Device used for vertically sorting materials from continuous whole conveying surface

A technology for conveying surfaces and materials, which is applied in the field of devices for vertical sorting of materials from a continuous conveying surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

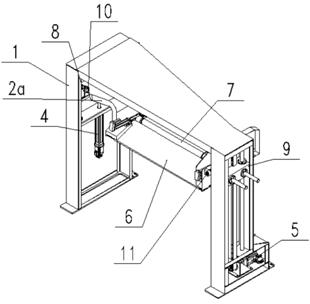

[0036] An apparatus for depositing a material from a continuous overall conveying surface, comprising a support system 1, a lifting system 2, a truss table 2a, and an access delivery system 3, and a lifting system 2 are mounted on a support system 1, a lifting system 2 includes a high-end lifting system 4 and a low-end lifting system 5, a high-end lifting system 4, and the low-end lifting system 5 are respectively mounted on both sides of the support system 1, and the trussing table 2a is respectively connected to the high-end lifting system 4 and the low-end lifting system, respectively. The connection 5 is connected, the access delivery system 3 includes a climbing delivery system 6, the flip delivery system 7, and the gripping mechanism 12, the climbing delivery system 6 is fixed above the trussing table 2a, and the flip delivery system 7 is disposed in the climbing delivery system 6. The exit end, the grab mechanism 12 is fixed to the front of the hoveroid transport system 6. ...

Embodiment 2

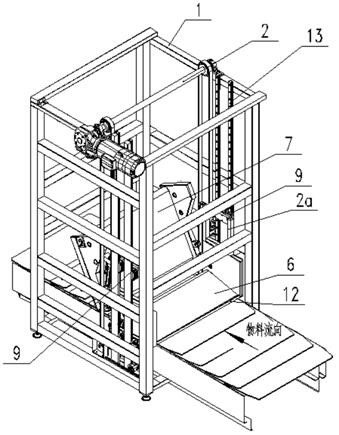

[0054] A method for the continuous material from the entire web transport apparatus perpendicular to the plane of the sorting, the delivery platform when the former is applied only when a horizontal plane, comprising a support system 1, the lift system 2, 2a and the cargo conveyor system 3, acess, lift 2 is a single drive system, mounted on both sides of the support system 1, 2a on both sides of the cargo bed 2 are respectively connected to the lifting system, comprising a transport system 3 acess climbing delivery system 6, reverse transport system 7, grasping mechanism 12 , climbing delivery system 6 is mounted above the cargo bed 2, 7 reverse transport system 2 is mounted above the material outlet end of the cargo bed, is provided at the outlet end of the conveyor system 6 climbing, climbing gripping mechanism 12 is mounted on the delivery system 6 inlet end.

[0055] As a preferred, the climbing delivery system 6 is a belt conveyor, a belt conveyor material inlet end employ a ...

Embodiment 3

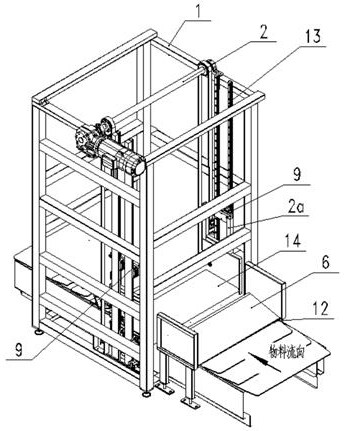

[0070] A method for the continuous material from the entire web transport apparatus perpendicular to the plane of the sorting, the delivery system acess independently disposed distal lift system 2, system 1 comprises a support, lift system 2, 2a and the cargo conveyor system 3 acess , lift system 2 as a single drive means mounted on both sides of the support system 1, provided with a cargo bed 2a splice device 14, both connected to the lift system 2, respectively, comprises a transport system 3 acess climbing delivery system 6, gripping means 12, gripping means 12 is mounted at the inlet end 6 climbing delivery system.

[0071] Preferably, the delivery system acess support frame 3 by a corresponding independent lifting system provided on the conveying surface of the front end 2 of the main conveyer line, with the lifting system 2 is not moved up and down.

[0072] As a preferred, the climbing delivery system 6 is a belt conveyor, a belt conveyor material inlet end employ a wedge-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com