Non-pneumatic tire and its manufacturing method

A technology of tires and annular parts, applied in non-pneumatic tires, tire parts, vehicle parts, etc., can solve the problems of heavy and firm tires, deterioration of load-supporting performance or durability, and lack of excellent performance of pneumatic tires. The effect of stress concentration and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

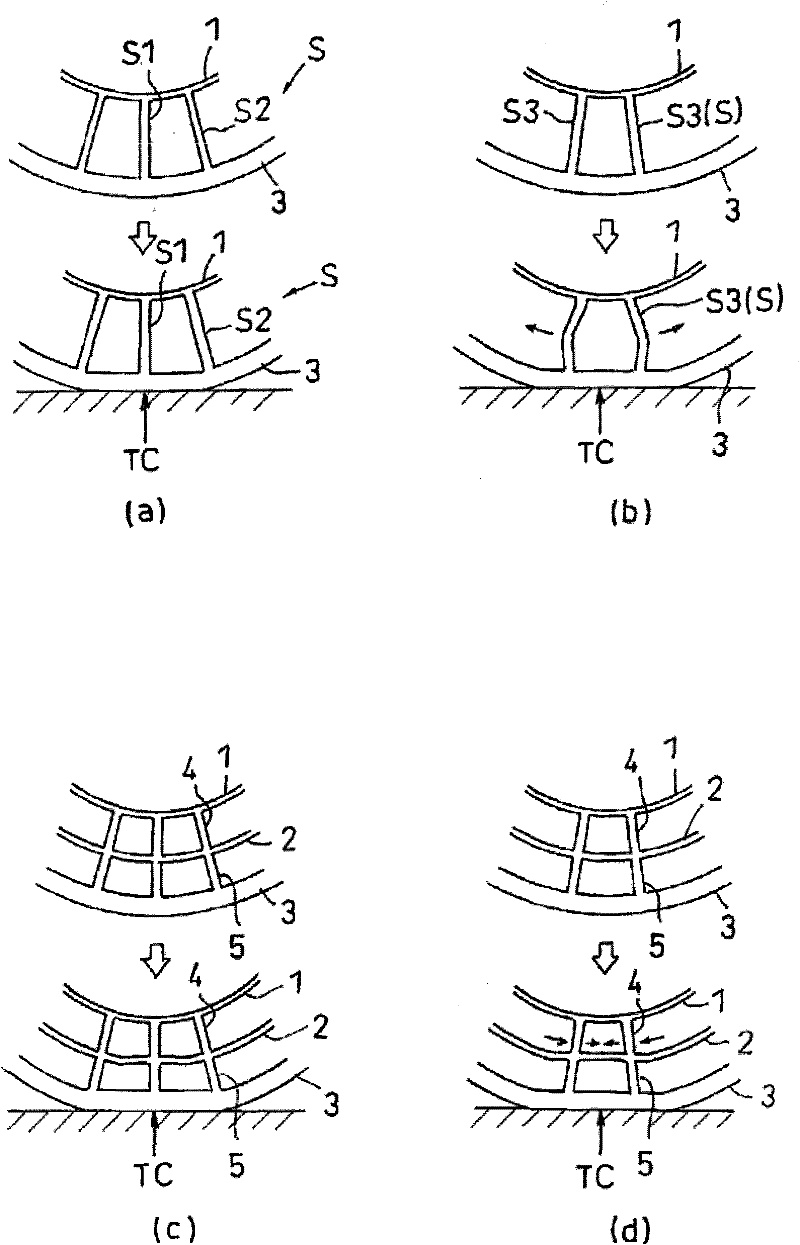

[0096] (1) In the above-mentioned embodiment, the example in which the flat inner connection part and the outer connection part are arranged in parallel in the axial direction is shown, but as Figure 5 As shown in a to d, the shapes and formation directions of the inner connecting portion and the outer connecting portion can take various shapes.

[0097] For example, if Figure 5 As shown in a, the arrangement direction of the outer connecting portion 5 (and the same for the inner connecting portion) may be inclined from the direction of the axis O.

