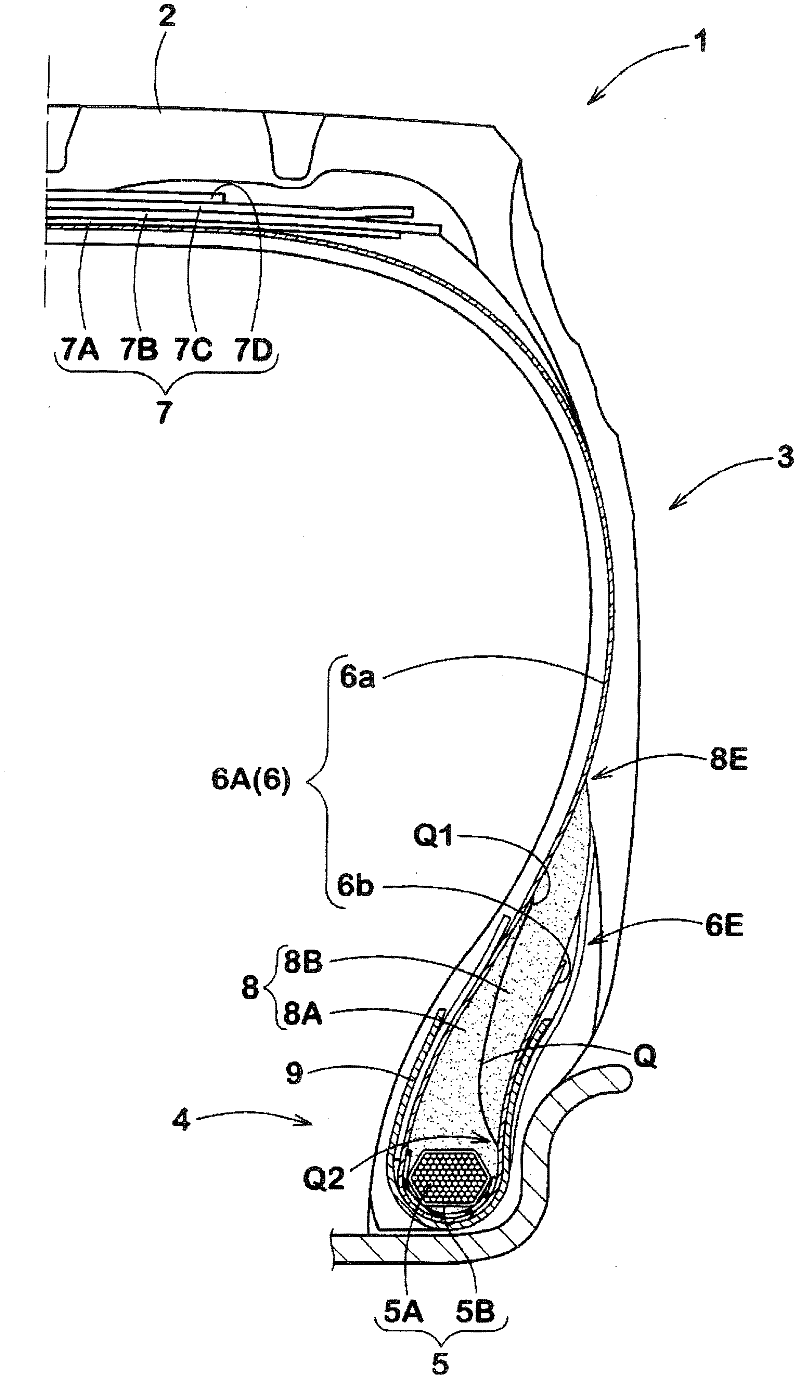

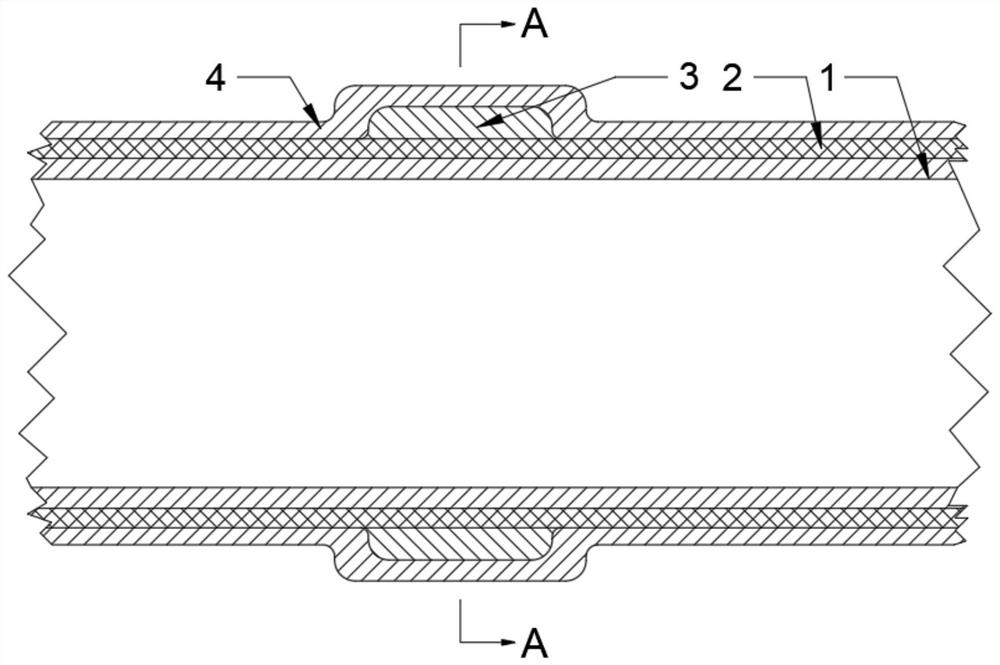

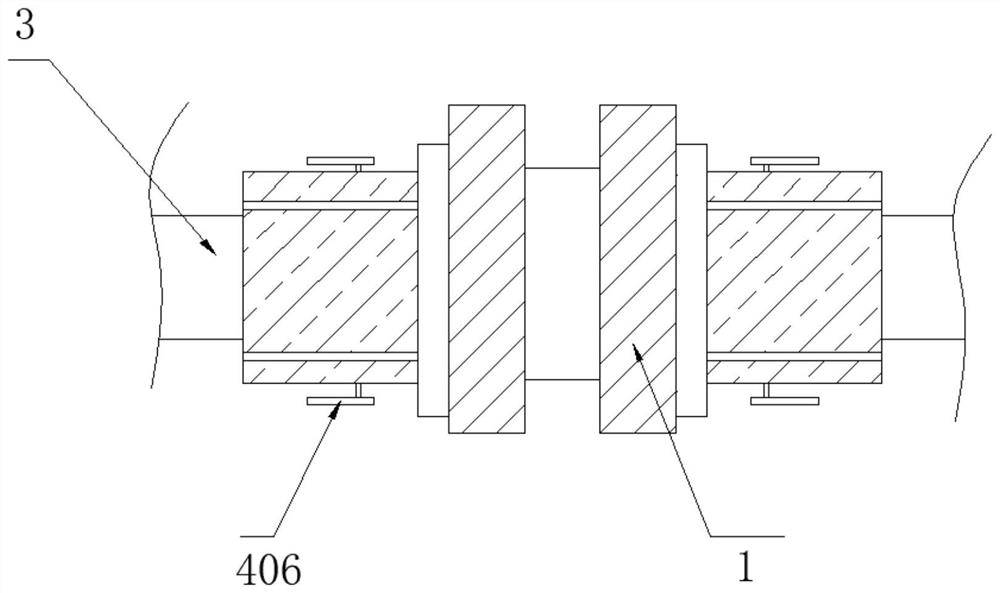

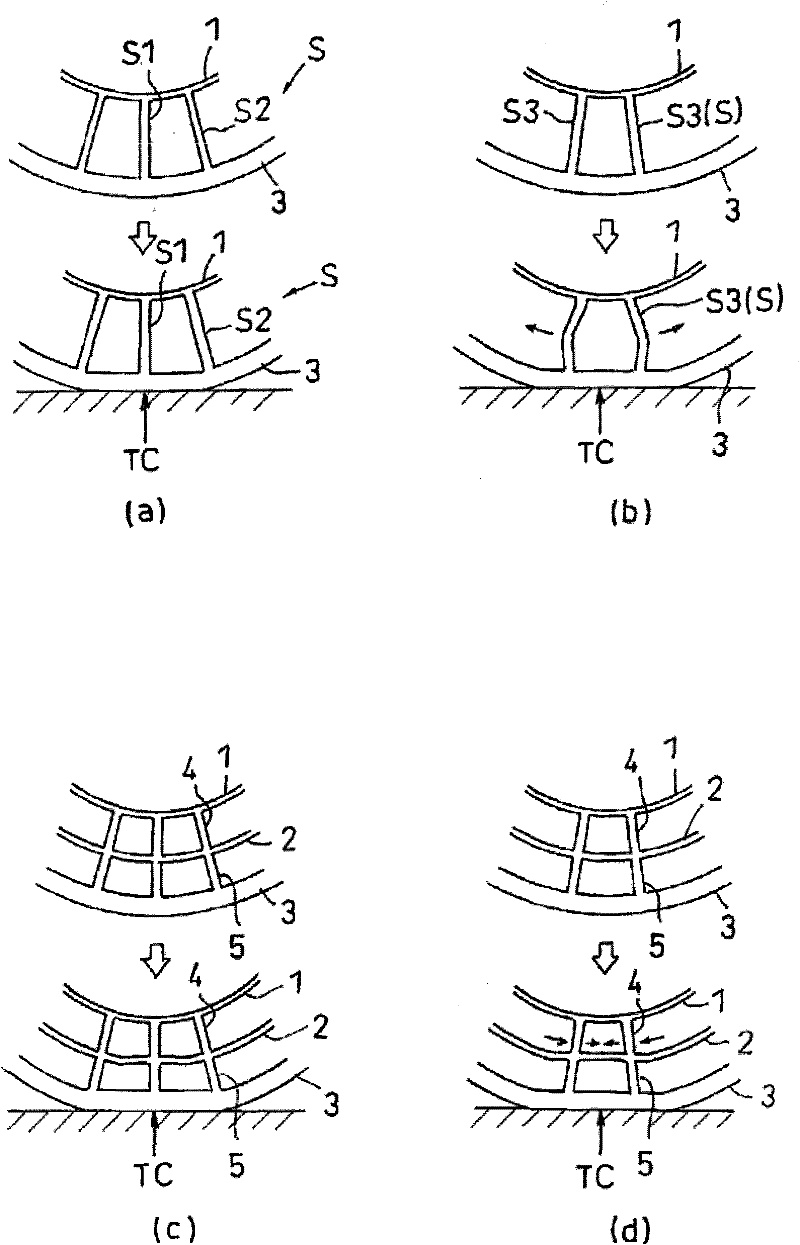

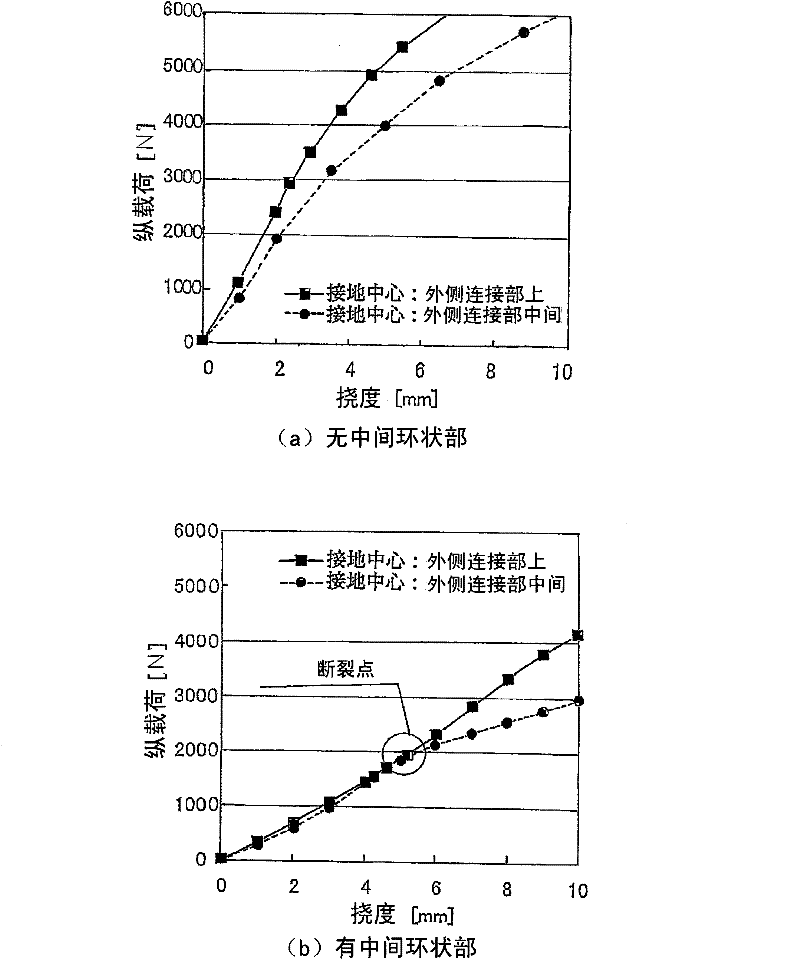

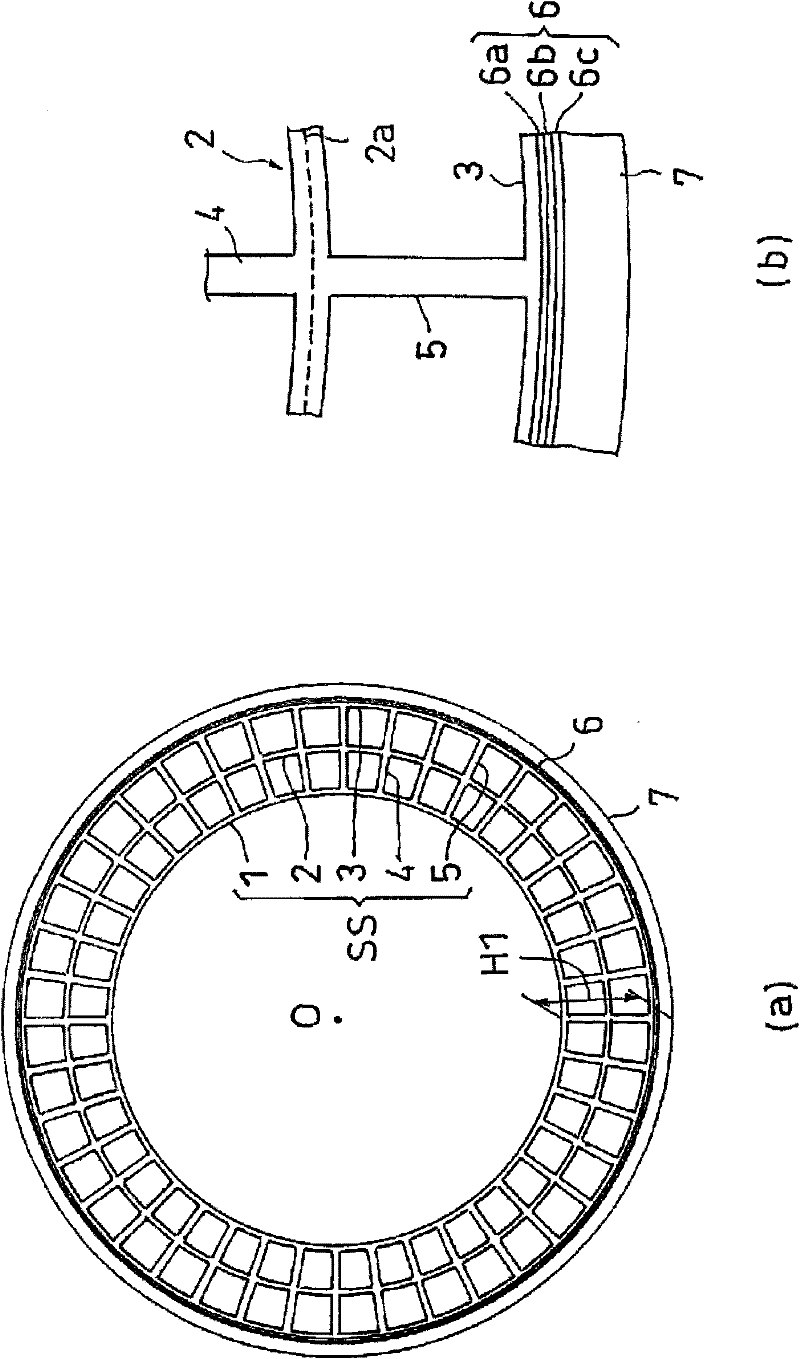

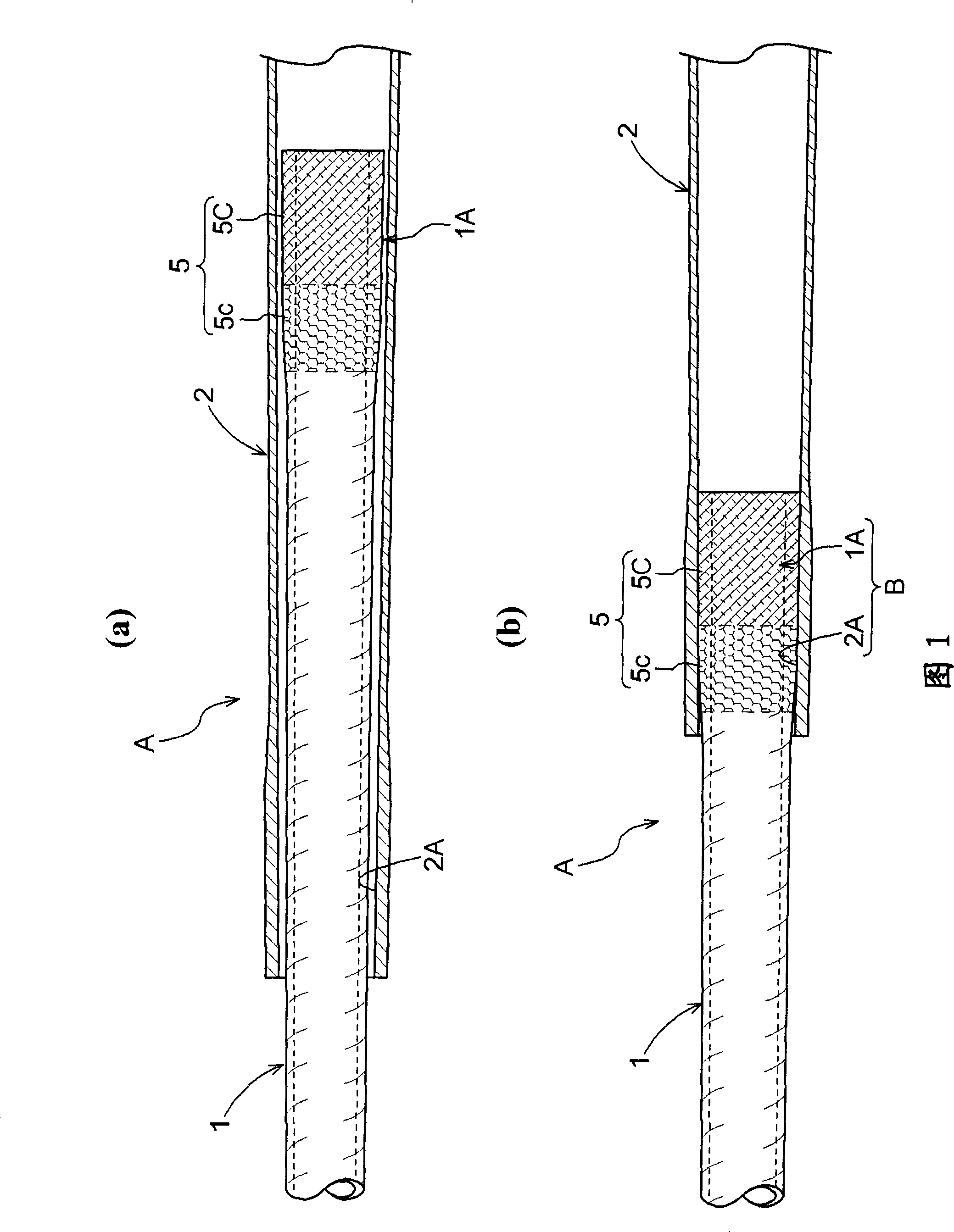

Non-pneumatic tire and its manufacturing method

InactiveCN101668646BImprove enhanced performanceIncreased durabilityNon-inflatable tyresMechanical engineering

Owner:TOYO TIRE & RUBBER CO LTD

Novel reinforcing structure for automobile longitudinal beam

PendingCN113753129AImprove practicalityReduce manufacturing costUnderstructuresInternal combustion piston enginesStructural engineeringMechanical engineering

Owner:湖北智博伟业汽车部件有限公司

High-strength integrated bent sill

ActiveCN111483909AImprove structural strengthEasy to manageSheet joiningBuilding liftsStructural engineeringUltimate tensile strength

The invention discloses a high-strength integrated bent sill. The high-strength integrated bent sill comprises a sill part provided with a sill groove, a first bent part which is connected with one side of the sill part and formed by bending, a sill supporting plate part which is connected with the