Double-sided open-type plumbing box for wiring electric wires

An open type, wire technology, applied in the field of double-sided open wire wiring pipe boxes, can solve the problems of reduced dimensional accuracy, tool breakage, processing difficulties, etc., and achieves increased manufacturing convenience, wiring operation convenience, and combination operation convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The purpose, features and advantages of the above-mentioned present invention will be further clarified by the following detailed description. Below, illustrate according to the drawing that attaches the feasible embodiment of the present invention:

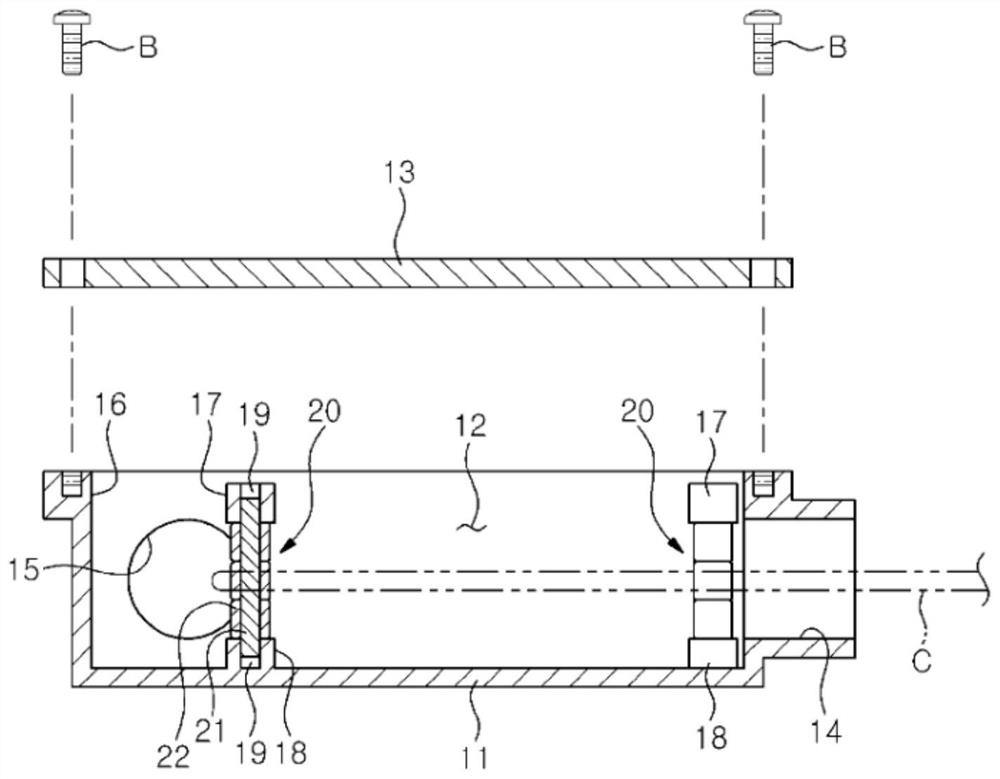

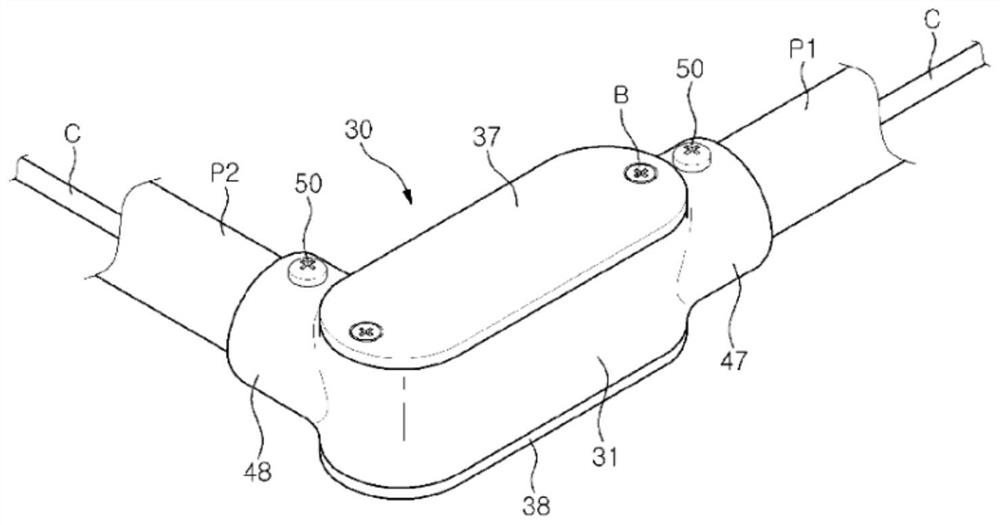

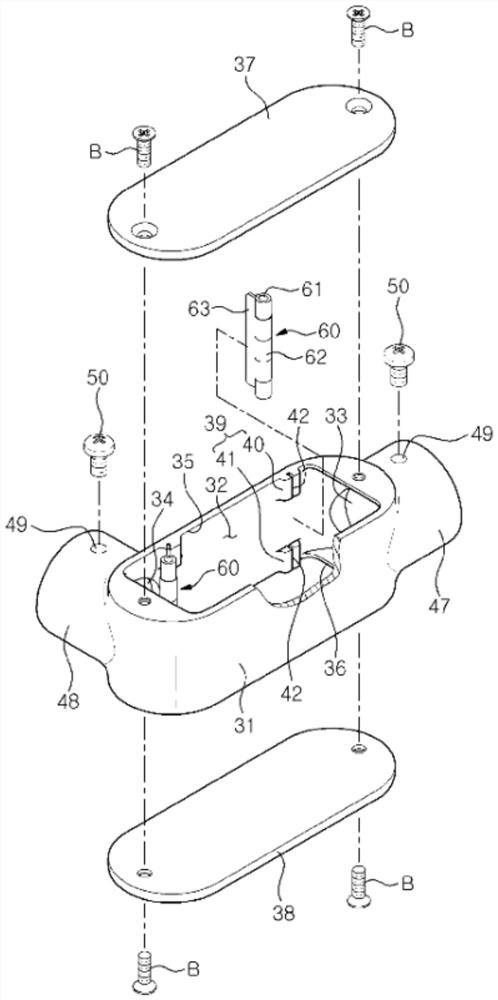

[0042] Figure 2 to Figure 12 are drawings of various embodiments of the invention. Such as figure 2 As shown, the distribution box 30 of the present invention is composed of a box body 31 of a certain size and a first cover plate 37 and a second cover plate 38 combined on both sides of the box body 31, and the first pipe body P1 and the second pipe body are connected on both sides. The protruding connectors 47 and 48 of P2 are integrally formed, and fastening bolts 50 for fixing the respective pipe bodies P1 and P2 are connected to the connectors 47 and 48 .

[0043]This piping box 30 is interposed between the pipe bodies P1 and P2 extended to a certain length so that cables C such as electric wires pass through them....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com