Molten steel furnace

A molten steel furnace and water furnace technology, which is used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of easy turning, power consumption, inconvenient unloading of the molten steel furnace, etc., and achieves improved stability and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

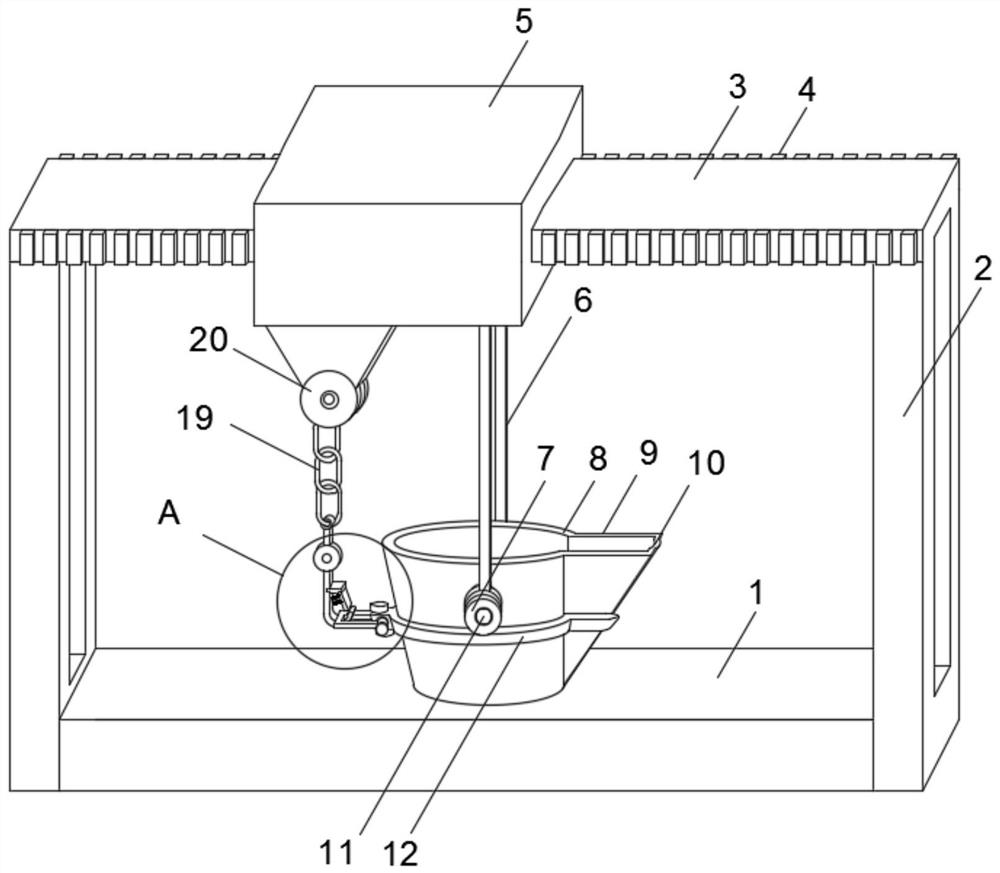

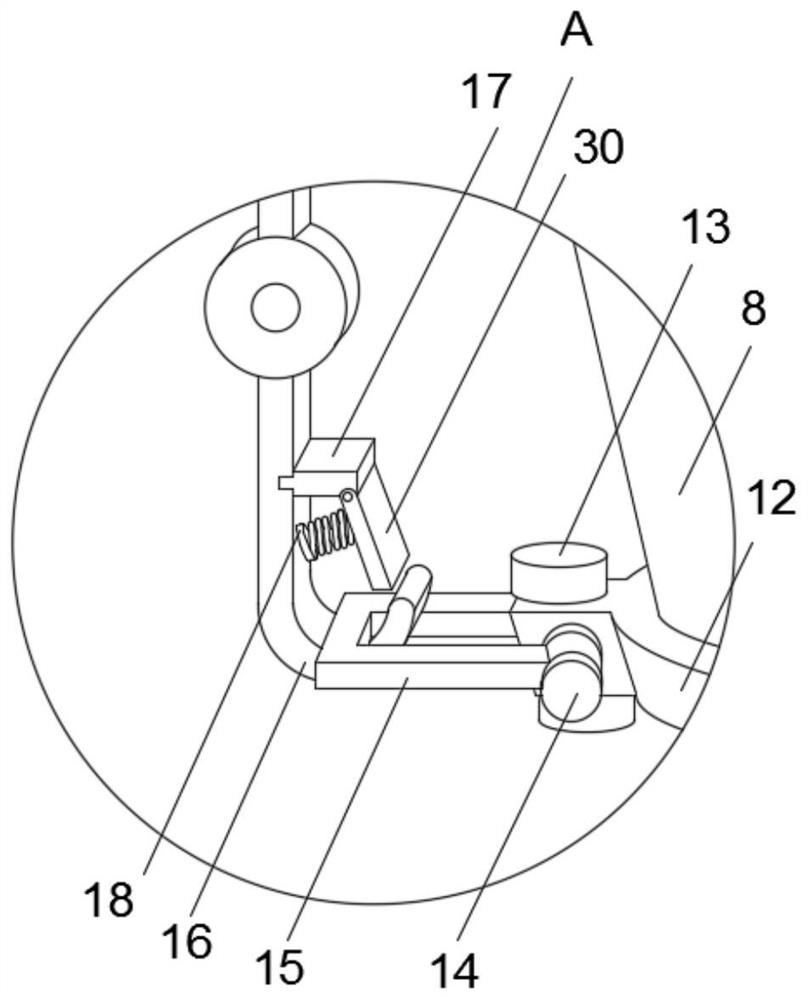

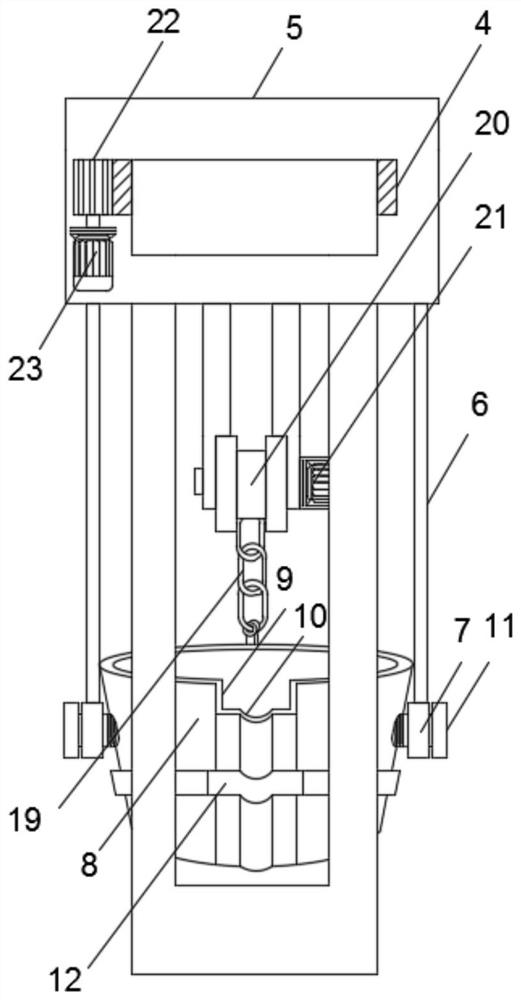

[0032] Refer to attached Figure 1-Figure 4 , a molten steel furnace in this embodiment, comprising a conveying device body 1, a slider 5, a molten steel furnace 8 and a conveying device two body 25, a supporting plate 2 is installed on the top of the conveying device body 1, and the top of the supporting plate 2 is fixedly connected to a sliding track 3 , a rack 4 is installed on one side of the support plate 2, a slider 5 is sleeved on the outer surface of the sliding track 3, a suspension rod 6 is installed on the bottom of the slider 5, the bottom end of the suspension rod 6 is fixedly connected to the collar 7, and the molten steel furnace 8 is installed on one side There is a pouring port 9, and the top of the pouring port 9 is provided with an arc-shaped slot 10. The outer surface of the molten steel furnace 8 is sleeved with a side surround 12, and a hole rivet 13 is installed on one side of the side surround 12, and the inner wall of the hole rivet 13 is socketed with ...

Embodiment 2

[0041] Refer to attached Figure 5-Figure 6 , a kind of molten steel furnace of this embodiment, comprises, concretely, conveying device two body 25 comprises wide steel hook 16, and wide steel hook 16 side is equipped with linear motor 26, and wide steel hook 16 side outer surface is provided with sliding groove 28 , the output end of the linear motor 26 is equipped with a telescopic rod 27, and the telescopic rod 27 is slidably connected in the sliding groove 28 and is fixedly connected with the rotating clamp plate 30 with a pin shaft, and is driven by the staff linear motor 26 to slide and push to the right in the sliding groove 28 Rotate the clamping plate 30 with the pin shaft, and put down the hinge 19, so that the wide steel hook 16 moves downward, and take out the wide steel hook 16, then by turning the fixing screw 11, remove the rotating rings 15 on both sides, and finally hang it by a crane. Lower molten steel furnace 8, reach the effect of unloading molten steel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com