Patents

Literature

42results about How to "Improve centrality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

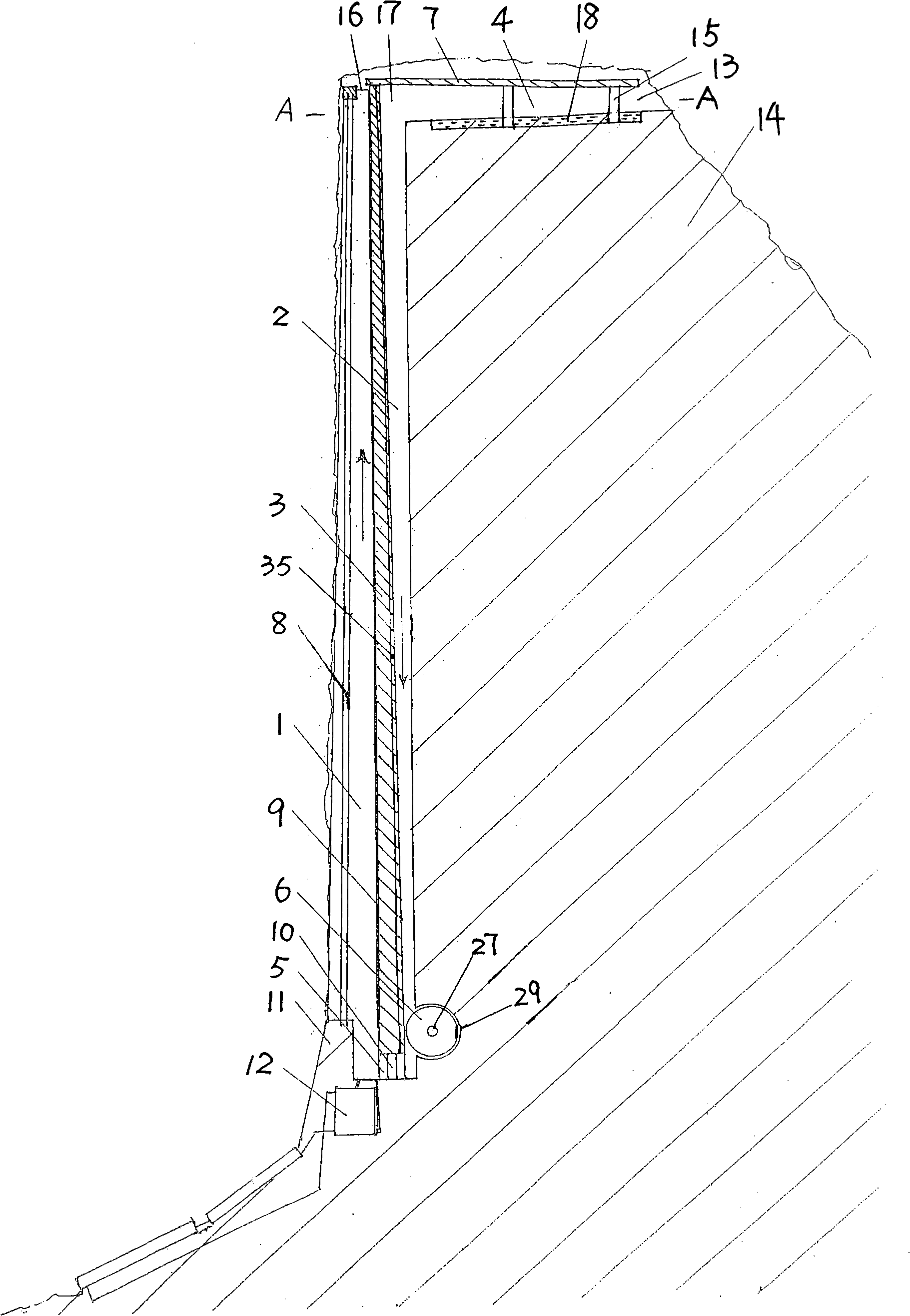

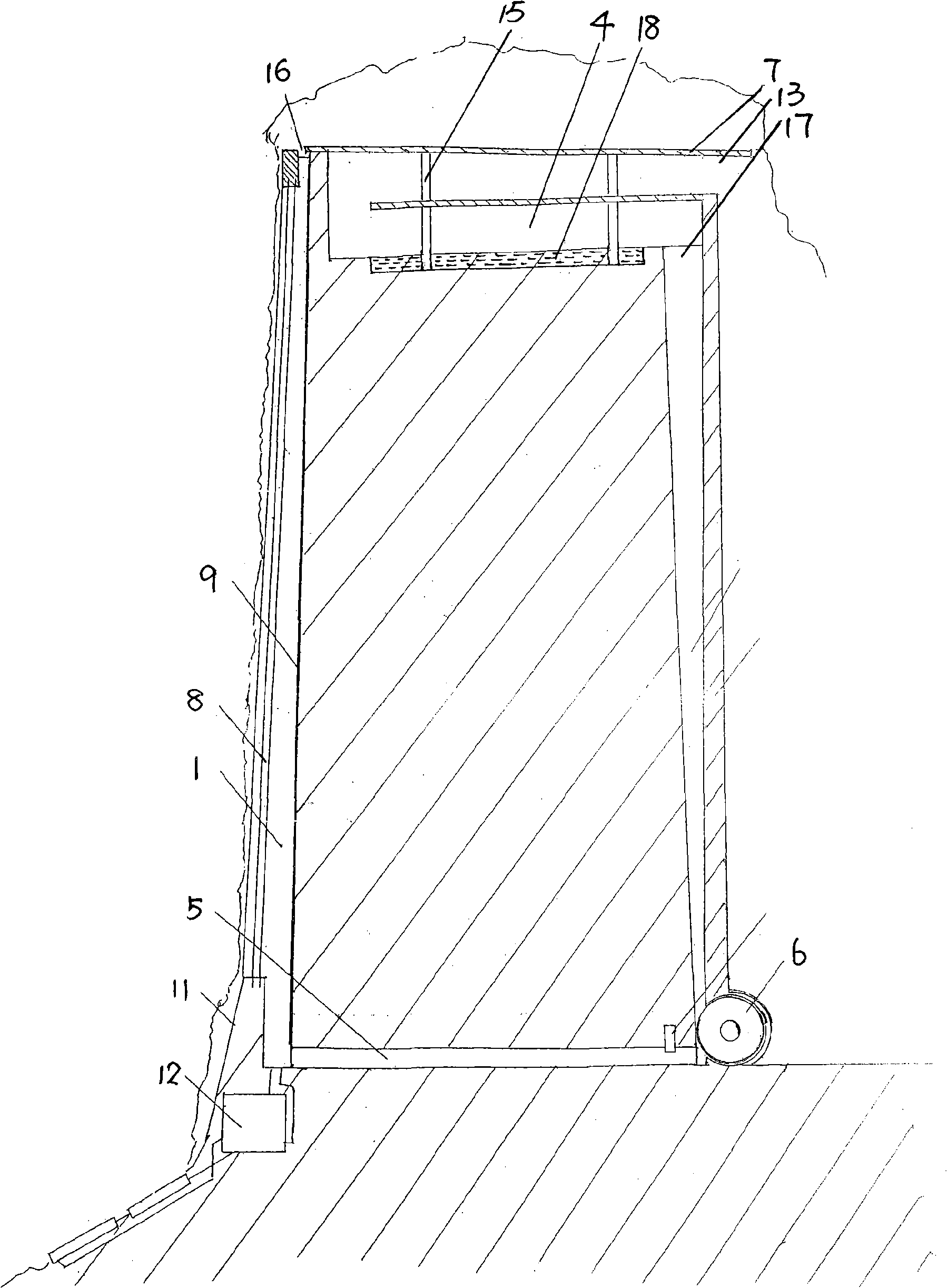

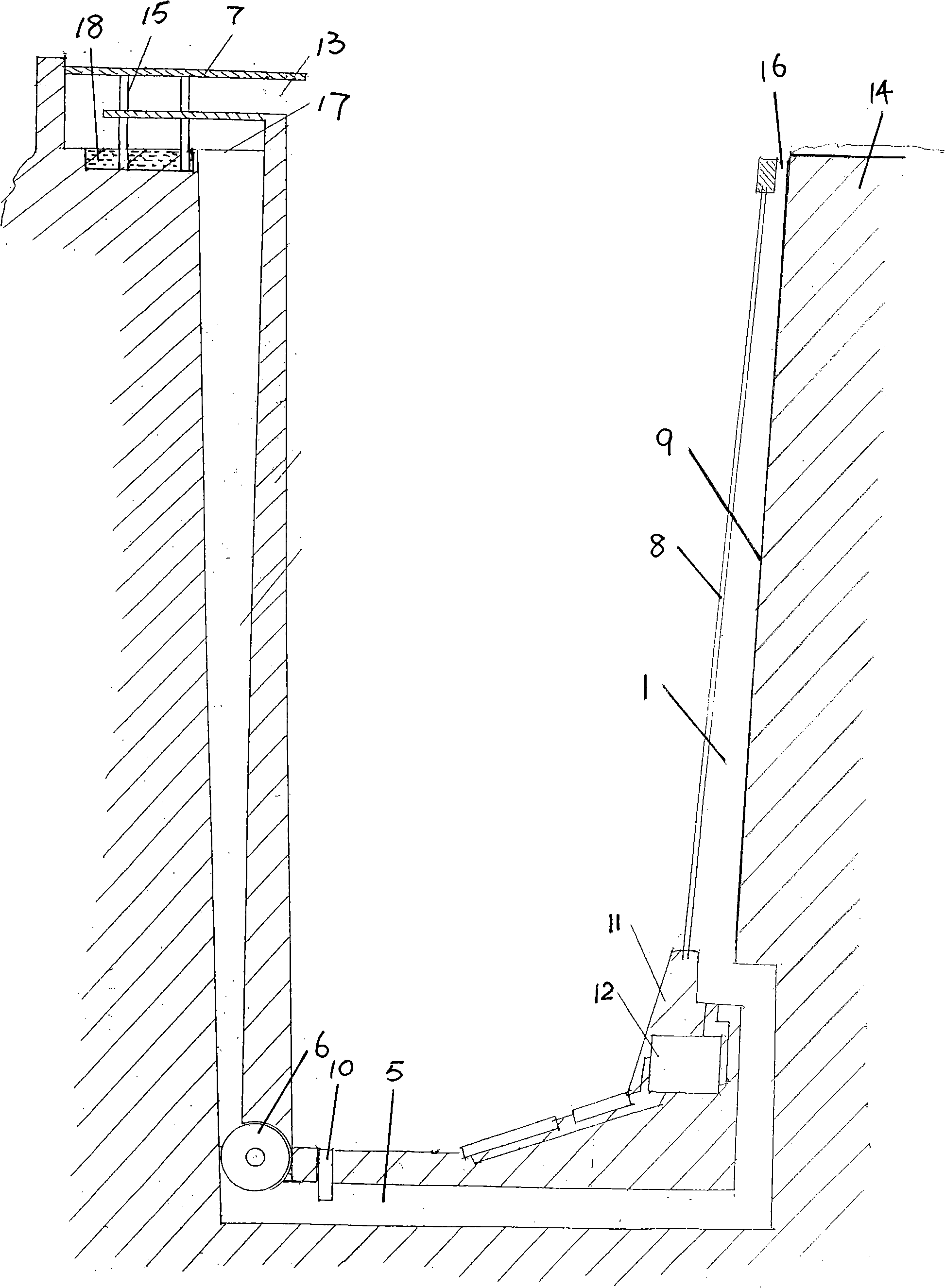

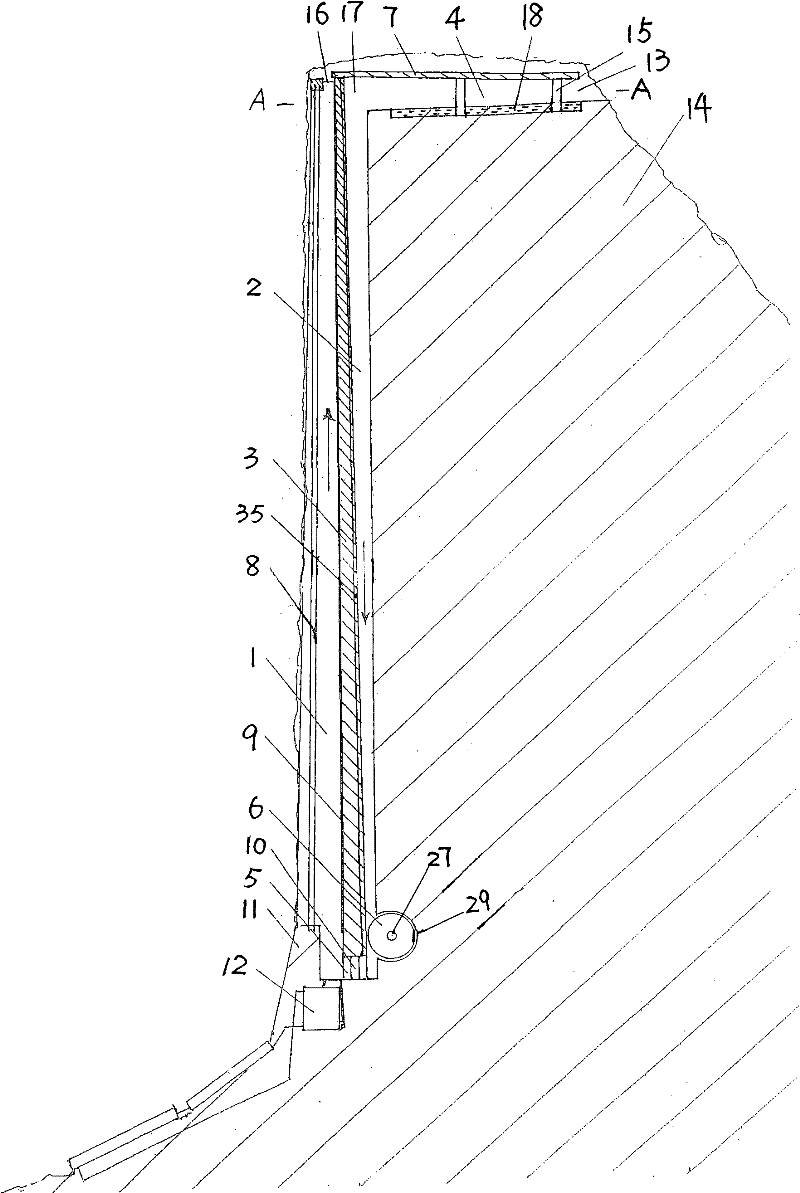

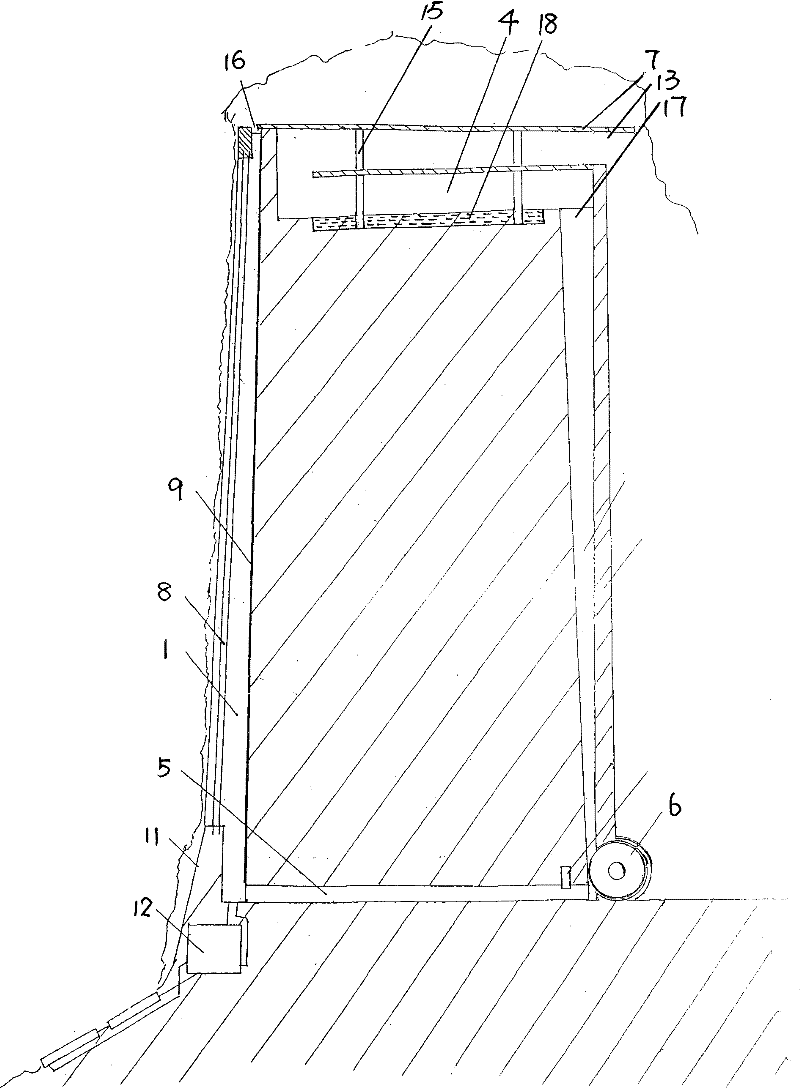

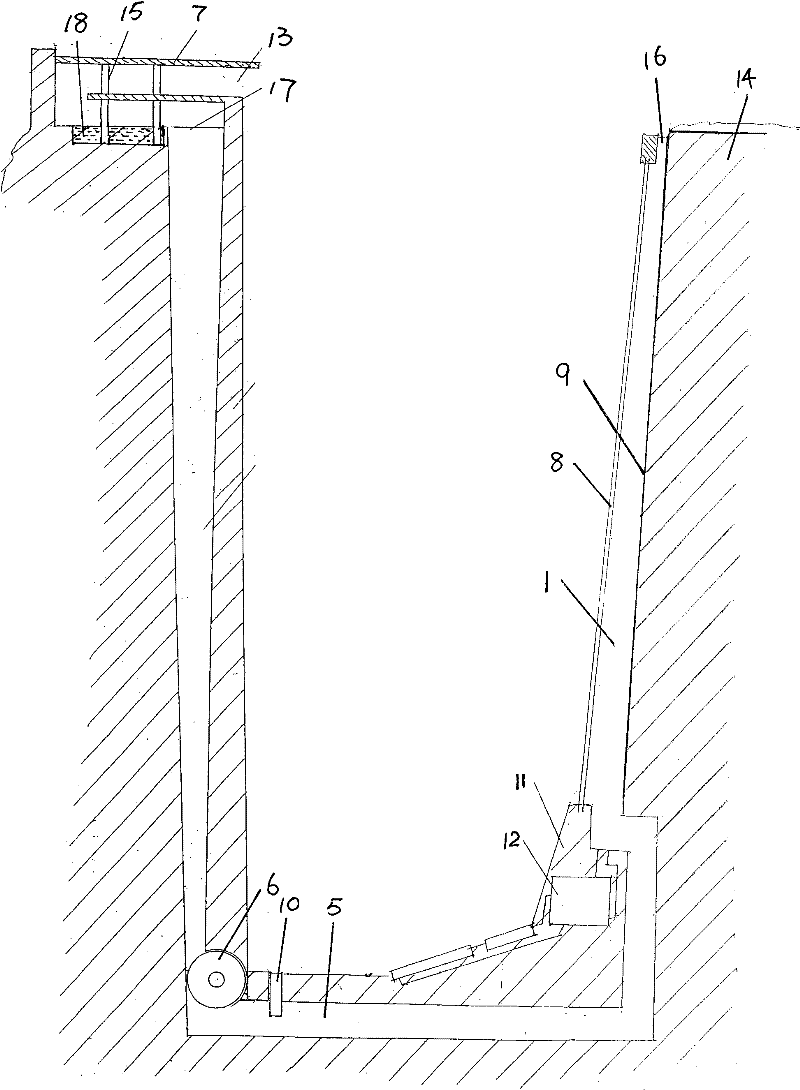

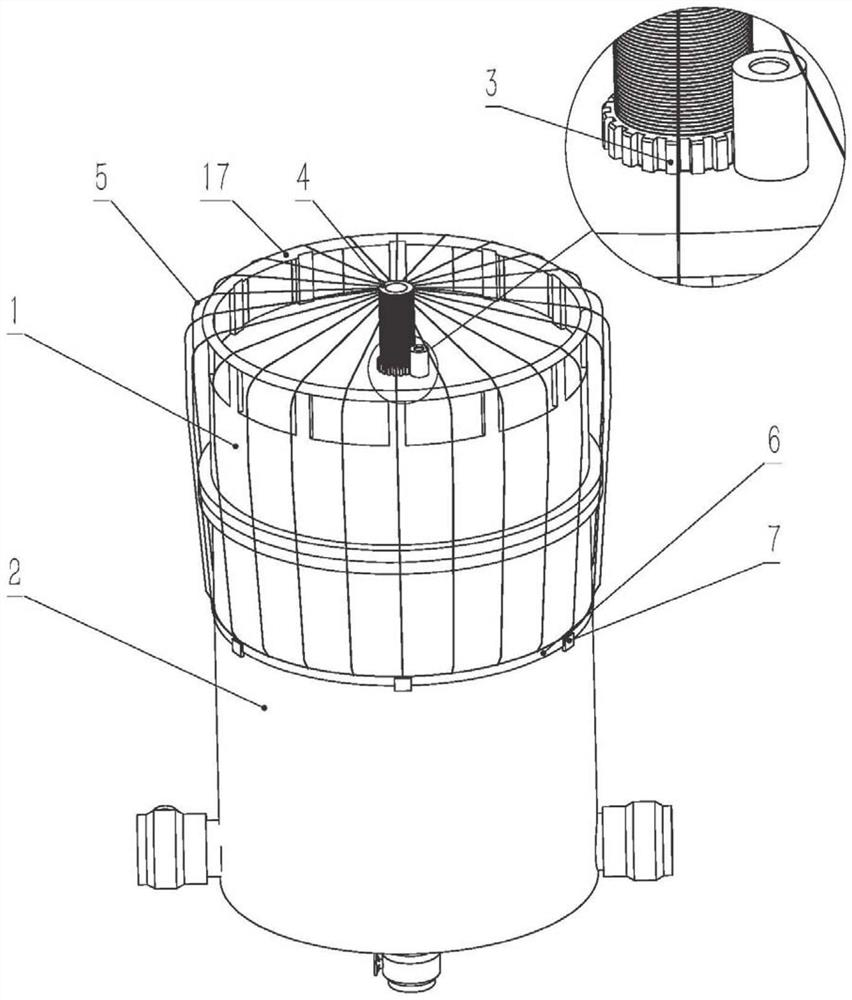

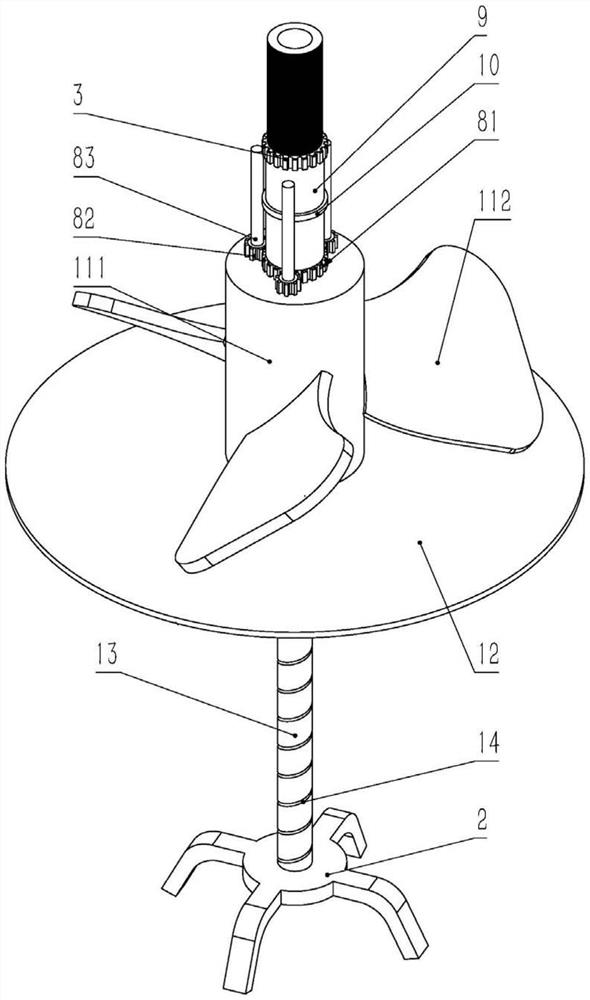

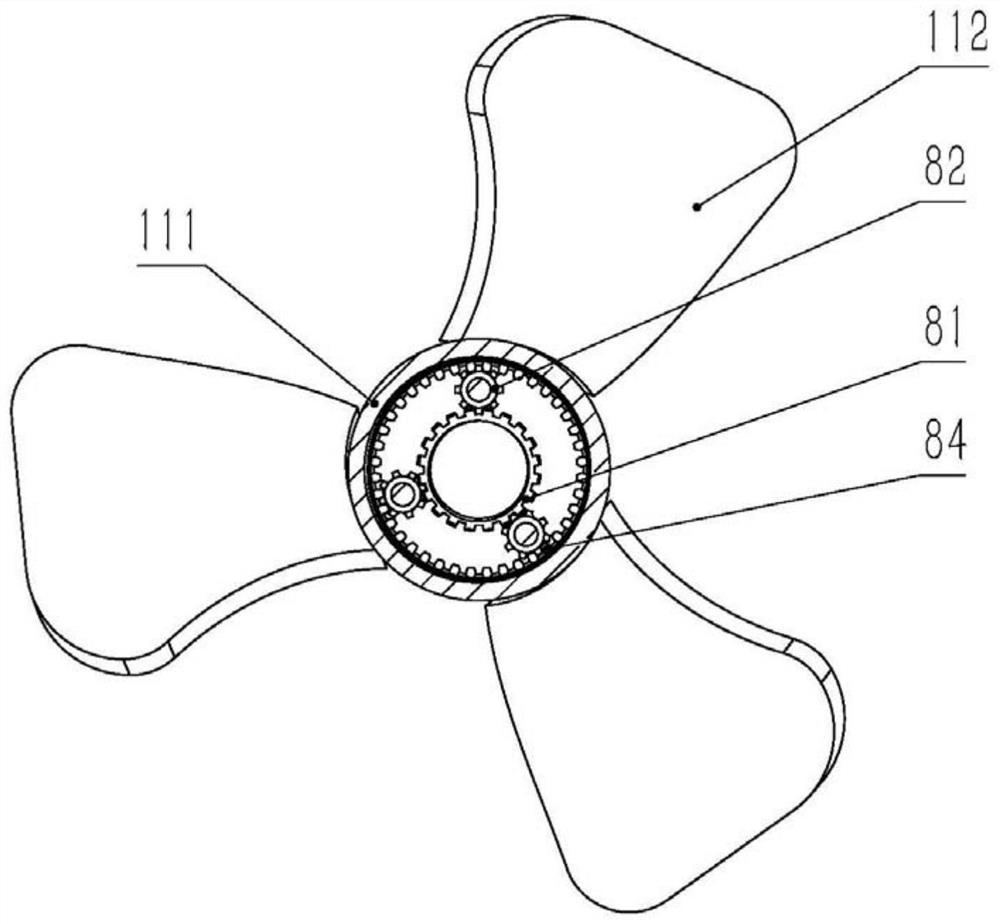

Solar energy wind power generation tower

InactiveCN101539117AStrong driving forceImprove centralitySolar heat devicesWind motor combinationsNew energySolar power

The invention belongs to the technical field of utilizing the solar energy to make wind power and utilizing the wind power to generate electricity, in particular to a solar energy wind power generation tower which solves the problems that the existing solar generating equipment has high cost and low utilization rat and the utilization rate of the wind energy generating equipment has low utilization rate. The solar energy wind power generation tower comprises a thermal-arrest tower and a convection tower; the thermal-arrest tower is internally provided with a gas ascending passage; the outer side of the sunny slope of the gas ascending passage is provided with a double-layer transparent glass and the bottom of the inner side is provided with an absorbing coat; the highest point of the gas ascending passage is communicated with atmosphere; the convection tower is internally provided with a gas descending passage, the bottom of the gas descending passage is provided with a wind turbine, and the top of the gas descending passage is provided with a cold air inlet; the lowest point of the gas ascending passage is communicated with the lowest point of the gas descending passage; the output end of the wind turbine is connected with the input end of a generator. The invention finds a new channel for developing pollution free new energy with low cost, big, middle and small-sized solar power generation and small and middle-sized wind power generation by depending on crude natural conditions.

