Elevator rope and method of manufacturing said elevator rope

A technology for elevator ropes and steel cords, which is applied in the field of elevator ropes and can solve problems such as cracks in the tearing force coating and rising shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

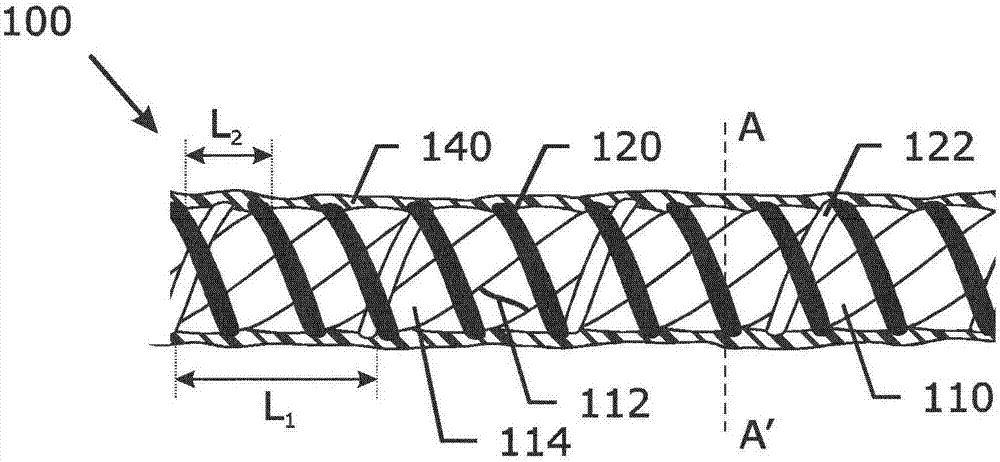

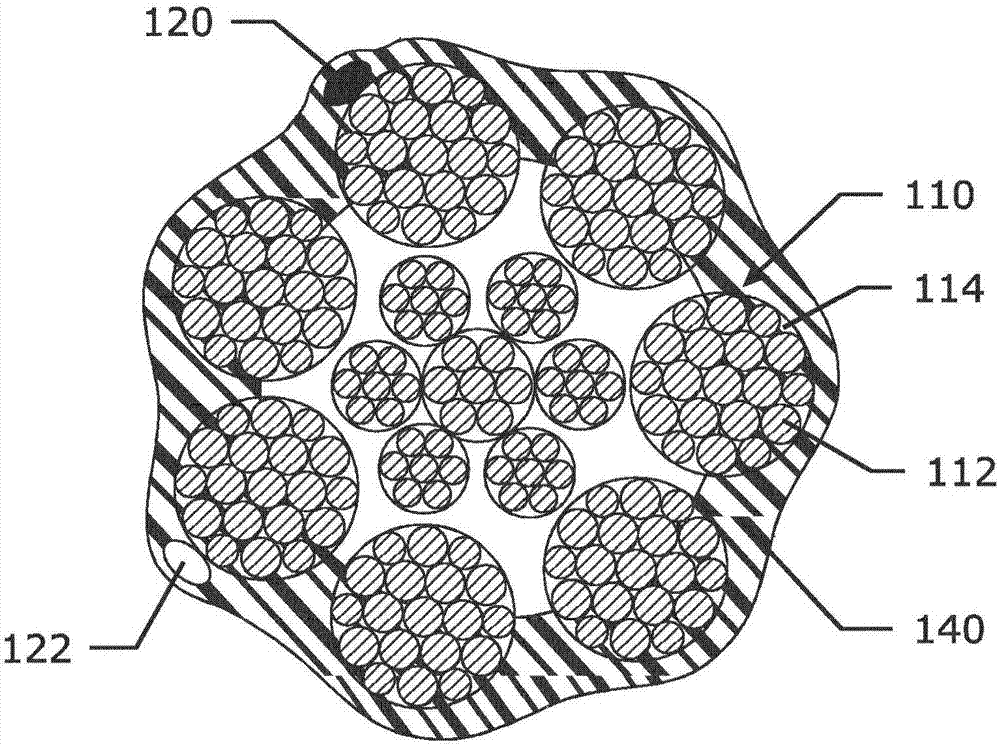

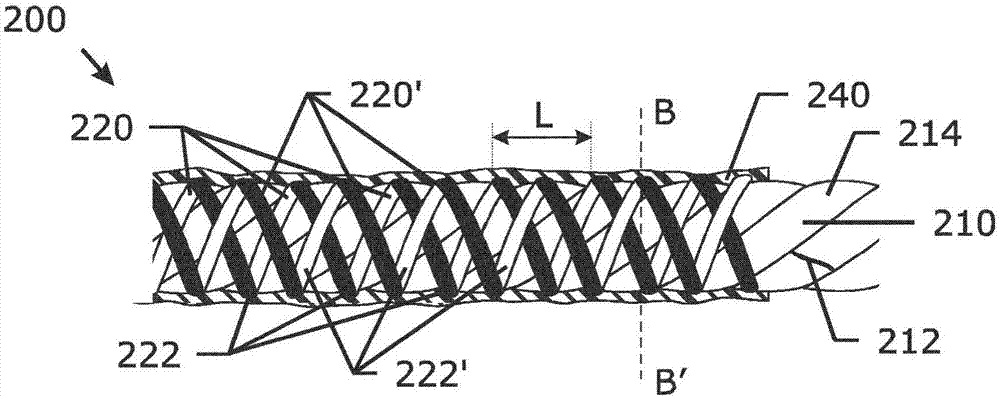

[0068] In the first example of the present invention ( Figure 1a and b), the following types of steel cords were made:

[0069] {[(0.34+6×0.31) 12.5s +6×(0.25+6×0.25) 12.5z ] 25s +

[0070] 7×(0.34+6×(0.31|0.33|0.25) 20s} 50Z

[0071] Six 0.31 diameter wires are twisted in the "s" direction with a lay length of 12.5 around a 0.34 diameter center core wire. On this core strand, 6 inner layer strands are cabled with a lay length of 25 in the s direction (with a core monofilament of 0.25, around the core monofilament of 0.25, 6 are twisted with a lay length of 12.5 in the z direction 0.25 outer monofilament). Finally around the core strand seven outer strands twisted in parallel in a Valenton configuration with a 0.34 core monofilament surrounded by 6 0.31 monofilaments are closed at a lay length of 50 in the Z direction, at On top of the six 0.31 monofilaments, 6 alternating monofilaments of 0.33 and 0.25 were twisted in the "s" direction with a lay length of 20. So 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com