Quantitative weighing equipment for flour

A technology of equipment and flour, applied in the direction of solid materials, packaging automatic control, packaging, etc., can solve the problem of low weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

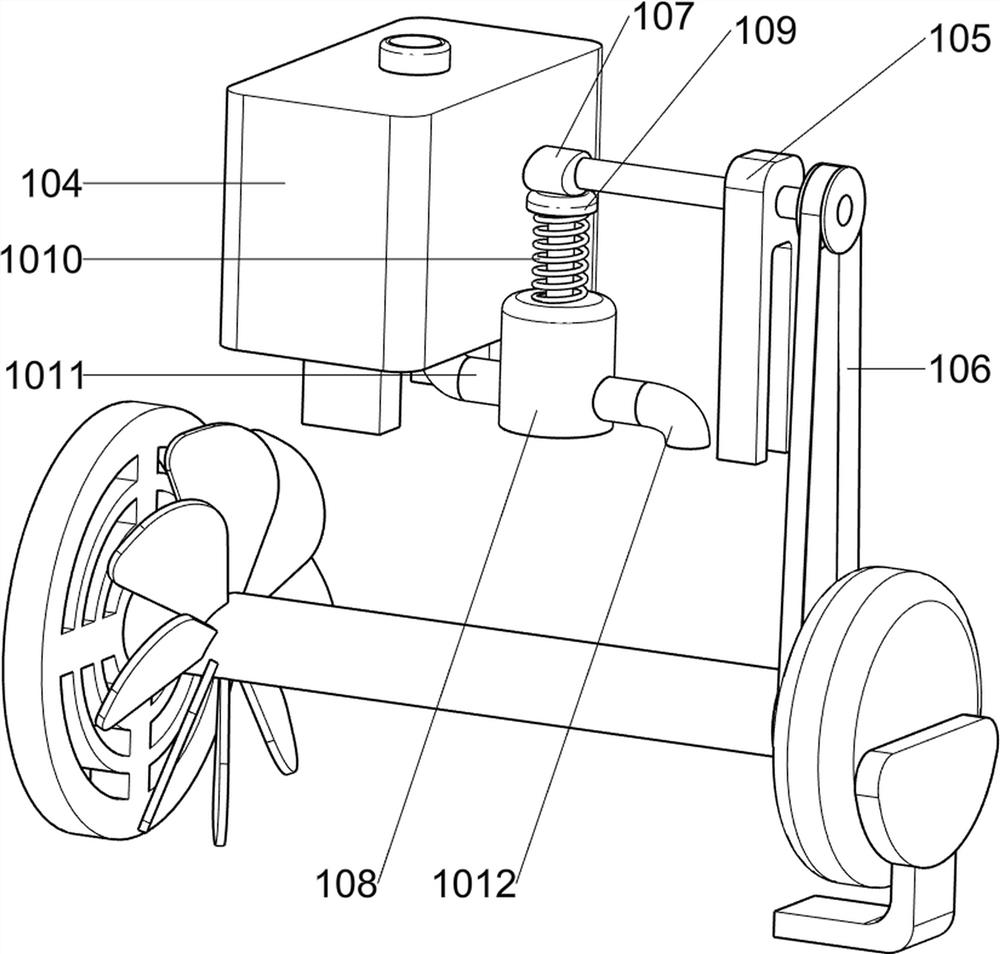

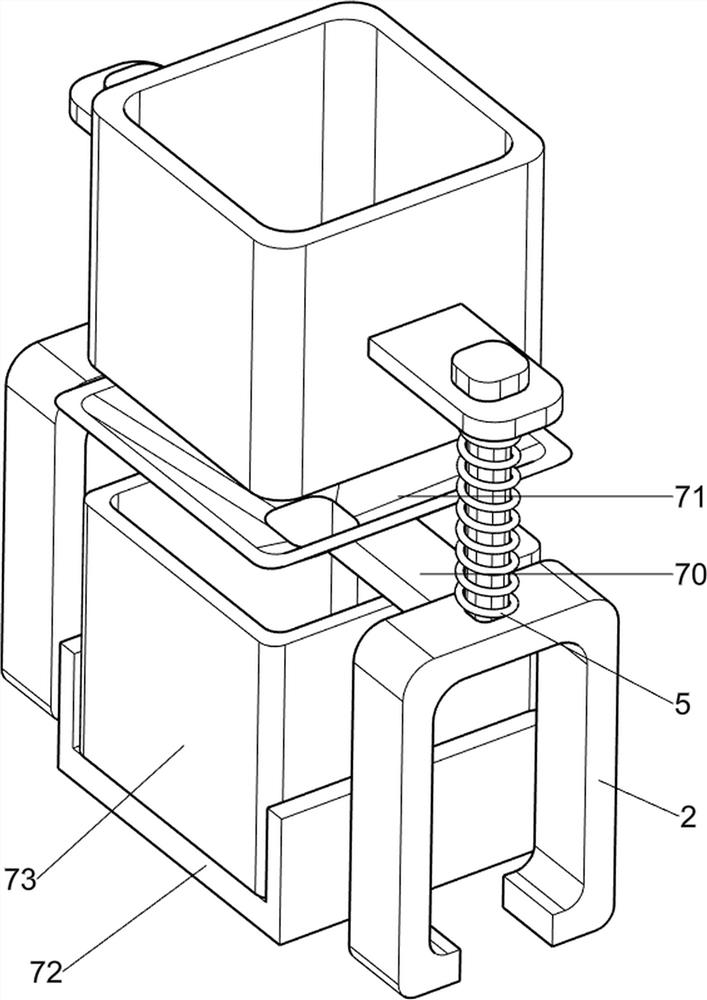

[0030] A quantitative weighing device for flour, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first mounting block 2, a second mounting block 3, a first charging box 4, a first spring 5, a first slider 51, a sliding mechanism 6 and a charging mechanism 7, and the top right of the base 1 The first installation block 2 is arranged symmetrically on the front and rear sides, the top of the first installation block 2 is provided with the second installation block 3, and the first loading box 4 is provided slidingly between the second installation blocks 3, and the first loading box 4 The first spring 5 is set between the first mounting block 2, the first spring 5 is sleeved on the second mounting block 3, the bottom of the first loading box 4 is slidingly provided with a first slider 51, and the base 1 The top is provided with a sliding mechanism 6, and the top of the base 1 is provided with a charging mechanism 7.