first bent part, formed by bending and located below the sill part, a first sill installation part which is connected with the sill supporting plate part and formed by bending, and a second sill installation part which is connected with the other side of the sill part and is formed by bending, wherein the sill supporting plate part is connected with the sill part through a first connecting piece; the first sill installation part is connected with the second sill installation part through a second connecting piece; and a plurality of notches distributed in an extending direction of the sill groove are formed in the sill supporting plate part, and reinforcing parts formed by bending are arranged on edges of the notches. The sill is good in structural strength, low in manufacturing cost and high in manufacturing efficiency.

Owner:浙江富士美电梯有限公司

Spherical tank support structure

ActiveCN104110576BEnhanced resistance to horizontal loadsEven by forceContainer filling methodsContainer discharging methodsLoad resistanceMaterial consumption

The invention discloses a spherical tank supporting structure. The spherical tank supporting structure comprises a plurality of supporting pillars of a spherical tank, one end of the supporting pillars close to the spherical tank, that is the upper end of the spherical tank is connected with the tank wall in the lower temperature zone of the spherical tank, and the supporting structure also comprises a supporting ring matched with the supporting pillars to support the spherical tank. The structure is used for solving the problems of difficult welding, large material consumption and poor performances of equatorial tangent supporting pillar structures in the prior art, and the supporting pillars in the invention are shorter than the supporting pillars in the equatorial tangent supporting structures, so the material is saved, the cost is reduced, and the overall horizontal load resistance of the spherical tank is enhanced; and the supporting ring is arranged in the connection of the supporting pillars and the spherical tank, so the contact area of the spherical tank and the supporting structure is enlarged, thereby the whole force bearing of the spherical tank is uniform, the spherical tank has a good stability, and the resistance to horizontal earthquake load, wind load and other outside force loads of the spherical tank is improved.

