A silk reeling rope threading water tank device and temperature control method

A technology of water tank and high temperature area, applied in the direction of silk reeling, etc., can solve the problems of low temperature, loss of sericin, large reeling and folding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

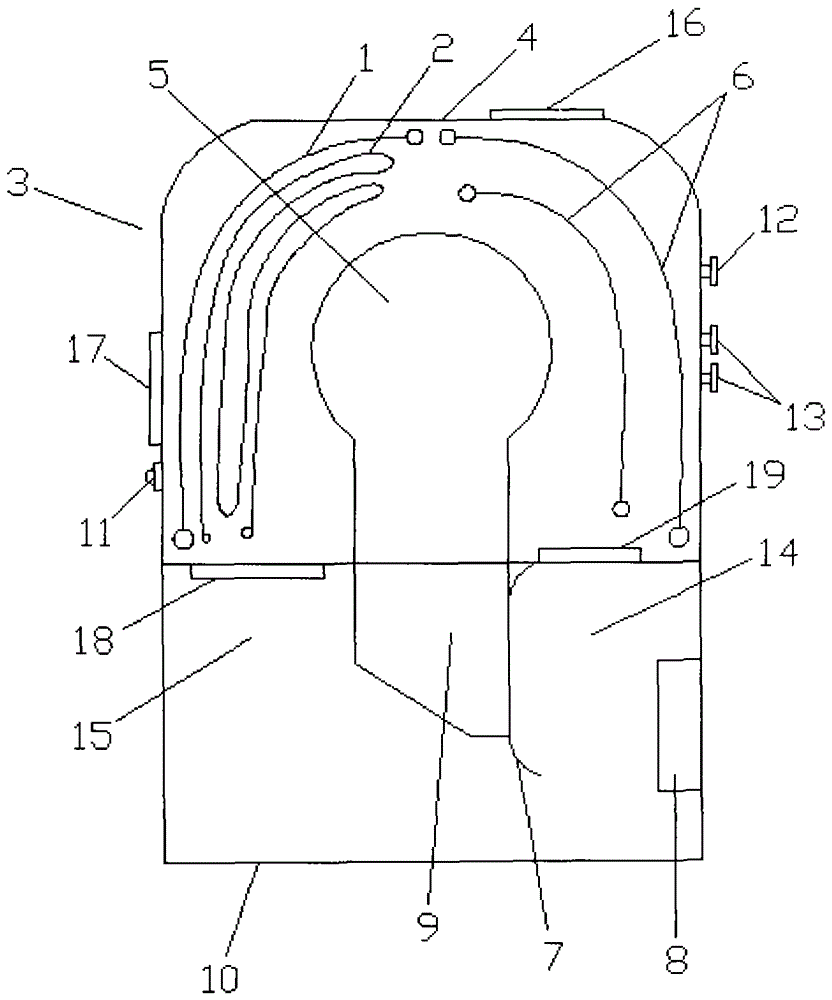

[0015] see figure 1 As shown, a kind of reeling silk threading water tank device, comprises the threading water tank 3 that is made up of threading water tank 4 and threading water tank 10, and the threading device that is respectively arranged on threading water tank 4, threading water tank 10 The installation platform 5 and the installation platform 9 of the threading device, and the steam pipeline arranged at the bottom of the Suoxu water tank 4 divide the Suoxu water tank 4 into two parts, the steam heating pipeline 6 in the low temperature zone and the steam heating pipeline 2 in the high temperature zone, and they are placed in the high temperature zone The temperature-controlled heating pipe 1 next to the steam heating pipe 2, and the thermosensitive electronic switch 11 arranged on the left side of the Suoxu water tank 4 and connected to the power supply, and the electric steam valve 12 arranged on the right side of the Suoxu water tank 4 and the manual The steam valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com