Owner:STATE GRID CORP OF CHINA +1

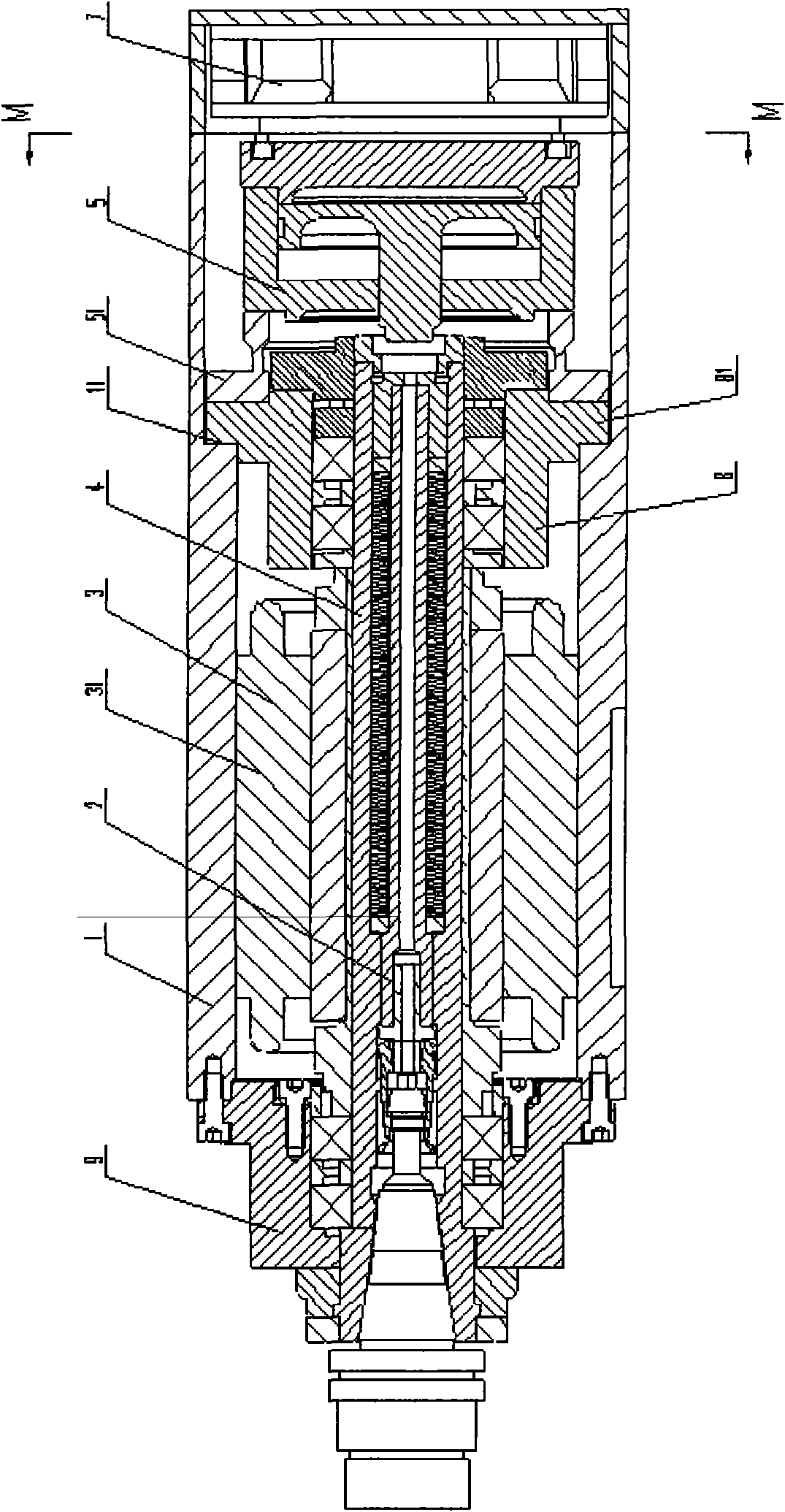

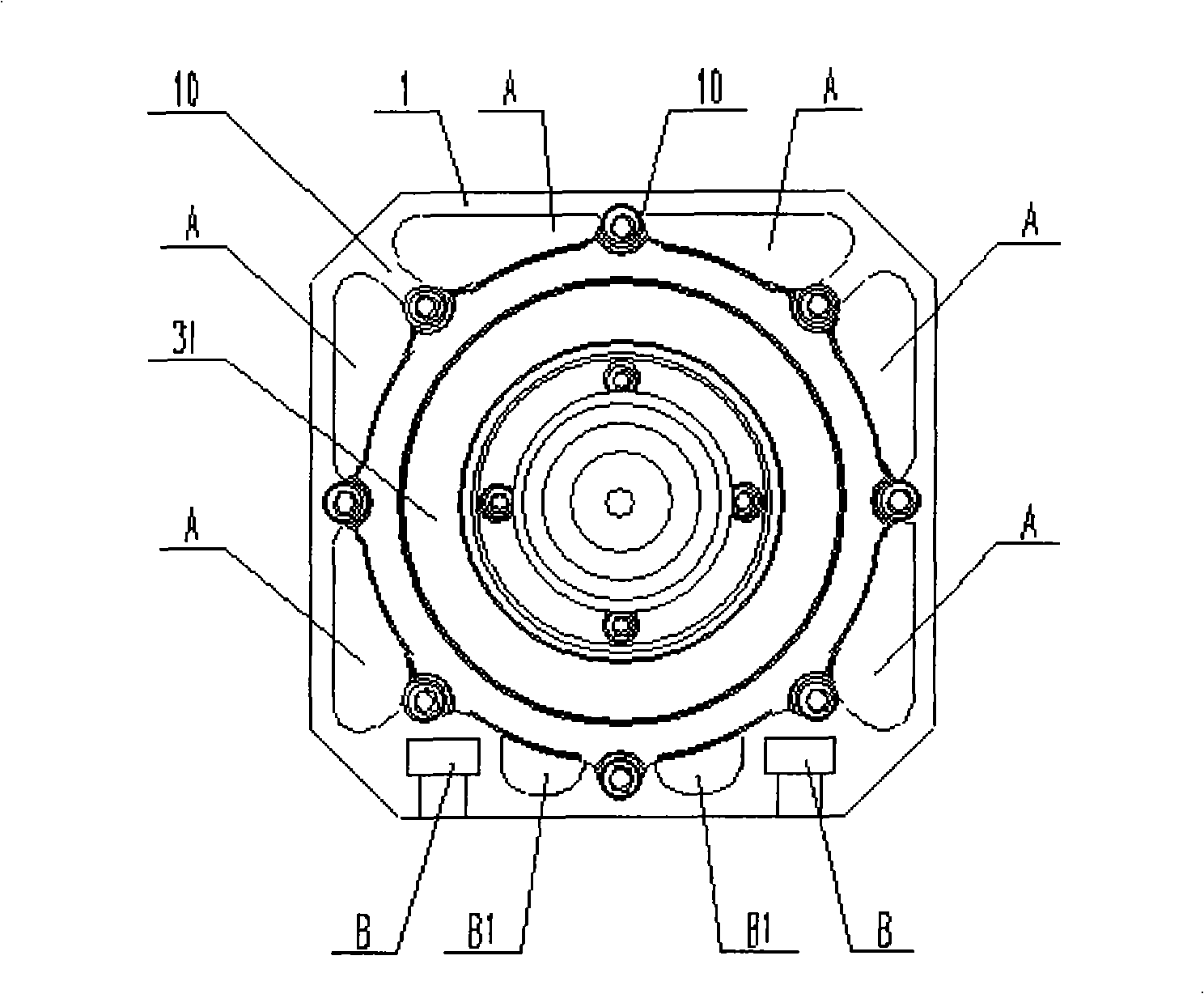

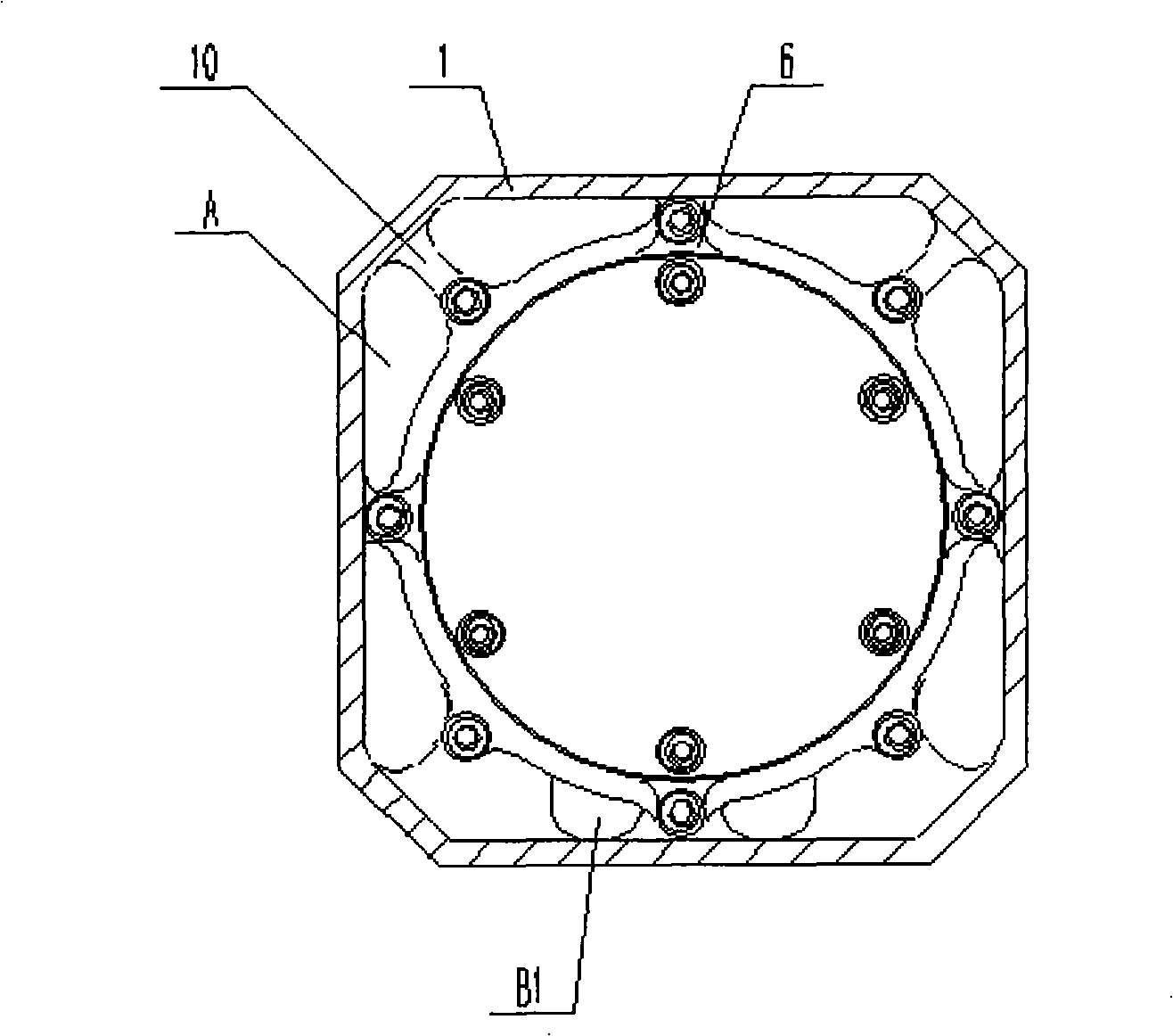

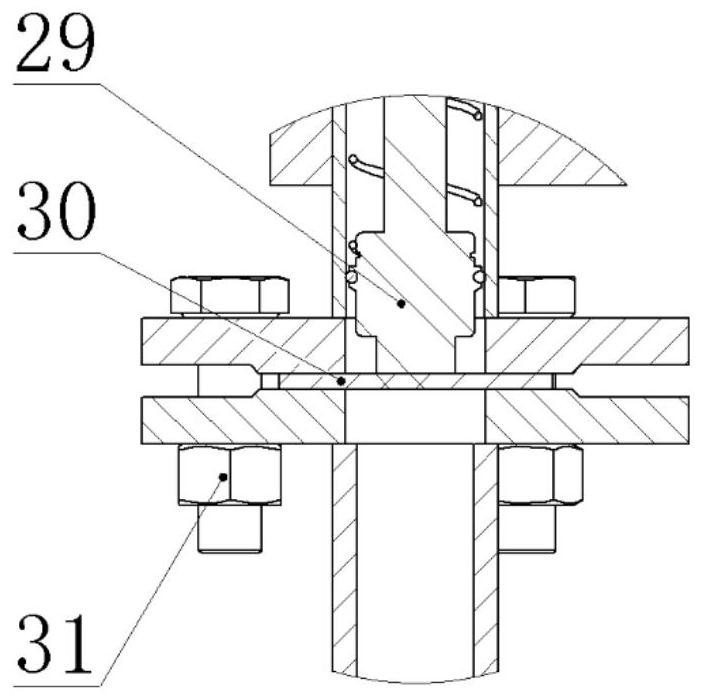

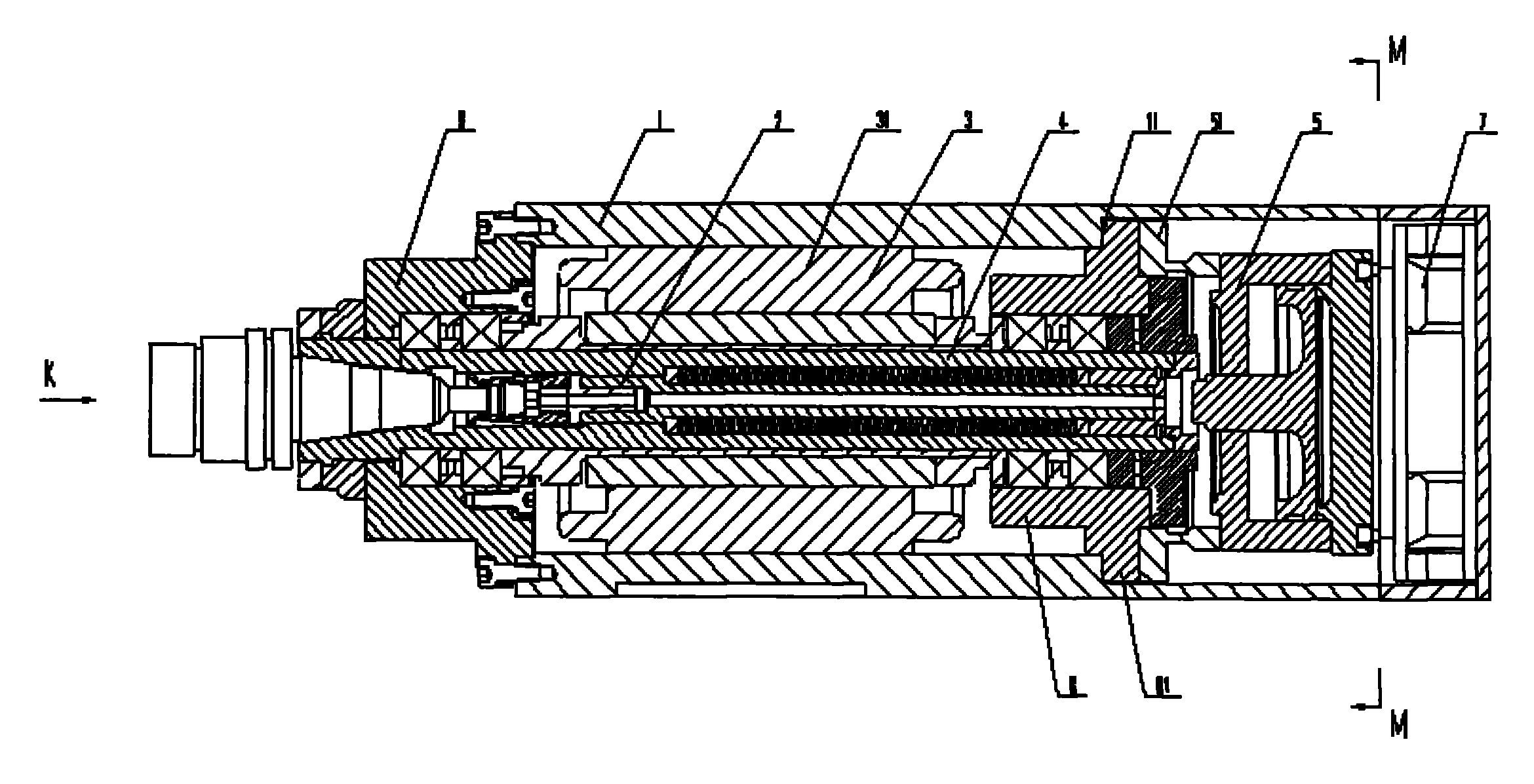

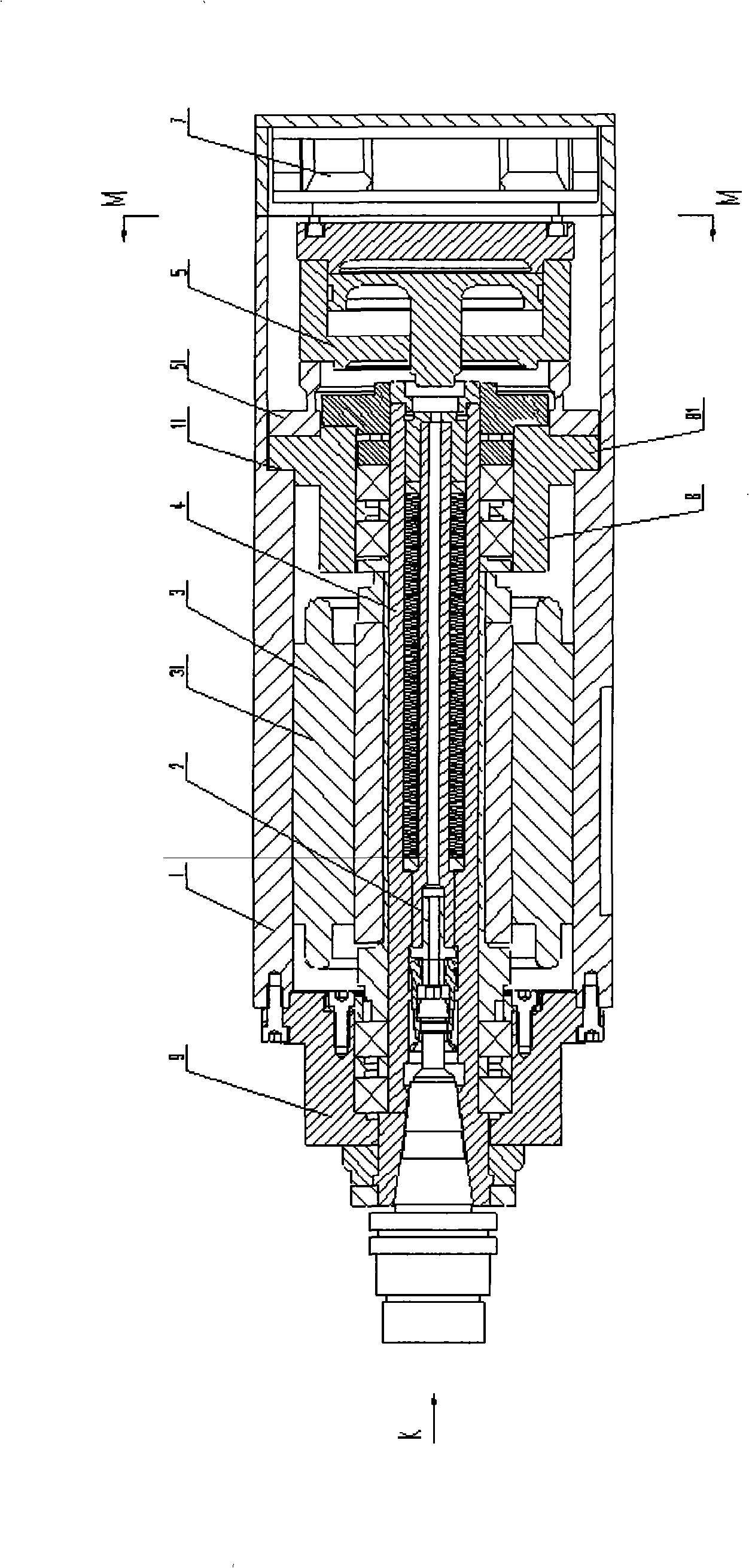

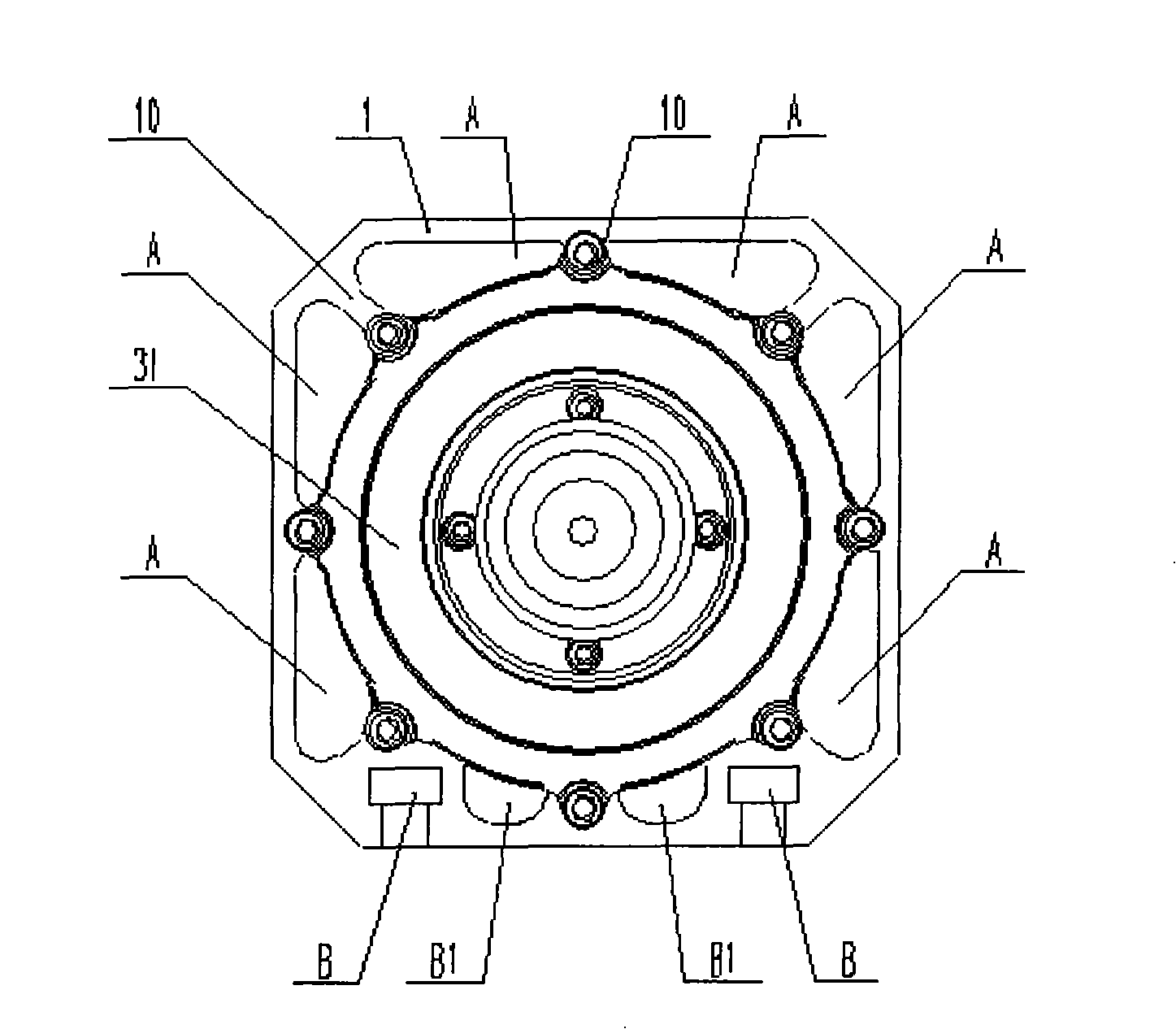

High-speed automatic tool changing electrical spindle cooling structure

InactiveCN101524855AImprove centralityImprove balanceProfiling/shaping machinesNumerical controlElectricity

The invention provides a high-speed automatic tool changing electrical spindle cooling structure, wherein, a spindle is fixed at an integrated casing by a front bearing support and a back bearing support; a cooling fan is installed at the back end of the casing; the inner wall of the casing is provided with a convex shoulder type spigot; the back end of the back bearing support is provided with a flange which props against the spigot and is fixed at the casing; the front bearing support, the back bearing support and a position of the flange at a tool changing cylinder corresponding to reinforcement beams arranged at the casing are provided with screw holes and are fixed with the casing by bolts; and a gap is arranged between the adjacent reinforcement beams to form a penetration type axial air course. The electrical spindle cooling structure is provided with the axial air course between the casing, the bearing supports and the cylinder, thereby improving the air cooling performance of the electrical spindle; a fixed structure is more reasonable; the centre aligning performance of the electrical spindle is higher; and the electrical spindle cooling structure ensures that the electrical spindle used in wood numerical control machining center bears stable cutting force and keeps high dynamic balance during machining. The electrical spindle does not require arranging a lateral air course at the casing and ensures that the structure is compacter and nicer.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

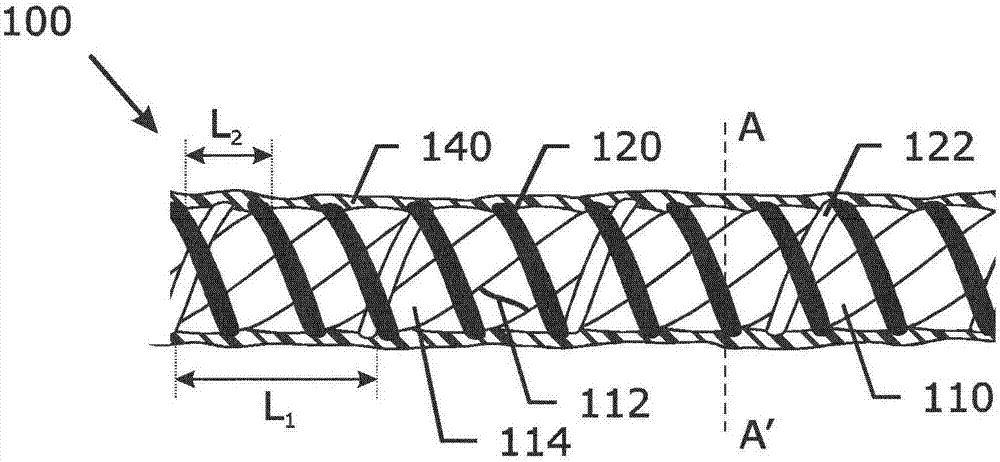

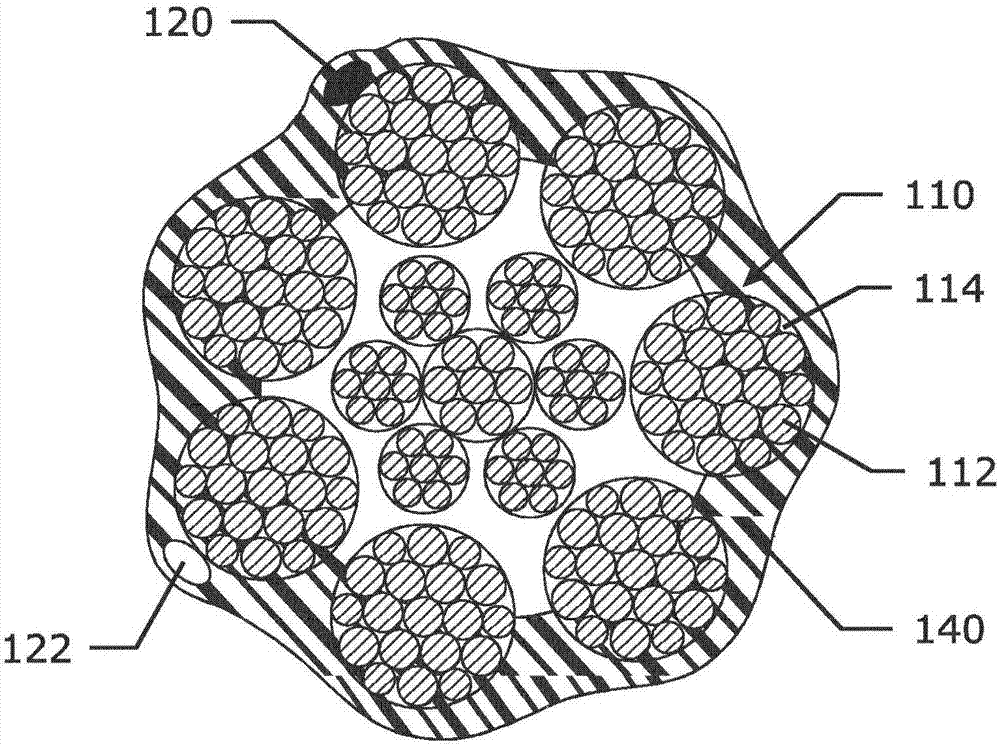

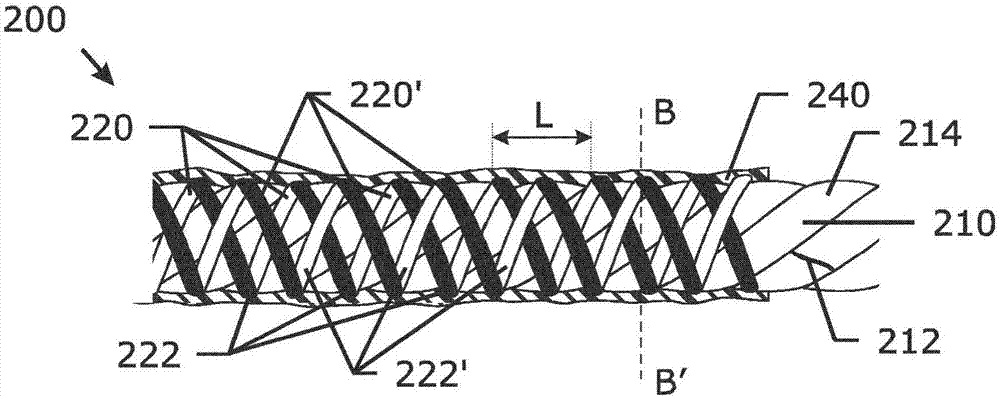

Elevator rope and method of manufacturing said elevator rope

