Method for obtaining profile of rake face of hobbing and chamfering cutter

A technology for chamfering cutters and rake faces, which is used in manufacturing tools, components with teeth, gear teeth manufacturing tools, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0048] In this embodiment, the method for obtaining the rake face profile of the hobbing and chamfering tool includes the following steps:

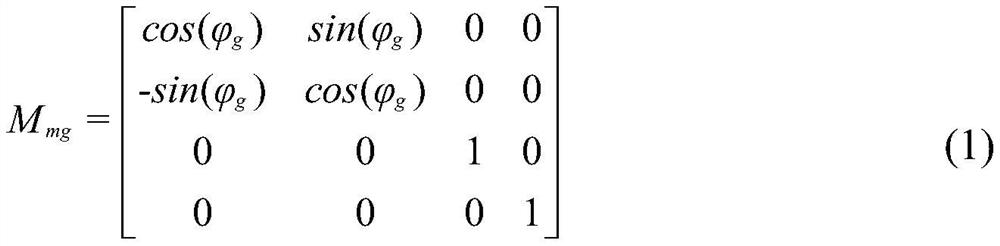

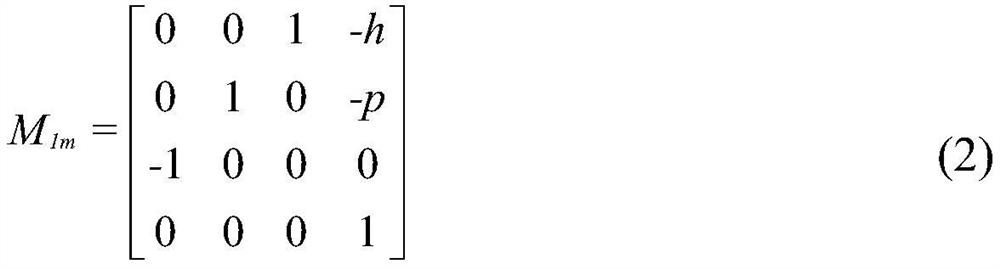

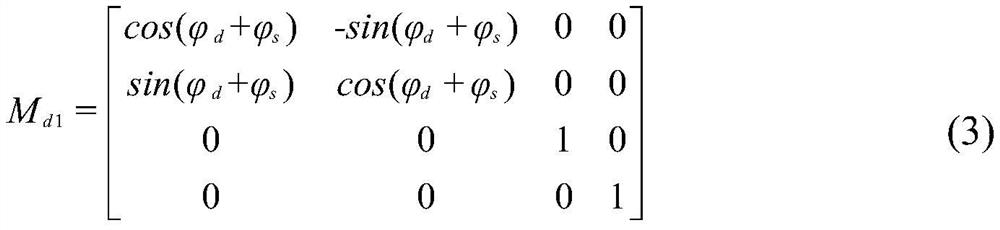

[0049] 1) According to the installation pose of the hobbing and chamfering tool, establish a space-generated kinematic relationship coordinate system between the hobbing-cutting and chamfering tool and the cylindrical gear, and the space-generated kinematic relationship coordinate system includes: the gear static coordinate system o m -x m the y m z m , gear moving coordinate system o g -x g the y g z g , tool static coordinate system o 1 -x 1 the y 1 z 1 and tool moving coordinate system o d -x d the y d z d ,

[0050] Gear moving coordinate system o g -x g the y g z g Fixedly connected with the cylindrical gear, at the initial position, the gear moving coordinate system o g -x g the y g z g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com