Treatment device for FPC circuit board production waste

A technology for producing waste materials and processing devices, which is applied in grain processing, static electricity, electrical components, etc. It can solve the problems of material waste, impurities stuck in the crushing shaft, damage to workpieces, etc., and achieve the effect of improving the quality of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

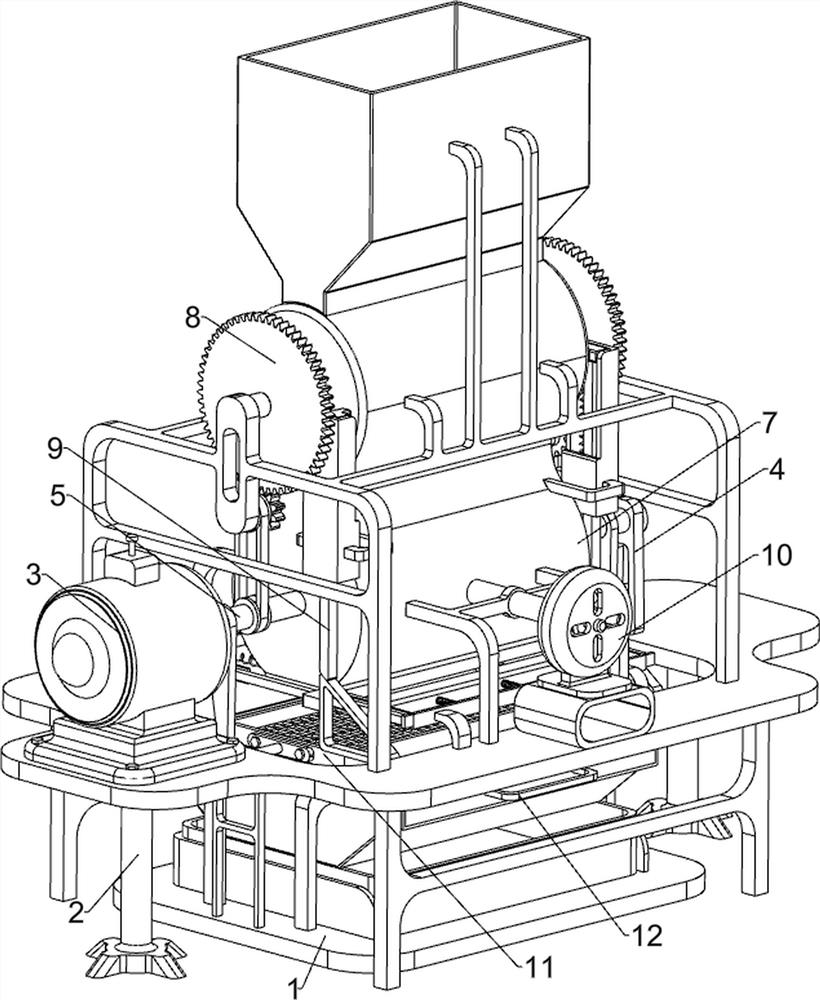

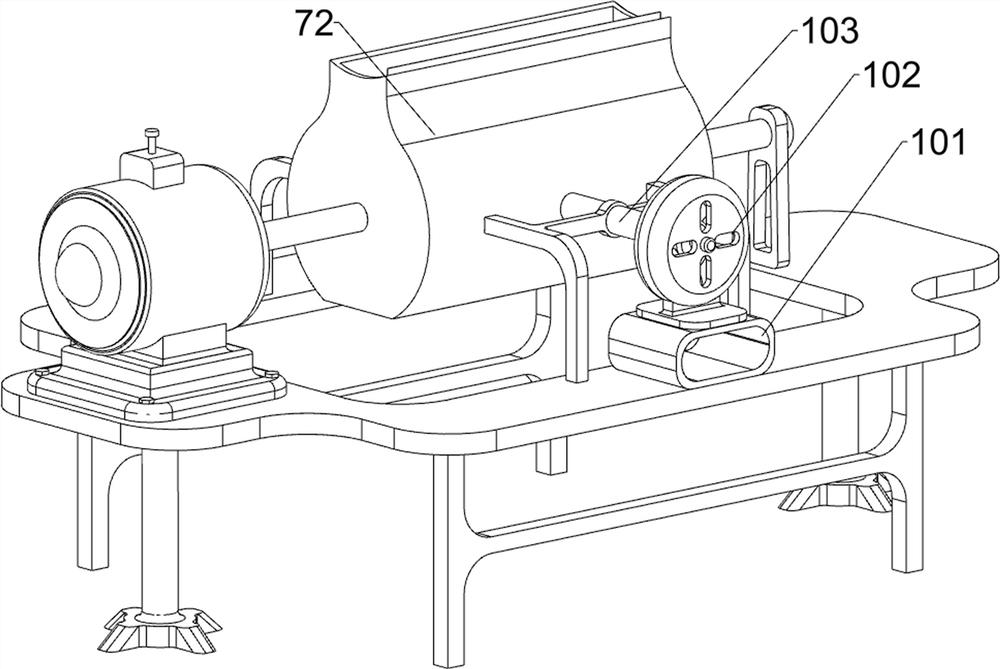

[0049] A kind of processing device for the production waste of FPC circuit board, such as figure 1 As shown, it includes a bottom plate 1, a mounting seat 2, a servo motor 3, a bearing seat 4, a rotating shaft 5, a crushing tool 6, a mounting mechanism 7 and a blanking mechanism 8, which is provided with a bottom plate 1 and a mounting seat 2, and the mounting seat 2 is located at Above the bottom plate 1, a servo motor 3 is provided on the left side of the top of the mounting seat 2, and a bearing seat 4 is provided on the right side of the top of the mounting seat 2. The upper part of the bearing seat 4 is rotatably provided with a rotating shaft 5, and the rotating shaft 5 is connected to the output shaft of the servo motor 3. The rotating shaft 5 is provided with a crushing cutter 6, and an installation mechanism 7 is connected between the top of the mounting seat 2 and the top of the base plate 1. The top of the mounting seat 2 is provided with a blanking mechanism 8, and ...

Embodiment 2

[0052] On the basis of Example 1, such as figure 2 , image 3 , Figure 8 with Figure 9 As shown, the mounting mechanism 7 includes a mounting frame 71, a crushing chamber 72, a guide groove plate 73 and a collection frame 74, and the mounting frame 71 is arranged on both sides of