An elevator rope (100) comprises a steel cord (114) and an elastomer jacket (140) surrounding the steel cord. One or more yarns (120, 122) are wrapped or braided or knitted around the steel cord before the elastomer jacket is applied. The yarns are therefore integrated into the polymer jacket. The yarns induce a pattern at the surface of the polymer jacket. By amending the yarn structure, the surface pattern of the polymer jacket can be changed. This has an implication on the friction of the elevator rope on the sheave on which it is running. Furthermore, the integrated yarns help to preserve the integrity of the elastomer jacket. In a second aspect of the invention a method is claimed wherein first one or more yarns are wrapped, braided or knitted around the steel cord prior to extrusion of the elastomer. The yarn mantle ensures a good centricity of the elastomer jacket and an improved processability of the elevator rope.

Owner:BEKAERT ADVANCED CORDS AALTER NV

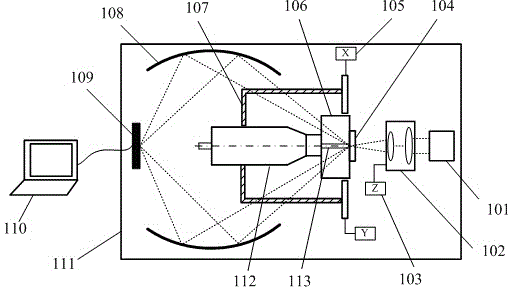

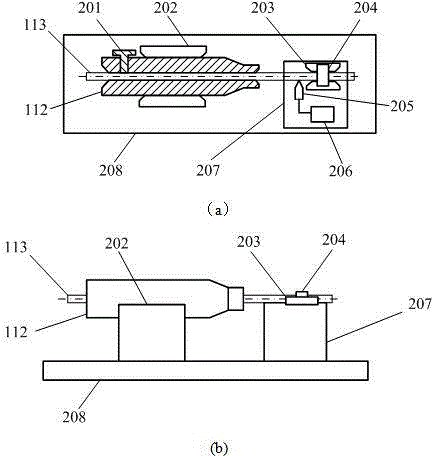

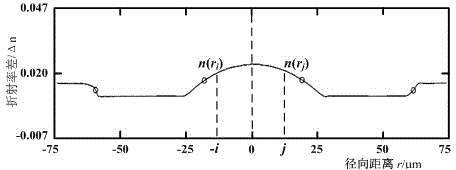

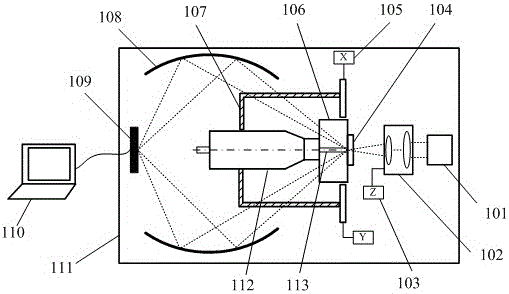

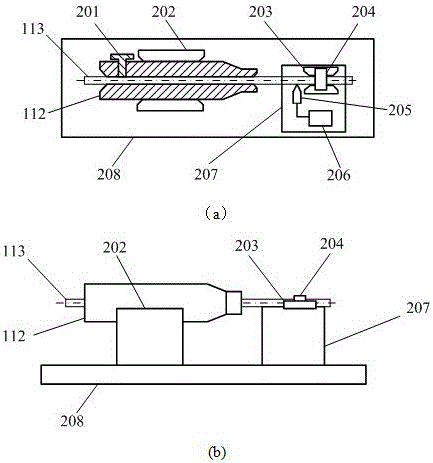

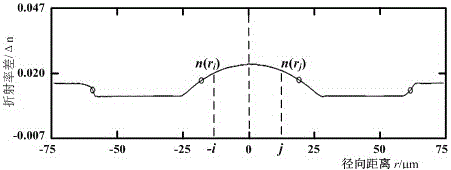

Device and method for measuring focusing constant g of self-focusing optical fiber

ActiveCN104535302AOptimize focus and centralityRealize automatic precision alignment and linear scanningPhase-affecting property measurementsTesting optical propertiesComputational physicsMeasurement device

The invention discloses a device and method for measuring the focusing constant g of a self-focusing optical fiber. The measuring device comprises an optical fiber preprocessing device and an optical fiber refractive index measuring device. Cover glass is arranged in the center of a hole in the bottom of a sample cavity through gel, the sample cavity is cleaned, and the matching solution is injected in the sample cavity till the sample cavity is full of the matching solution. A bare optical fiber is arranged in an optical fiber clamp, and the bare optical fiber is clamped in a clamping frame after being cut and polished. The optical fiber is pushed till the end face of the optical fiber makes contact with the cover glass. An automatic alignment and one-dimensional linear scanning mode is set in a computer, and a refractive index distribution skeleton map is rapidly obtained. According to the refractive index distribution skeleton map detected by the measuring device, the refractive index data in a fiber core are extracted, and the measurement on the focusing constant g and the center refractive index n0 of the self-focusing optical fiber is achieved through the curve fitting algorithm.

