Lifter ejector pin linkage mechanism

A technology of linkage mechanism and inclined top spring, which is applied in the field of injection molds, can solve the problems of speeding up the demoulding speed and difficulty of demoulding, and achieve the effect of improving the demoulding rate, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

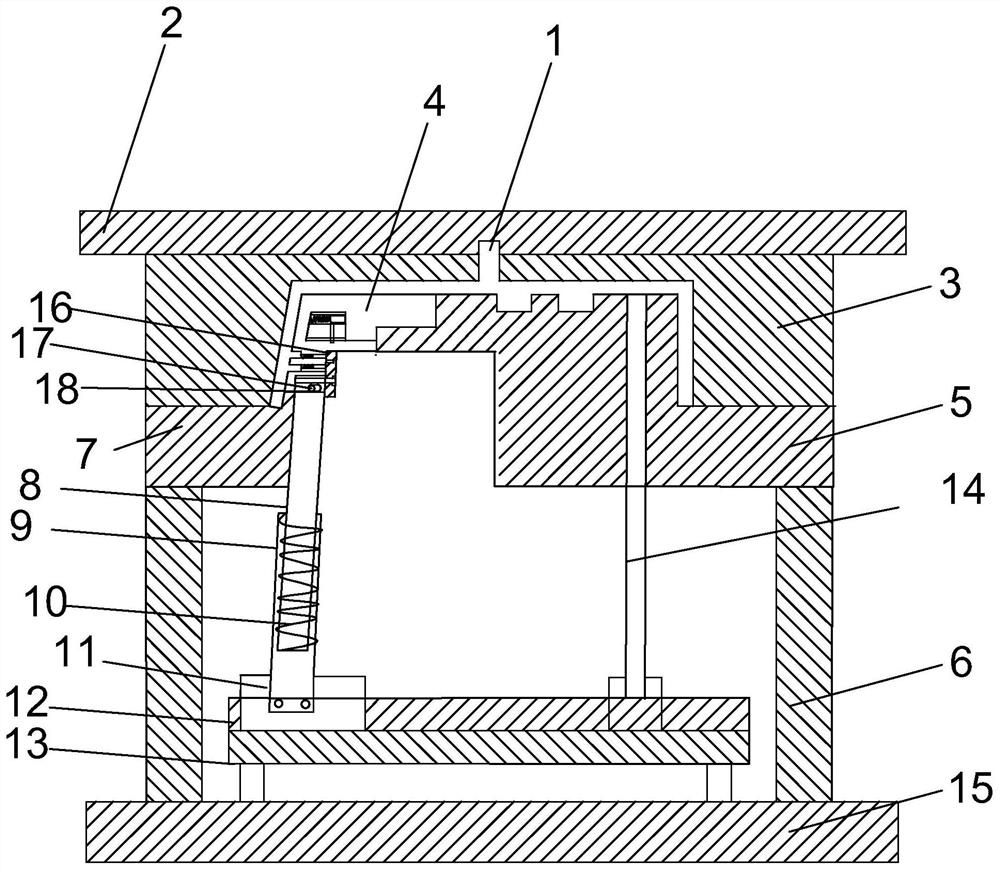

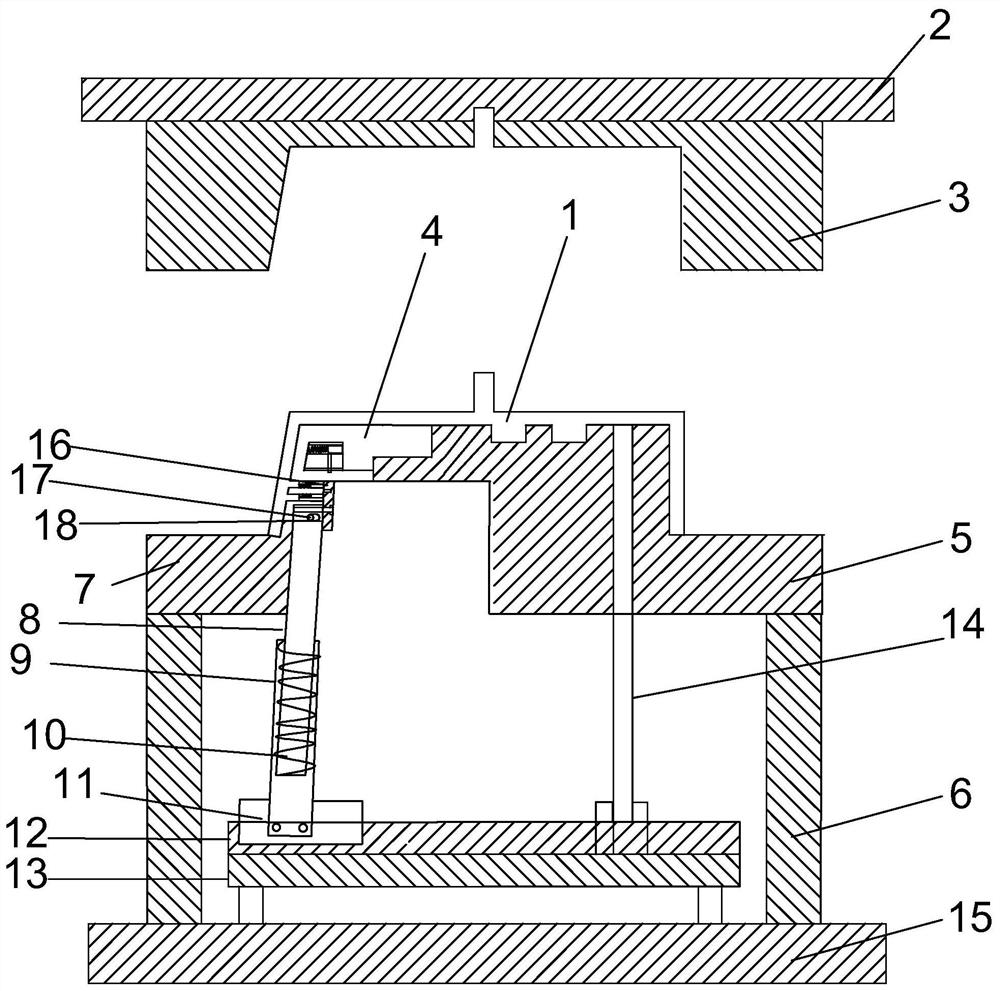

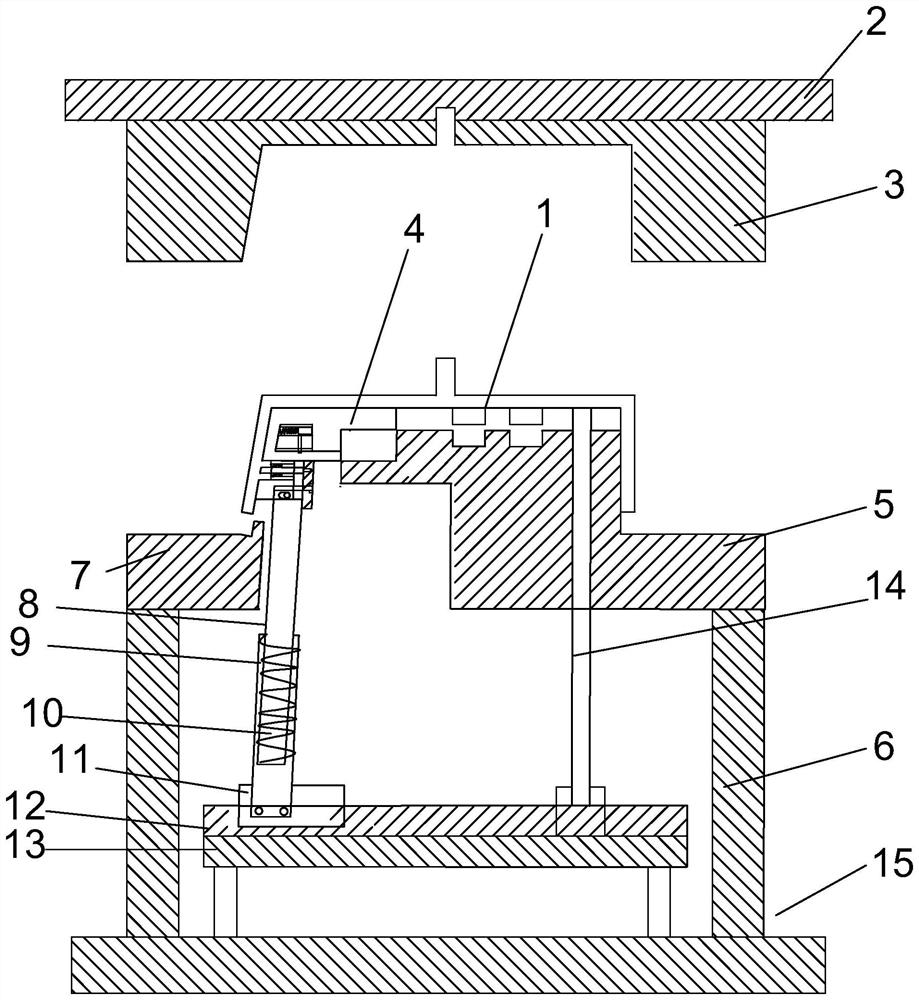

[0025] This embodiment proposes a kind of linkage mechanism of inclined ejector pin, refer to figure 1, comprising a slanted top block 4, the bottom of the slanted top block 4 is connected with a first slanted top rod 8, the top of the first slanted top rod 8 is provided with a limit nut 17, and the bottom of the slanted top block 4 is provided with a waist-shaped stop hole 18, the limit The nut 17 is slidably connected to the waist-shaped limiting hole 18, and the second inclined ejector rod 9 is provided at the lower part of the first inclined ejector rod 8. Sliding block 4 is provided with slide tube 41, and slide tube 41 is provided with drive spring 43 inside, and one end of drive spring 43 is provided with and contacts with the inner wall of slant block 4, and the other end of drive spring 43 is fixedly connected with guide block 42, guides The bottom of the block 42 is provided with a guide rod 44 , and the bottom of the guide rod 44 is slidably connected to the waist-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com