Processing and meat mincing method for meat products

A technology of meat products and minced meat, applied in cleaning methods and utensils, chemical instruments and methods, grain processing, etc., to achieve the effect of improving the quality of mincing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

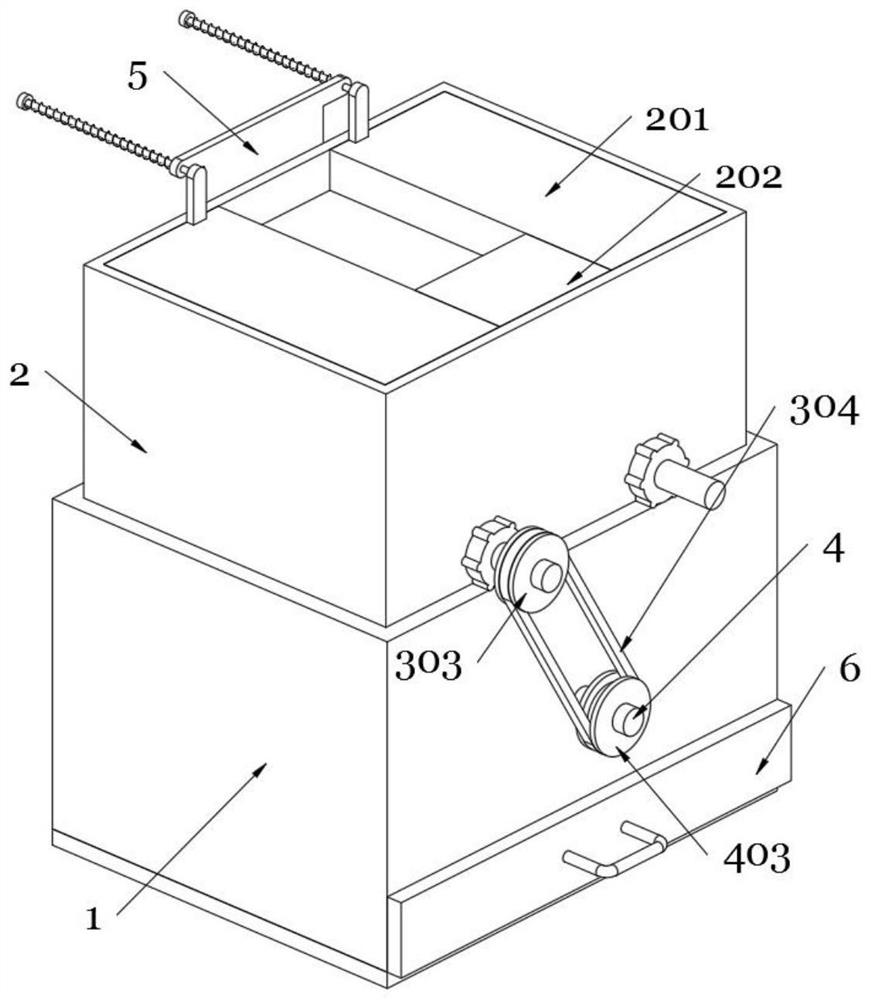

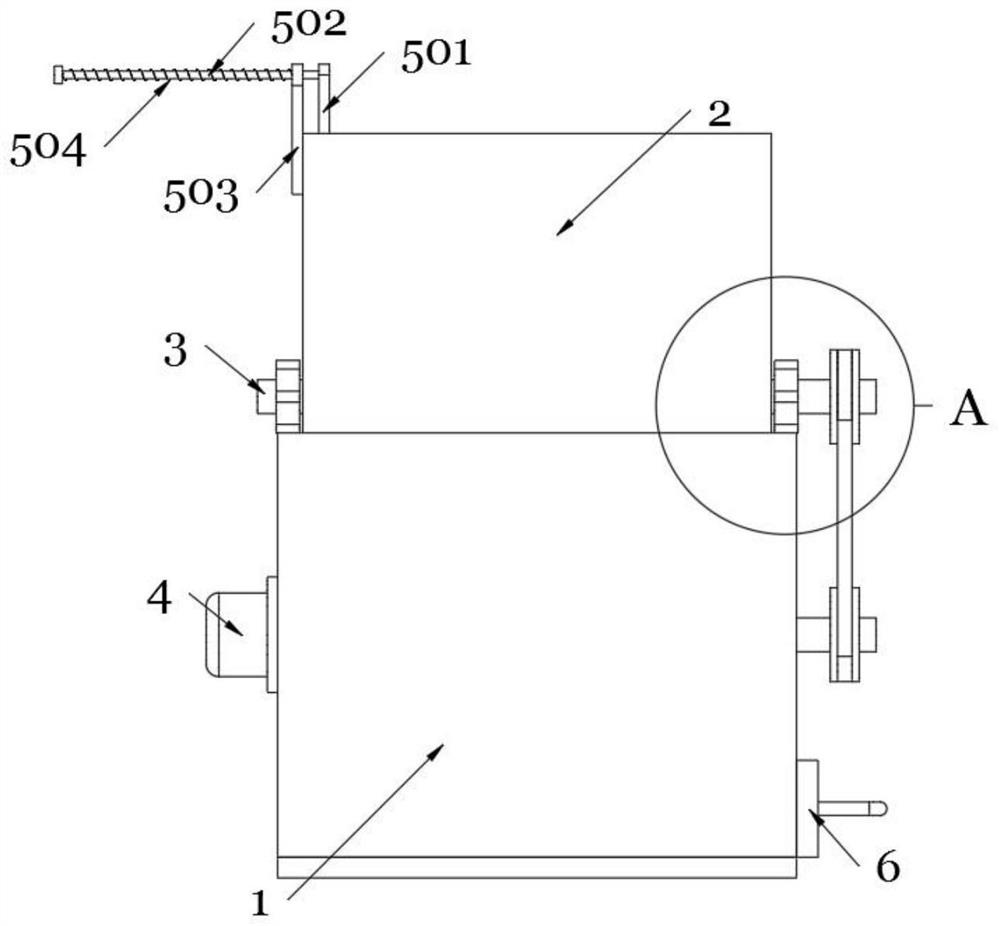

[0054] as attached figure 1 To attach Figure 8 Shown:

[0055] The present invention provides a meat processing and grinding method. The meat processing and grinding method realizes the processing and grinding of meat products by using a special processing and grinding device; the special processing and grinding device includes:

[0056] Box A1;

[0057] The box A1 is a rectangular box structure;

[0058] Box B2, box B2 is slidingly connected in box A1;

[0059] Meat grinding structure 3, the meat grinding structure 3 is installed on the box B2;

[0060] The driving part 4, the driving part 4 is installed on the box body A1;

[0061] The cover plate structure 5 is installed on the box body B2.

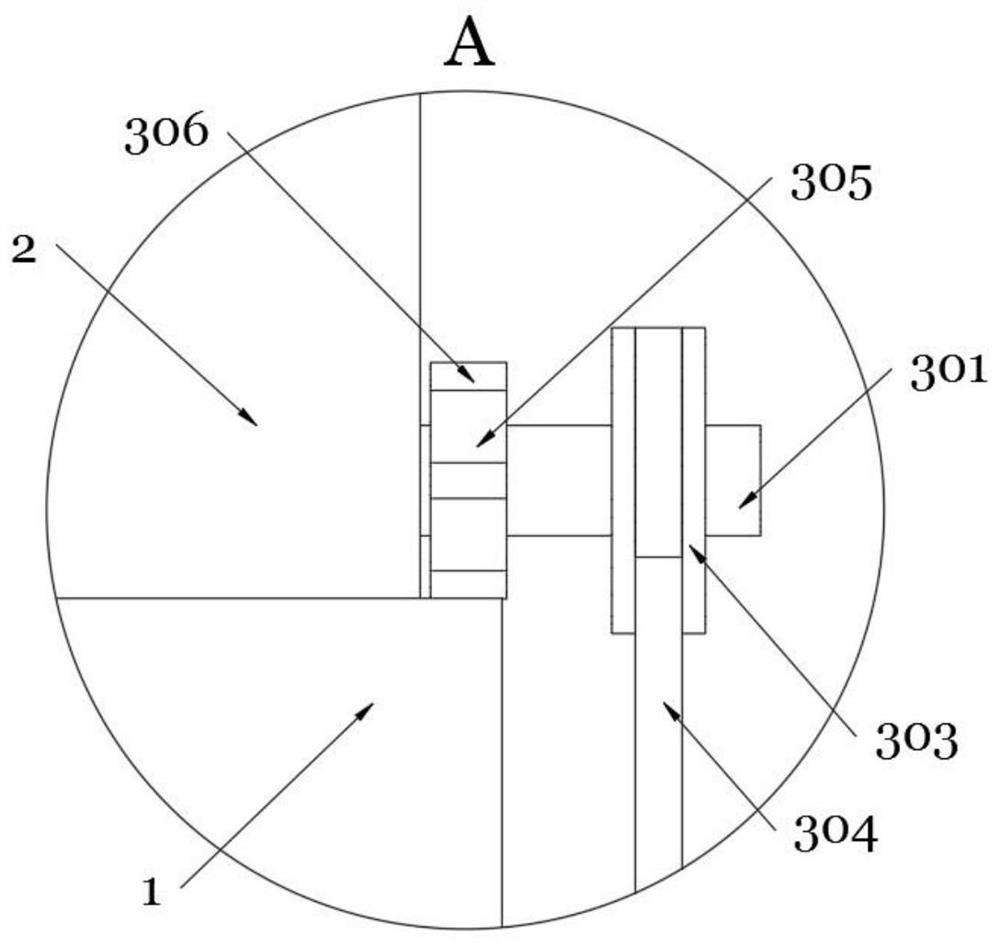

[0062] Reference as Figure 4 , mince structure 3 includes:

[0063] There are two rotating shafts A301, and the two rotating shafts A301 are rotatably connected to the box body B2; each rotating shaft A301 is equipped with seven gears 302, and the seven gears 302 on the two rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com