High-speed automatic tool changing electrical spindle cooling structure

A technology of automatic tool change and cooling structure, which is applied in special forming/shaping machines, wood processing appliances, manufacturing tools, etc., can solve the problem of not being able to cool the shell, and achieve the effect of reasonable cooling structure, beautiful structure, and ensuring normal operation.

Inactive Publication Date: 2011-01-05

BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to improve the deficiencies of the prior art, overcome the defects that the electric spindle cannot form an axial air duct in its longitudinal direction, and can not cool the casing well, and provide a cooling method that uses air circulation to cool effectively. Discharge the heat generated by the electric spindle, so as to ensure the high speed, high precision and high stability of the electric spindle cooling structure for high-speed automatic tool change electric spindle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

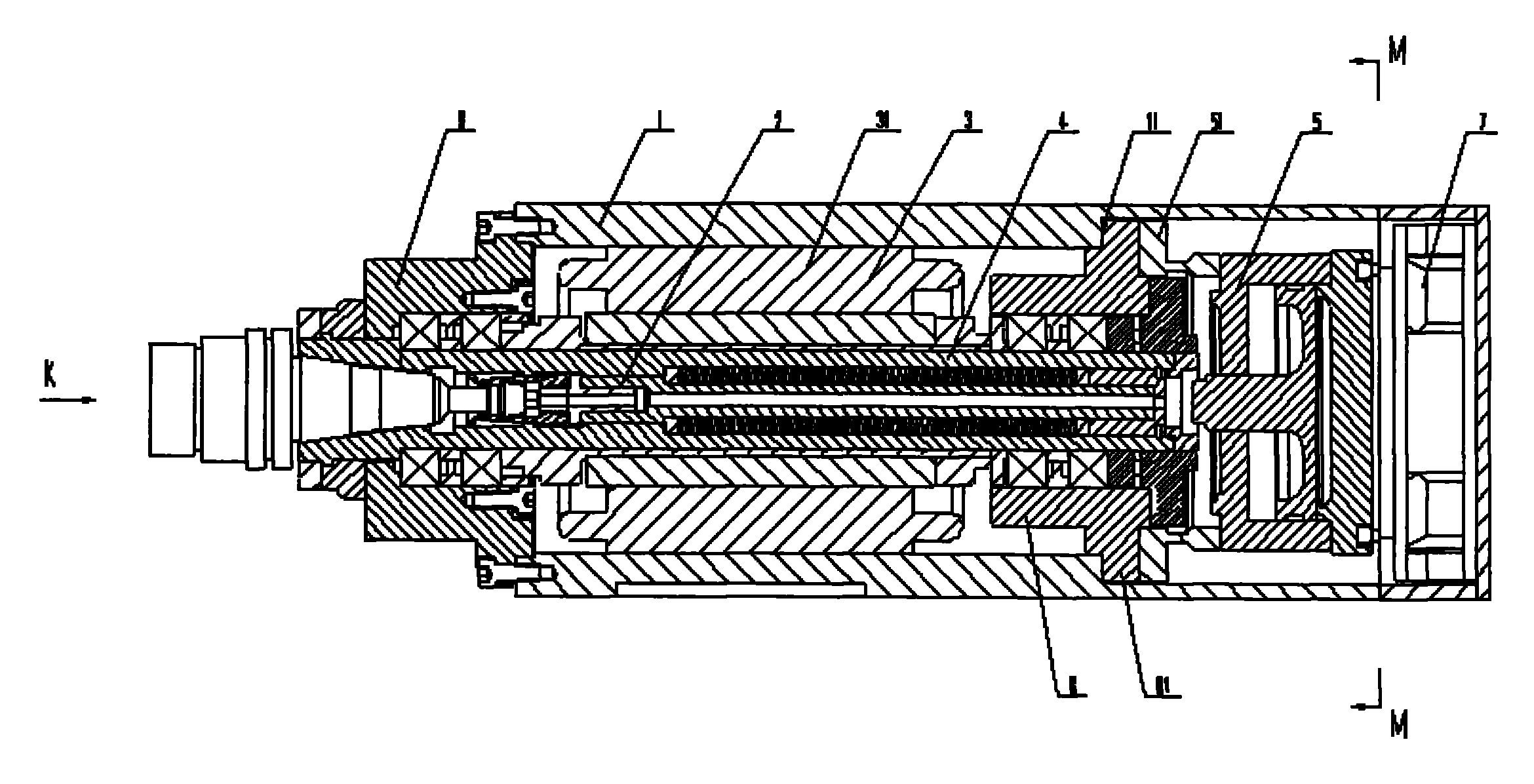

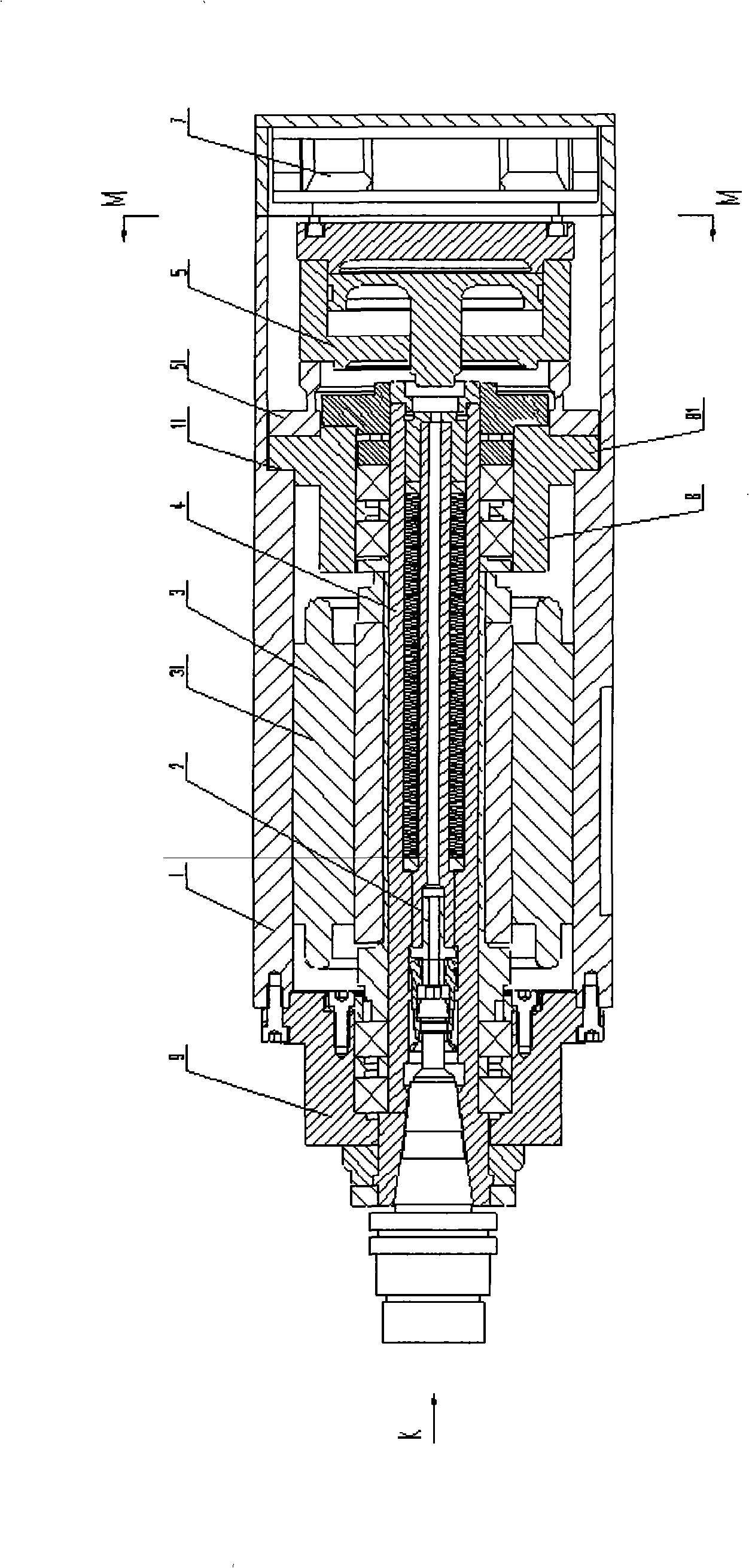

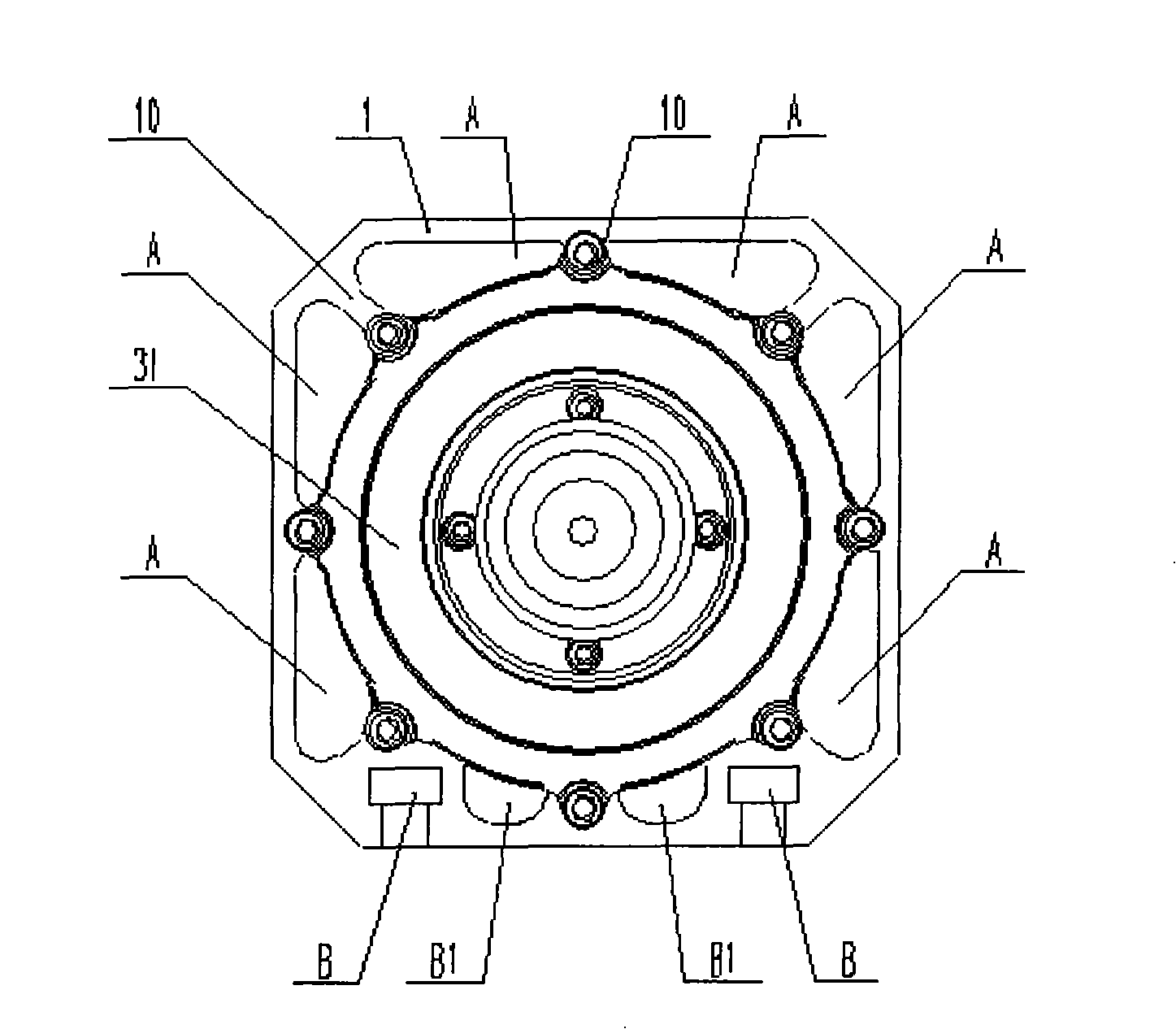

