Elevator guide shoe wheel device

A guide shoe and elevator technology, applied in the field of elevators, can solve the problems of uneasy, bumpy, and unsatisfactory effects of elevator personnel, and achieve the effect of ensuring personnel safety and avoiding rapid descent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

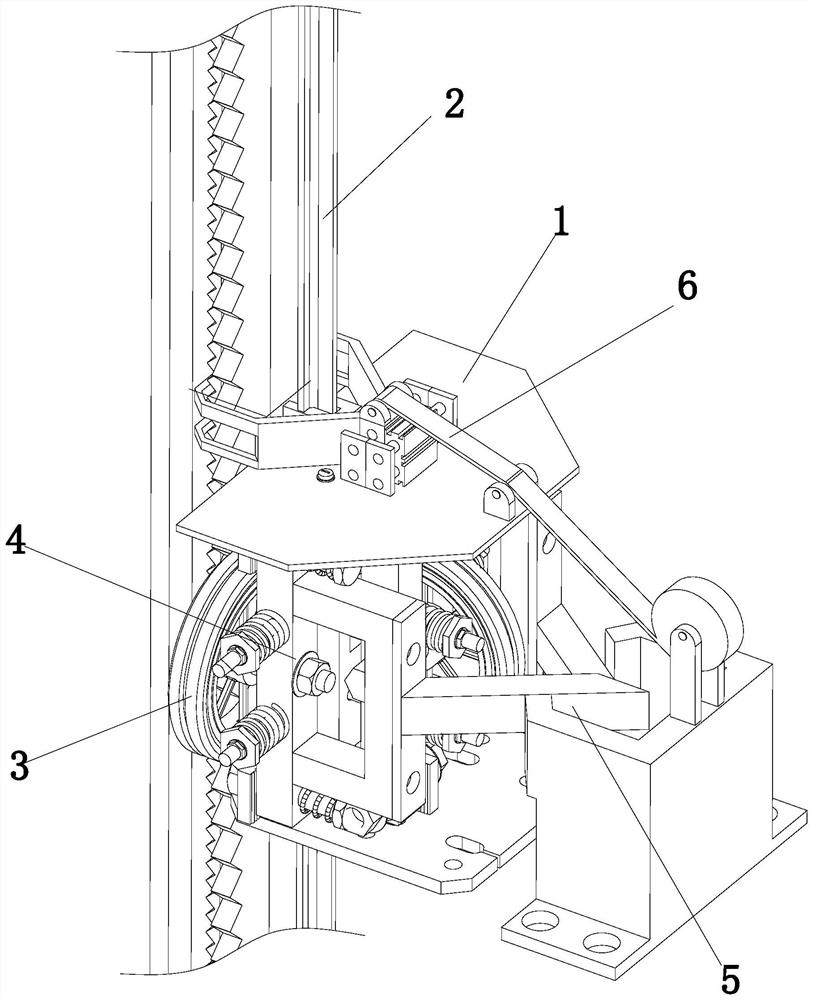

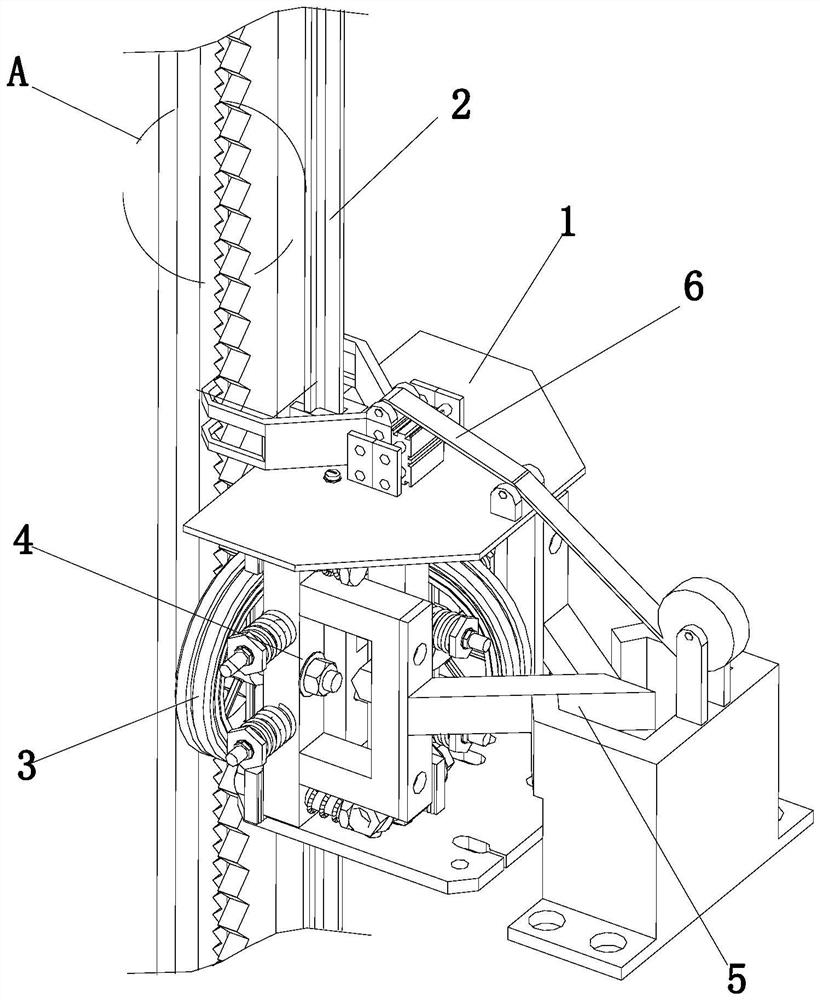

[0062] Please refer to Figure 1-19 , the present embodiment discloses an elevator guide shoe wheel device, including a support frame 1, the support frame 1 includes a horizontally arranged top plate 11 and a bottom plate 12, and several vertical rods 13 are arranged between the top plate 11 and the bottom plate 12, The support frame 1 is fixedly installed on the top of the elevator;

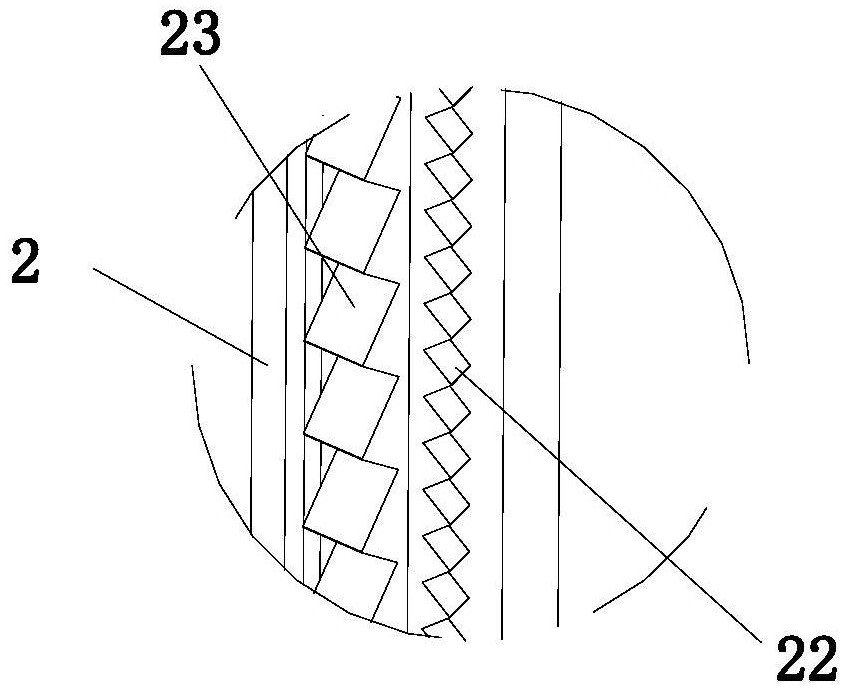

[0063] Further, the guide shoe wheel 3 device also includes a vertical slideway 2 and several guide shoe wheels 3, all guide shoe wheels 3 are slidably matched with the vertical slideway 2, and several abutting mechanisms are arranged on the support frame 1 4. All guide shoe wheels 3 make themselves close to the vertical slideway 2 through the abutting mechanism 4 .

[0064] Further, the abutment mechanism 4 includes a vertical slide bar 41, and several horizontal guide bars 14 are fixedly installed on each vertical bar 13, and the vertical slide bar 41 is simultaneously guided with all horizon...

Embodiment 2

[0074] This embodiment discloses a method for using an elevator guide shoe wheel device, which includes the following steps:

[0075] Step S1: All the guide shoe wheels 3 are slidingly matched with the vertical slideway 2. After long-term use, the distance between the vertical slideway 2 and the guide shoe wheel 3 increases, and the push spring 42 pushes, and the vertical slide bar 41 moves toward the vertical slideway 2, while the limit helical tooth plate 43 and the helical tooth section 47 cooperate to prevent the vertical slide bar 41 from regressing, so that the guide shoe wheel 3 is always attached to the vertical slideway 2; the limit helical tooth plate 43 and the helical tooth section 47, so that the vertical slide bar 41 can only move towards the vertical slideway 2, and cannot retreat, while avoiding that the push spring 42 is compressed for a long time and loses its elastic restoring force, and cannot act on the vertical slideway 2. Situation on rod 41.

[0076]St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com