Full-automatic silk reeling machine for tussah cocoons

A silk reeling machine, fully automatic technology, applied in silk reeling and other directions, can solve the problems of unfavorable cocoon volume and stable cocoon virtuous cycle, the silk reeling machine cannot be continuous and efficient, and the refining effect of the refining mechanism is not good. The effect of fine time, reducing the drift of Zhengxu cocoon, and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

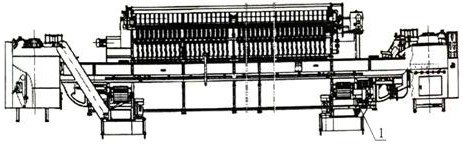

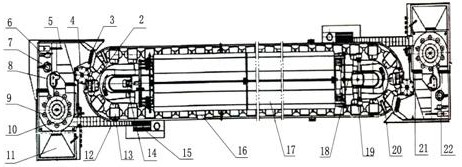

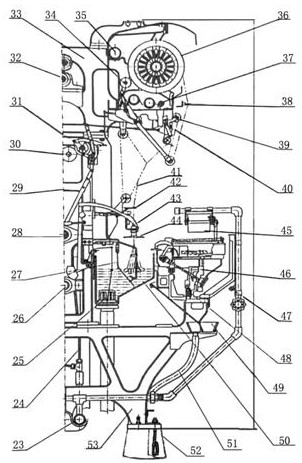

[0060] The longitudinal composition of automatic silk reeling machine of the present invention is as figure 1 , figure 2As shown, a silk reeling machine is equipped with a cable threading machine and a separating machine at each end, and is equipped with an automatic detection mechanism 2, an automatic cocoon adding mechanism 3, a silk braid 4, a triangular wire transfer device 5, a needle catcher 6, and an eccentric Disc finishing mechanism 7, sawtooth sheet roughening mechanism 8, threading mechanism 9, braided transmission box 10, new cocoon replenishing device 11, threaded cocoon conveying device 12, garden gate type separator 15, threadless cocoon transfer bucket 21. There is a threaded cocoon transfer bucket 22; the middle part is the fuselage, including the automatic silk reeling part 17, the cocoon feeding machine 13, the cocoon fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com