[0098] and, if Figure 5 As shown in b, the outer connecting portion 5 (the inner connecting portion is also the same) may be in the shape of a curved flat plate.

[0099] and, if Figure 5 As shown in c, the outer connection part 5 (the inner connection part is also the same) can also be in the shape of a flat plate with a rim 5a.

[0100] and, if Figure 5 As shown in d, a plurality of outer connection portions 5 may be f...

Embodiment

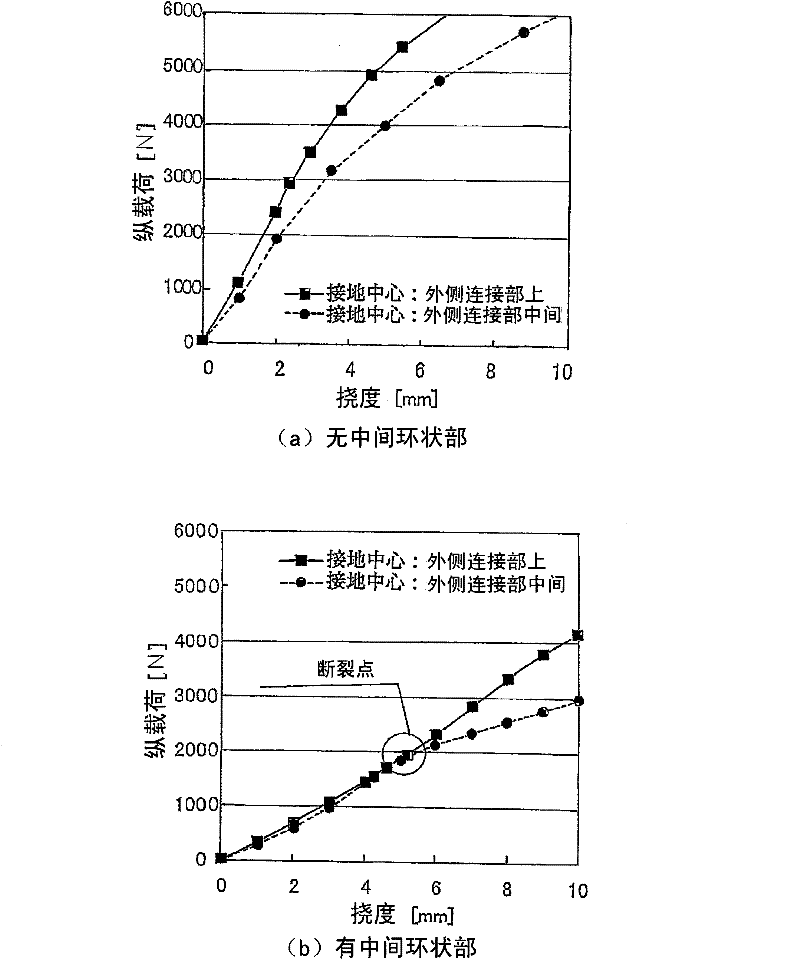

[0107] Hereinafter, Examples etc. which concretely show the structure and effect of this invention are demonstrated. In addition, the evaluation items in Examples etc. were measured as follows.

[0108] (1) Maximum ground pressure

[0109] It refers to the case where the outer end point of the outer wheel bar (or wheel bar) is on the grounding center and the center position of the outer end point of the adjacent outer wheel bar (or wheel bar) is on the grounding center when bearing a longitudinal load of 2000N The amount of averaging the maximum ground pressure in each ground plane in the case of , is represented by an index when comparative example 1 is set to 100. The smaller the value, the better.

[0110] (2) Maximum ground pressure difference

[0111] It refers to the case where the outer end point of the outer wheel bar (or wheel bar) is on the grounding center and the center position of the outer end point of the adjacent outer wheel bar (or wheel bar) is on the grou...

