Indoor environment purification structure with plasma

An indoor environment and plasma technology, which is applied in the field of indoor environment purification, can solve the problems of time-consuming and laborious filter replacement, failure to find the filter in time, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

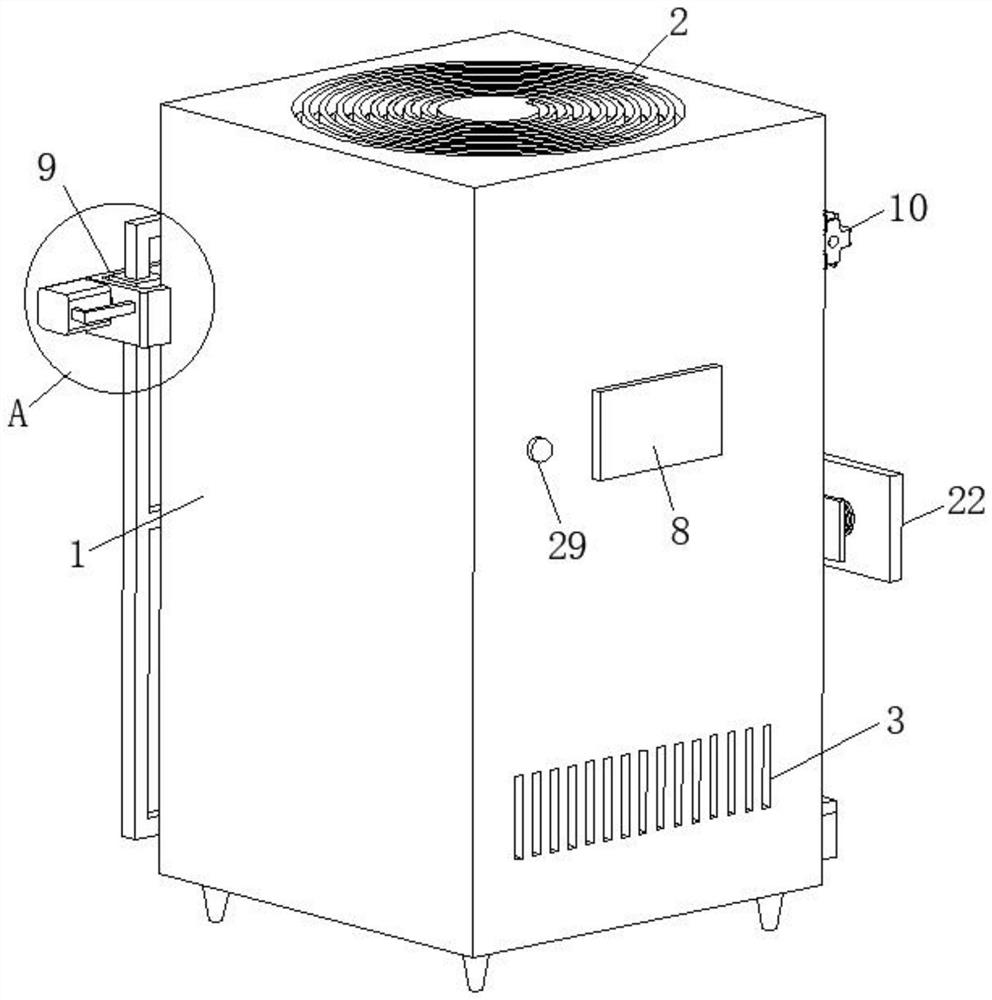

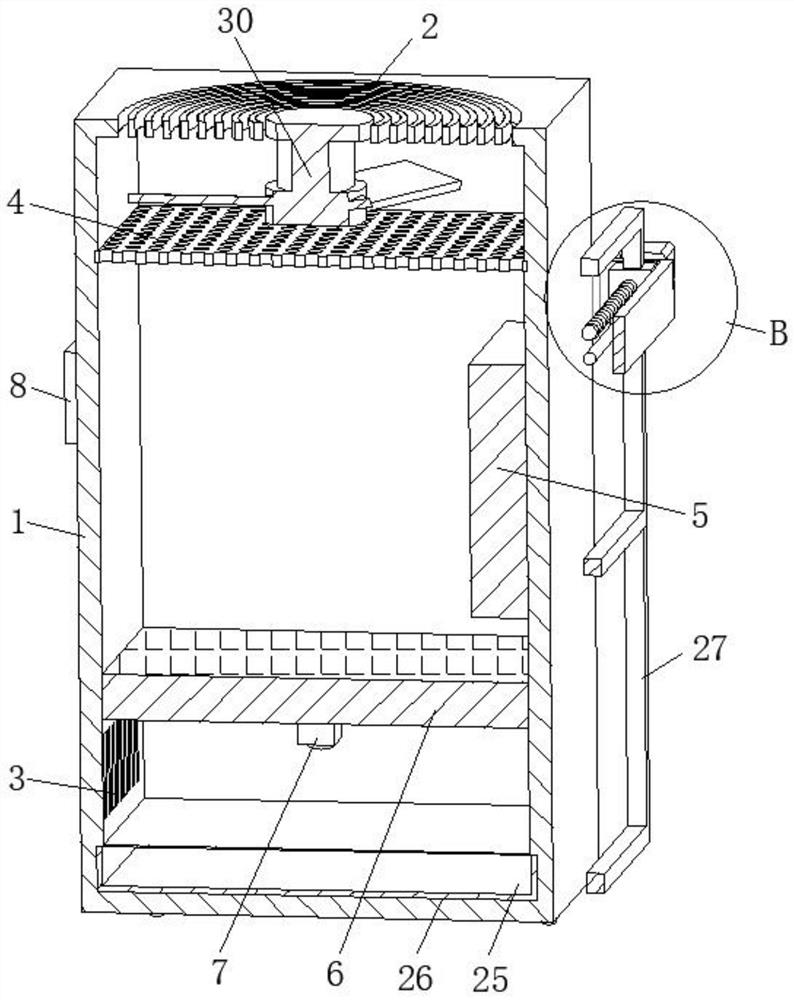

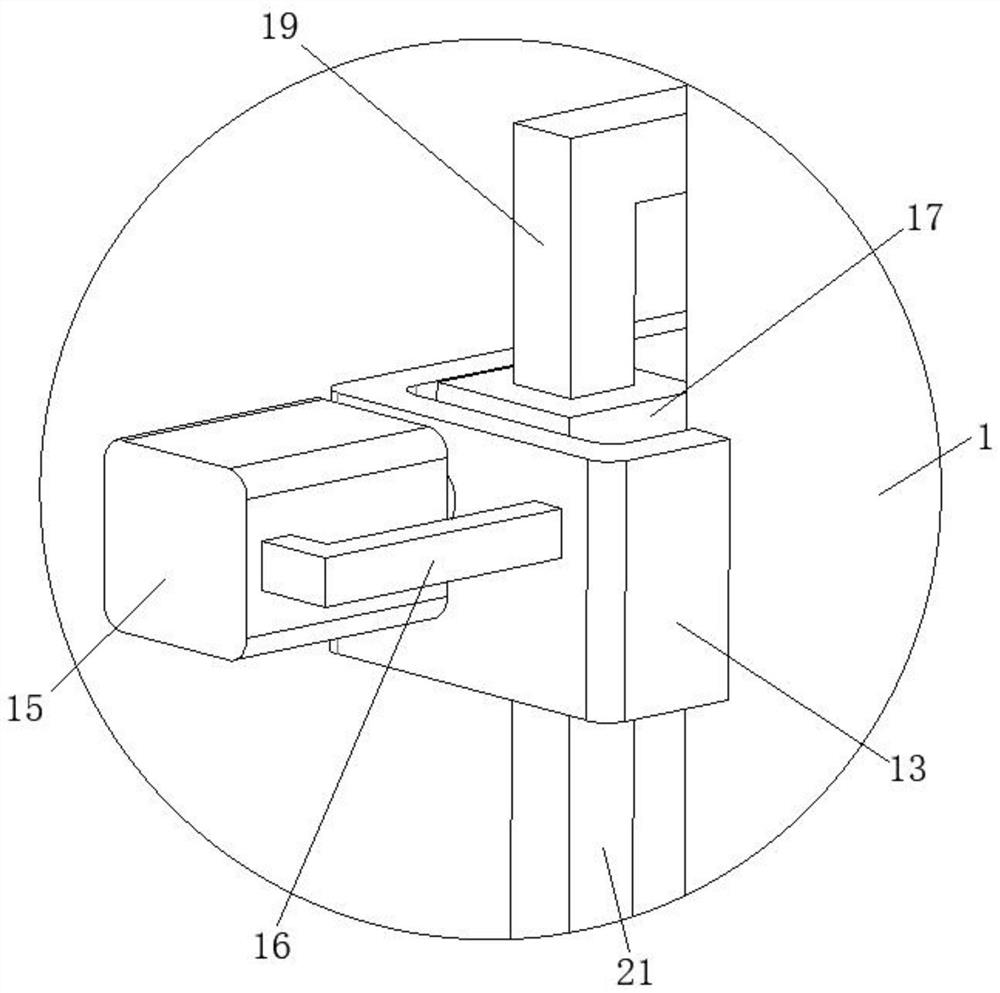

[0037] like Figure 1 to Figure 9 As shown, the indoor environment purification structure with plasma according to the embodiment of the present invention includes a purification box 1, the top of the purification box 1 is provided with an air inlet 2, the bottom end is provided with an air outlet 3, and the lower part of the air inlet 2 is fixedly installed There is a fan 30, a filter plate 4 is arranged below the fan 30, the filter plate 4 is slidably inserted into the filter box, a plasma generator 5 is arranged below the filter plate 4, and is fixed with the purification box 1, the An activated carbon laminate 6 is arranged between