Owner:SHANGHAI UNIV

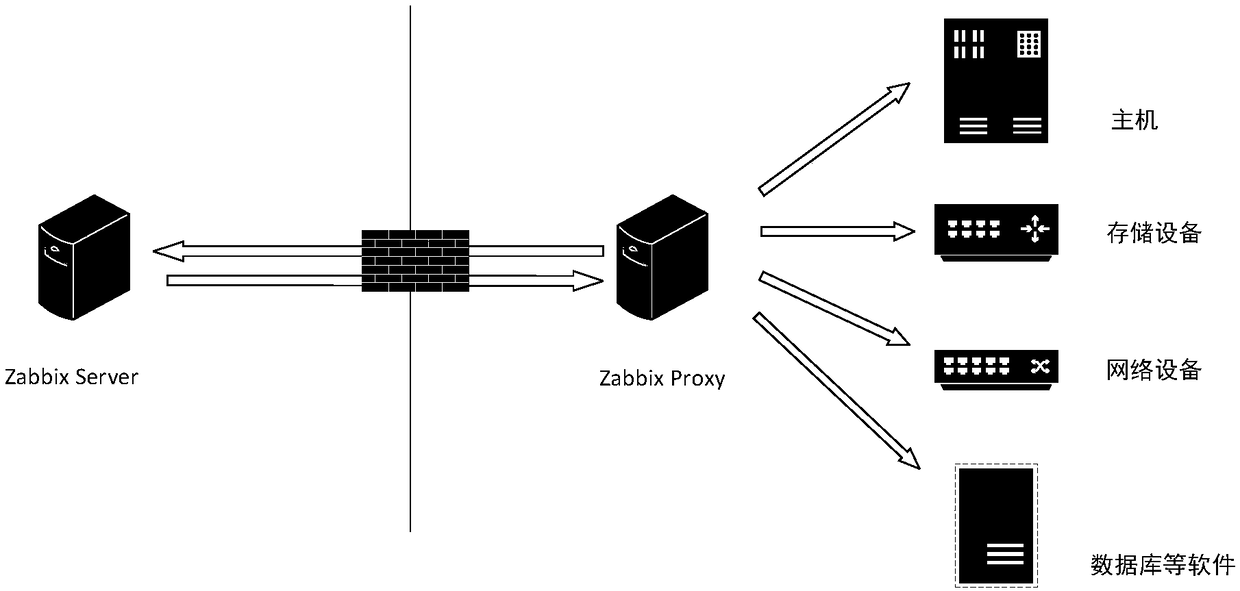

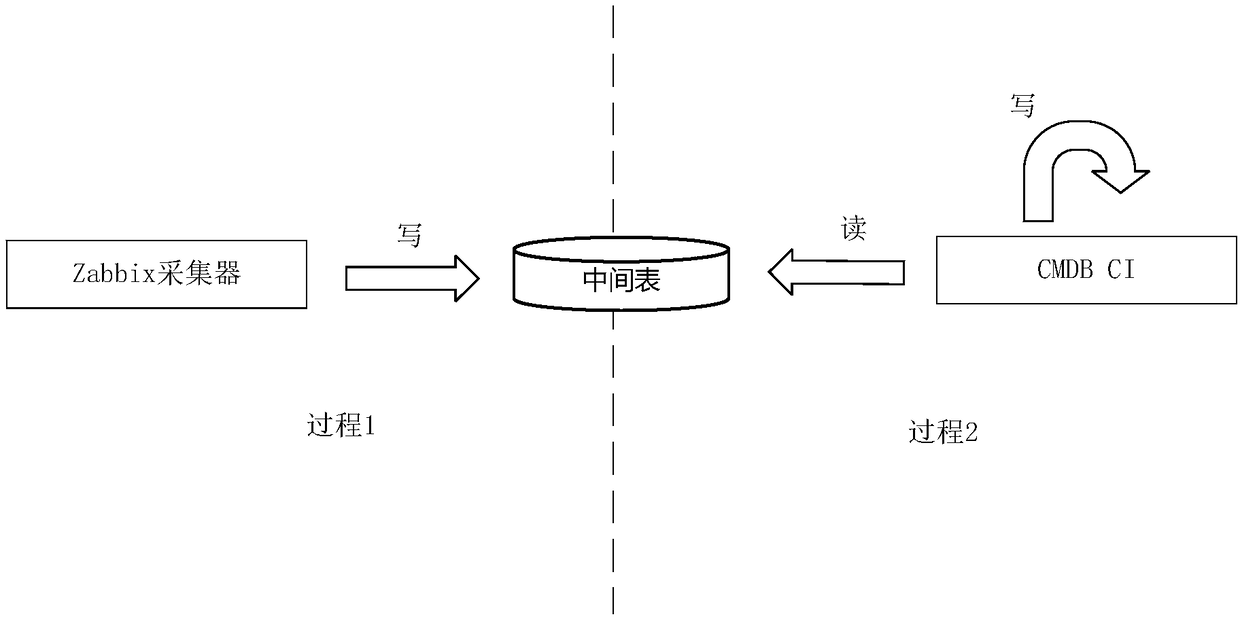

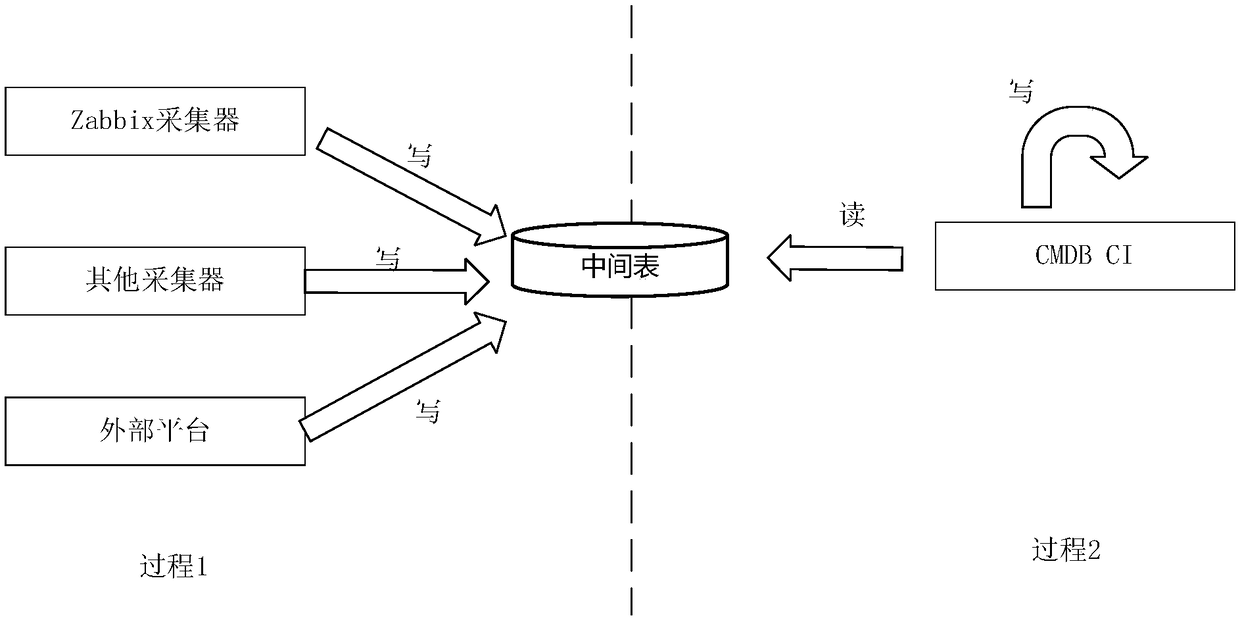

A method for automatically synchronize CMDB based on Zabbix monitor and acquisition

InactiveCN108989385AIncrease diversityImprove centralityTransmissionSpecial data processing applicationsConfiguration itemData mining

The invention discloses a method for realizing automatic synchronization of CMDB based on Zabbix monitoring and acquisition, which comprises the following steps: S1) an intermediate table object is created as a transitioner between Zabbix collector and CMDB configuration item; 2) mapping relation between the intermediate table object and the Zabbix collector and the CMDB configuration item is respectively established; S3) the Zabbix collector writes the collected data to the intermediate table through the mapping relation; S4) The CMDB CI reads the intermediate table and synchronizes to the CIattributes through the mapping relationship, thus completing the automatic synchronization from Zabbix to the CMDB CI. The method for realizing automatic synchronization of CMDB based on Zabbix monitoring and collection provided by the invention can solve the problems of comprehensiveness and manageability of data collection by using an automatic discovery program, is easy to integrate a plurality of discovery programs, realizes flexible expansion of discovery content, and improves data identification and management capability.

Owner:潘叶 +1

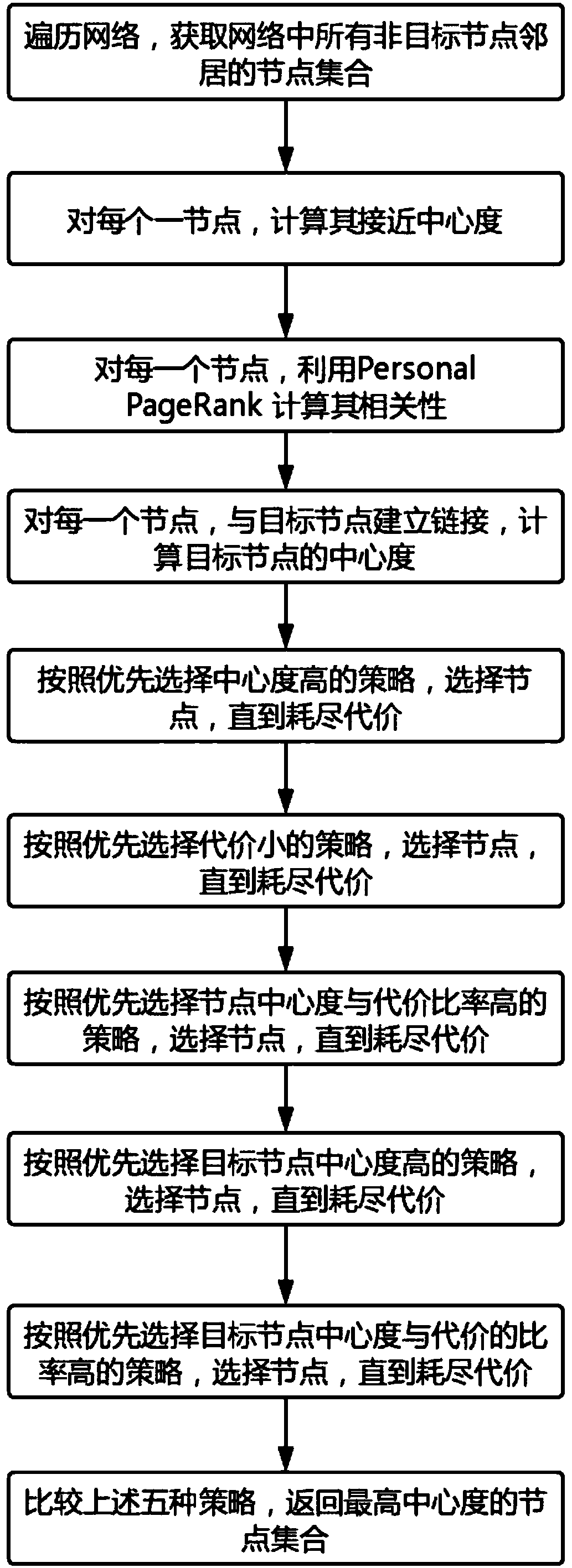

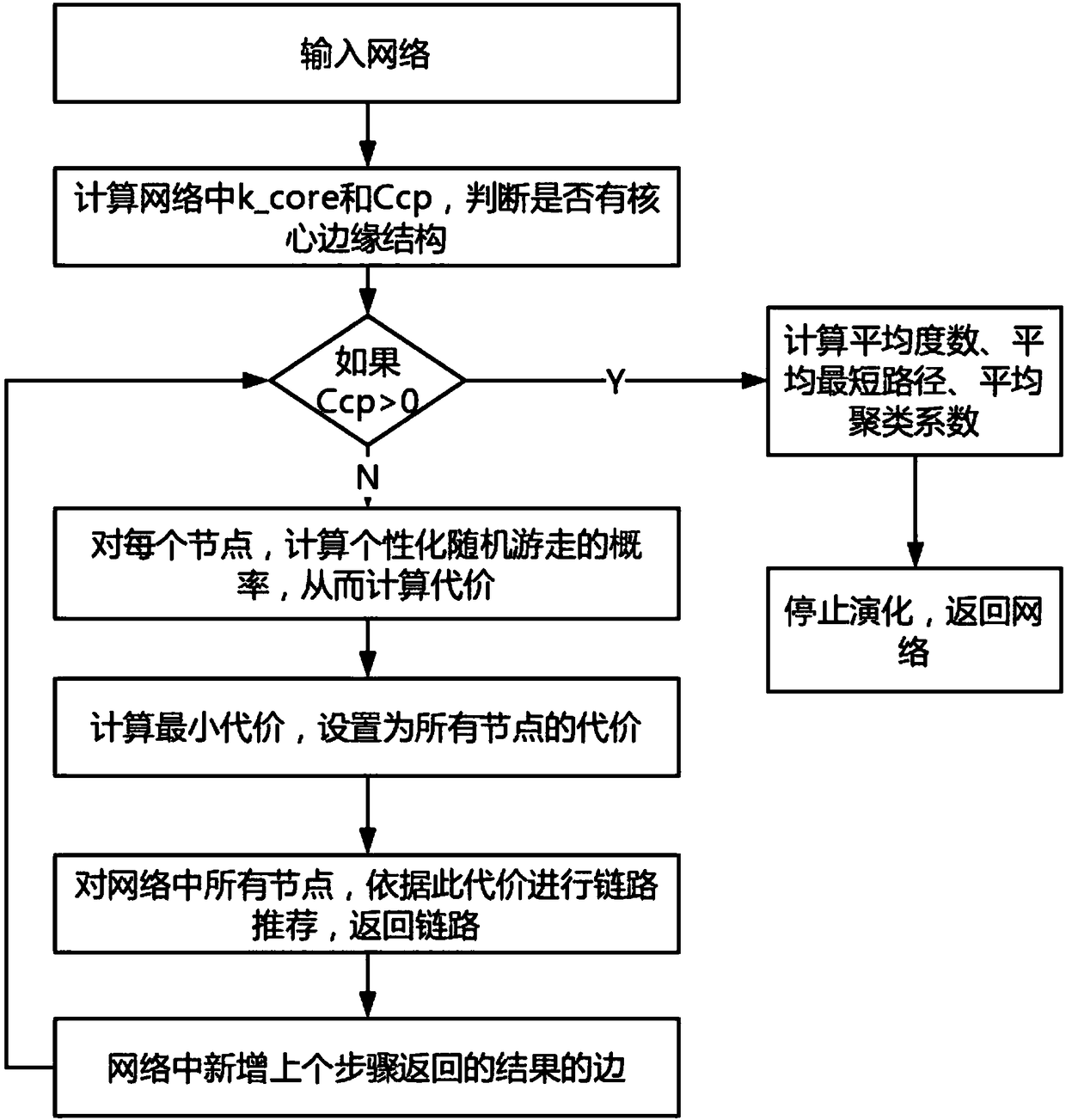

Social network link recommendation method and network evolution model implementation design

ActiveCN108133426ASolve forecasting problemsIncrease influenceData processing applicationsEdge structureNetwork model

The invention relates to a social network link recommendation method and network evolution model implementation design, and belongs to the technical field of network science. The invention comprises alink recommendation algorithm based on cost and income under limited price and a social network dynamic evolution design based on the game theory. The link recommendation algorithm traverses the contribution of all links for a target node by all potential links, the nodes with a highest contribution and cost ratio are selected in sequence to obtain a node set on a premise that total cost does notexceed, and then, the nodes with highest contribution are selected in sequence to realize the maximize the closeness centrality of the target node. The network evolution model implementation design assumes that the competition of nodes in the network is non-cooperation, a network evolution result is explored, and the formation of a network core-edge structure is mined. By use of the method and the design, the strong core-edge structure can be quickly evolved in a non-core-edge network.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Polyethylene with a high vinyl content and with a low MFR

ActiveUS11286315B2Easy to processImprove liquidityPlastic/resin/waxes insulatorsPolymer sciencePower cable

The invention relates to a polyethylene having a melt flow rate at (2.16) kg loading (MFR2), determined according to method ISO1133-1:2011, which MFR2 is A g / 10 min and A1≤A≤A2; wherein A1 is (0.5) and A2 is (1.70), and containing a total amount of vinyl groups which is B vinyl groups per (1000) carbon atoms, and B1≤B, wherein B1 is (0.45), determined according to method ASTM D6248-98, a polymer composition, an article being e.g. a cable, e.g. a power cable, and processes for producing a polyethylene, a polymer composition and an article, and an article; useful in different end applications, such as wire and cable (W&C) applications.

Owner:BOREALIS AG

Solar energy wind power generation tower

InactiveCN101539117BStrong driving forceImprove centralitySolar heat devicesMachines/enginesNew energyEngineering

The invention belongs to the technical field of utilizing the solar energy to make wind power and utilizing the wind power to generate electricity, in particular to a solar energy wind power generation tower which solves the problems that the existing solar generating equipment has high cost and low utilization rat and the utilization rate of the wind energy generating equipment has low utilization rate. The solar energy wind power generation tower comprises a thermal-arrest tower and a convection tower; the thermal-arrest tower is internally provided with a gas ascending passage; the outer side of the sunny slope of the gas ascending passage is provided with a double-layer transparent glass and the bottom of the inner side is provided with an absorbing coat; the highest point of the gas ascending passage is communicated with atmosphere; the convection tower is internally provided with a gas descending passage, the bottom of the gas descending passage is provided with a wind turbine, and the top of the gas descending passage is provided with a cold air inlet; the lowest point of the gas ascending passage is communicated with the lowest point of the gas descending passage; the output end of the wind turbine is connected with the input end of a generator. The invention finds a new channel for developing pollution free new energy with low cost, big, middle and small-sized solar power generation and small and middle-sized wind power generation by depending on crude natural conditions.

Owner:STATE GRID CORP OF CHINA +1

Cable made from crosslinkable composition without antioxidant and with beneficial methane formation

ActiveUS20210163637A1Good anti-sag performanceEasy to processPlastic/resin/waxes insulatorsPower cablesPolymer sciencePower cable

The invention relates to a cable comprising layer(s), which layer(s), is / are obtained from a polymer composition, wherein the polymer composition comprises a polyethylene and a crosslinking agent, wherein the polymer composition contains a total amount of vinyl groups which is B vinyl groups per 1000 carbon atoms, and B1≤B, wherein B1 is 0.88, when measured prior to crosslinking according to method ASTM D6248-98; and wherein the crosslinking agent is present in an amount which is Z wt %, prior to crosslinking, based on the total amount (100 wt %) of the polymer composition, and Z≤Z2, wherein Z2 is 0.60, the cable, e.g. being a power cable, and processes for producing the cable; the cable useful in different end applications, such as wire and cable (W&C) applications.

Owner:BOREALIS AG

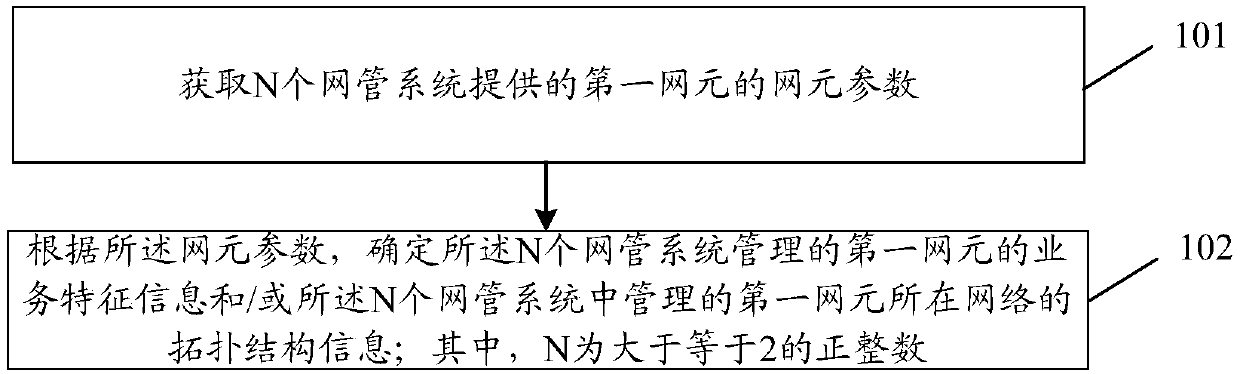

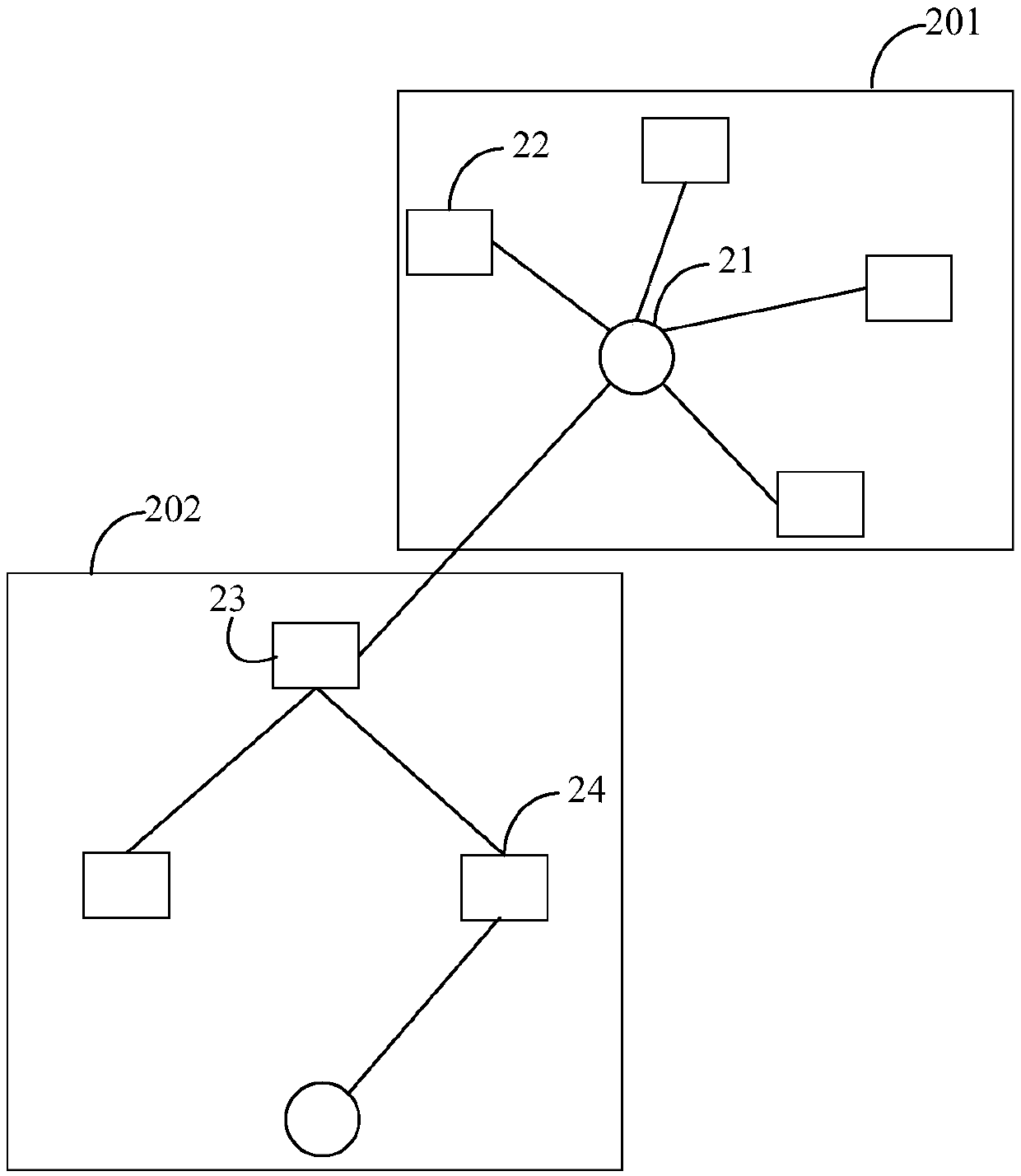

Network element information processing method and device, network platform and storage medium

InactiveCN111200514AImprove unityImprove centralityData switching networksSystems managementEngineering

The embodiment of the invention discloses a network element information processing method. The method comprises the following steps: acquiring network element parameters of a first network element provided by N network management systems; determining service feature information of the first network element managed by the N network management systems and / or topological structure information of a network where the first network element managed by the N network management systems is located according to the network element parameters, wherein N is a positive integer greater than or equal to 2. The embodiment of the invention also discloses a network element information processing device, a network platform and a computer storage medium.

Owner:CHINA MOBILE COMM GRP CO LTD

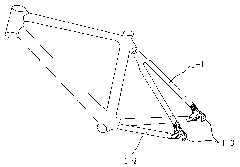

Forming process of rear triangular pipe fitting and claw hook of composite material frame

The invention discloses a forming process of a rear triangular pipe fitting and a claw hook of a composite material frame. The forming process comprises the following steps of: firstly, performing various parts of a rear triangular pipe fitting and a claw hook of a frame with a carbon fiber composite material; splicing; filling yarn; and arranging in a die to finish a frame by integral forming. The new forming process of a rear triangular structure of a carbon fiber bicycle frame is adopted to ensure the integrity of the rear triangle of a composite material bicycle so as to enhance the strength of the rear triangle of the composite material bicycle, the tire position, the accuracy of the claw hook, the accuracy from the center of the rear claw hook to a five-way joint or a brake hole of a rear upper fork while enhancing the stability of the rear triangle, saving the cost of raw materials to the maximum extend and improving the utilization rate of raw materials. The invention has the advantages and the efficacy of enhancing the strength of the bicycle rear triangle, improving the size accuracy from the claw hook to the five-way joint or the brake hole of the rear upper fork and the centrality of the claw hook, decreasing the cost of raw materials, improving the utilization rate of the raw materials, having simple structure by the integral forming technology, reducing the steps needed by a manufacture process, shortening the time consumption, and the like.

