Spherical tank support structure

A technology of support structure and spherical tank, which is applied in the method of container discharge, container filling method, gas/liquid distribution and storage, etc., can solve the problems of large amount of materials, difficult welding, poor performance, etc., and achieve material saving and material saving. , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

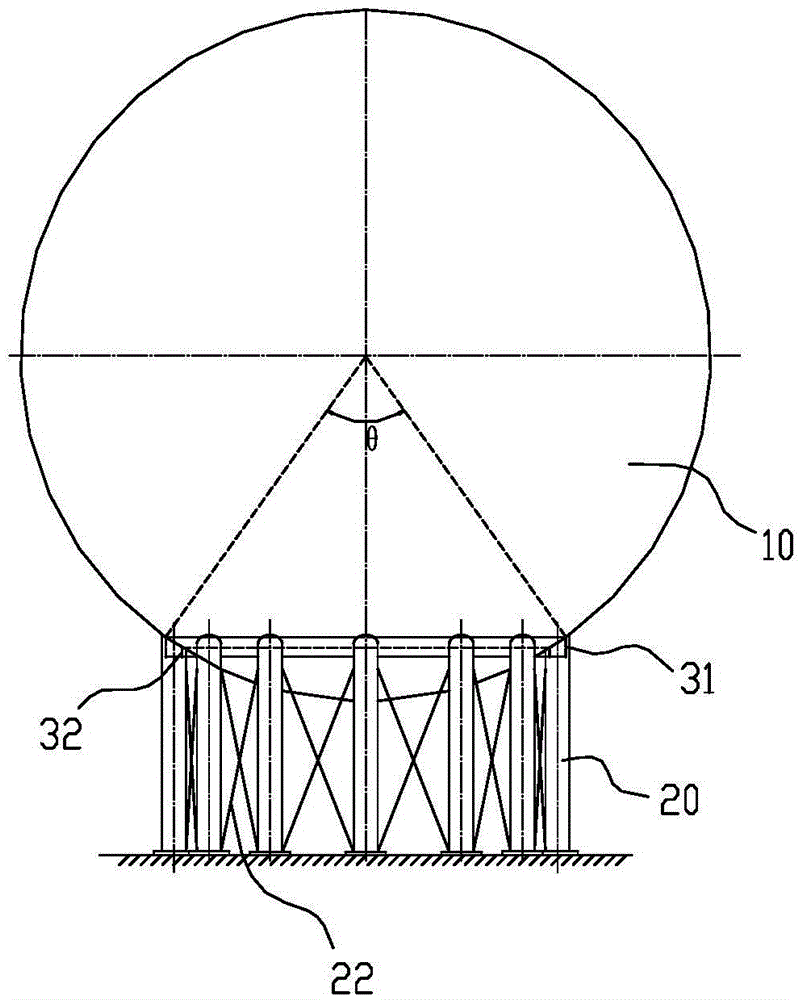

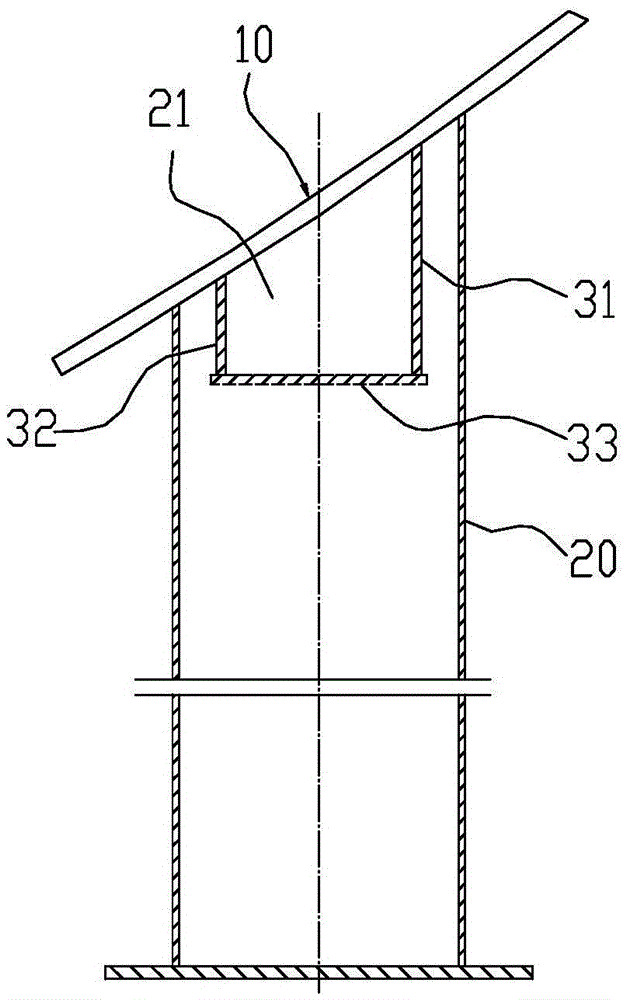

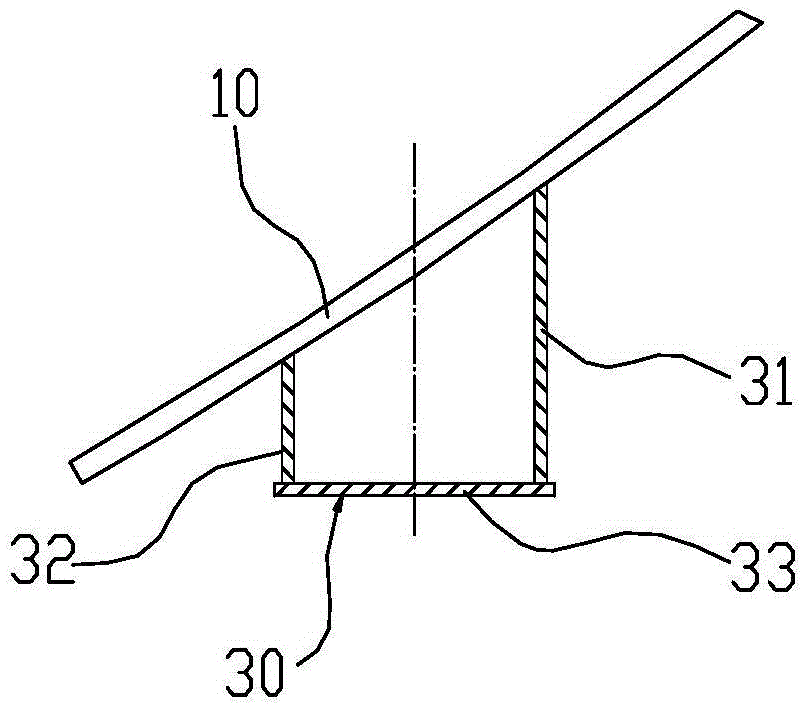

[0022] Such as figure 1 As shown, a spherical tank support structure includes a plurality of pillars 20 supporting the spherical tank 10, the end of the pillar 20 close to the spherical tank 10, that is, the upper end, is connected with the tank wall at the lower temperate zone of the spherical tank 10, this The support structure also includes a support ring 30 that cooperates with the pillar 20 to support the spherical tank 10 .

[0023] The upper end of the pillar 20 is provided with an arc-shaped groove 21 for installing the support ring 30, and the end of the support ring 30 away from the spherical tank 10, that is, the lower end, is inserted into the arc-shaped groove 21. The upper end of the ring 30 and the upper end of the strut 20 are in the same area that is tangentially attached to the tank wall of the spherical tank 10 .

[0024] The side walls of the pillars 20 are provided with an upper ear plate and a lower ear plate, and a tie rod 22 is provided between the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com