The invention provides a high-speed automatic tool changing electrical spindle cooling structure, wherein, a spindle is fixed at an integrated casing by a front bearing support and a back bearing support; a cooling fan is installed at the back end of the casing; the inner wall of the casing is provided with a convex shoulder type spigot; the back end of the back bearing support is provided with aflange which props against the spigot and is fixed at the casing; the front bearing support, the back bearing support and a position of the flange at a tool changing cylinder corresponding to reinforcement beams arranged at the casing are provided with screw holes and are fixed with the casing by bolts; and a gap is arranged between the adjacent reinforcement beams to form a penetration type axial air course. The electrical spindle cooling structure is provided with the axial air course between the casing, the bearing supports and the cylinder, thereby improving the air cooling performance ofthe electrical spindle; a fixed structure is more reasonable; the centre aligning performance of the electrical spindle is higher; and the electrical spindle cooling structure ensures that the electrical spindle used in wood numerical control machining center bears stable cutting force and keeps high dynamic balance during machining. The electrical spindle does not require arranging a lateral aircourse at the casing and ensures that the structure is compacter and nicer.

Description

A Cooling Structure of High Speed Automatic Tool Changing Electric Spindle technical field The invention relates to a cooling structure of a high-speed automatic tool-changing electric spindle for a numerical control machining center, in particular to a high-speed automatic tool-changing electric spindle for a wood numerical control machining center for cooling by air circulation. Background technique In the modern wood industry, high-speed milling is the main form of deep wood processing. Combining the theory of wood processing technology and the principle of high-speed milling, wood CNC machining centers require high-speed CNC systems and excellent servo motor characteristics, as well as high-speed spindles to improve the accuracy and efficiency of machining workpieces, especially in In wood processing, the motor spindle speed often needs to reach about 12,000-24,000 RPM to ensure that the surface of the wood workpiece has a high roughness, so as to realize the functio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27C5/00

Inventor 张伟王晓军

Owner BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com