Embodiment 1

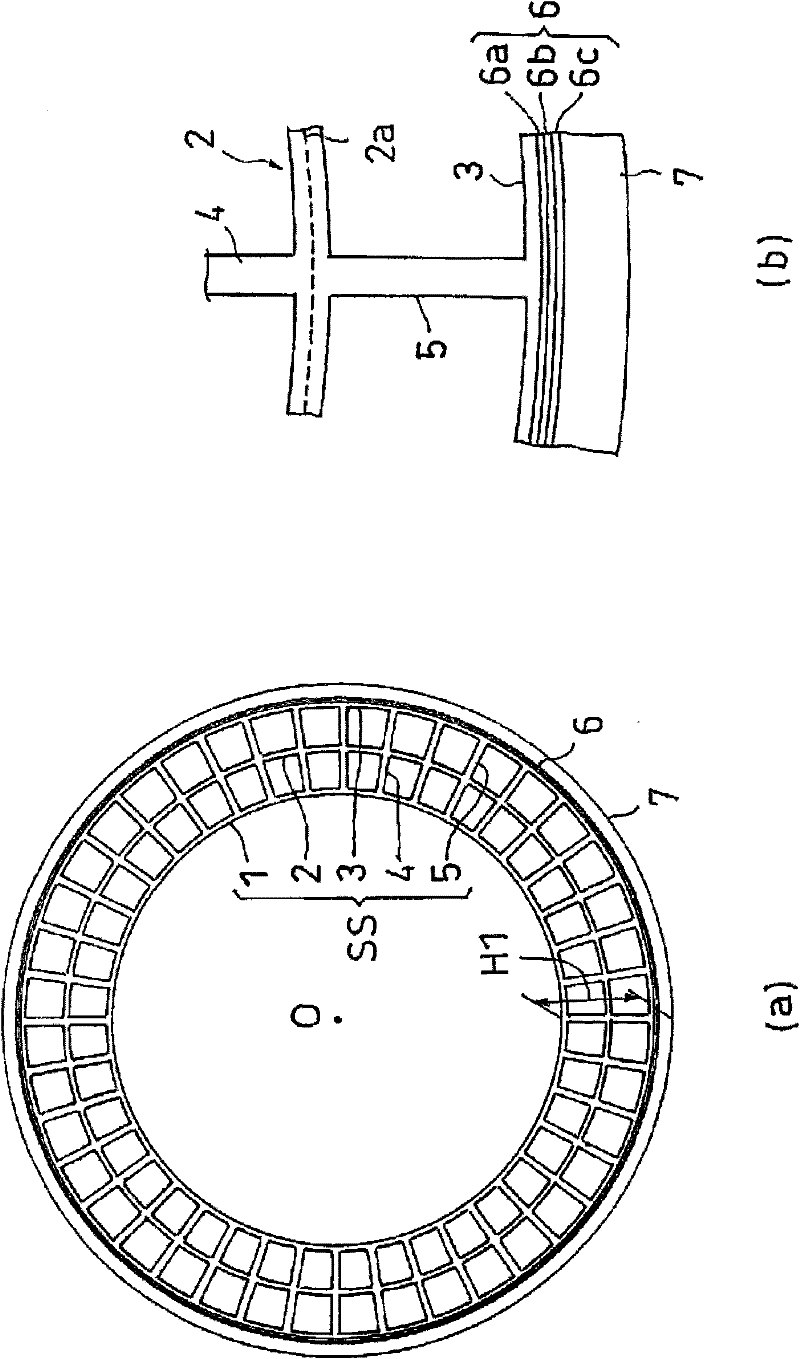

[0126] According to the dimensions and physical properties shown in Table 1, a support structure having an inner ring, an intermediate ring, an outer ring, and an inner wheel bar (upright in the radial direction) and an outer wheel bar (upright in the radial direction) connecting each ring was manufactured, A non-pneumatic tire having two layers of reinforcing layers and tire rubber provided on its outer periphery was produced, and the above-mentioned performance was evaluated. The results are combined and shown in Table 1. Also, the results of the rigidity variation test are shown in Figure 6 middle.

[0127] And, the molding of support structure is carried out as follows, use the mold that has the space part corresponding to support structure, on the part corresponding to the intermediate ring of this space part, dispose the glass fiber material of mesh shape shown in Table 1, after that Fill the entire space of the mold with a raw material solution of an elastic material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com