Owner:HEFEI GENERAL MACHINERY RES INST

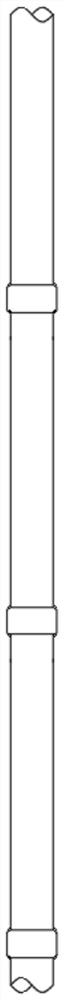

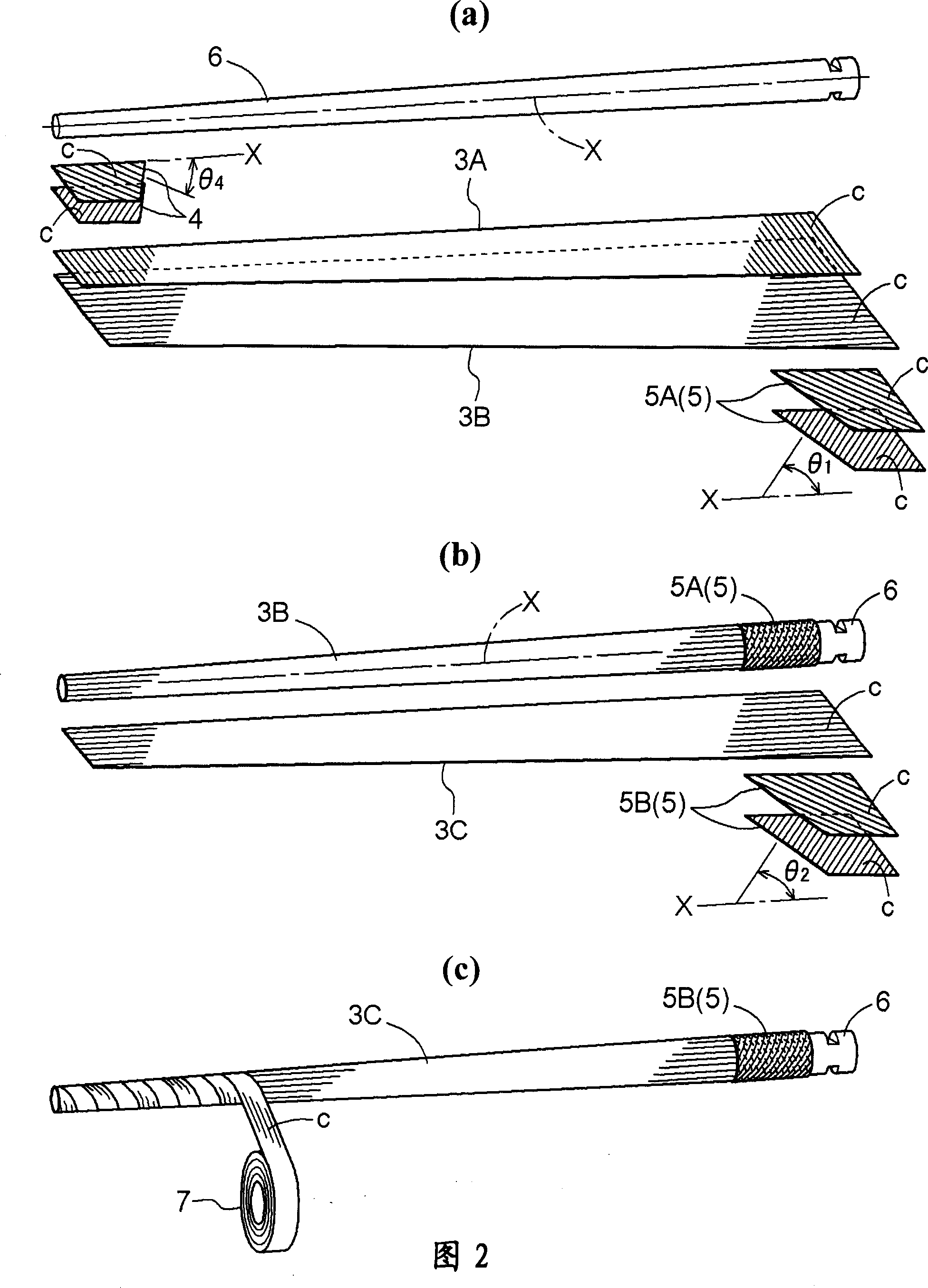

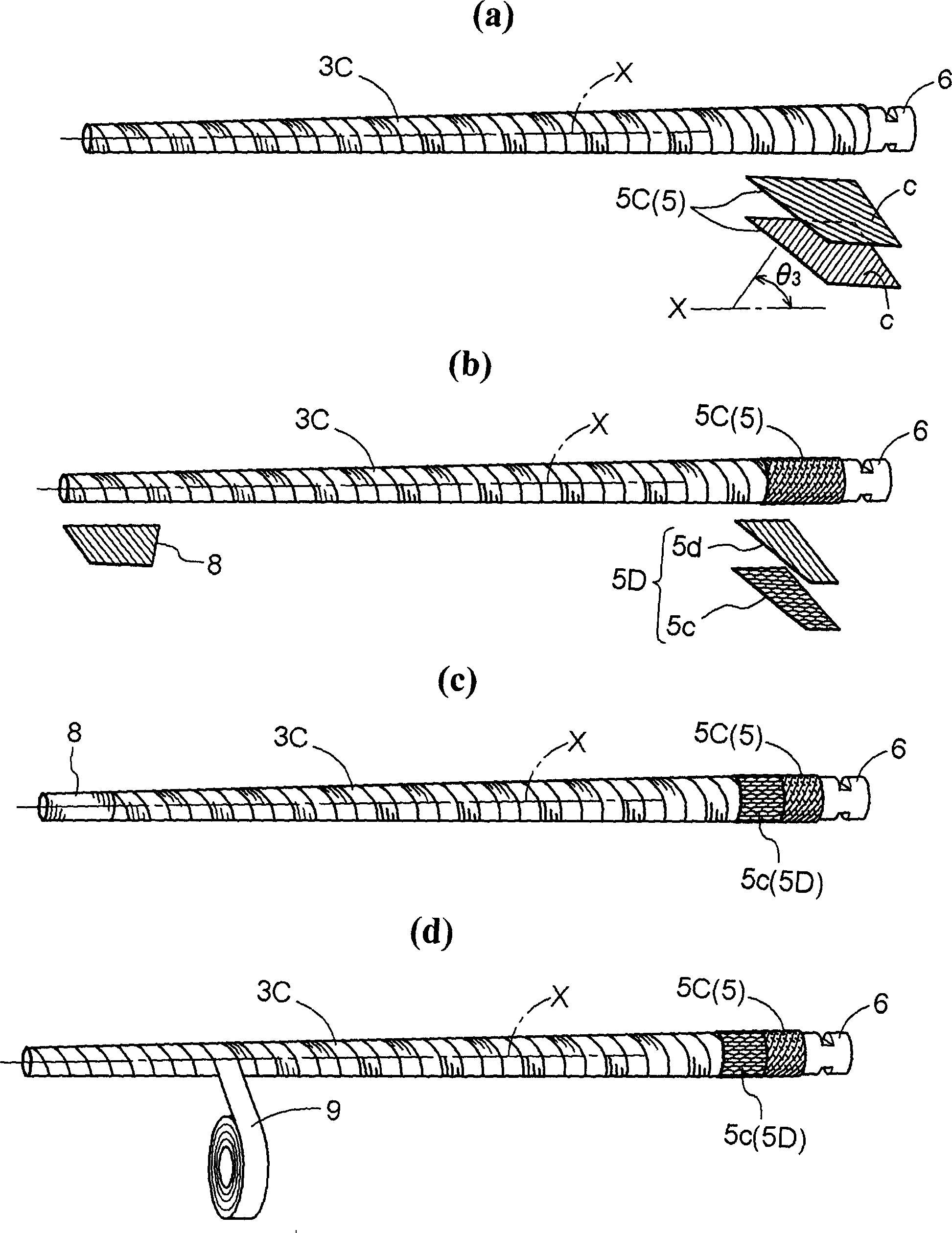

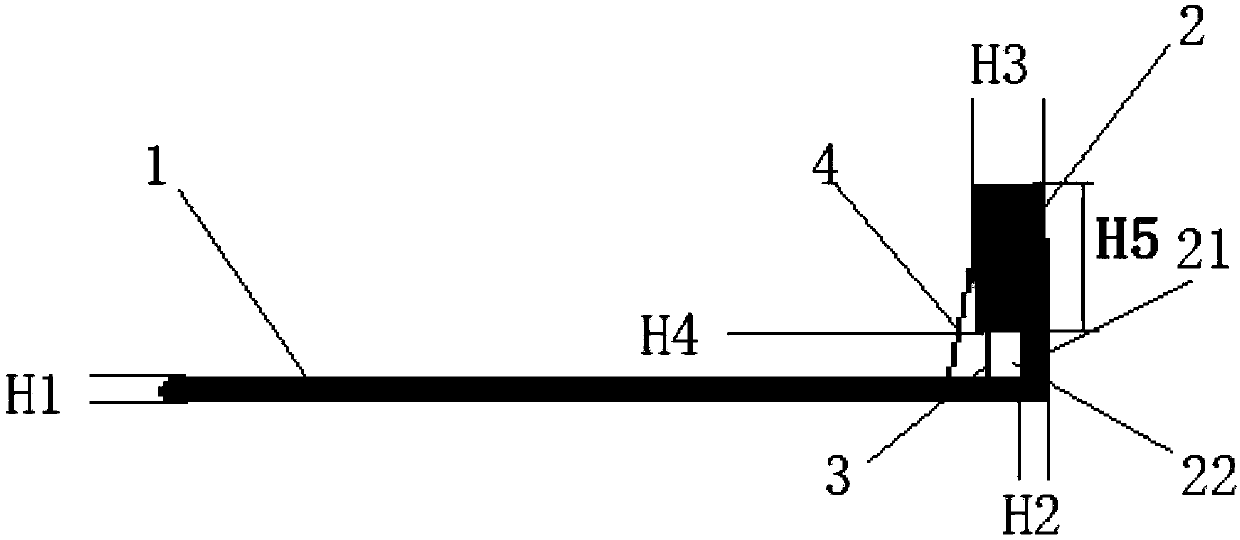

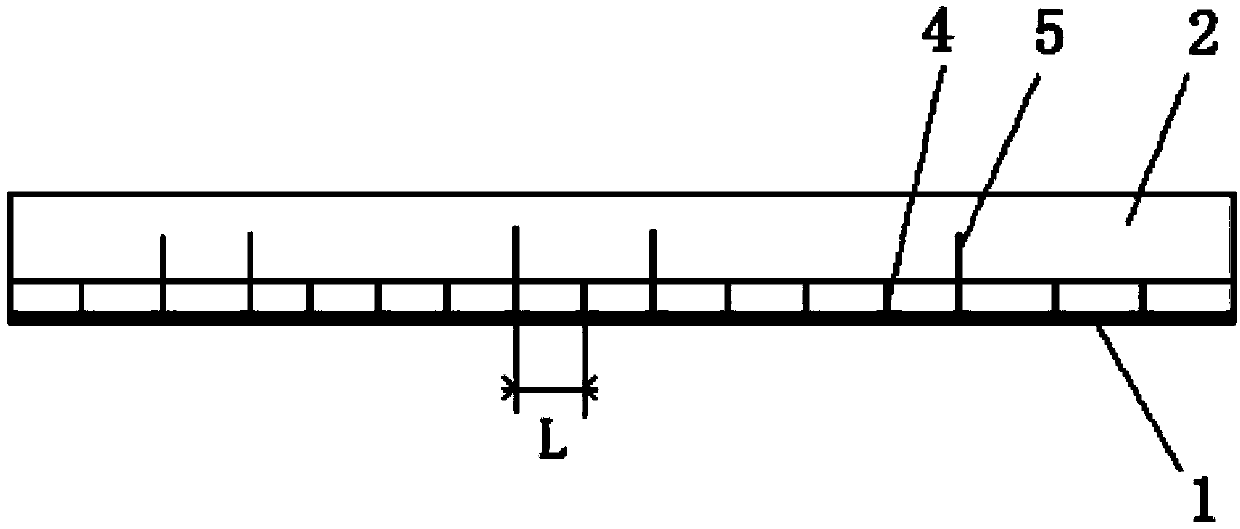

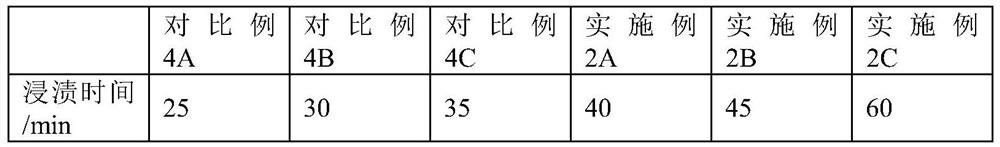

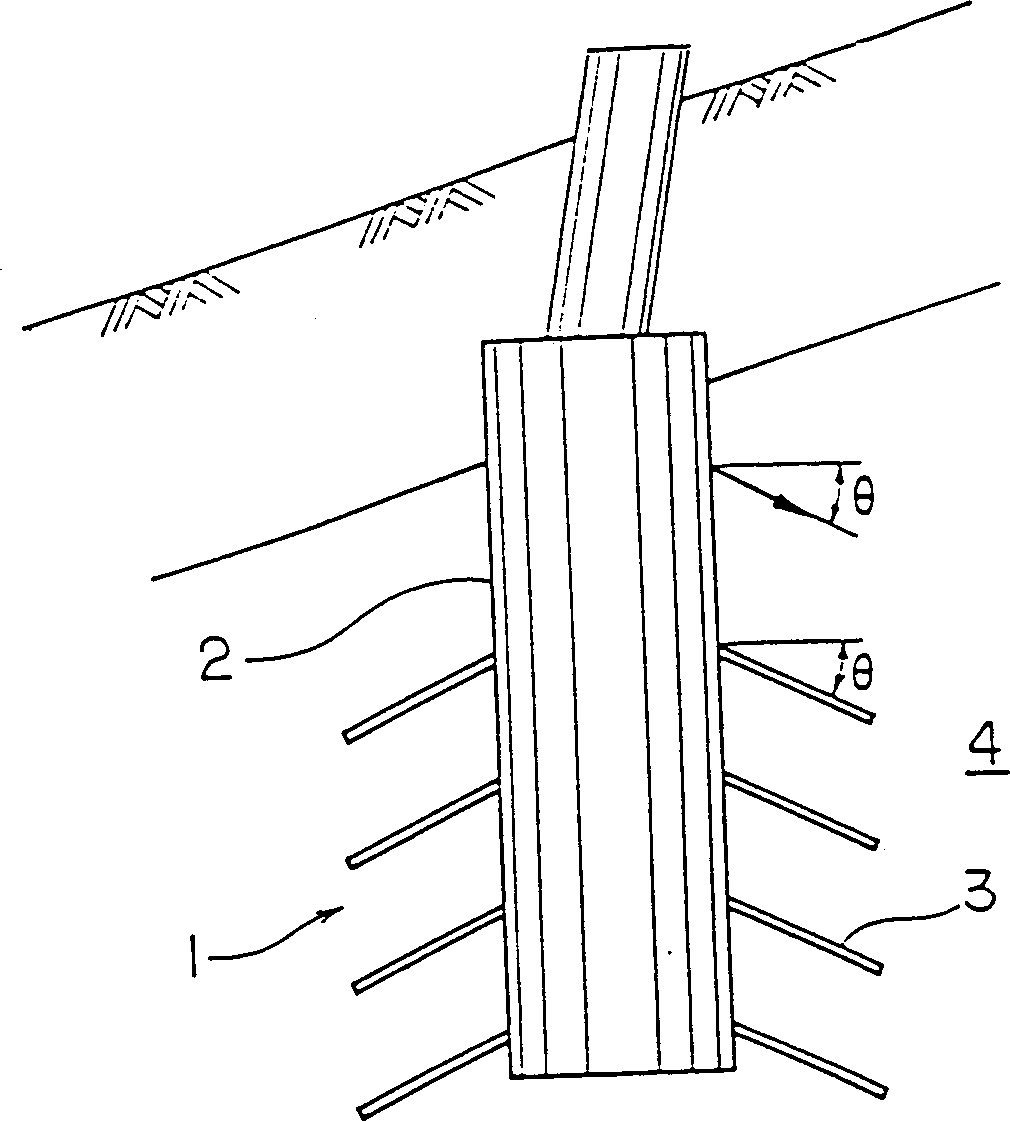

Rod of fishing pole and method for manufacturing same

ActiveCN1846485BImprove the immunityImprove enhanced performanceLamination ancillary operationsLaminationFiberEngineering

The invention relates to a fishing rod, which can avoid plastic deformation and crack, to generate smooth bend when fishing, wherein it has several strengthen plates (5) layered with the inner and outer sides of main plate (3); at least of strengthen plate is between the inner and outer layers; the strengthen plate is formed by two sheets of pre-dipped materials, as strengthen fiber (c) group drawing parallel with the rod axle at incline angle (theta) and the strength fiber (c) group symmetry with the rod axle.