the top of the mounting seat 2, and the crushing chamber 72 is connected between the top of the mounting frame 71. , The crushing tool 6 is located in the crushing chamber 72, the top of the bottom plate 1 is slidingly placed with a collection frame 74, and the bottom of the mounting seat 2 is provided with a guide groove plate 73.

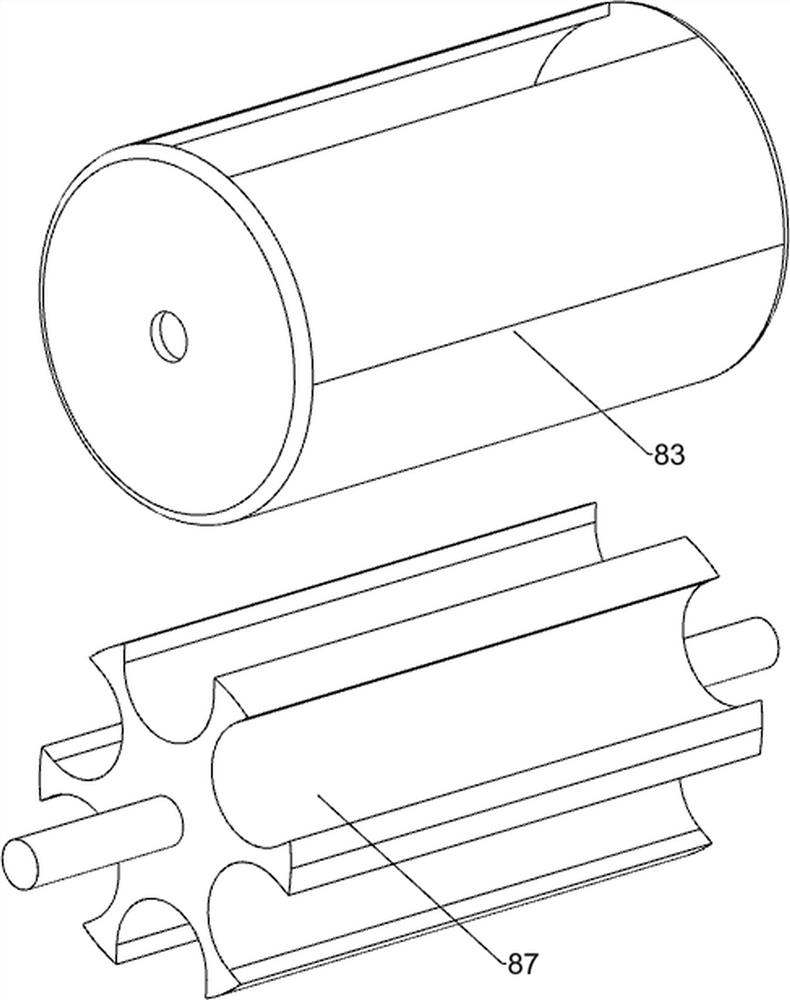

[0053] The blanking mechanism 8 includes a support frame 81, a discharge frame 82, a guide cylinder 83, a pulley assembly 84, a first transmission gear 85, a second transmission gear 86 and a sheave 87, and the top of the mounting seat 2 is provided with a support frame 81, which supports A discharge frame 82 and a guide cylinder 83 are connected between the front a...

Embodiment 3

[0056] On the basis of Example 2, such as Figure 4 to Figure 7 As shown, an automatic discharge mechanism 9 is also included, and the automatic discharge mechanism 9 includes a guide frame 91, a driving rod 92, a first wedge block 93, a guide bracket 94, a second wedge block 95, a first limit spring 96, Blanking baffle plate 97 and back-moving spring 98, mounting seat 2 tops are provided with guide frame 91, and the sliding type on guide frame 91 is provided with blanking baffle plate 97, and both sides before and after the blanking baffle plate 97 are all with guide frame 91 inwalls. Connect with a plurality of return springs 98, the left and right sides of the blanking baffle 97 are provided with a second wedge block 95, the left and right sides of the rotating shaft of the sheave 87 are provided with a driving lever 92, and the front side of the crushing chamber 72 is symmetrically provided with a guide Support 94, on the guide bracket 94, all slides are provided with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com