Rod of fishing pole and method for manufacturing same

A technology for fishing rods and rod bodies, applied in fishing rods, chemical instruments and methods, laminating devices, etc., can solve the problems of lack of free operability, decrease in rod rigidity, etc., and achieve suppression of separation of reinforcing fibers, improvement of resistance, and suppression The effect of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

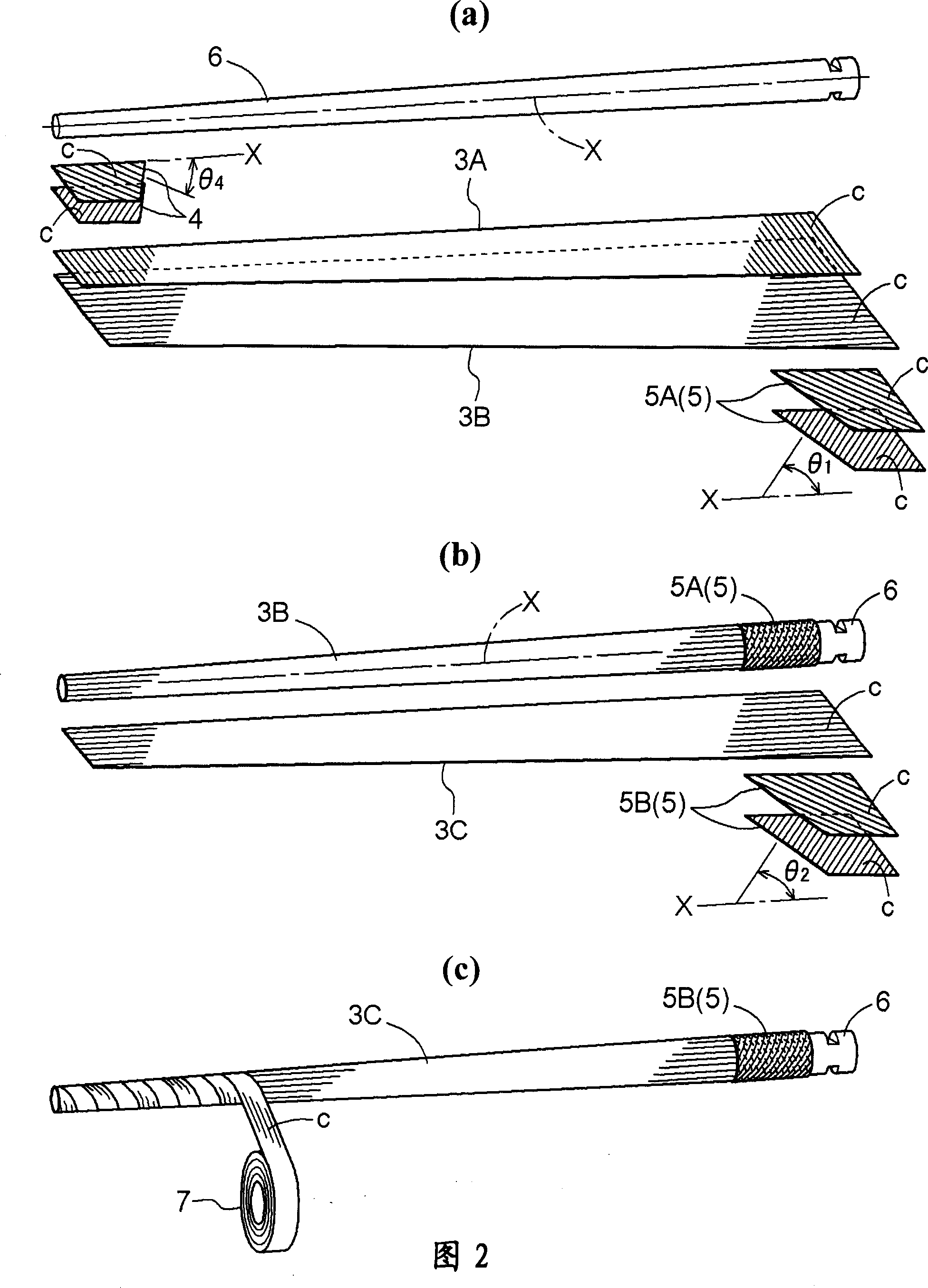

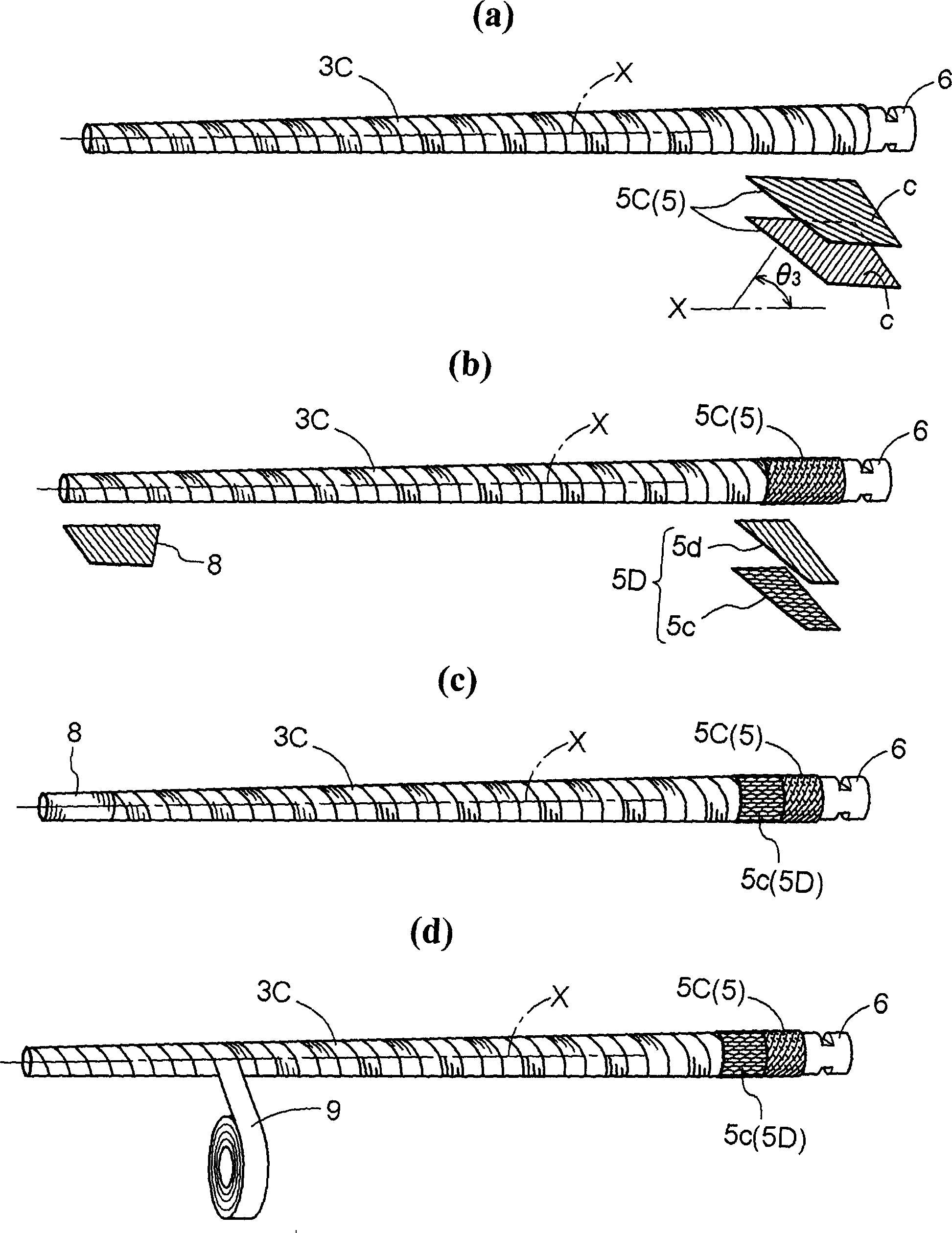

[0045] Next, the structure used for the draw-out type stream pole A which has multi-section pole bodies, such as a set of 8, is demonstrated.