Owner:SHIMANO INC

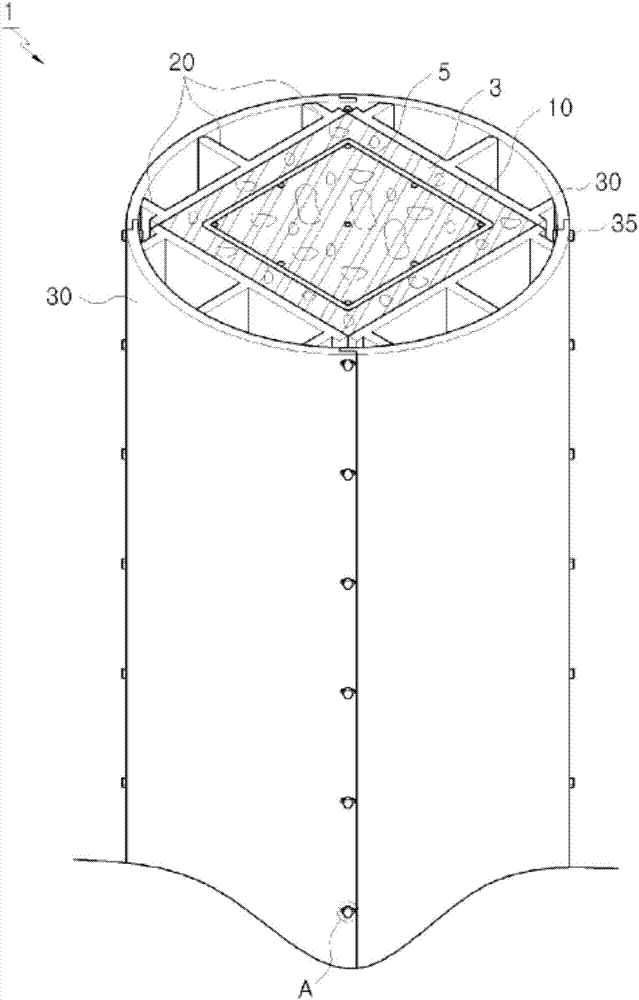

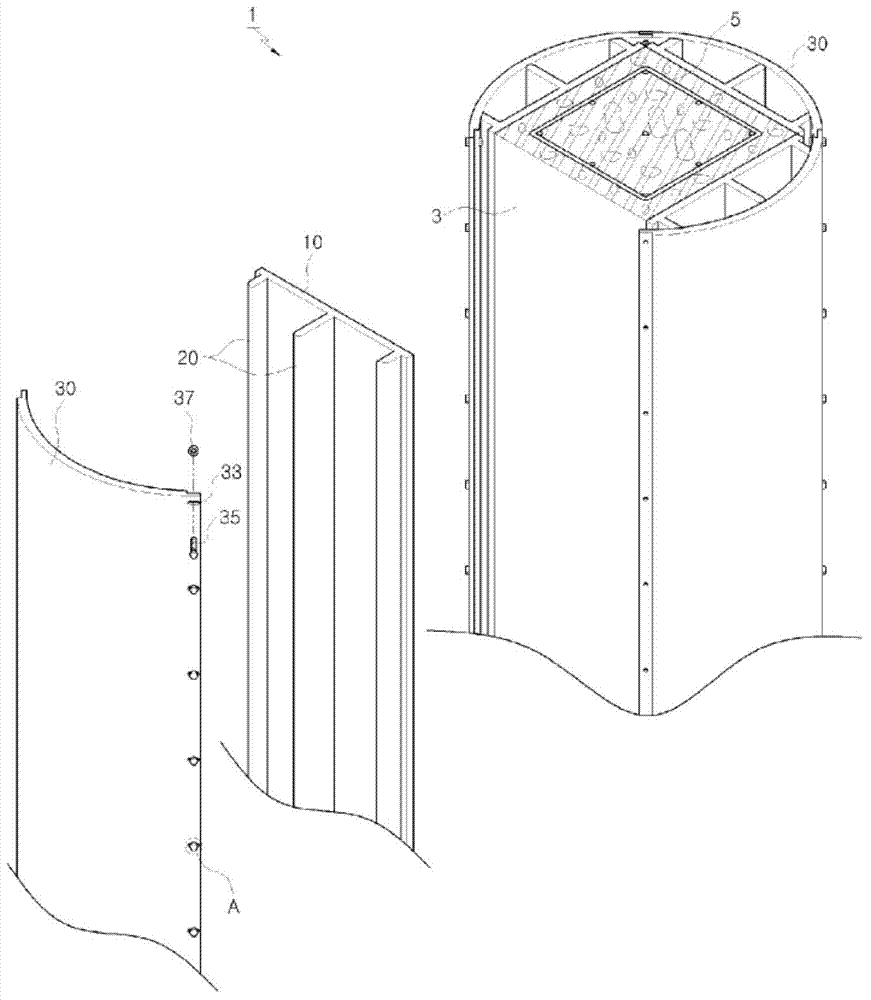

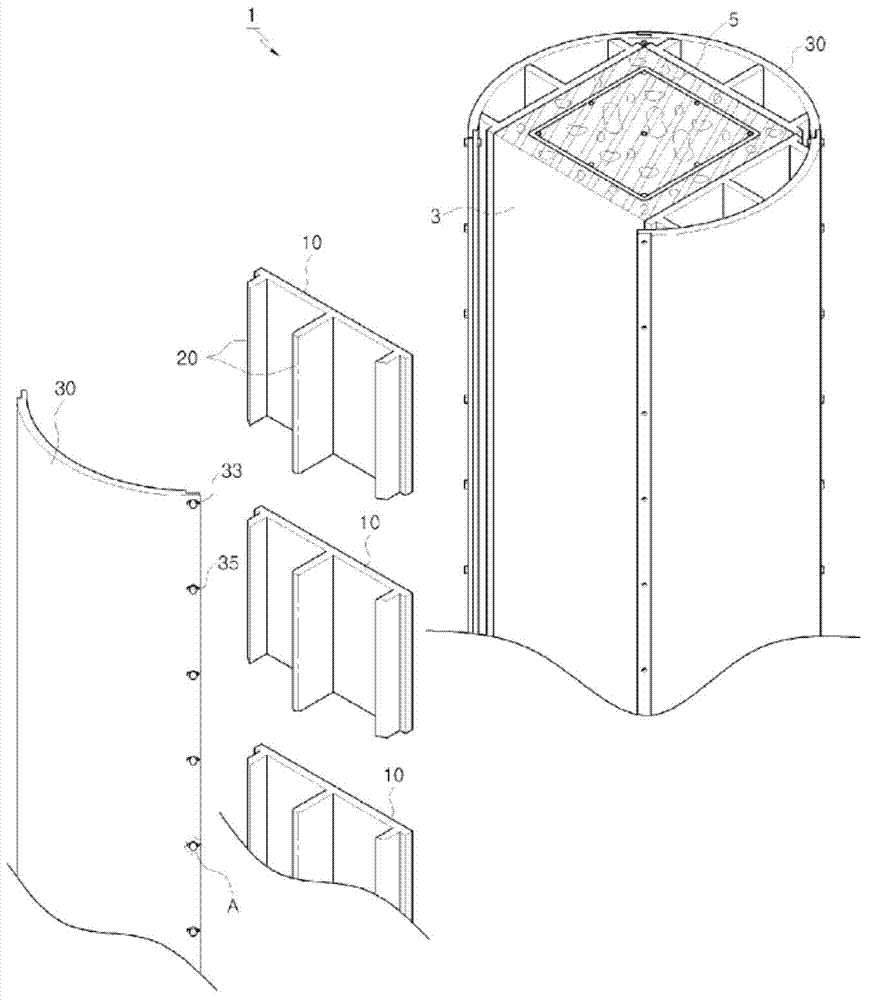

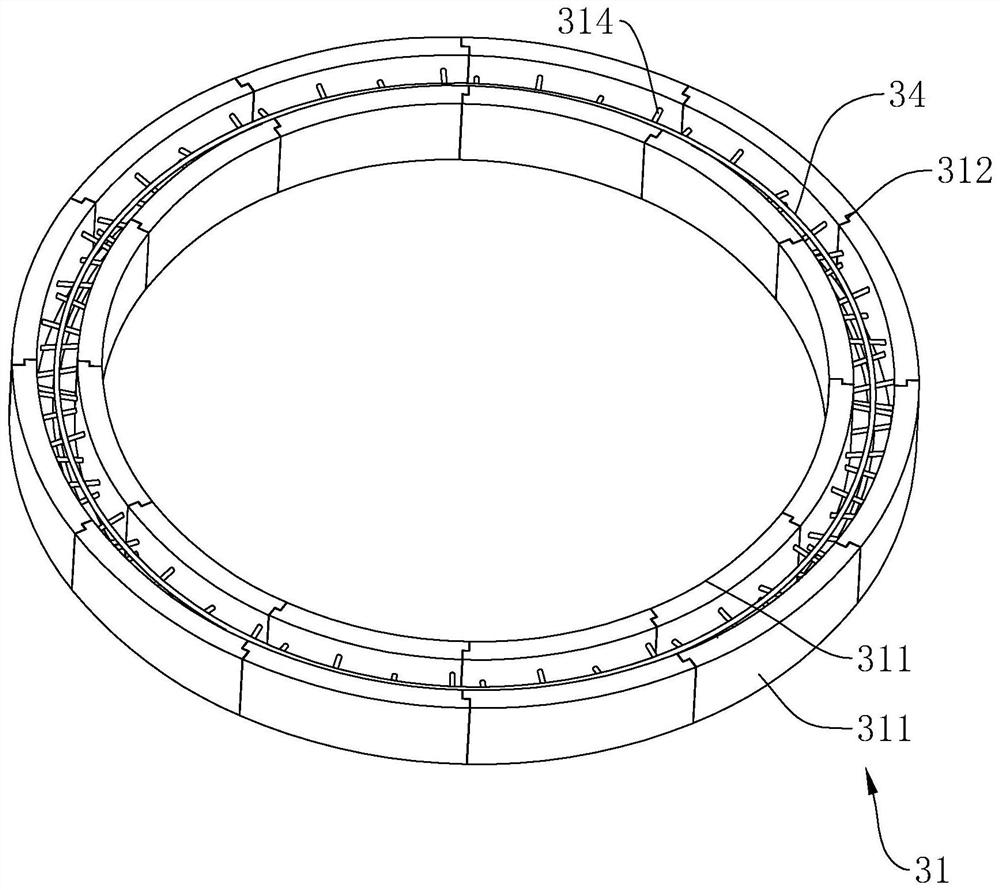

A kind of municipal inspection well structure and construction method thereof

ActiveCN111636484BHigh strengthClosely connectedArtificial islandsUnderwater structuresBrickArchitectural engineering

The invention relates to a municipal inspection well structure and a construction method thereof, which includes a well pit, and a well body is arranged inside the well pit, and the well body includes a plurality of modular blocks arranged in layers, and the modular blocks include two mutually The main block bodies are arranged in parallel and at intervals. The inside of the main block body is provided with steel mesh, and the connecting steel bars are arranged between the steel mesh in the two main block bodies. The main reinforcement is connected to each layer of modular blocks. The length of the main reinforcement is The direction is set along the arrangement direction of each layer of modular blocks. The main reinforcement is located in the middle of the connecting steel bar and is fixedly connected with the connecting steel bar. A concrete layer is poured between the two main block bodies. The upper part of the well body is provided with As for the well cover, the lower part of the well body is provided with a through hole for passing through the pipeline. The invention has the effect of improving the strength of the concrete layer.

