Teaching demonstration equipment for electronic computer software development

An electronic computer and software development technology, which is applied in computing, computer display casing, electrical digital data processing, etc., can solve the problem of sensitivity reduction and achieve the effect of improving fluency and avoiding touch sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

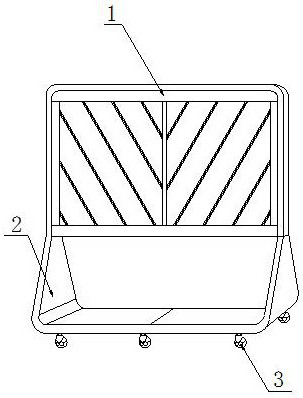

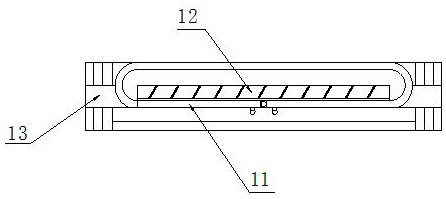

[0030] as attached figure 1 to attach Figure 6 Shown:

[0031] Its structure includes an equipment table 1, a support frame 2, and sliding wheels 3. The bottom of the equipment table 1 is embedded and connected with the top of the support frame 2, the bottom of the support frame 2 is spirally connected with the top of the sliding wheel 3, and the upper end of the sliding wheel 3 Cooperate with the overall clearance of the equipment table 1, the equipment table 1 includes an airtight cover 11, a demonstration frame 12, and a table body 13, the bottom of the table body 13 is embedded and connected with the top of the support frame 2, and the inner wall of the airtight cover 11 is connected to the demonstration frame 12, the outer wall is embedded and connected, and the demonstration frame 12 is integrally fitted with the internal clearance of the table body 13, and the inner surface of the table body 13 is embedded and connected with the outer wall of the airtight cover 11.

...

Embodiment 2

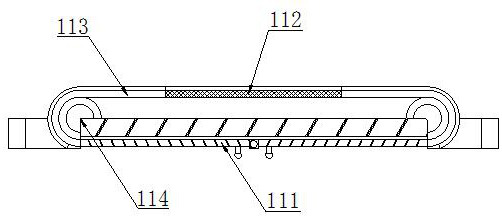

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] Wherein, the demonstration stand 12 includes an all-in-one machine 121, a display screen frame 122, and a radiator 123. The all-in-one machine 121 is integrally matched with the surface of the platform body 13, and the outer wall of the all-in-one machine 121 is embedded and connected with the inner wall of the airtight cover 11. The surface of the all-in-one machine 121 is engaged with the surroundings of the display screen frame 122, and the inner side of the display screen frame 122 is positively matched with the radiator 123. Both ends of the radiator 123 are bolted to the back end of the all-in-one machine 121. The radiator 123 is composed of three cooling fans. The cooling fan in the middle is used as a suction fan, and the left and right sides are exhaust fans. The two ends of the radiator 123 are fixed to the back of the all-in-one machine 121 with bolts. The internal heat circulation enables the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com