High-strength integrated bent sill

An integrated, high-strength technology, applied in the direction of thin-plate connection, connecting components, elevators in buildings, etc., can solve the problems of low search efficiency, manual loading and unloading, and high management difficulty coefficient, and achieve labor cost input Low, the effect of improving manufacturing efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

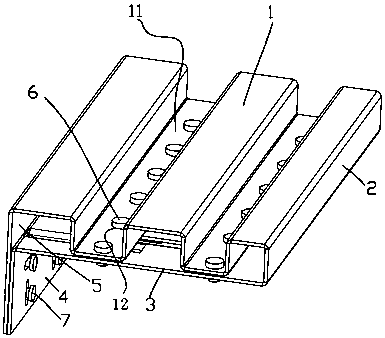

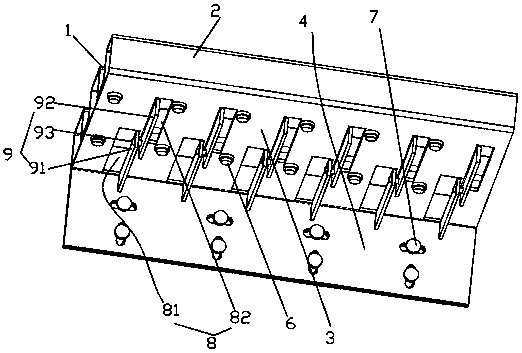

[0023] Embodiment 1: as Figure 1-2 As shown, a high-strength integrated bending sill is formed by bending galvanized sheets or steel plates, and includes a sill portion 1 having a sill groove 11 and a passage connecting one side of the sill portion 1. The bent first bent portion 2, the bent sill support plate 3 connected to the first bent portion 2 and located below the sill 1, and the ground The sill installation part 1 4 formed by bending connected to the sill part 3, and the sill installation part 2 5 formed by bending connected to the other side of the sill part 1; the first bending part 2 and the sill part 1 are preferably at an angle of 90 degrees, and the sill supporting plate part 3 and the sill part 1 are arranged in close contact, so that the supporting effect on the sill part 1 is better;

[0024] The sill supporting plate part 3 is connected with the sill part 1 through a connector 6;

[0025] The first sill installation part 4 is connected to the second sill in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com