Owner:厦门新富复材科技有限公司

Crosslinkable composition without antioxidant and beneficial methane formation with reduced crosslinking

PendingUS20210163636A1Improve the immunityEasy to processPlastic/resin/waxes insulatorsPower cablesPolymer sciencePower cable

The invention relates to a polymer composition comprising a polyethylene and a crosslinking agent, characterized in that the polymer composition contains a total amount of vinyl groups which is B vinyl groups per 1000 carbon atoms, and B1≤B, wherein B1 is 0.88, when measured prior to crosslinking according to method ASTM D6248-98; and in that the crosslinking agent is present in an amount which is Z wt %, based on the total amount (100 wt %) of the polymer composition, and Z≤Z2, wherein Z2 is 0.30, an article being e.g. a cable, e.g. a power cable, and processes for producing a polymer composition and an article; useful in different end applications, such as wire and cable (W&C) applications.

Owner:BOREALIS AG

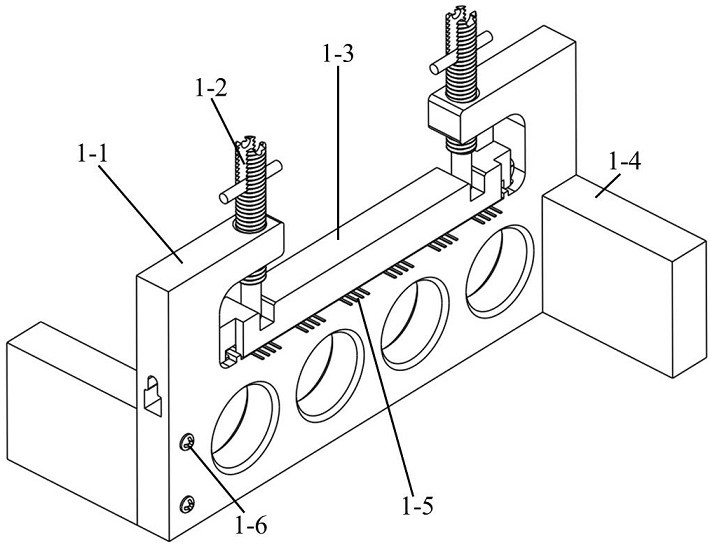

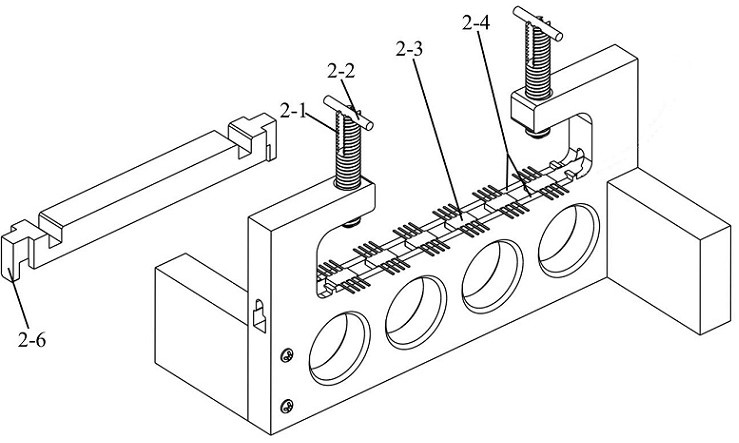

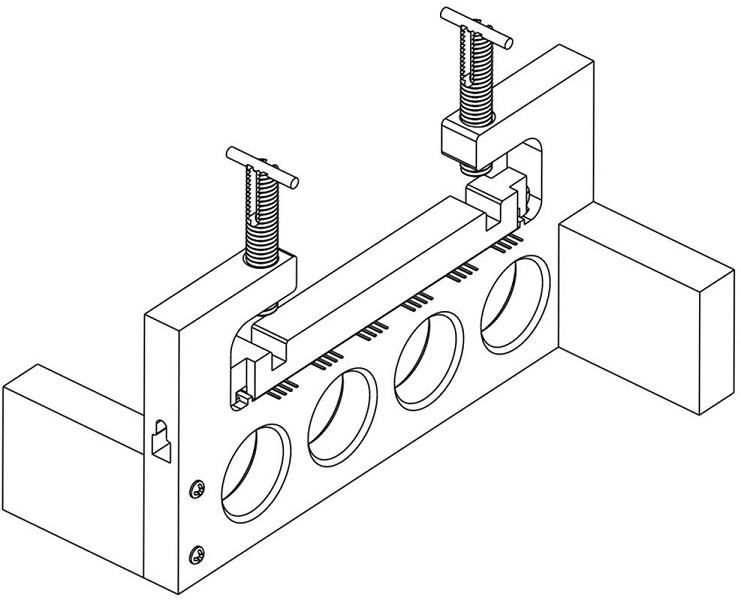

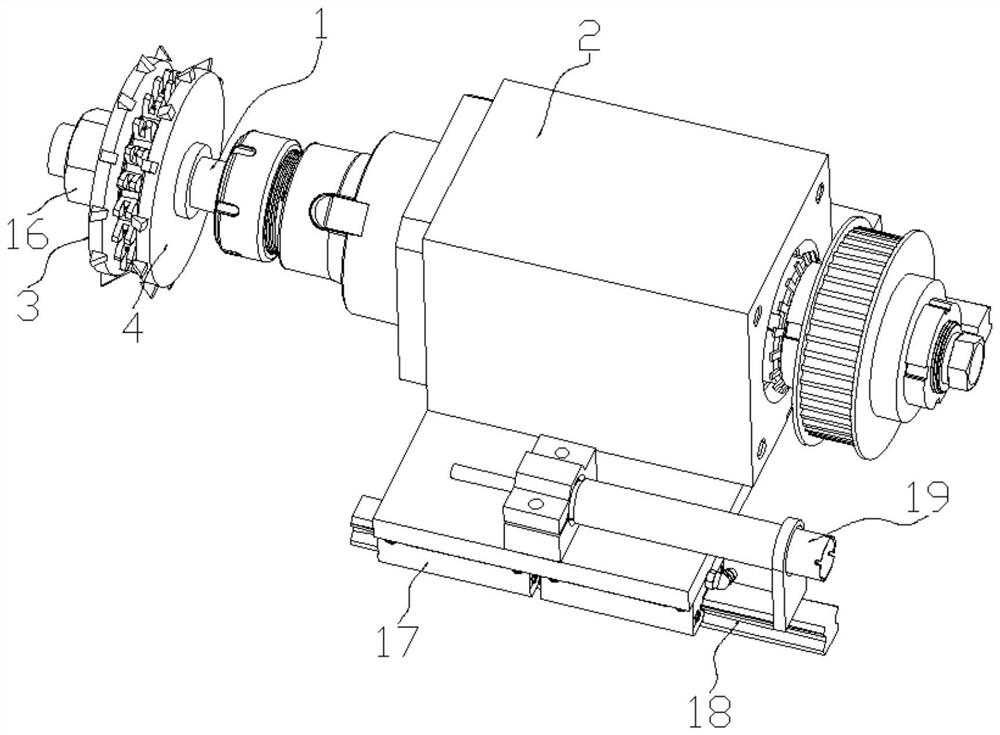

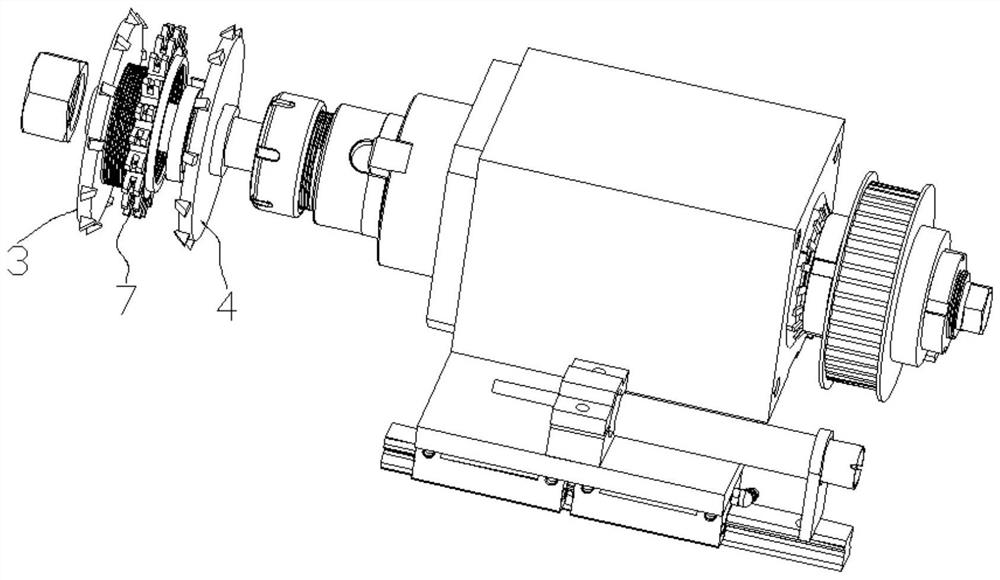

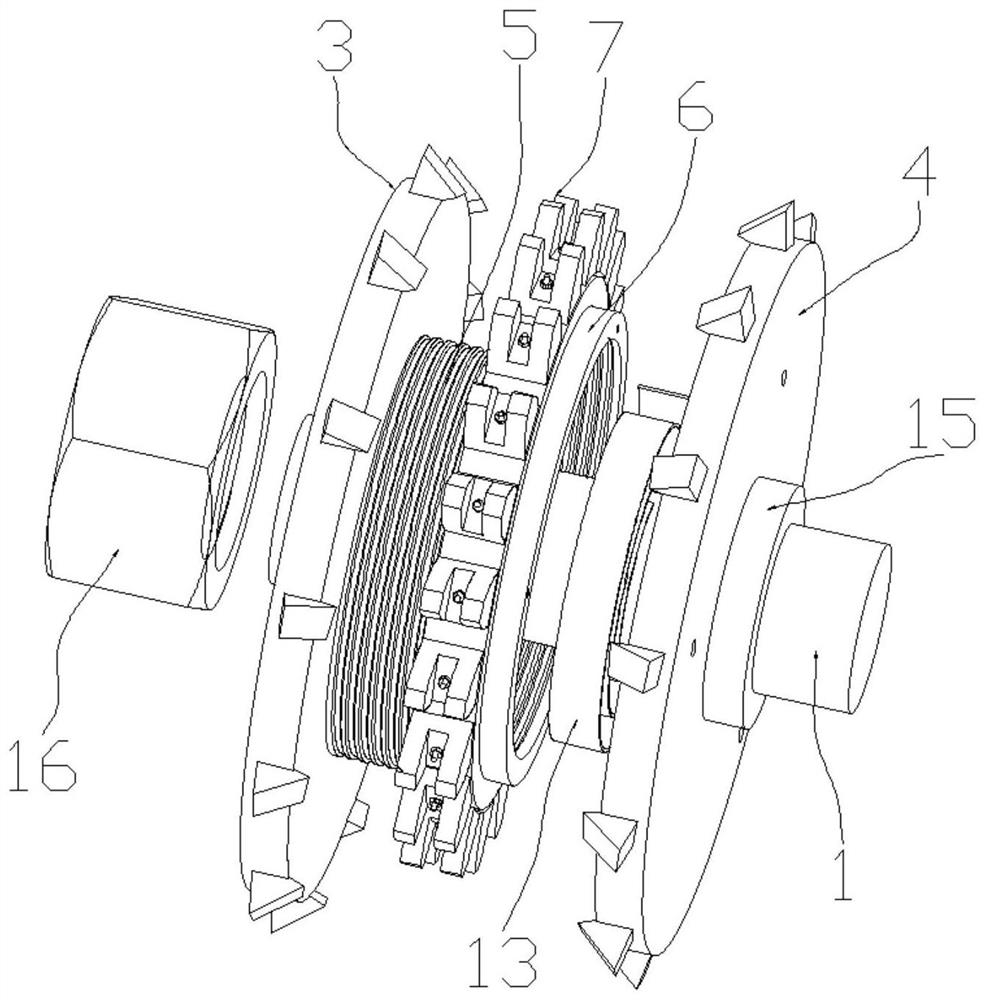

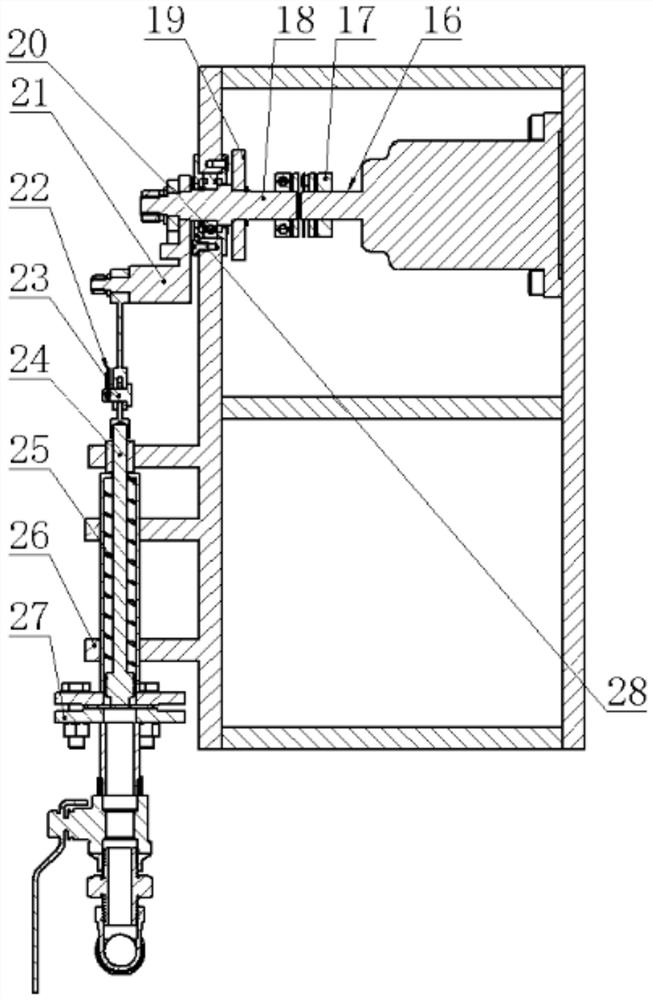

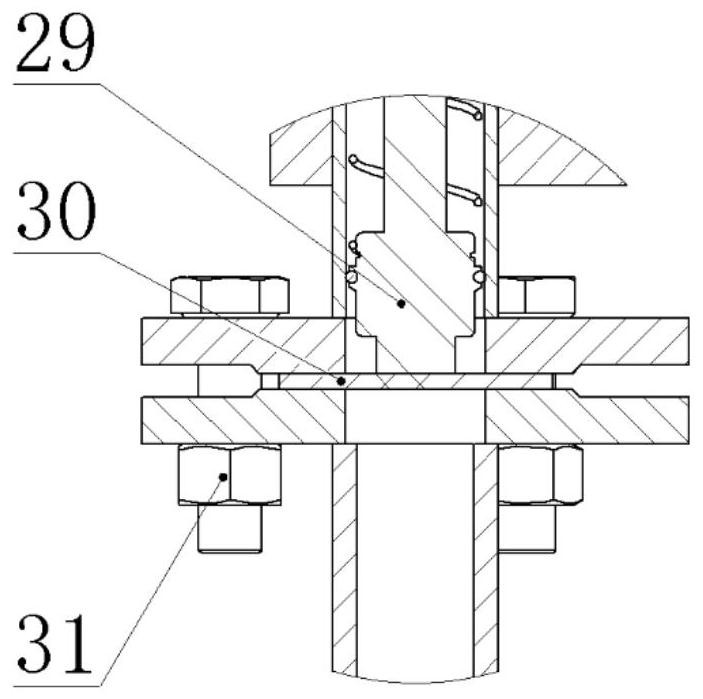

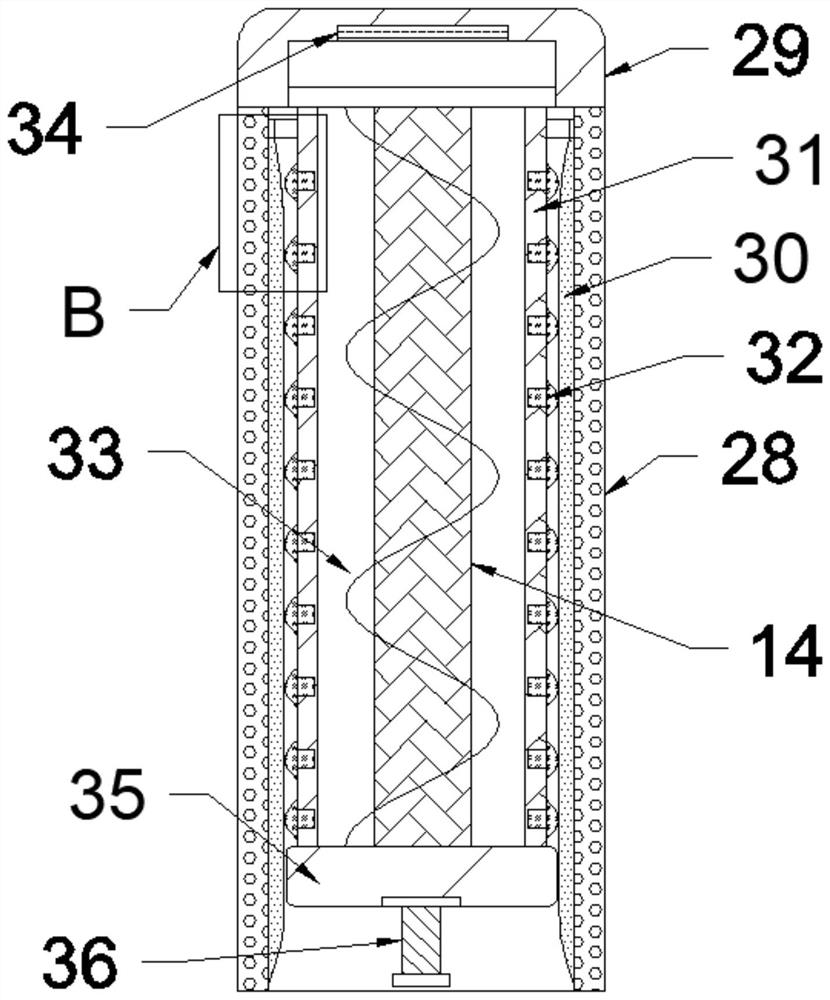

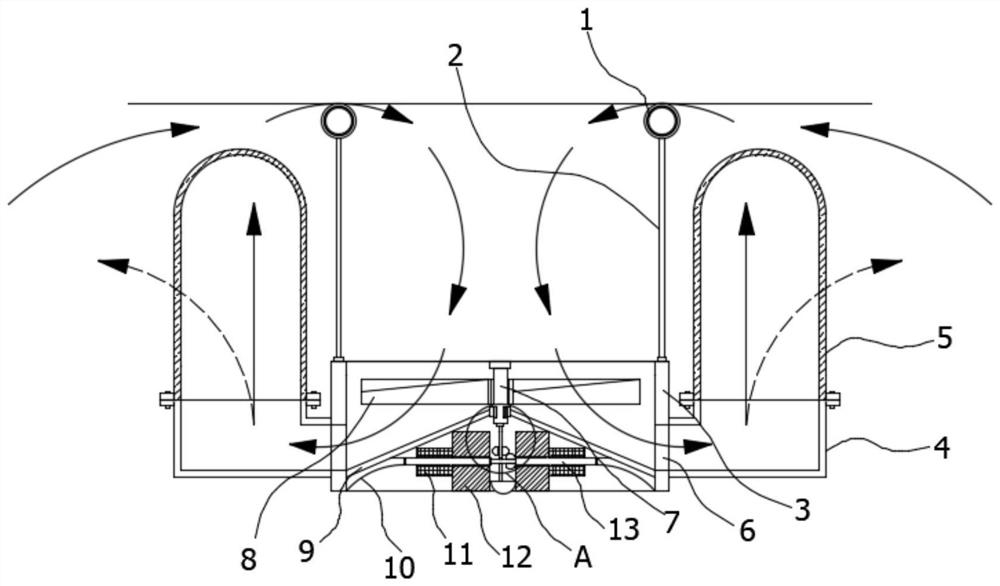

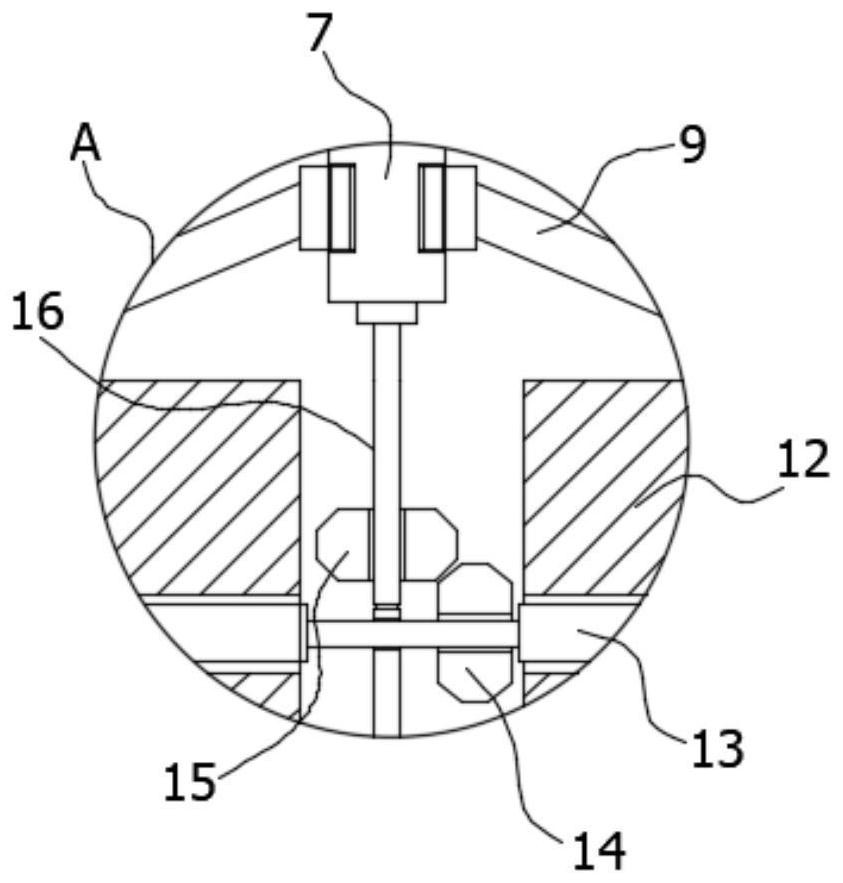

A mechanically driven continuous impact pressure wave generator and a pipeline abnormal state detection device based on it

ActiveCN112856238BReasonable structural designImprove centralityFlywheelsPipeline systemsElectric machineSpring force