the plasma generator 5 and the air outlet 3, the activated carbon laminate 6 is fixed with the purification box 1, a wind sensor 7 is fixed under the activated carbon laminate 6, and the purification box 1 is provided with a wind sensor 7. There is a control module 8, a drive device 9 is fixed on the purification box 1, the filter plate 4 is fix...

Embodiment 2

[0042] like Figure 1 to Figure 9 As shown, this embodiment is basically the same as the first embodiment. Preferably, a plurality of springs 23 are fixedly installed on the mounting plate 22, and a buffer pad 24 is fixedly installed at one end of the springs 23. The filter plate 4 is connected to the buffer pad. 24 rotates against each other, and the downward rotation of the filter plate 4 first offsets the buffer pad 24 and the spring 23 to reduce the downward impact force of the filter plate 4 and avoid too much vibration. The dust on the filter plate 4 is scattered in the air, reducing The vibration after the impact force is small, and the dust on the surface of the filter plate 4 can be gently shaken and dropped, effectively avoiding dust scattering.

Embodiment 3

[0044] like Figure 1 to Figure 9 As shown, this embodiment is basically the same as the first embodiment. Preferably, a collection box 25 is provided under the filter plate 4, a placement slot 26 is provided at the bottom end of the filter box, and the collection box 25 is slidably inserted into the placement slot. In 26, the end of the collection box 25 is fixed with a third connecting rod 27, and the third connecting rod 27 is fixed with the second connecting piece 16;

[0045] A baffle plate 28 is fixed on the outside of the placement slot 26. The baffle plate 28 is located above the collection box 25 and is fixed to the filter box. The collection box 25 is pulled out with the movement of the third connecting rod, and the dust on the surface of the filter plate is lightly shaken. Dropped into the collection box 25, and then inserted into the placement slot 26, the baffle 28 is located above the collection box 25, which can block the part of the installation box leaking out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com