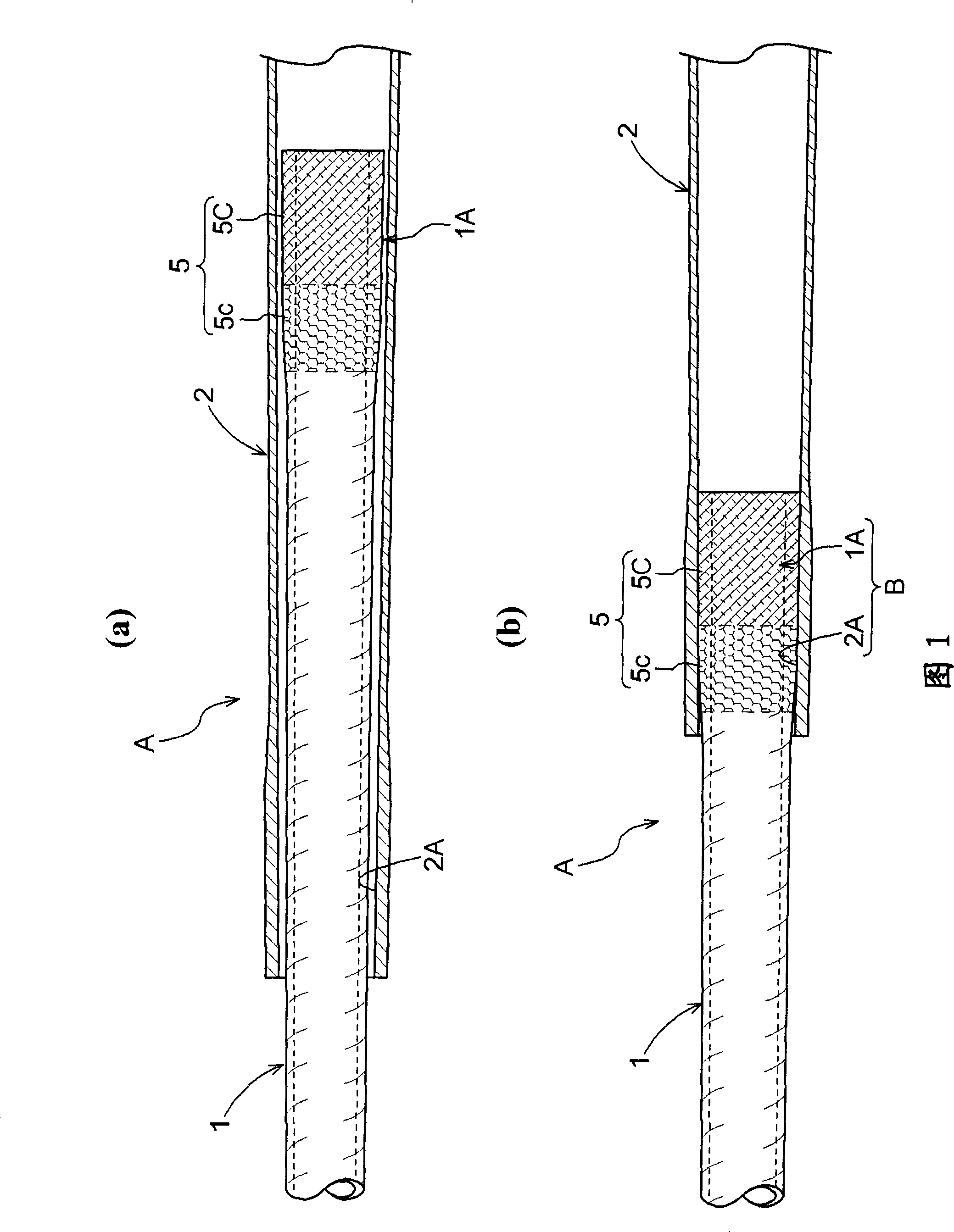

[0046] Here, the structure of the joint part adopted for the middle pole from the fourth section pole to the penultimate section pole will be mainly described. In the description, the side pulled out is defined as the tip side body 1 , and the side where the tip side body 1 is held is defined as the tail side body 2 . Such as figure 1 As shown in (a), the rod body 1 on the slightly side of the rod is held in the rod body 2 on the tail side so that it can move forward and backward freely, and, as shown in figure 1 As shown in (b), in the state where the pole body 1 on the pole side is pulled out, the outer peripheral surface 1A of the tail end of the pole body 1 on the pole side 1 and the inner peripheral surface 1A of the pole end of the pole body 2 on the tail side are aligned. 2A are fitted into each other in a state of being press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com