Owner:XI AN JIAOTONG UNIV

High-speed automatic tool changing electrical spindle cooling structure

InactiveCN101524855BImprove centralityReasonable cooling structureProfiling/shaping machinesNumerical controlElectricity

The invention provides a high-speed automatic tool changing electrical spindle cooling structure, wherein, a spindle is fixed at an integrated casing by a front bearing support and a back bearing support; a cooling fan is installed at the back end of the casing; the inner wall of the casing is provided with a convex shoulder type spigot; the back end of the back bearing support is provided with aflange which props against the spigot and is fixed at the casing; the front bearing support, the back bearing support and a position of the flange at a tool changing cylinder corresponding to reinforcement beams arranged at the casing are provided with screw holes and are fixed with the casing by bolts; and a gap is arranged between the adjacent reinforcement beams to form a penetration type axial air course. The electrical spindle cooling structure is provided with the axial air course between the casing, the bearing supports and the cylinder, thereby improving the air cooling performance ofthe electrical spindle; a fixed structure is more reasonable; the centre aligning performance of the electrical spindle is higher; and the electrical spindle cooling structure ensures that the electrical spindle used in wood numerical control machining center bears stable cutting force and keeps high dynamic balance during machining. The electrical spindle does not require arranging a lateral aircourse at the casing and ensures that the structure is compacter and nicer.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

A telescopic shaft positioning and pressing device pin bilateral cutting device

ActiveCN110640055BSolve the need for bilateral croppingQuick loading and unloadingStructural engineeringCutting tool

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

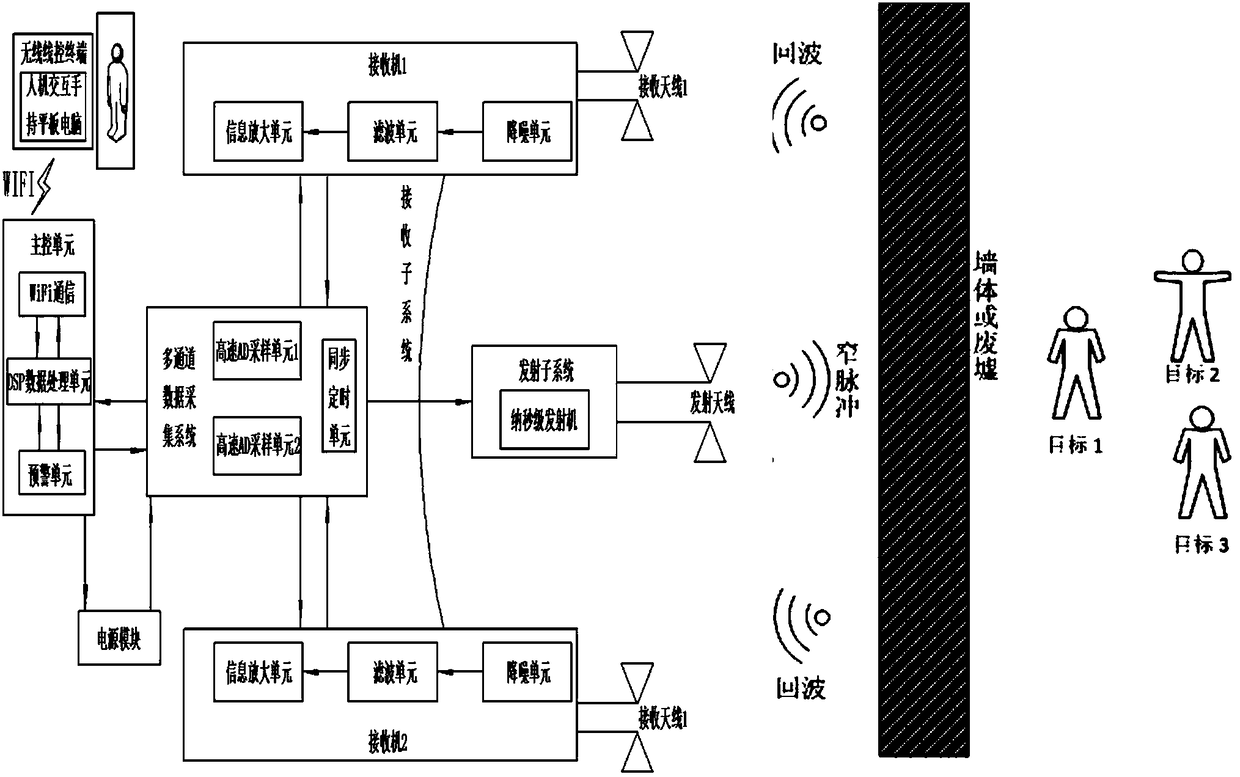

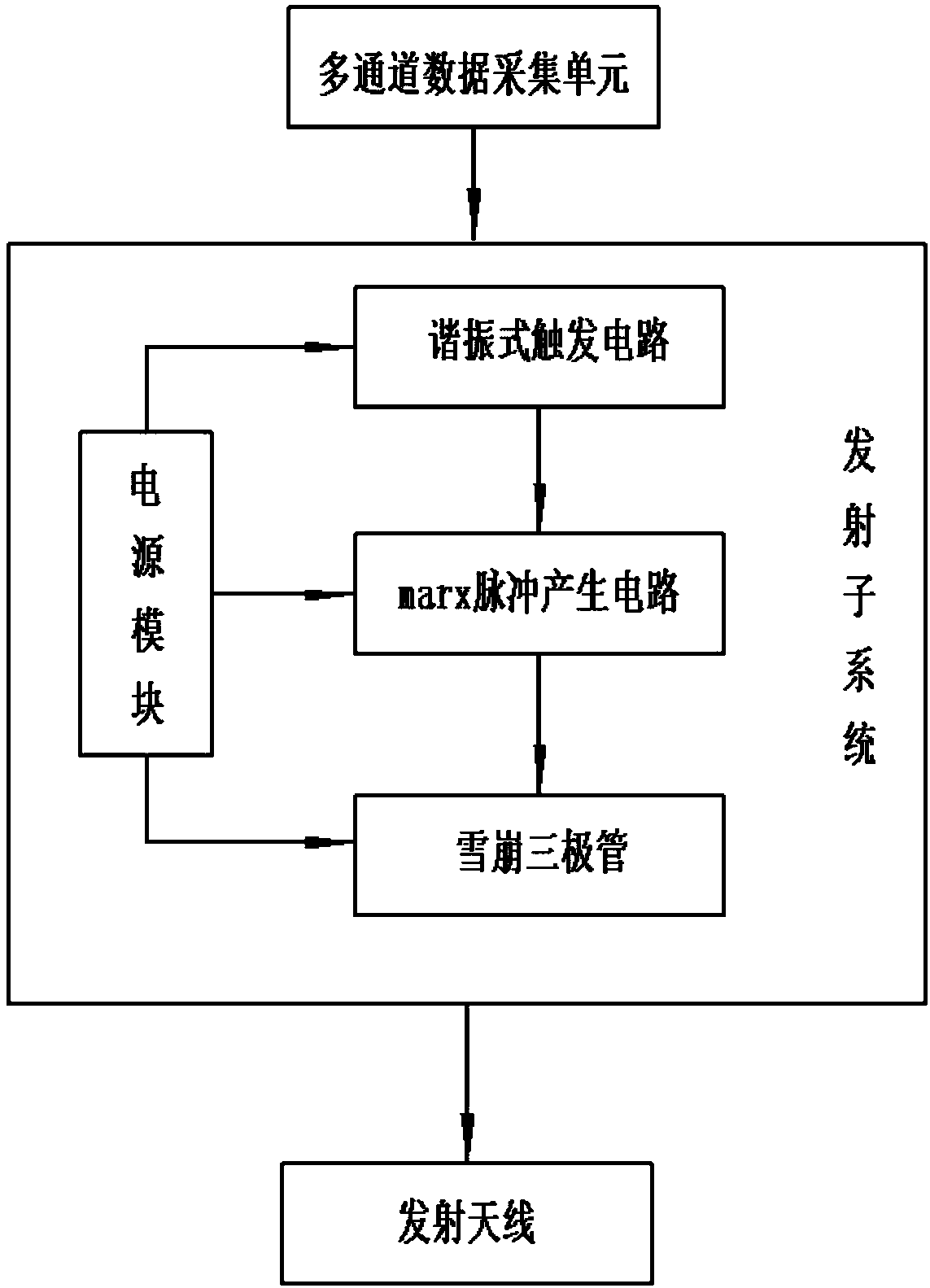

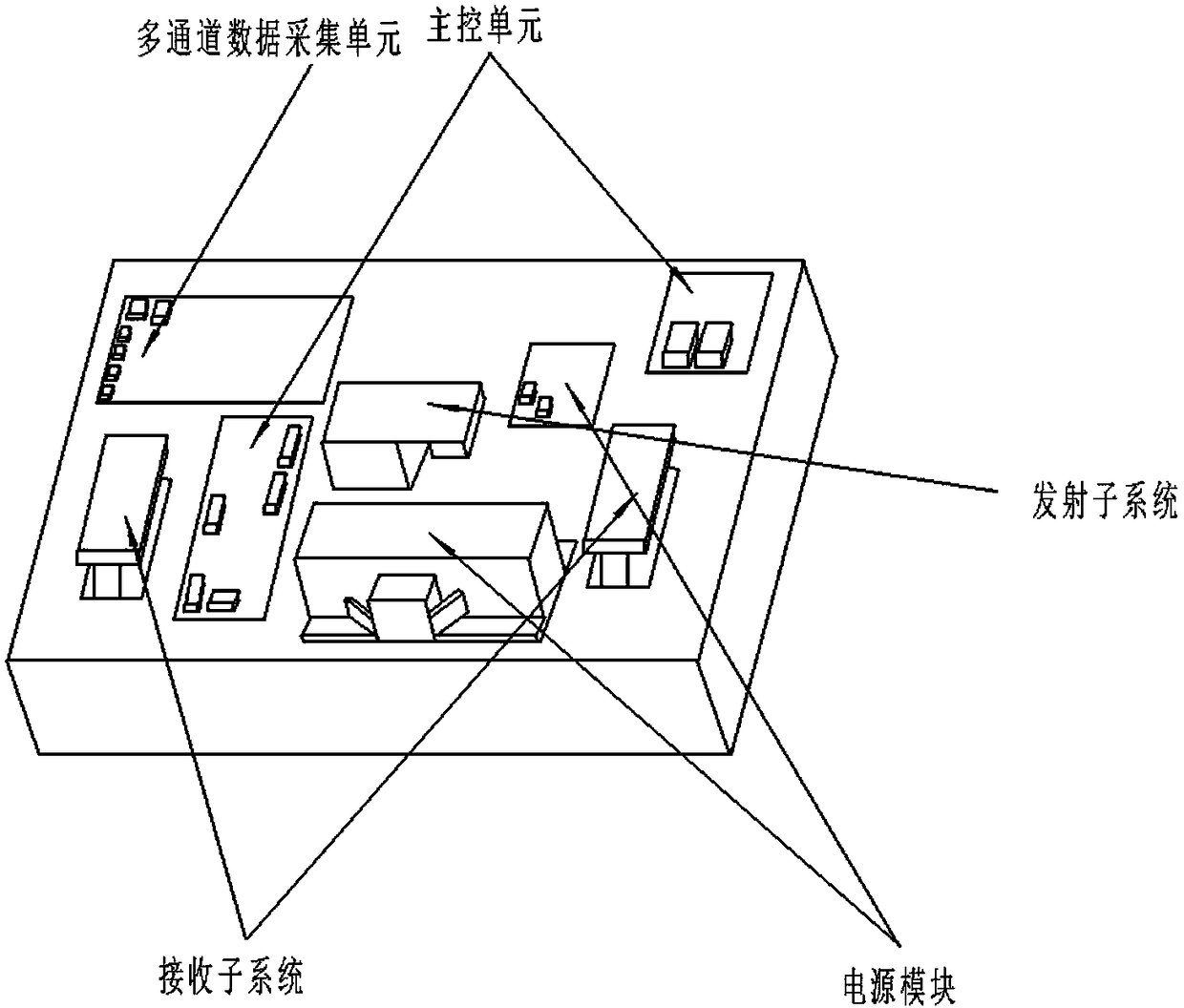

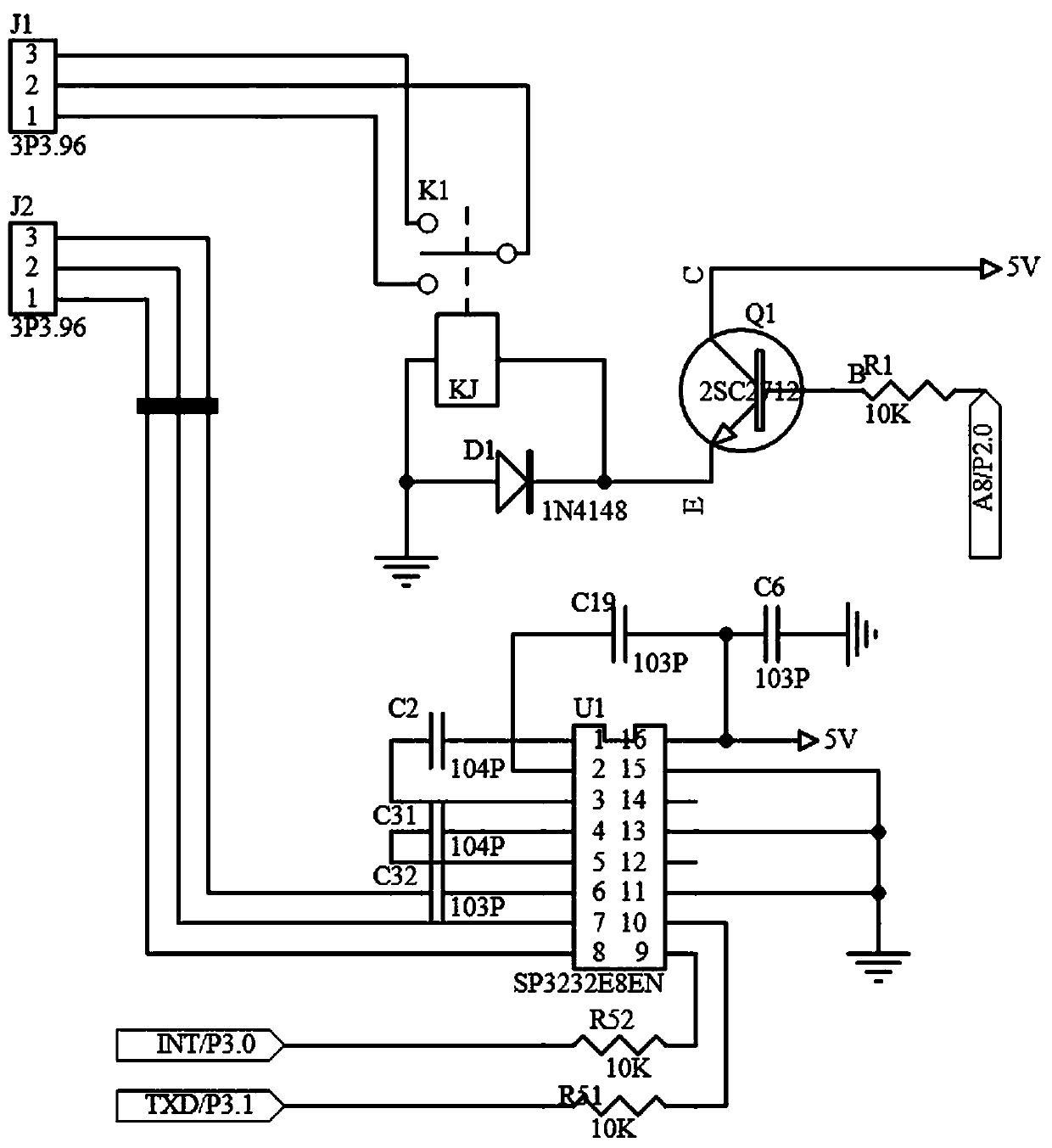

3D radar life detecting and positioning device with high resolution and high penetrability

ActiveCN108490435AStable synchronous superpositionImprove stabilityTransmission systemsRadio wave reradiation/reflectionCollection systemData acquisition

The invention discloses a 3D radar life detecting and positioning device with high resolution and high penetrability. The device comprises an emission subsystem, a reception subsystem, a multichanneldata collection system, a master control unit, a wireless display control terminal and a power supply module; the nanosecond level high-amplitude pulse emission subsystem is composed of a marx pulse generation circuit, three avalanche triodes and a resonant trigger circuit; echoes are received by the reception subsystem, processed by a noise reduction unit, a filtering unit and a signal amplification unit, and sent to the multichannel data collection system for sampling, a sampling result is input and output to the master control unit in which a Linux system is operated by a DSP data processing module and a WiFi communication in parallel, and bidirectional data communication of the wireless display control terminal is realized by 2.4GWiFi. Thus, the device can realize 3D life detection andpositioning, pulses are prevented from distortion, 3D simulated images are clearer, and received weak signals are stronger.

Owner:湖南正申科技有限公司

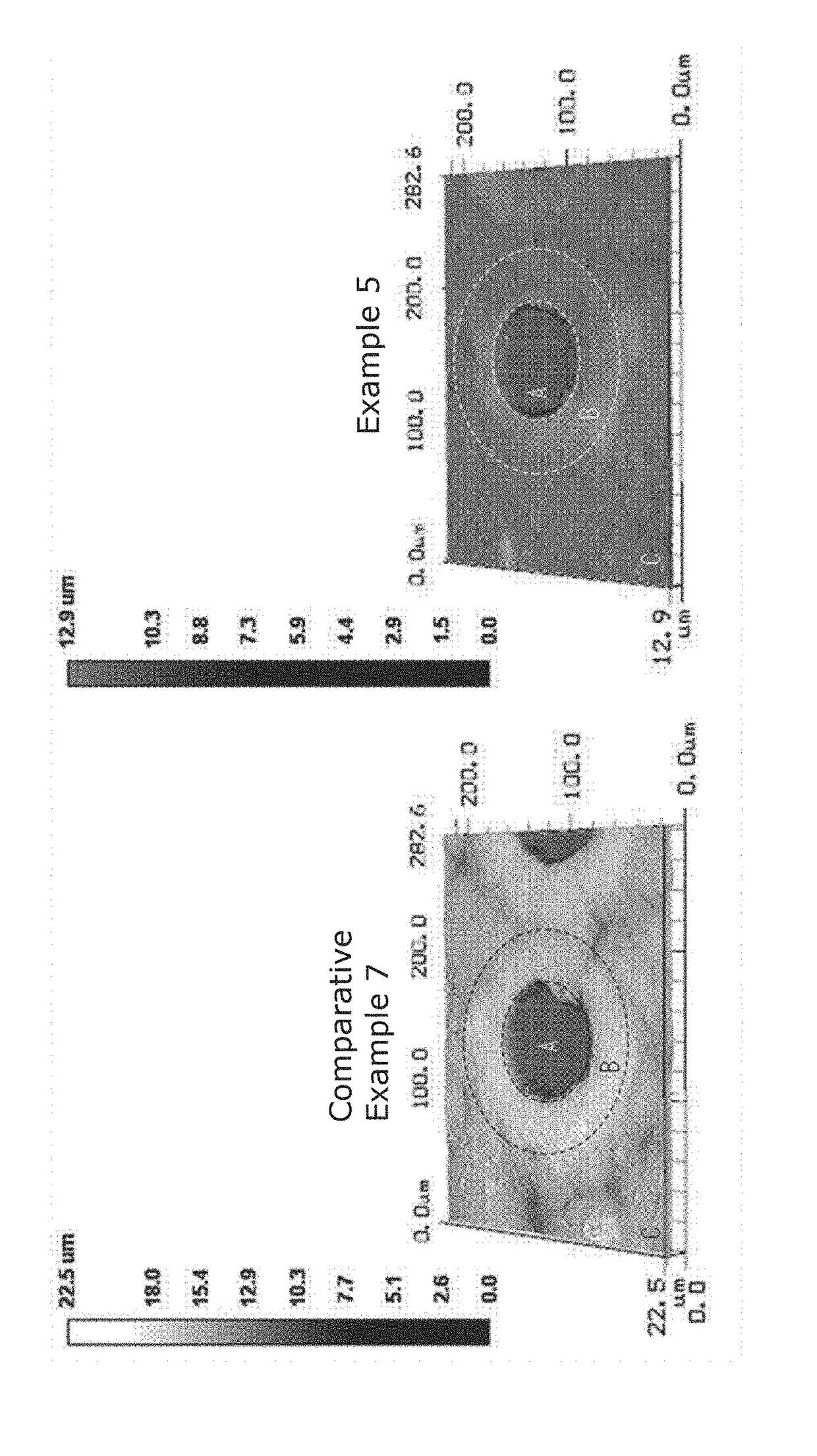

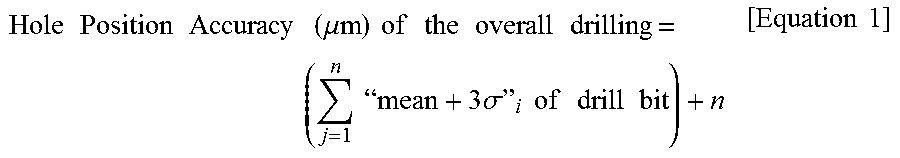

Entry sheet for drilling and drilling method

ActiveUS9826643B2Improve accuracyIncrease resistancePrinted circuit manufactureMetal working apparatusWater solublePolyresin

Owner:MITSUBISHI GAS CHEM CO INC

Production method of carbon fiber heating cable

ActiveCN107567120AIncrease outer diameter roughnessImprove centralityHeating element shapesFiberFrost

The invention discloses a production method of a carbon fiber heating cable. The production method of the carbon fiber heating cable comprises the following steps: S1, gel refining: adding rubber, vulcanizing agent, defrosting agent and color master batch in the double-roller blending rolls, refining to obtain coating silica gel with uniform color; S2, primary coating of carbon fiber precursor: performing primary coating on the carbon fiber precursor at 350 degrees centigrade by means of a silica gel extruder a; S3, secondary coating of the carbon fiber precursor: performing secondary coatingon the carbon fiber precursor performed the primary coating at the temperature of 300 degrees centigrade by means of a silica gel extruder b, and obtaining the carbon fiber heating cable finally. According to the invention, the secondary coating technology is used by the production method of the carbon fiber heating cable, therefore, the outer diameter of the carbon fiber heating cable is increased, the centrality and toughness of the cable is enhanced, and the service life of the cable is lengthened; moreover, the proportioning method of the coating silica gel is reasonable, and the ratio ofthe defrosting agent is increased, therefore, the frost resistance of the finished product of carbon fiber heating cable is improved, and the using effect is improved.

