Reinforcing structure formed on large plane

A technology to strengthen the structure and large plane, applied in the direction of coating, etc., can solve the problems of unqualified products, warping of the plane, etc., and achieve the effect of improving the strengthening effect and ensuring the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

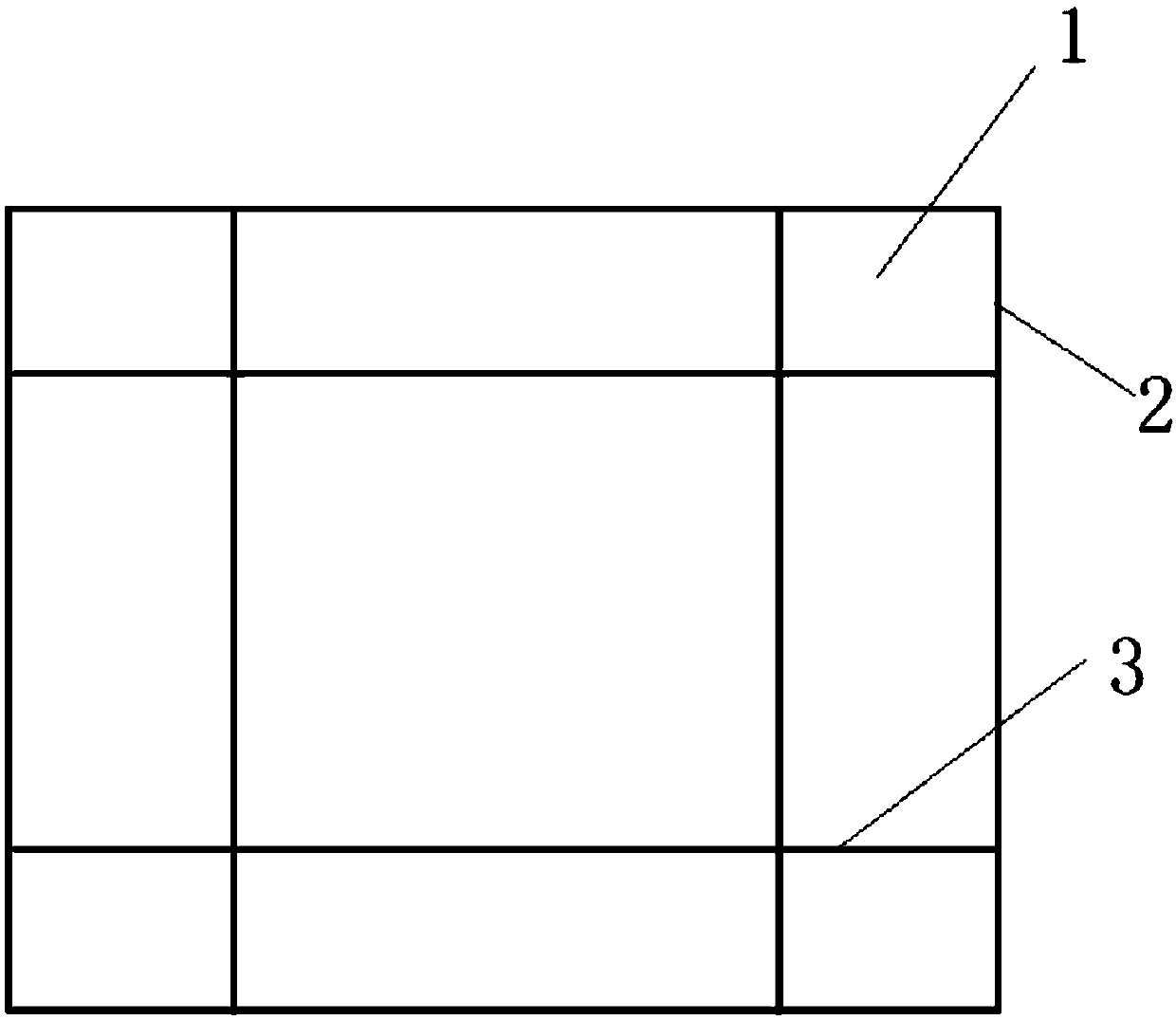

[0046] This embodiment provides a reinforcement structure formed on a large plane, such as figure 1 Shown include:

[0047] A reinforcing edge 2 arranged on the edge of the plastic plate 1 and a number of reinforcing strips 3 arranged in parallel in the middle of the plastic plate 1;

