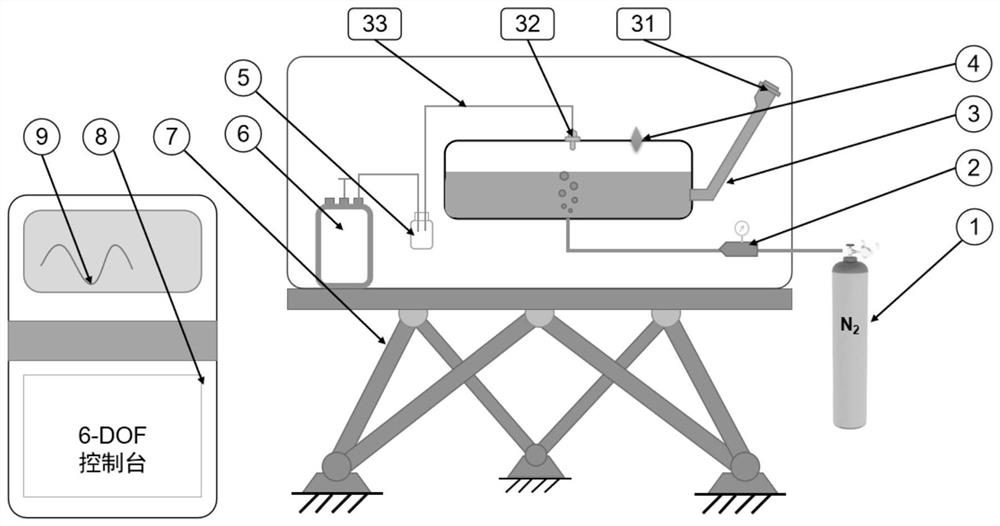

Method for detecting dynamic air permeability of gasoline fuel tank assembly

A detection method and fuel tank technology, applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as reduced working capacity and permanent damage of carbon tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0035] A fuel tank is a device for storing fuel in a vehicle. Due to the volatile nature of gasoline, one or more gravity valves are arranged on the upper surface of the fuel tank assembly during design, so that the fuel tank can be used under any working conditions (stationary or dynamic driving, at any angle). The volatilized oil vapor is discharged into the atmosphere to ensure that the pressure of the fuel tank is not too high. The shape of the fuel tank is generally designed to be irregular according to the layout requirements. Excessive pressure of the fuel tank will cause the deformation of the fuel tank. Generally, the pressure of 10kPa will cause a certain weak position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com