[0031] The sliding mechanism 6 ...

Embodiment 2

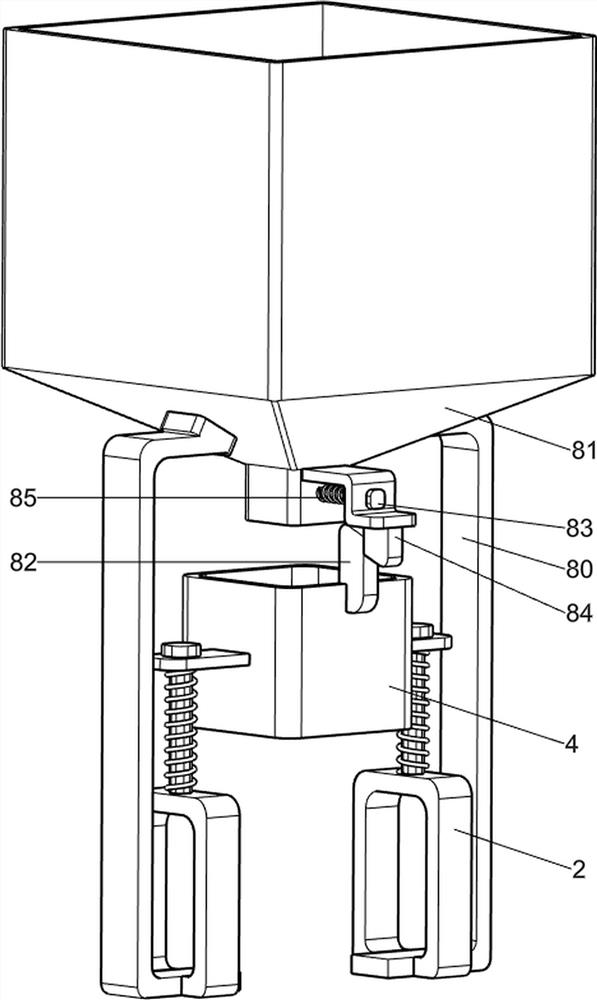

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a blanking mechanism 8, and the blanking mechanism 8 includes the seventh mounting block 80, the third charging box 81, the first wedge block 82, the eighth mounting block 83, the second wedge block 84 and the second spring 85, the top right side of the base 1 is symmetrically provided with a seventh mounting block 80 front and back, a third charging box 81 is arranged between the top of the seventh mounting block 80, and a first wedge-shaped block 82 is provided on the left side of the first charging box 4 , the left side of the lower part of the third charging box 81 is provided with an eighth mounting block 83, and the eighth mounting block 83 is slidably provided with a second wedge-shaped block 84, and the second wedge-shaped block 84 slides at the bottom of the third charging box 81 , A second spring 85 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com