Owner:河南世安建设集团有限公司

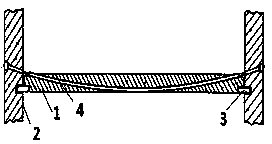

Beam and stand column connecting structure

InactiveCN103669563AImprove carrying capacityImprove seismic performanceShock proofingShock resistanceBearing capacity

The invention discloses a beam and stand column connecting structure which is used in construction for solving the problems that in the prior art, a prefabricated beam is low in bearing capacity and shock resistance. The beam and stand column connecting structure comprises a beam and stand columns. The two ends of the beam are hinged to the two stand columns respectively. The beam and stand column connecting structure is characterized in that the beam and stand column connecting structure further comprises a tensioning rope, the tensioning rope penetrates through the beam in the length direction of the beam, and the two ends of the tensioning rope extend out of the beam and are connected with the two stand columns respectively. The tensioning rope serves as an auxiliary reinforcing structure, the bearing capacity of the beam can be improved, the shock resistance of the beam can also be improved, and the beam and stand column connecting structure does not occupy extra space and does not influence construction.

Owner:CHONGQING CHENGSHUO TECH

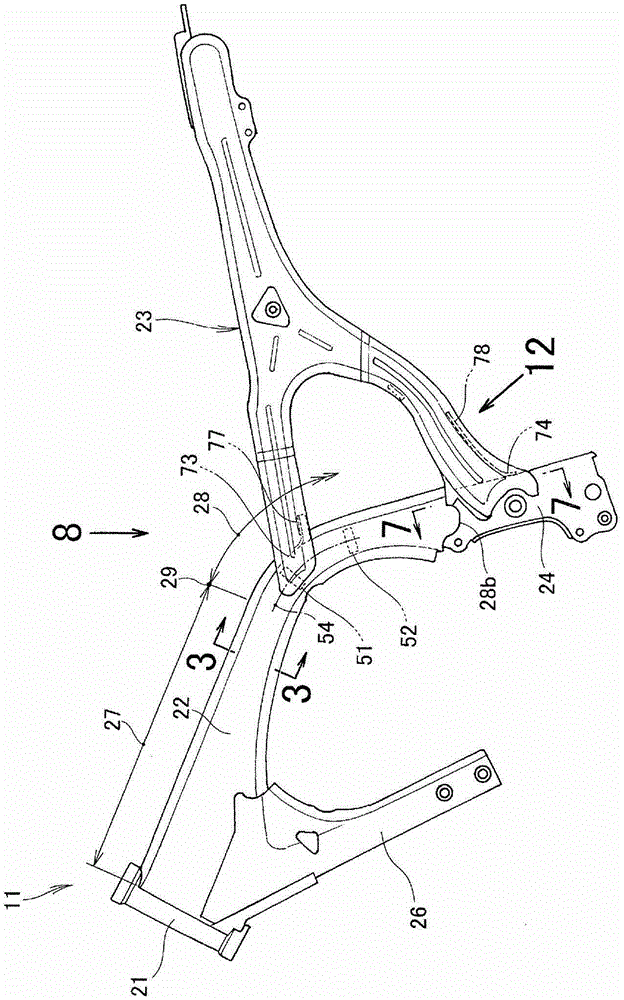

Body structure

Owner:HONDA MOTOR CO LTD

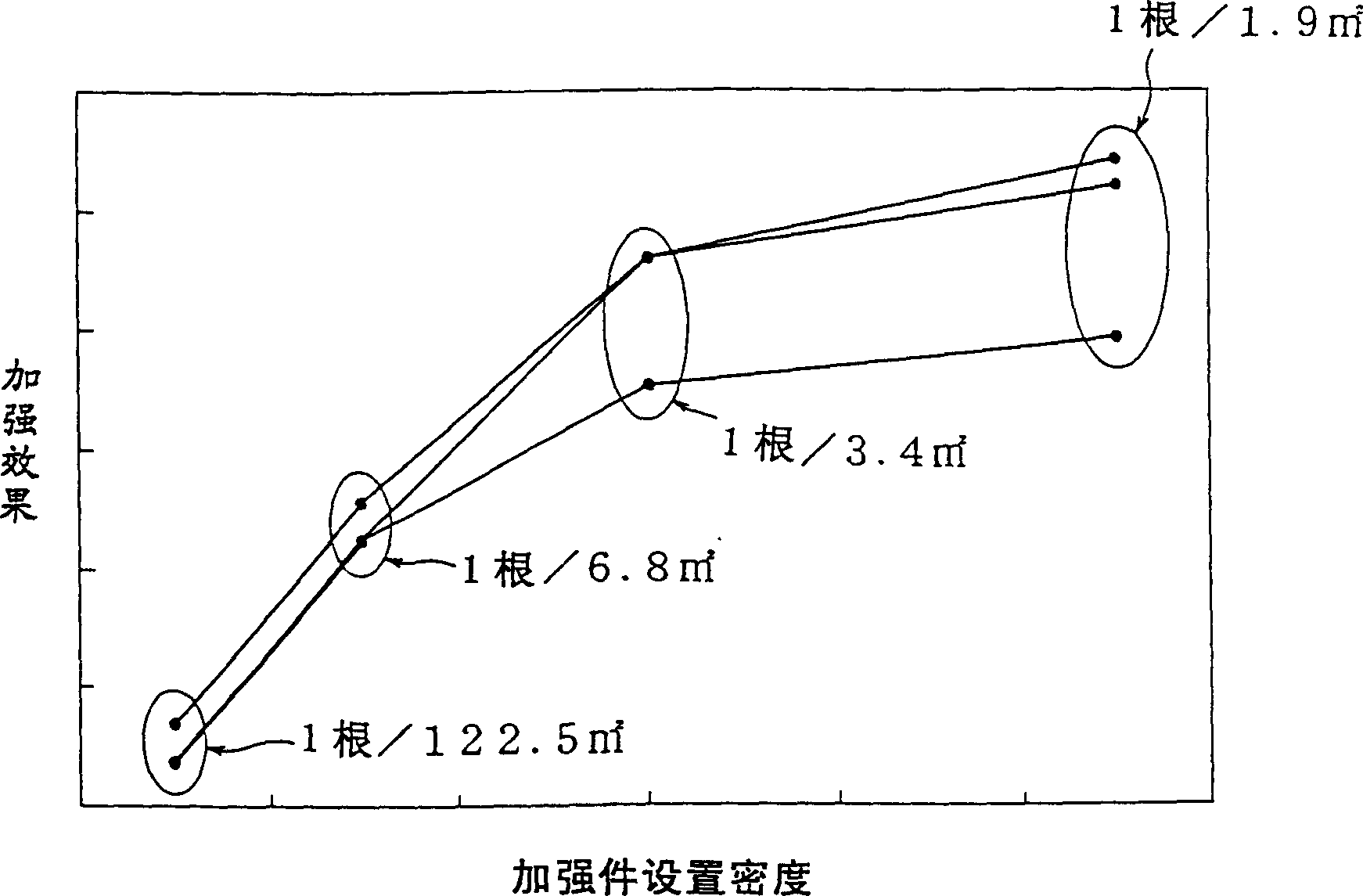

Reinforcing structure formed on large plane

Owner:长亨汽配工业(昆山)有限公司

Steel bar connecting structure of prefabricated cement component

ActiveCN109057169AImprove enhanced performanceSolve the problem of poor steel connection structureBuilding reinforcementsRebarUltimate tensile strength

The invention relates to the technical field of steel bar connecting structures, and discloses a steel bar connecting structure of a prefabricated cement component. The steel bar connecting structurecomprises a bottom plate; a plurality of evenly distributed first sleeves are fixedly arranged at the upper end of the bottom plate; the openings of the first sleeve are upward; certain sides of the plurality of first sleeves are provided with first threaded holes; a first fastening bolt is in threaded connection to the interior of each of the plurality of first threaded holes; a steel bar is sheathed in the interior of each of the plurality of first sleeves; the ends, located in the interiors of the first sleeves, of the plurality of steel bars are fixedly connected to the first sleeves by means of the first fastening bolts; the side wall of each of the plurality of steel bars is in fixed cup joint with two symmetrically-arranged ring-shaped connection blocks; the upper end of each ring-shaped connection block is provided with four symmetrically-distributed mounting holes. The steel bar connecting structure of the prefabricated cement component can effectively strengthen the connection of the plurality of steel bars, so as to improve the holding power of the steel bars and improve the reinforcing effect of the steel bars on the strength of the cement component, and can be easily used by people.