Owner:甘肃华强新能源科技发展有限公司

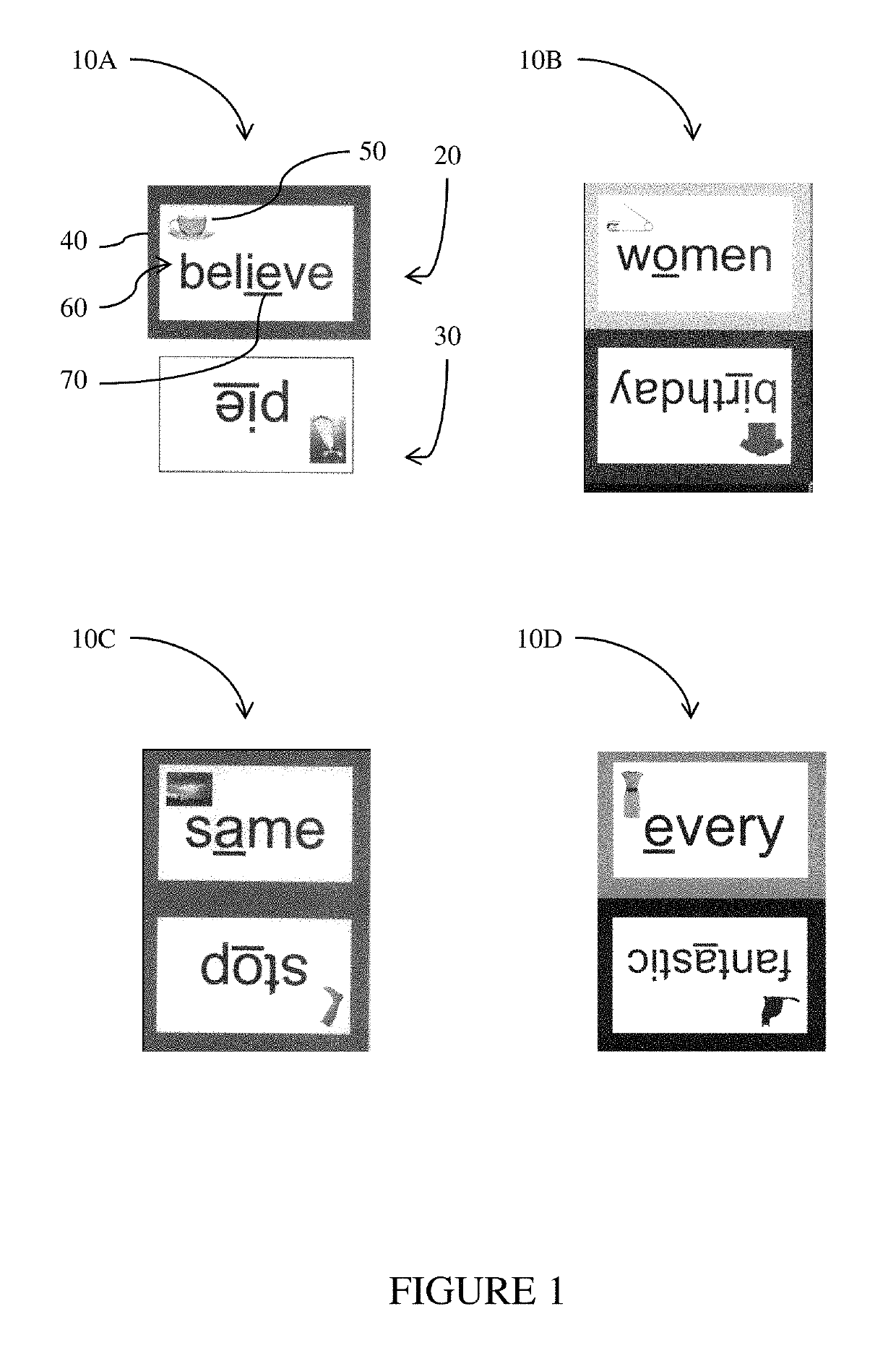

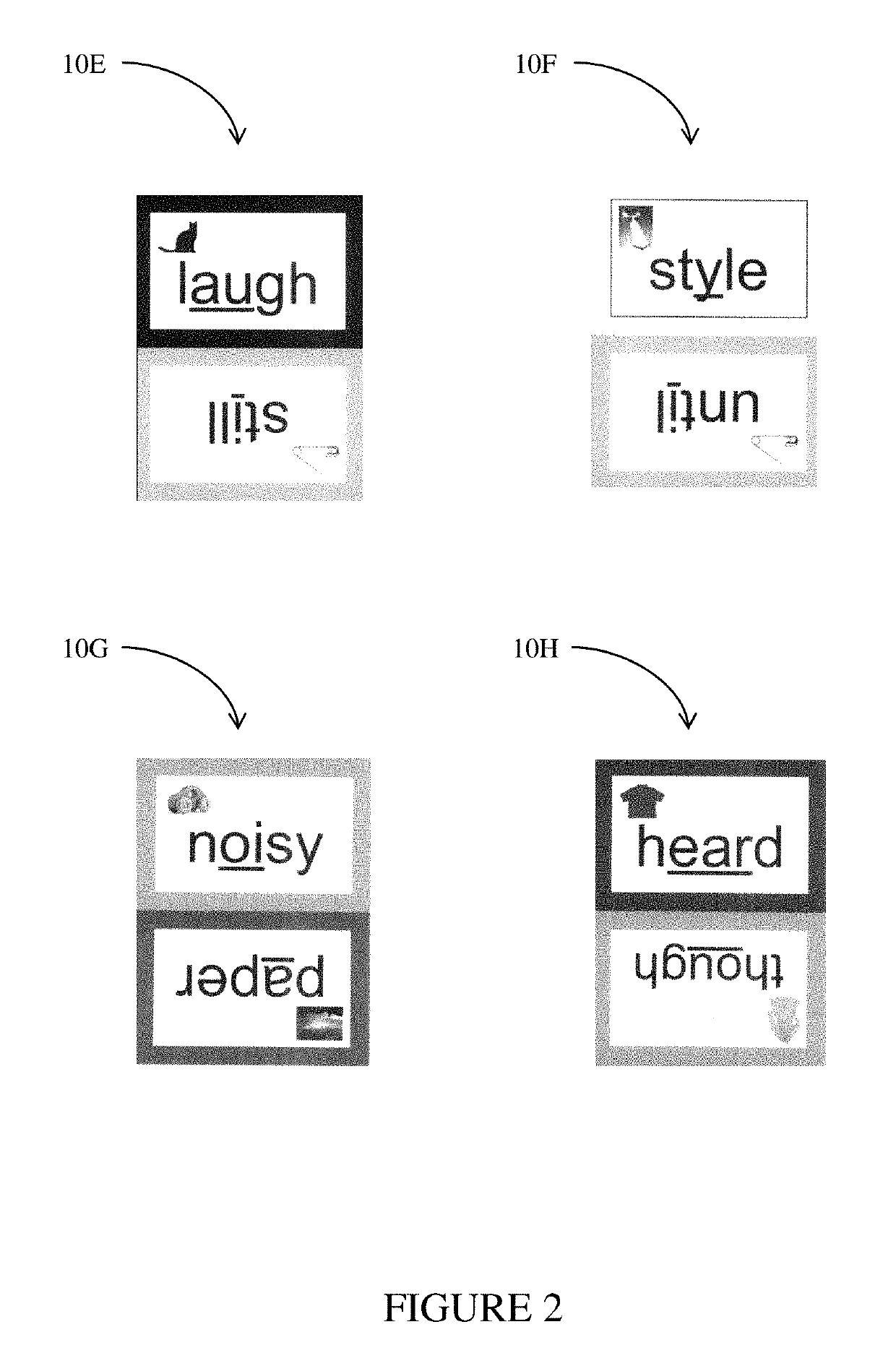

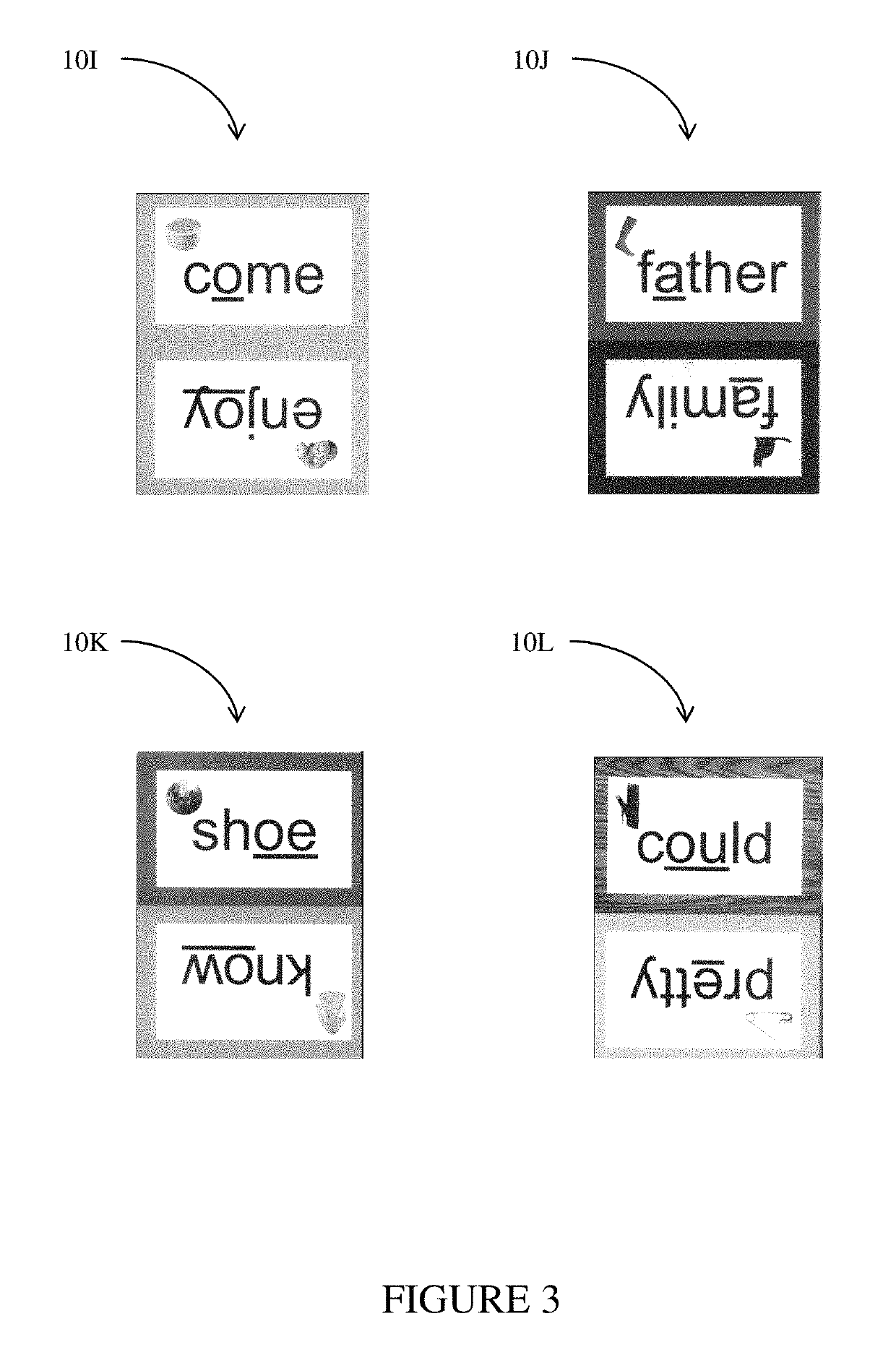

Game with visual cueing system and oral-aural learning routine

ActiveUS10446056B1Convenient and accurate judgmentEliminate needIndoor gamesTeaching apparatusVowelPlaying card

An audiovisual cueing system includes a visual game focusing on the fifteen vowel sounds of American English. Players take spoken turns corresponding with a sound-based word pattern determined by cards in play. Each card includes a color border, image, and featured word. The stressed vowel sounds in the color and object guide players to use the same sound in the underlined part of the featured word despite different spelling patterns. Players compare colors on cards in hand with a discard pile card, and if there is a match, the matched card is discarded and six corresponding words spoken in succession (e.g., “blue moon soon, blue moon June”). The act of speaking these words in succession provides a moment of learning and practice that benefits the player, while the game objective (winning) compels the learner to persist. The first player to discard all cards in hand is awarded points or wins.

Owner:ENGLISH LANGUAGE TRAINING SOLUTIONS LLC

Measuring device and method for focusing constant g of self-focusing fiber

ActiveCN104535302BFocusImprove centralityPhase-affecting property measurementsTesting optical propertiesMeasurement deviceComputational physics

Owner:SHANGHAI UNIV

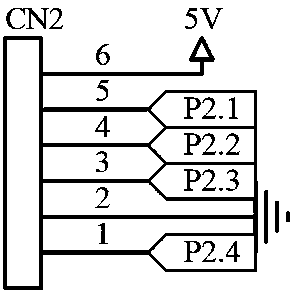

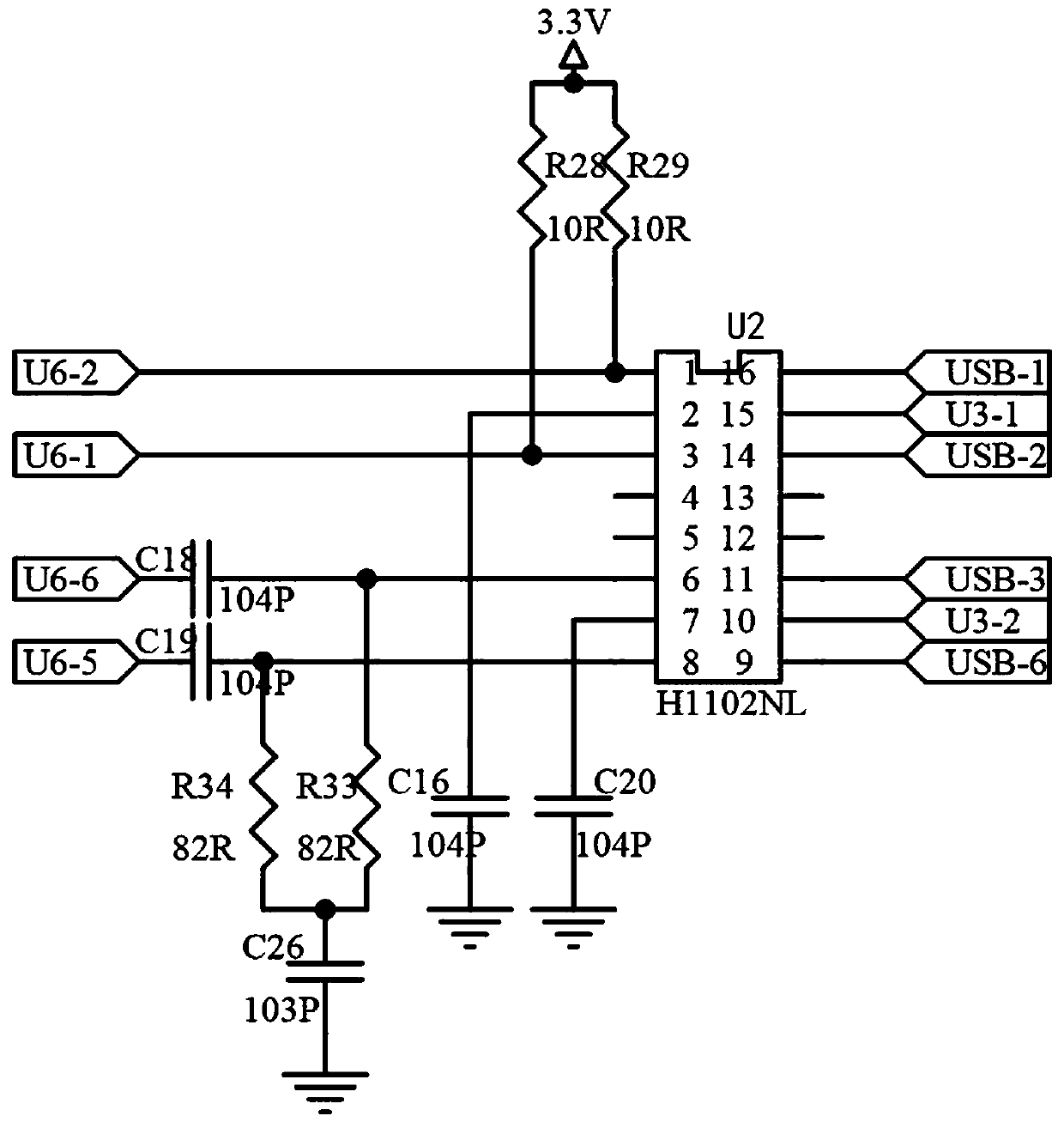

Intelligent reading and writing device and method for RFID (Radio Frequency Identification)

ActiveCN107679589AAchieve synergyImprove centralityCo-operative working arrangementsPurchasingComputer science

The invention discloses an intelligent reading and writing device and method for RFID (Radio Frequency Identification). Simultaneous reading and writing for low-frequency, high-frequency and ultrahigh-frequency RFID tags are achieved through using the intelligent reading and writing device for RFID and the method applied to the device. In addition, the simultaneous reading and writing range can beadjusted according to actual requirements. Furthermore, the intelligent reading and writing device is provided with a communication module, thereby enabling multiple devices to operate in a networking manner. The intelligent reading and writing device can also be combined with a status indicator lamp of production and manufacturing equipment, thereby reducing the purchasing cost, achieving the coordination, concentration and stability of work and reducing the maintenance cost.

Owner:NINGBO TENGZHI INFORMATION TECH CO LTD

Gear chamfering device

The invention discloses a gear chamfering device, which belongs to the technical field of gear processing, and comprises a rotating shaft, a driving device for driving the rotating shaft to rotate, a rack for mounting the driving device, a first cutter head and a second cutter head, the first cutter head and the second cutter head are in transmission fit with the rotating shaft, and the first cutter head and the second cutter head are mutually symmetrical; serrated cutters of the first cutter head and the second cutter head are opposite to each other, so that the first cutter head and the second cutter head are separated to form a space for chamfering the outer edges of the two sides of a gear; according to the device, the follow-up meshing disc is arranged, when the gear continues to feed after meeting the technological requirements, and the follow-up meshing disc and the second cutter disc rotate relatively, the proximity switch receives an instruction, and the controller controls the driving device to stop; by adopting the device disclosed by the invention, the technical problem that the chamfering precision is low due to the fact that the gear feeding is judged by adopting the manual proficiency degree in a traditional mode is solved.

Owner:CHONGQING JUJIA MACHINERY

A device and method for RFID intelligent reading and writing

ActiveCN107679589BAchieve synergyImprove centralityCo-operative working arrangementsEmbedded systemUltrahigh frequency

The invention discloses an intelligent reading and writing device and method for RFID (Radio Frequency Identification). Simultaneous reading and writing for low-frequency, high-frequency and ultrahigh-frequency RFID tags are achieved through using the intelligent reading and writing device for RFID and the method applied to the device. In addition, the simultaneous reading and writing range can beadjusted according to actual requirements. Furthermore, the intelligent reading and writing device is provided with a communication module, thereby enabling multiple devices to operate in a networking manner. The intelligent reading and writing device can also be combined with a status indicator lamp of production and manufacturing equipment, thereby reducing the purchasing cost, achieving the coordination, concentration and stability of work and reducing the maintenance cost.

