Grain juicer capable of improving pulp quality

A juicer and high-quality technology, which is applied in the field of grain milling, can solve the problems of insufficient fineness of slurry, grain floating skin affects taste, and low production efficiency, so as to improve the fineness and quality, improve the fineness of grinding and the pulping efficiency , noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

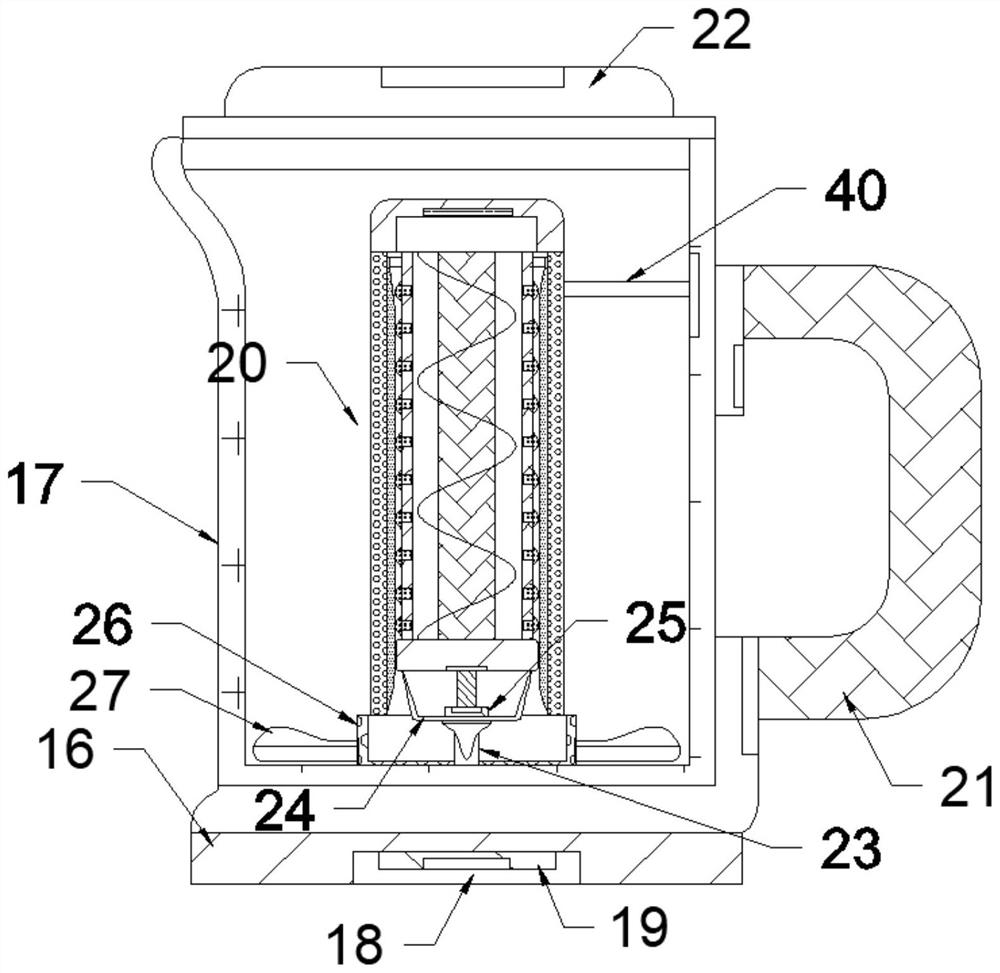

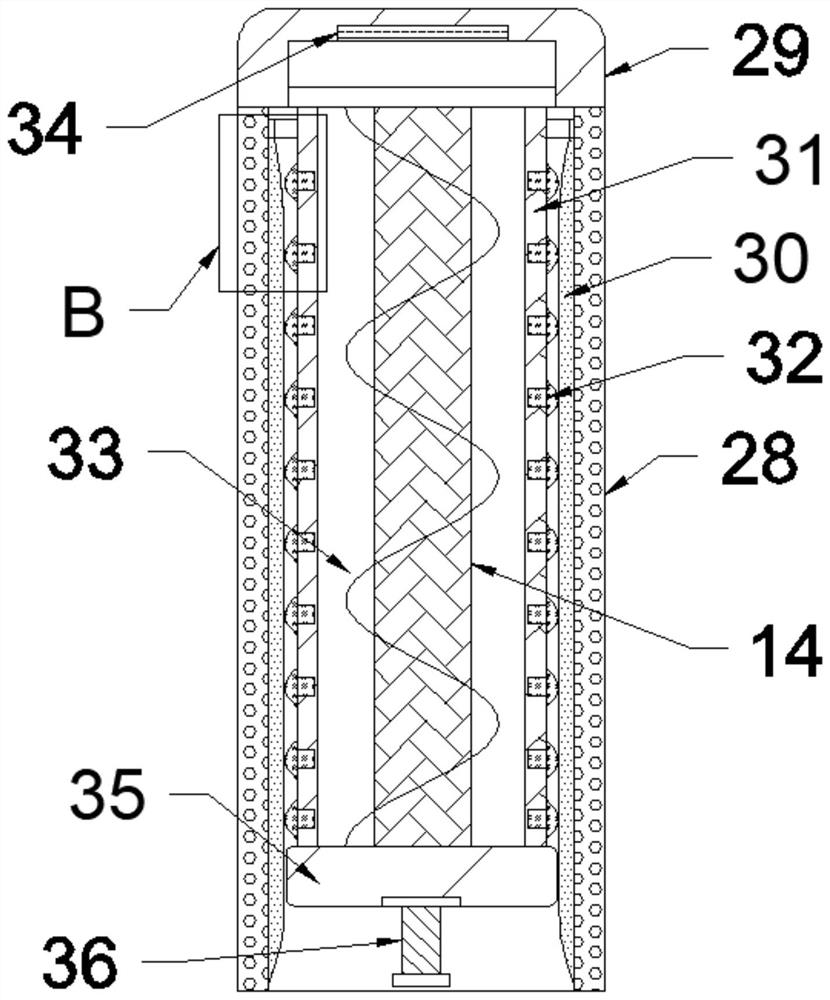

[0023] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

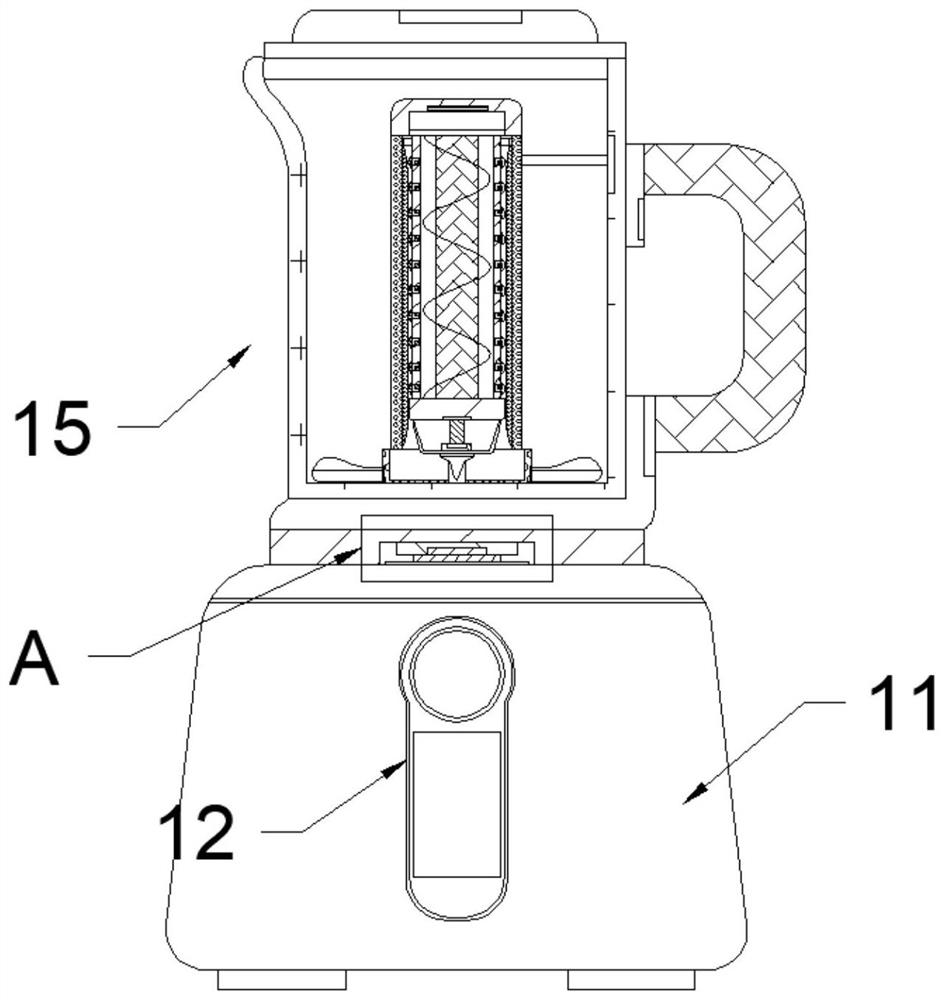

[0024] A grain juice extractor for improving pulp quality described in conjunction with accompanying drawings 1-5 includes a body base 11, and the body base 11 is detachably mounted with a juice extraction function device 15, and the juice extraction function device 15 includes a docking base 16. The docking base 16 is equipped with a juicing cylinder 17, and a transmission shaft 23 is installed in the rotation of the juicing cylinder 17. The transmission shaft 23 is equipped with a juicer blade 24, and the end of the transmission shaft 23 is installed with a Docking block 25, the transmission shaft 23 is equipped with a docking mesh cylinder 26, and the docking mesh cylinder 26 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com