A sewage processor with multi-stage treatment function

A technology of sewage treatment and processing, applied in the direction of chemical instruments and methods, fixed filter elements, separation methods, etc., can solve the problems of suspended matter discharge, solid particle filtration, etc., and achieve large sewage discharge and good sewage discharge effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

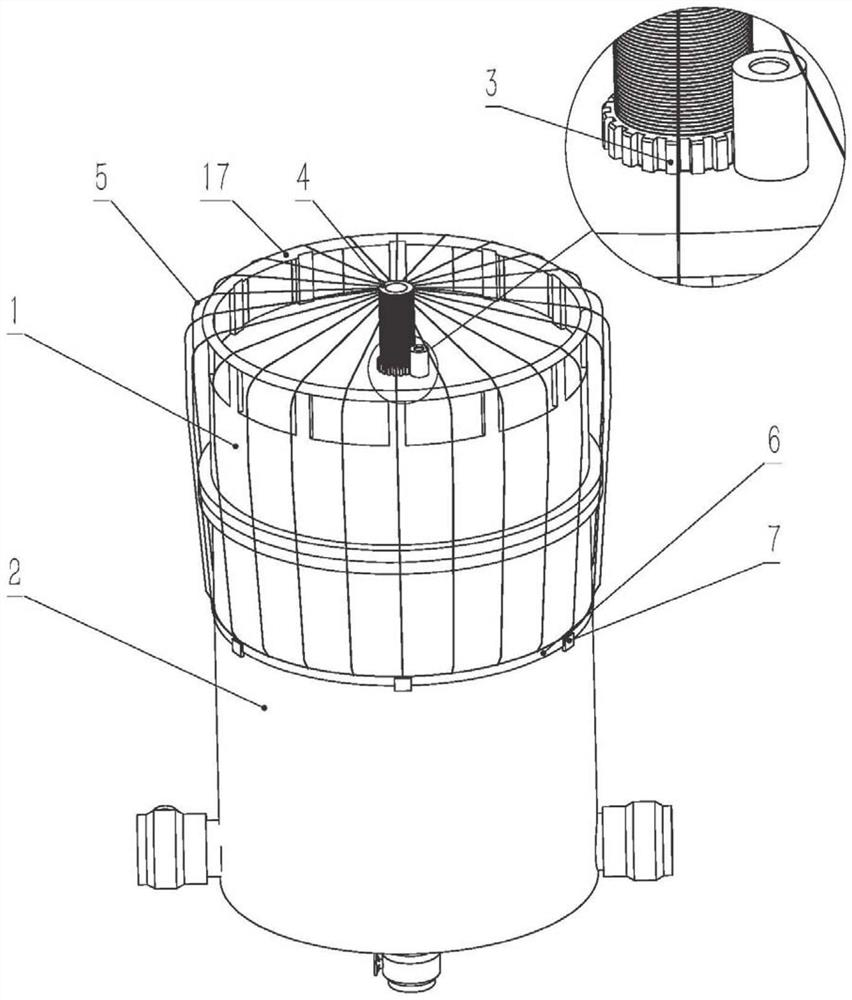

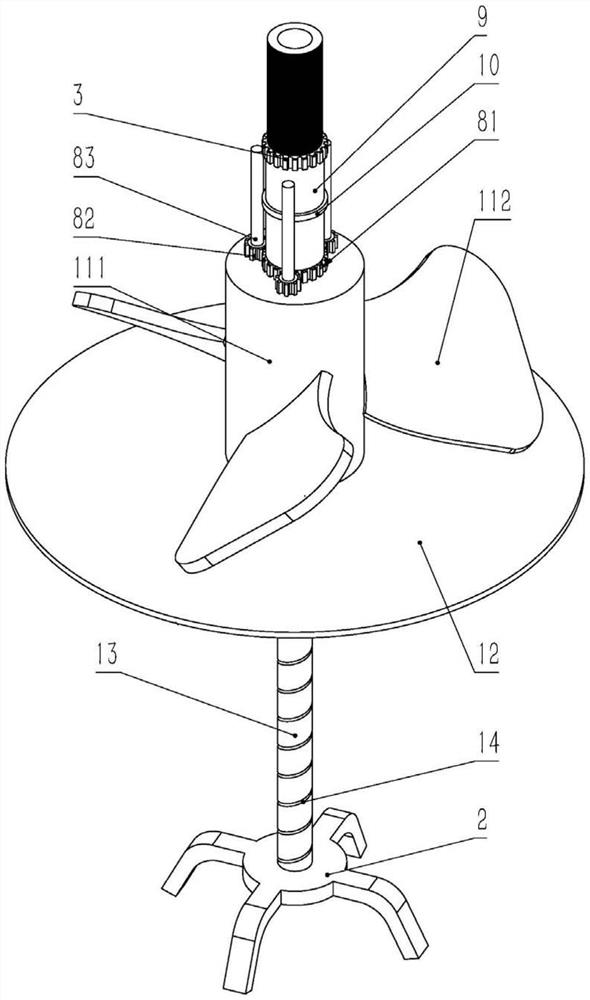

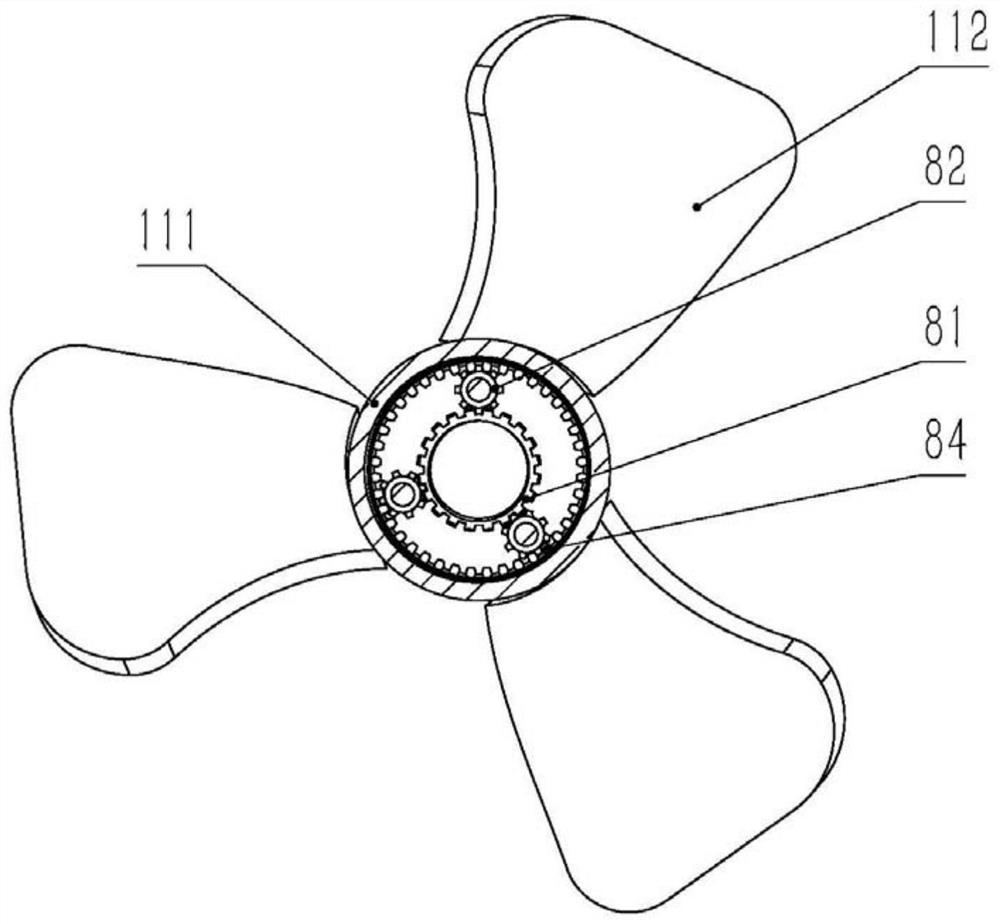

[0018] Depend on Figure 1 to Figure 7 Given, the present invention includes a processor 2 and a processor end cover 1 arranged vertically coaxially. The processor end cover 1 is located above the processor 2 and forms a cylindrical cavity structure connected with the processor 2 via a flange. The center of the upper end surface of the end cover 1 is provided with an upper gear 3 whose axis is vertical, the upper gear 3 is rotationally connected with the processor end cover 1, and the upper gear 3 is inserted with a vertical shaft coaxial with the upper gear 3 and can be vertically slid 4. The upper end of the vertical shaft 4 is placed outside the cavity structure of the cylinder, the lower end of the vertical shaft 4 penetrates through the center of the processor end cover 1 and extends downward, the inner ring of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com