Gear chamfering device

A chamfering and gear technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problems of poor uniformity and low chamfering precision, and achieve high centrality, high qualified rate of finished products, Effect of improving chamfering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

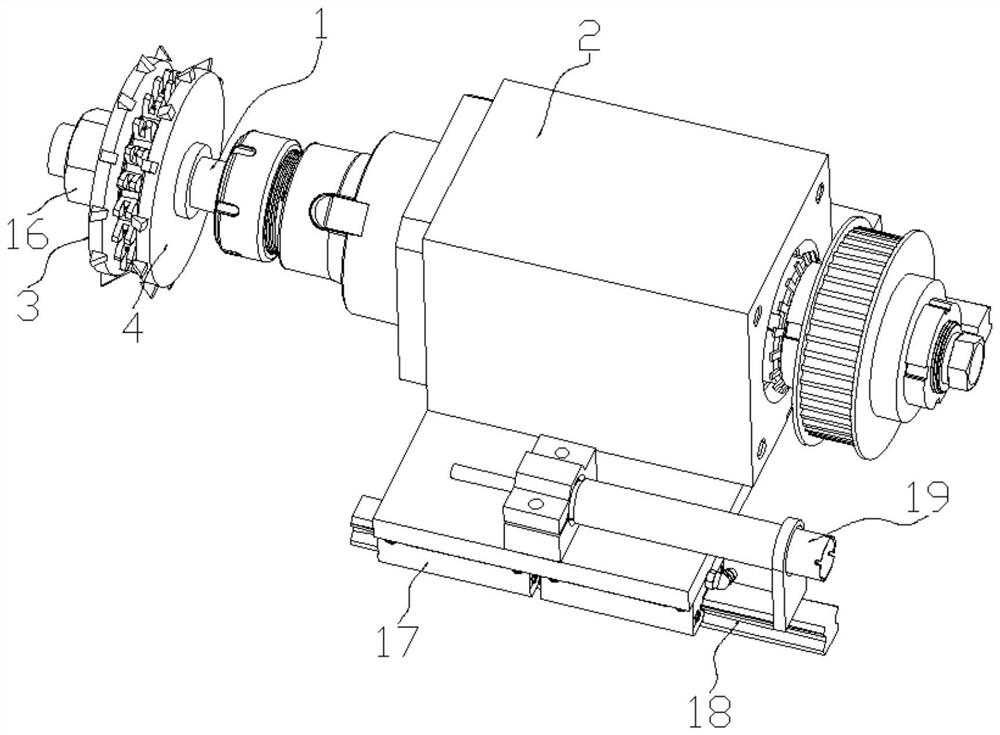

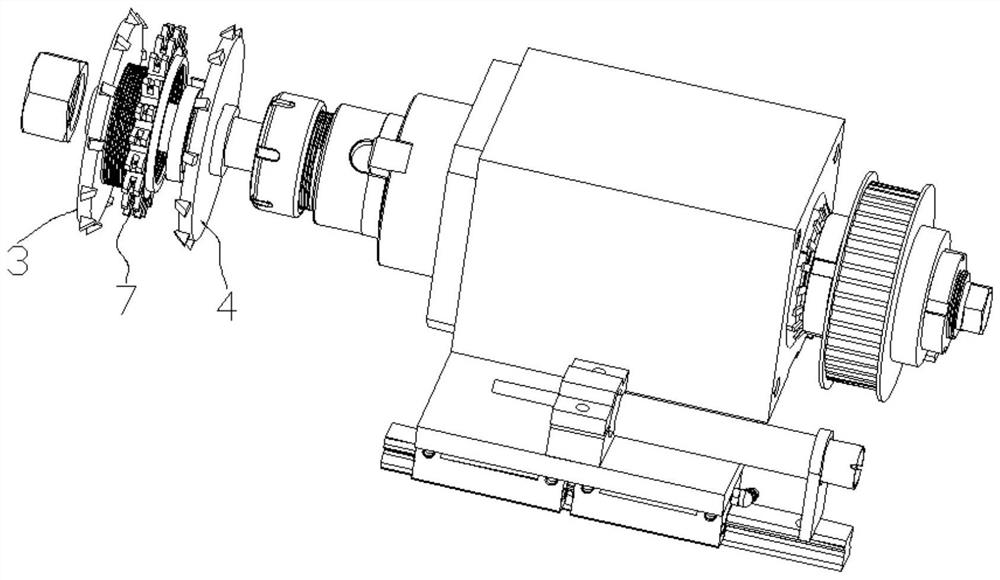

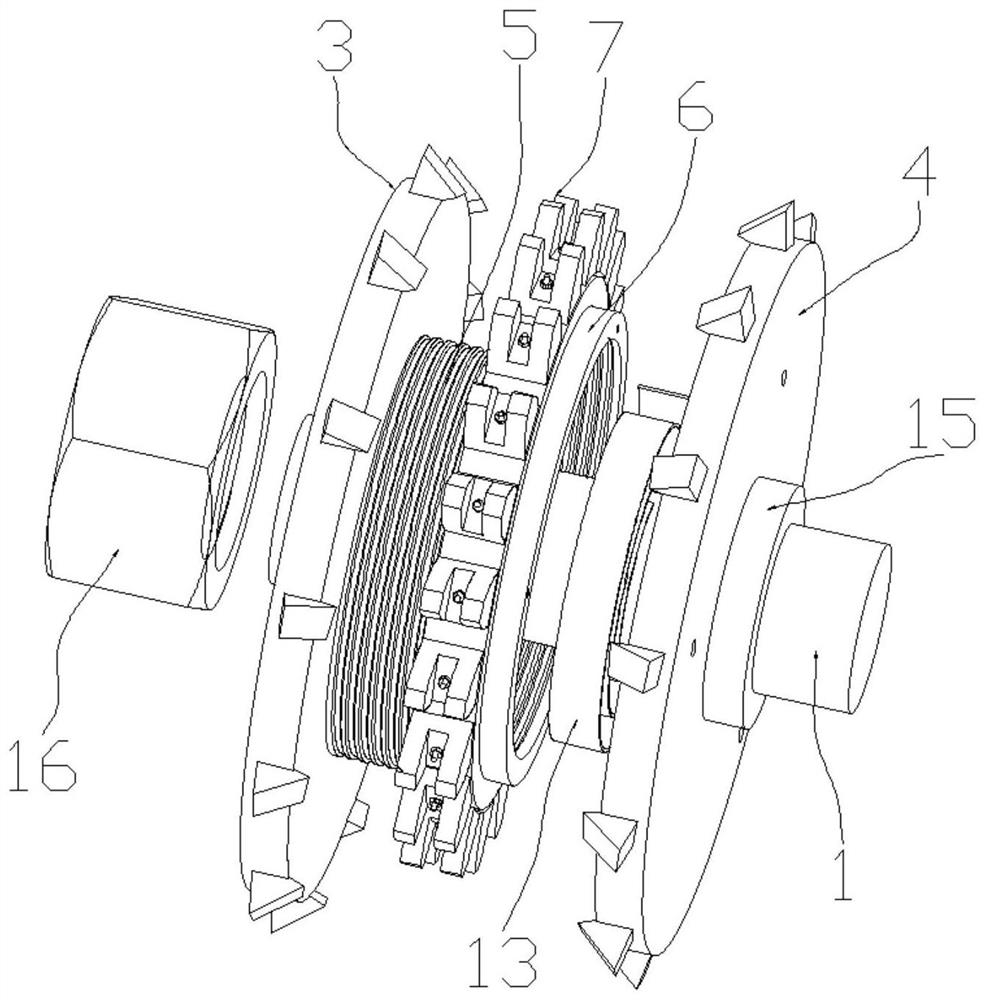

[0028] Example 1, such as Figure 1~2 , 6, a gear chamfering device of the present invention includes a rotating shaft 1, a driving device 2 for driving the rotating shaft 1 to rotate, a frame for installing the driving device 2, a first cutter head 3 and a second cutter head 3 that are in transmission with the rotating shaft 1 Two cutterheads 4, one end of the rotating shaft 1 is connected to the driving device 2, and the other end extends outward in a free state. The first cutter head 3 and the second cutter head 4 are symmetrical to each other, and their outer peripheral surfaces are provided with replaceable cutters. The cutters are triangular in shape and made of hard alloy. The inner side of the cutter extends inward for removing gears. The material of the outer surface, when the gear cutters of the first cutter head 3 and the second cutter head 4 are opposite, so that the first cutter head 3 and the second cutter head 4 are spaced apart to form a chamfering hole for the...

Embodiment 2

[0037] Example 2, such as Figure 7-8 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, a liquid bag 20 is provided between the inner side of the follower engagement plate 7 and the outer surface of the second connecting sleeve 6, and the follower engagement plate 7 The inner side and the outer surface of the second connecting sleeve 6 are provided with a locking groove 21 for limiting the position of the liquid bag 20. At the same time, the surface of the second connecting sleeve 6 is provided with a liquid channel 22, and the liquid channel 22 is connected with the joint 23. The liquid bag 20 is in communication, and the outer end surface of the second connection sleeve 6 is provided with a liquid injection port and a liquid discharge port. The liquid injection port and the liquid discharge port are both connected to the liquid passage 22. When used, the follow-up engagement plate 7 and the second connection sleeve 6 are clamped by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com