Owner:安徽省英剑科技发展有限公司

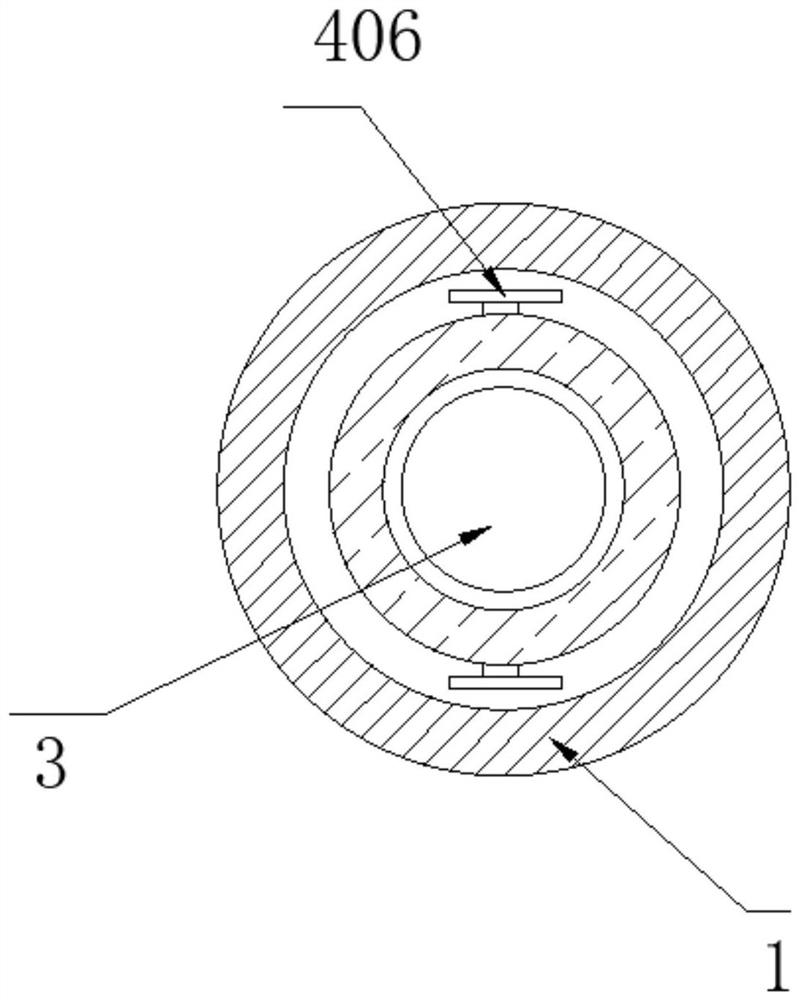

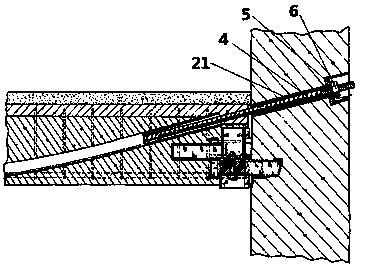

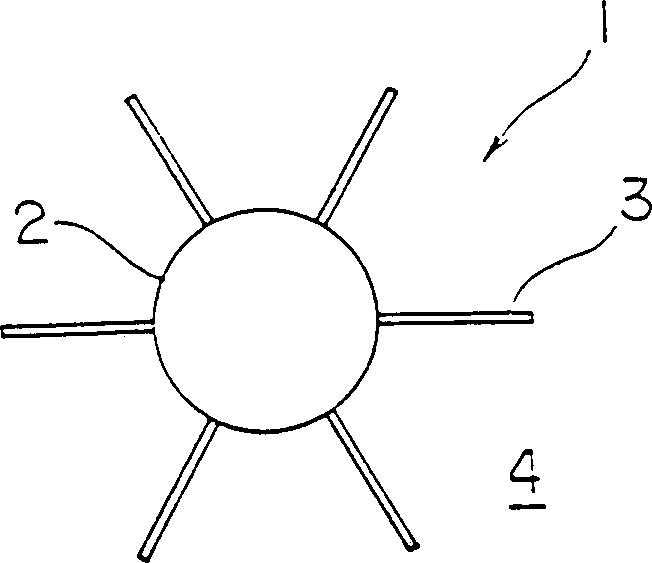

Wire drum

The invention relates to a wire drum. The wire drum comprises a winding wheel (1) and wheel discs (2) located on the two sides of the winding wheel (1), a containing groove (3) protruding from the inner surface of the winding wheel (1) is formed in the inner surface of the winding wheel (1), and a reinforcing plate (4) is arranged in the containing groove (3), and is in close contact with the inner surface of the winding wheel (1). According to the wire drum, the containing groove used for containing the reinforcing plate is formed in the inner surface of the winding wheel, the strength of thewinding wheel is greatly improved due to the existence of the reinforcing plate, and the traditional integrated structure of the reinforcing plate and the winding wheel is changed due to the existence of the containing groove; and a split structure of the reinforcing plate and the winding wheel is arranged so that the reinforcing plate can be replaced according to the requirement of actual situations, and the use cost is reduced.

Owner:扬州市润发机械有限公司

Municipal inspection well structure and construction method thereof

ActiveCN111636484AHigh strengthClosely connectedArtificial islandsUnderwater structuresArchitectural engineeringMesh reinforcement

The invention relates to a municipal inspection well structure and a construction method thereof. The municipal inspection well structure comprises a well pit, and a well body is arranged in the wellpit. The well body comprises a plurality of module building blocks arranged in layers, each module building block comprises two parallel main building block bodies arranged at intervals, reinforcing meshes are arranged in the main building block bodies, connecting reinforcements are arranged between the reinforcing meshes in every two main building block bodies, main reinforcements are connected to the module building blocks on each layer, the length direction of the main reinforcements is arranged in the distribution direction of the module building blocks on each layer, the main reinforcements are located in the middle parts of the connecting reinforcements and are fixedly connected with the connecting reinforcements, and a concrete layer is poured between every two main building block bodies. A well lid is arranged on the upper part of the well body, and a through hole is formed in the lower part of the well body, wherein a pipeline penetrates through the through hole. The municipalinspection well structure has the effect of improving the strength of the concrete layer.

Owner:河南世安建设集团有限公司

A kind of high-strength soft permeable cotton and its preparation process and cotton products

The invention relates to the technical field of polyurethane foam materials, and discloses a high-strength and soft permeable cotton, which solves the problem that the existing permeable cotton has low strength and is easy to be torn and damaged to cause wrinkles. It includes the following mass parts of raw materials mixed and foamed Obtain: 20-40 parts of polyether polyol, 3.5-4.8 parts of polyether, 5-7 parts of silicone oil, 24-40 parts of isocyanate, 8-12 parts of nano-tetrafluoroethylene powder with volume equivalent diameter of 400nm, 3 parts of water ~5 parts, catalyst 1~1.2 parts, polydimethylsiloxane 8~12 parts, vaporizing agent 2~10 parts, antioxidant 0.3~0.7 parts, vaporizing agent is dichloromethane or dichloroethane; composite catalyst Trimethylamine, triethylenediamine and stannous octoate are mixed at a mass ratio of 1:3:10. The obtained permeable cotton improves the tear resistance of the permeable cotton while maintaining the soft and permeable characteristics of the permeable cotton, and strengthens the permeable cotton. wrinkle resistance; also discloses the permeable cotton of the present invention and the cotton products made from the permeable cotton of the present invention, the cotton bale is permeable, breathable and wrinkle-resistant for a long time, and the finished product has a long service life.

Owner:泉州玺堡家居科技有限公司

Preparation method of grain boundary diffused heavy rare earth NdFeB magnet and NdFeB magnet

ActiveCN109935462BFill in the gapsImprove grain boundary diffusion efficiencyInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSolid solution

The invention relates to an NdFeB magnet, and discloses a preparation method of a grain boundary diffused heavy rare earth NdFeB magnet and the NdFeB magnet. The preparation method involves pressing NdFeB powder into a NdFeB rough billet and then immersing it in a heavy rare earth source for melting. solid solution and infiltration between the heavy rare earth source melt and the NdFeB rough billet, filling the gaps and defects in the NdFeB rough billet, and at the same time The heavy rare earth element diffuses in the grain boundary of the NdFeB rough blank, which improves the grain boundary diffusion efficiency of the heavy rare earth element, making it feasible for the grain boundary diffusion heavy rare earth element process to strengthen the coercive force of the thicker NdFeB magnet, and obtains A neodymium-iron-boron magnet with a thickness greater than 5mm and a coercivity enhancement effect higher than the existing process of grain boundary diffusion of heavy rare earth elements.

Owner:宁波雄海稀土速凝技术有限公司

Method of arranging reinforcement in forming foundation of ground reinforcing type and foundation body

Owner:THE TOKYO ELECTRIC POWER CO INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com