Stir-frying mechanism for tea production

A stir-frying mechanism and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of reducing tea production efficiency, not being able to fry tea, and affecting the appearance of tea, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

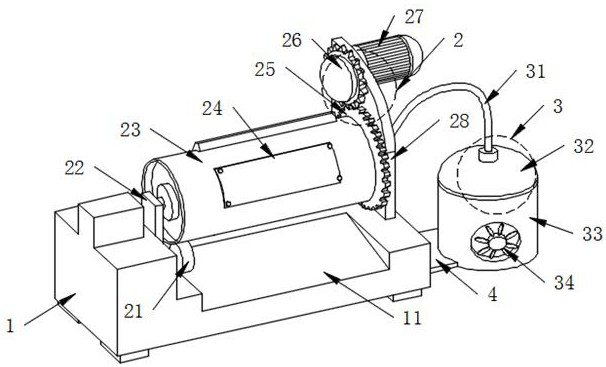

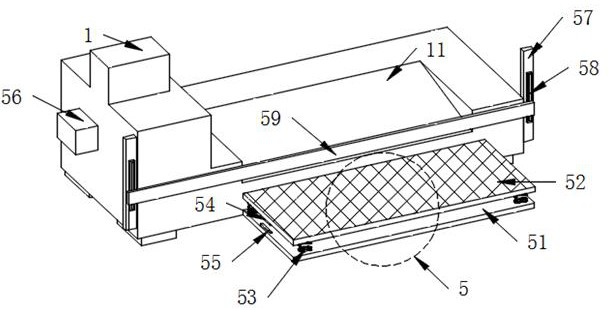

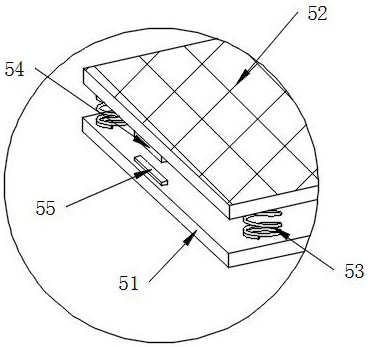

[0028] Such as Figure 1-5 As shown, the specific implementation method is:

[0029] The invention provides a stir-frying mechanism for tea production, which includes a stir-frying mechanism 2 arranged on a base 1 and a heating mechanism connected to the stir-frying mechanism 2. A stir-frying mechanism 3 for tea production. The stir-frying mechanism 2 includes a stirrer Stir-fry tube 23, the both sides of base 1 are respectively fixedly installed organic plate one 22, machine plate two 28, and stir fry tube 23 is installed on machine plate one 22, machine plate two 28 by bearing rotation simultaneously, and stir-fry tube 23 is near machine One side of plate two 28 is fixedly installed with driven gear 25, and drive gear 26 is installed by bearing rotation on machine plate two 28, and driving gear 26 is meshed with driven gear 25 simultaneously, and machine plate two 28 is fixedly installed with motor one 27. At the same time, the main shaft of the motor one 27 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com