Owner:NINGBO TENGZHI INFORMATION TECH CO LTD

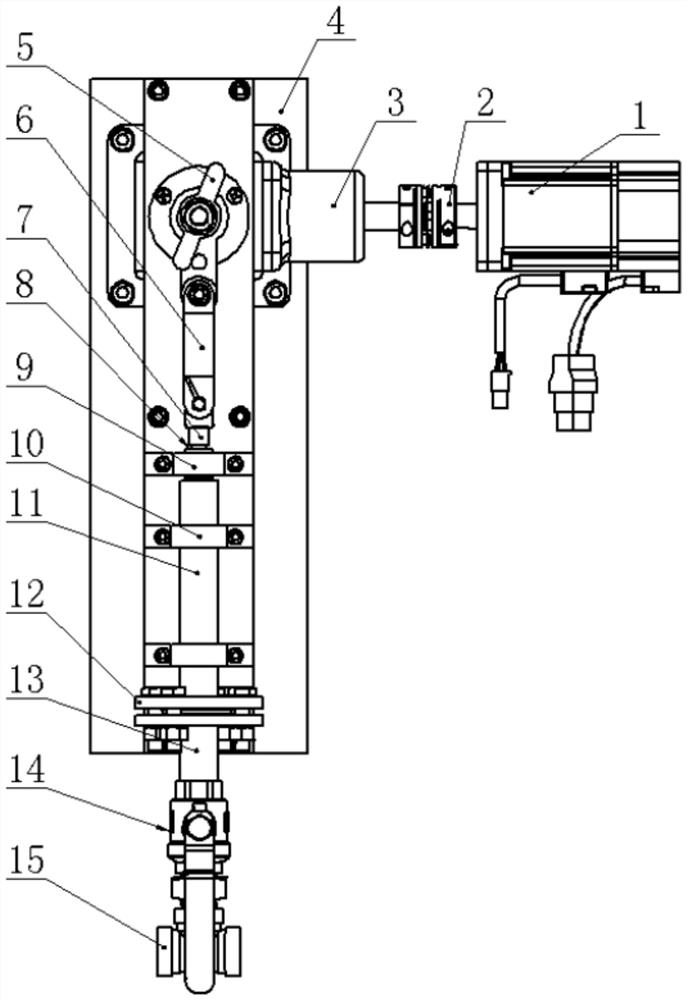

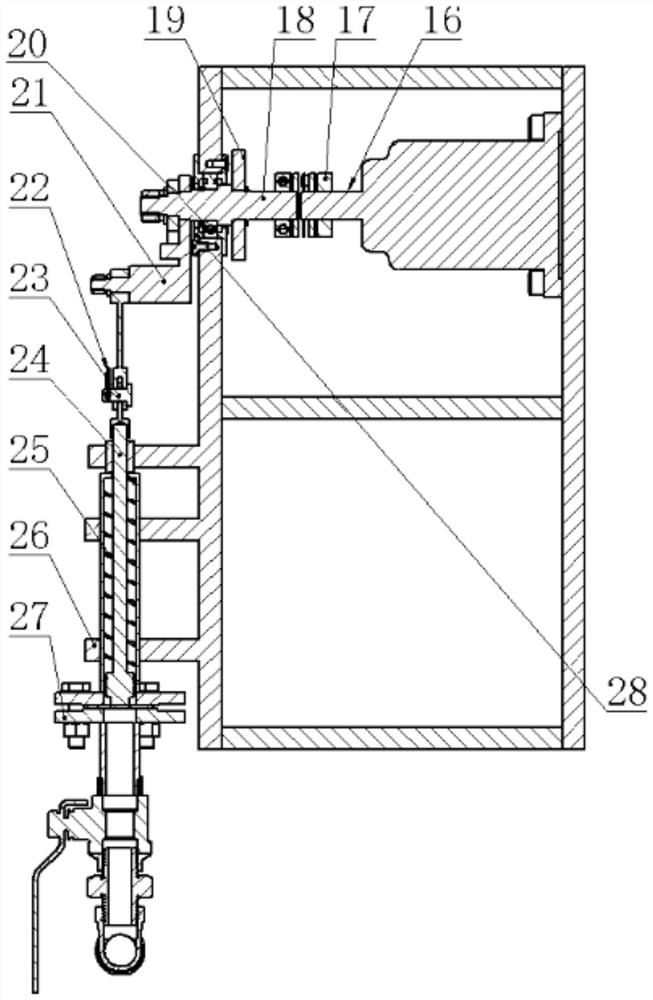

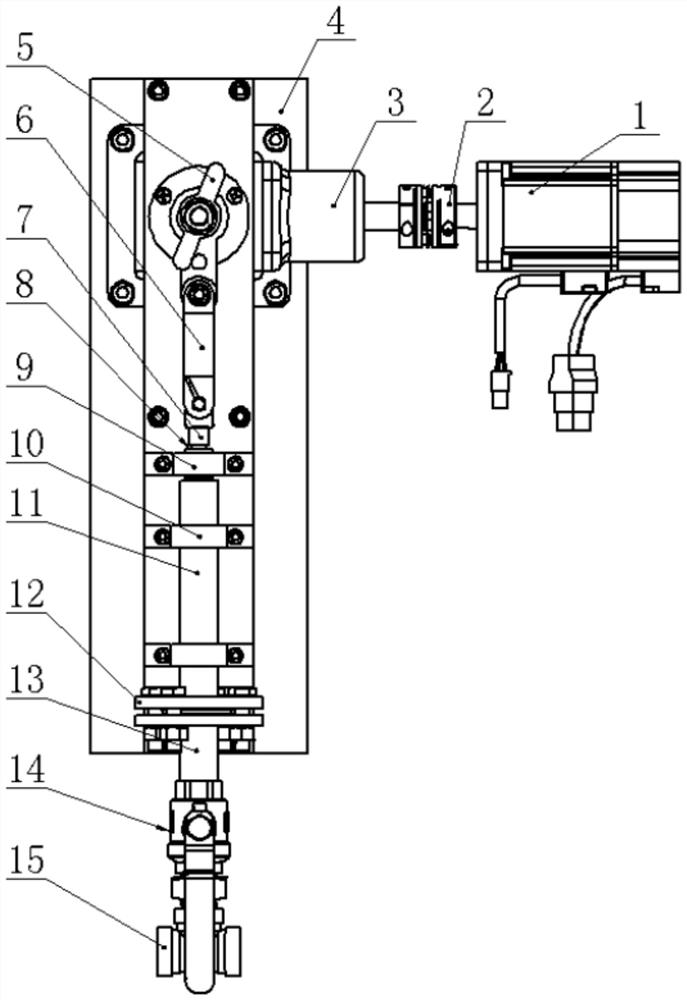

Mechanically-driven continuous impact type pressure wave generator and pipeline abnormal state detection device based on same

ActiveCN112856238AReasonable structural designImprove centralityFlywheelsPipeline systemsElectric machineryMan machine

The invention discloses a mechanically-driven continuous impact type pressure wave generator and a pipeline abnormal state detection device based on the same, and belongs to the technical field of pipeline detection. The device is reasonable in structural design and good in overall centering performance, a plunger, a plunger rod, a plunger rod connector and a piston sleeve are located on the same axis, running is stable, and the service life of the device is long. The plunger can rapidly impact a diaphragm along with rectilinear motion of the plunger rod in the piston sleeve under driving of spring force and a motor, pulse type pressure fluctuation is generated through deformation of the diaphragm, and then the pulse type pressure fluctuation is spread along a pipeline. The diaphragm isolates fluid flowing in the pipeline from gas in the piston sleeve, and a better sealing function is still achieved under very high pressure. A novel structural mode that the motor provides mechanical energy and a spring and a flywheel accumulate energy is adopted, so that whole equipment can generate continuous pressure waves; the whole device is positioned through a body fixing frame, the space of the device is compact, carrying is convenient, operation is easy, and high man-machine friendliness is achieved; and the structure is simple, sealing performance is good, and running is stable.

Owner:XI AN JIAOTONG UNIV

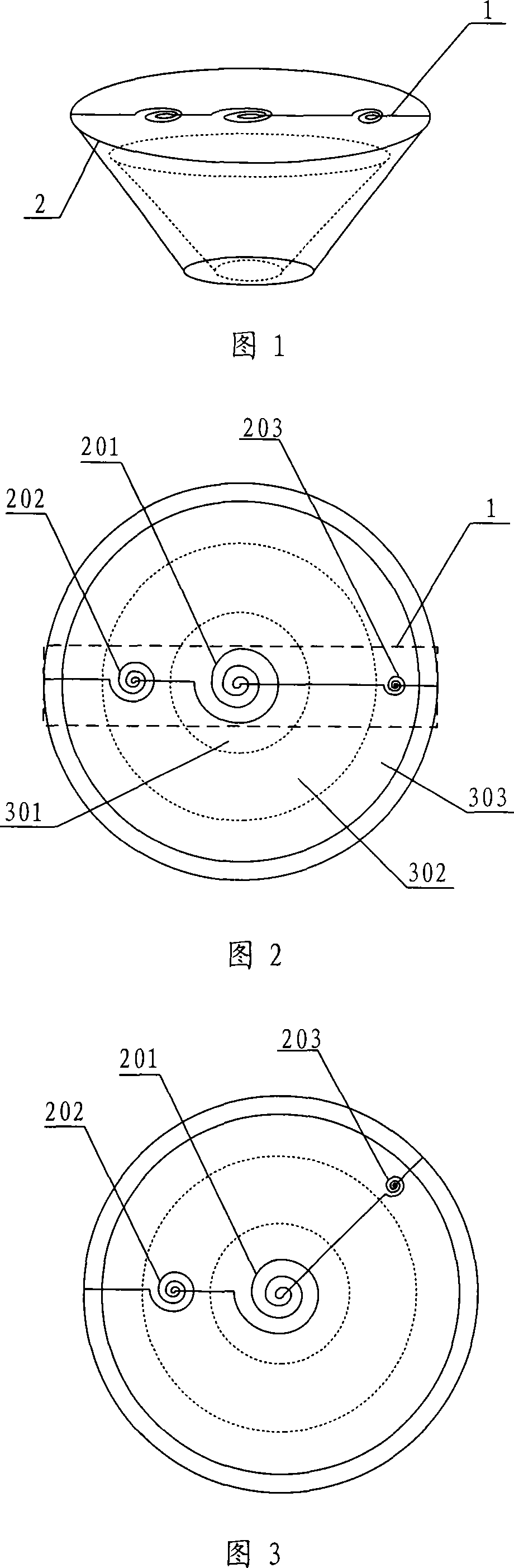

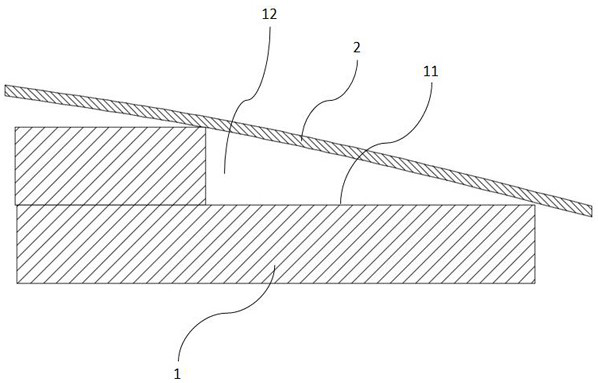

Loudspeaker and sound box

ActiveCN101521840BImprove centralityImprove sound qualityTransducer detailsTransducer diaphragmsEngineeringHigh-pitched

The invention provides a loudspeaker, which includes a speaker frame, the mouth of which is provided with a pilot frequency line passing the center of the mouth. The pilot frequency line includes threThe invention provides a loudspeaker, which includes a speaker frame, the mouth of which is provided with a pilot frequency line passing the center of the mouth. The pilot frequency line includes three helical sections sequentially connected on the same plane. The three helical sections are all of the structure of a flat spiral line and are further respectively arranged in a bass area, a mediant ae helical sections sequentially connected on the same plane. The three helical sections are all of the structure of a flat spiral line and are further respectively arranged in a bass area, a mediant area and a high pitch area of the mouth. The invention also provides a sound box, in which the loudspeaker of the proposal is arranged. By connecting the pilot frequency line in the loudspeaker, the inrea and a high pitch area of the mouth. The invention also provides a sound box, in which the loudspeaker of the proposal is arranged. By connecting the pilot frequency line in the loudspeaker, the invention realizes the effect of causing the high pitch, mediant and bass of music out from the loudspeaker to respectively have a convergence point on the pilot frequency line and improves the tone quavention realizes the effect of causing the high pitch, mediant and bass of music out from the loudspeaker to respectively have a convergence point on the pilot frequency line and improves the tone quality of the loudspeaker. Besides, through the arrangement of the loudspeaker in the sound box, the invention realizes the sound concentration of outside played music of the sound box and improves thelity of the loudspeaker. Besides, through the arrangement of the loudspeaker in the sound box, the invention realizes the sound concentration of outside played music of the sound box and improves thetone quality of the sound box.tone quality of the sound box.

Owner:赵明慧 +1

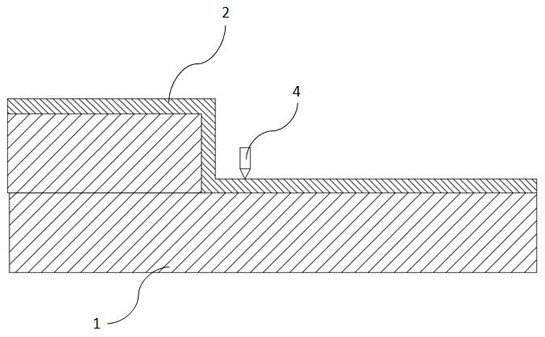

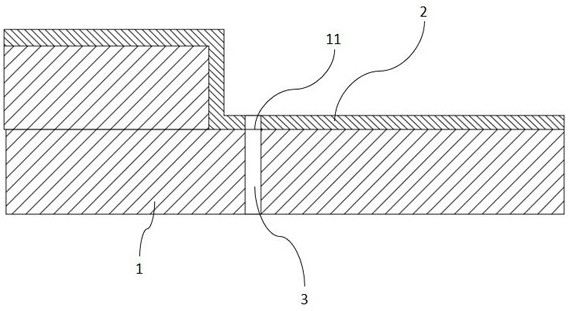

Method for Improving the Fuzziness of Rigid-Flex Board on Knife Face

ActiveCN113573485BImprove qualityEliminate gapsMultilayer circuit manufactureThermodynamicsEngineering

The invention discloses a method for improving the wool on the knife face of a rigid-flex board, which comprises the following steps: covering the knife face of at least part of the recessed area in the rigid-flex board with a film-coated aluminum sheet; The pressure towards the blade surface of the rigid-flex board, so that the coated aluminum sheet and the side wall of the concave area on the blade-facing surface of the rigid-flex board are completely attached; The recessed area is drilled to obtain a forming hole in the recessed area of the rigid-flex board; after the drilling of the rigid-flex board is completed, the coated aluminum sheet is removed. In the present invention, the gap between the film-coated aluminum sheet and the rigid-flex board is completely bonded to the side wall of the recessed area of the rigid-flex board, thereby preventing hairs from accumulating between the rigid-flex board and the film. The situation between the aluminum sheets, and the hairs are taken out of the rigid-flex board and the coated aluminum sheet after drilling, thereby improving the quality of the rigid-flex board after drilling.

Owner:FOREWIN FPC SUZHOU

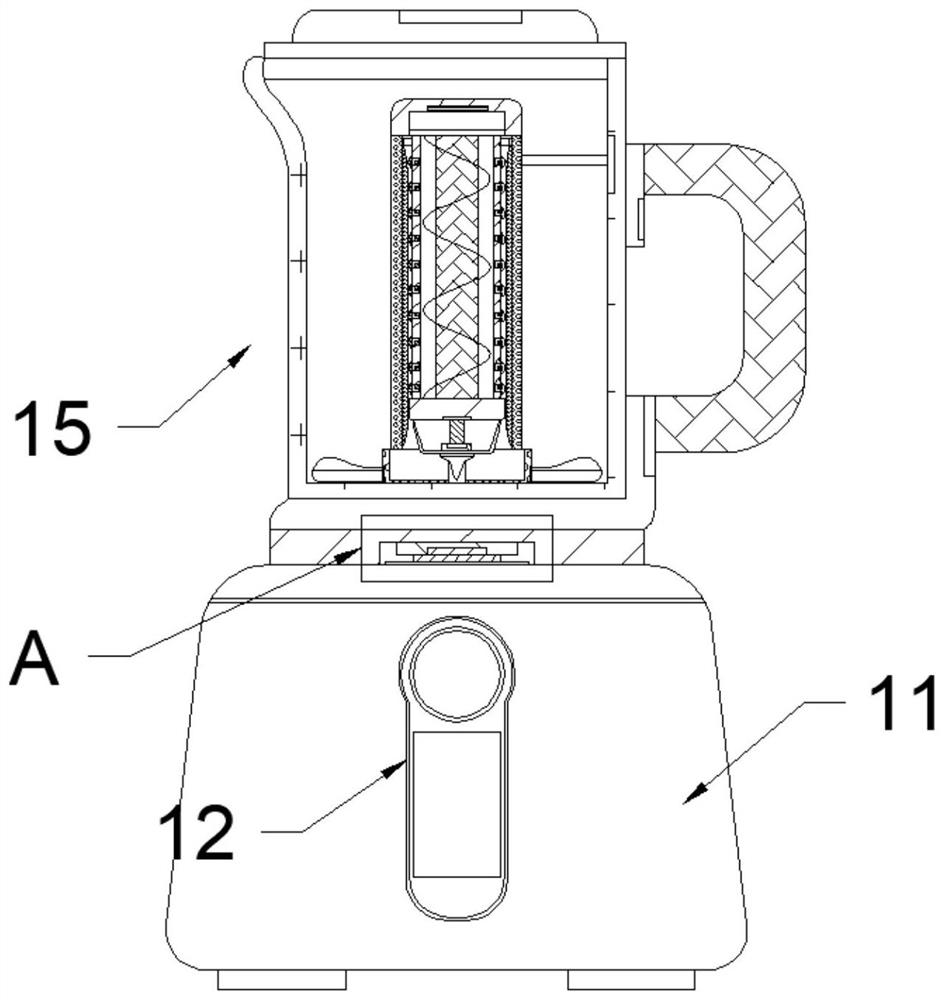

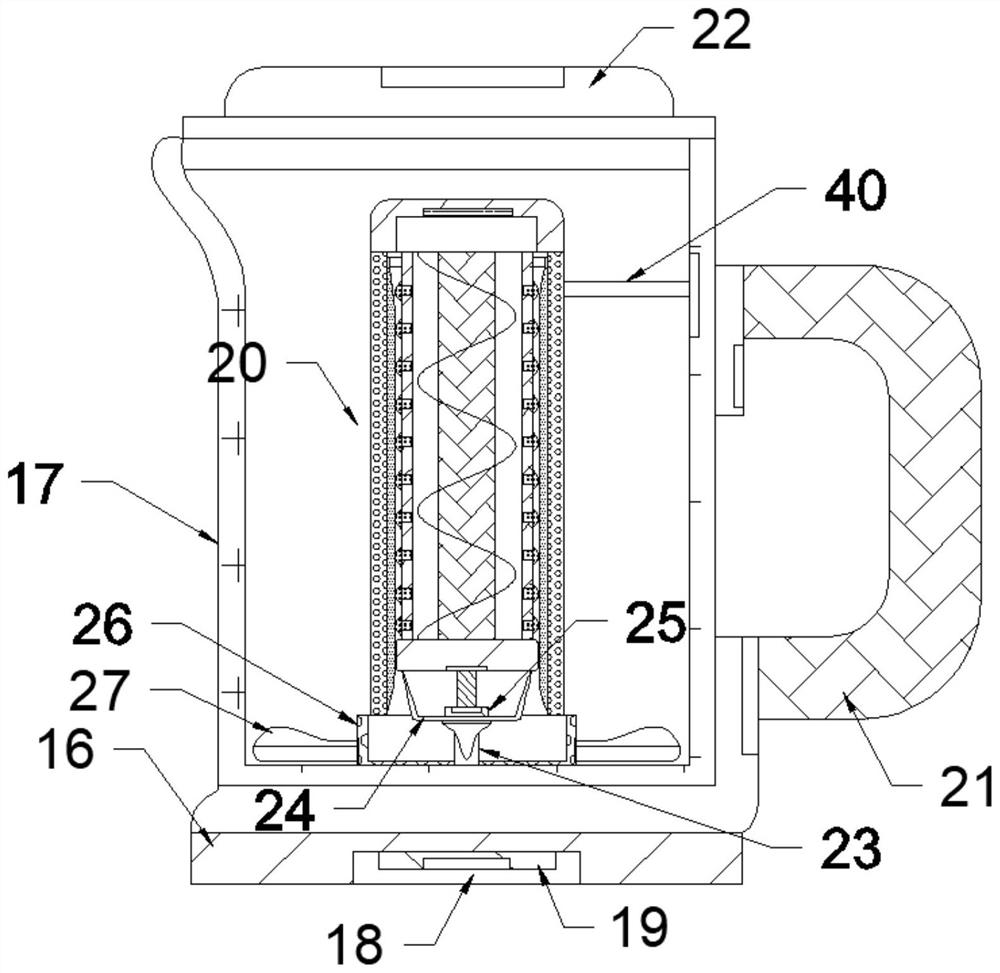

Grain juicer capable of improving pulp quality

PendingCN114451792AImproved fineness and qualityImprove Juicing QualityKitchen equipmentPaper recyclingEngineeringKnife blades

The invention relates to the related technical field of grain milling, and discloses a grain juicer capable of improving pulp quality, which comprises a machine body base, a juicing function device is detachably mounted on the machine body base, the juicing function device comprises a butt joint base, a juicing cylinder body is mounted on the butt joint base, a transmission shaft is rotatably mounted in the juicing cylinder body, and the transmission shaft is rotatably mounted on the butt joint base. A transmission shaft is installed in the juicing cylinder body, juicing blades are installed on the transmission shaft, a butt-joint block is installed at the tail end of the transmission shaft, a butt-joint net barrel is installed on the transmission shaft, stirring fan blades are installed on the butt-joint net barrel, and a separating and pulp filtering device is installed in the juicing cylinder body; according to the grain juicer capable of improving the quality of the pulp, the pulp separating and filtering system is arranged, the pulp separating and filtering device is carried in the juicing cylinder to be matched with a blade and a bottom stirring structure, grains in the pulp separating and filtering device are crushed and juiced through the blade in the juicing process, and the distribution position of the grains is controlled through a pulp filtering thin-hole barrel.

Owner:孔翔

A sewage processor with multi-stage treatment function

ActiveCN111729397BImprove centralityLarge amount of sewageFiltration circuitsStationary filtering element filtersGear wheelSewage

The invention relates to a sewage processor with multi-stage treatment function, which comprises a processor end cover and a processor, a vertical shaft sliding vertically on the processor end cover, a planetary gear train is arranged inside the processor, the vertical shaft passes through and treats The upper gear and the sun gear in the planetary gear system, which are rotatably connected by the end cover of the device, extend downward; the inner rings of the two gears are all threaded with the vertical shaft, and the outer ring of the ring gear of the planetary gear system is threaded with a shaft sleeve, and the shaft sleeve The lower part is connected with blades; the upper part of the processor has a plurality of through holes distributed around the circumference and the outside is provided with a blocking ring that can slide vertically, the blocking ring matches the through hole, and the upper end of the vertical shaft is connected with the blocking ring through a string; The sliding speed of the circular plate determines the discharge time of the suspended solids, and realizes the precise control of the suspended solids discharge; the blades stir in the clear water at a low speed, so that the suspended solids on the surface of the clear water slowly move around, realizing a large concentration of suspended solids; the concentrated suspended solids It flows out at a certain time, and has the characteristics of large amount of sewage discharge and good sewage discharge effect.

Owner:SHENZHEN DIANHANHAO CONSTR ENG

A polyethylene with a high vinyl content and with a low mfr

ActiveUS20210163638A1Improved sag performanceEasy to processPlastic/resin/waxes insulatorsPolymer sciencePower cable

The invention relates to a polyethylene having a melt flow rate at (2.16) kg loading (MFR2), determined according to method ISO1133-1:2011, which MFR2 is A g / 10 min and A1≤A≤A2; wherein A1 is (0.5) and A2 is (1.70), and containing a total amount of vinyl groups which is B vinyl groups per (1000) carbon atoms, and B1≤B, wherein B1 is (0.45), determined according to method ASTM D6248-98, a polymer composition, an article being e.g. a cable, e.g. a power cable, and processes for producing a polyethylene, a polymer composition and an article, and an article; useful in different end applications, such as wire and cable (W&C) applications.

Owner:BOREALIS AG

An aeration tank foam treatment device

ActiveCN111013237BAchieve rotationAchieve orientationFatty/oily/floating substances removal devicesLiquid degasification by filtrationTurbine wheelSludge

The invention discloses a foam treatment device for an aeration tank, which comprises a floating ring, a plastic diaphragm and an annular shell, the floating ring is fixedly connected to the upper end of the plastic diaphragm, the annular shell is fixedly connected to the lower end of the plastic diaphragm, the plastic The two sides of the diaphragm are symmetrically provided with grid sleeves, the two sides of the annular shell are symmetrically opened with openings, and the openings are connected with flow pipes, and the openings communicate with the grid sleeves through the flow pipes. A partition is arranged on the inner wall, and a first rotating shaft is rotatably connected above the partition, and a turbine is fixedly sleeved on the first rotating shaft. The turbine of the present invention rotates to guide the water flow, and a vortex will be formed inside the plastic diaphragm, and the foam around the device will flow to the vortex, and then realize the concentration effect on the foam, and even be guided into the grid sleeve, and the grid sleeve will collect it. Block the foam or sludge, so as to achieve the effect of foam treatment on the surface of sewage.

Owner:浙江润城环保集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com