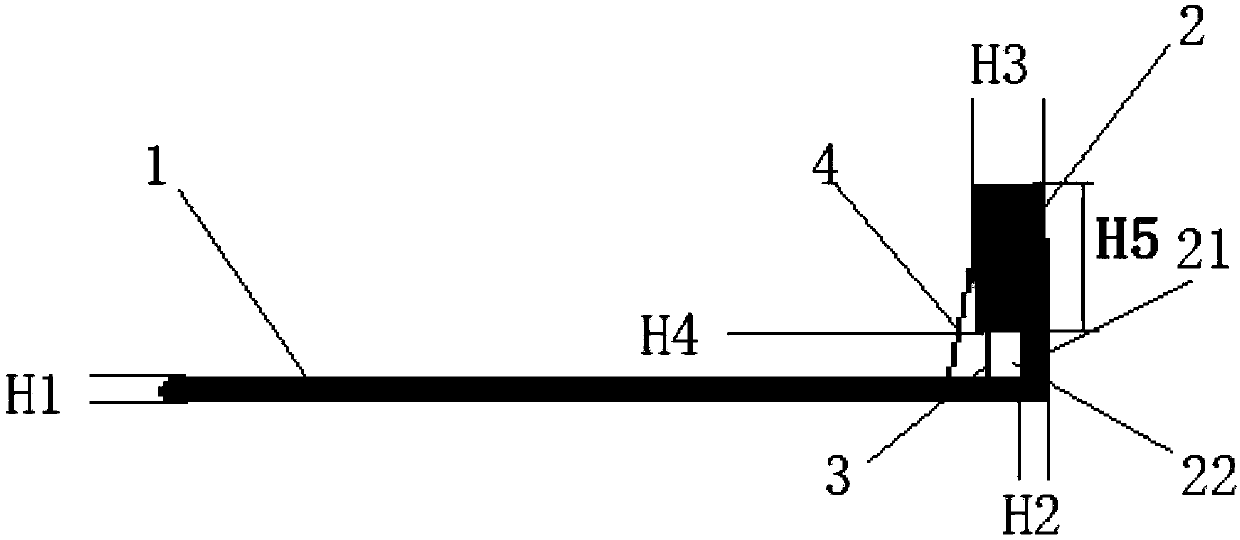

[0048] The reinforcing edge 2 is connected with the plastic plate 1 through the first connecting portion 21, so as to form a first groove 22 between the plastic plate 1, the first connecting portion 21 and the reinforcing edge 2;

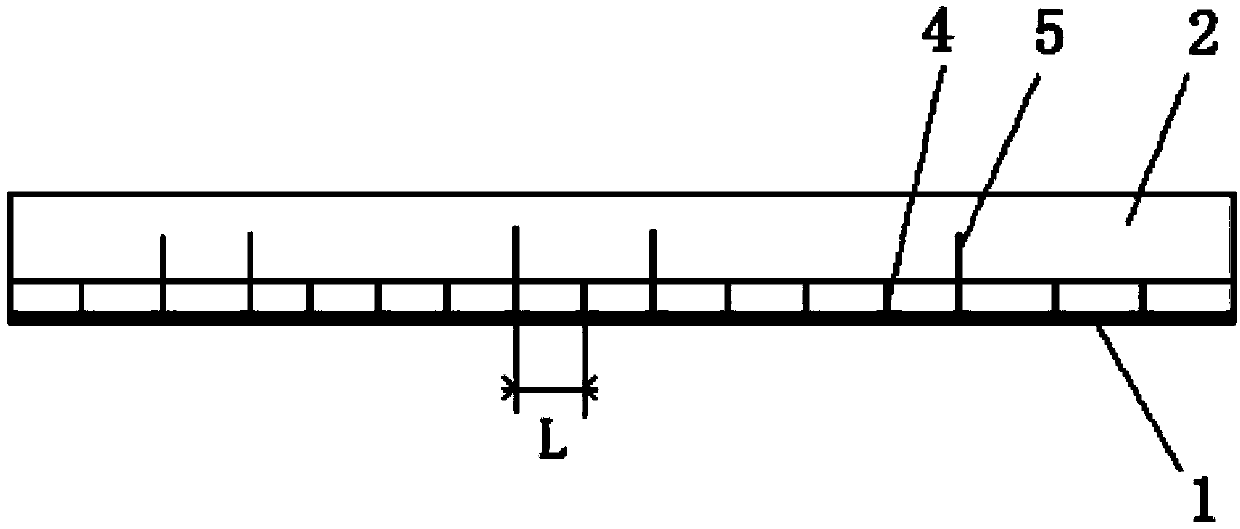

[0049] Each of the reinforcing strips 3 is connected to the plastic plate 1 through the second connecting portion 31, so as to form second grooves 32 on both sides of the reinforcing strip 3 between the plastic plate 1, the second connecting portion 31 and the reinforcing strip 3 and the third groove 33;

[0050] The first reinforcing rib 4 is perpendicular to the plastic plate 1 and has a thickness of 0.5-1mm. The first reinforcing rib 4 is located in the first gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com