Construction method for breaking SMW construction method pile tunnel portal through pipe jacking construction

A construction method and technology of construction method piles, which are applied in the fields of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of high safety risk, the risk of collision with operators, and risk reduction, so as to achieve a reasonable frame structure and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

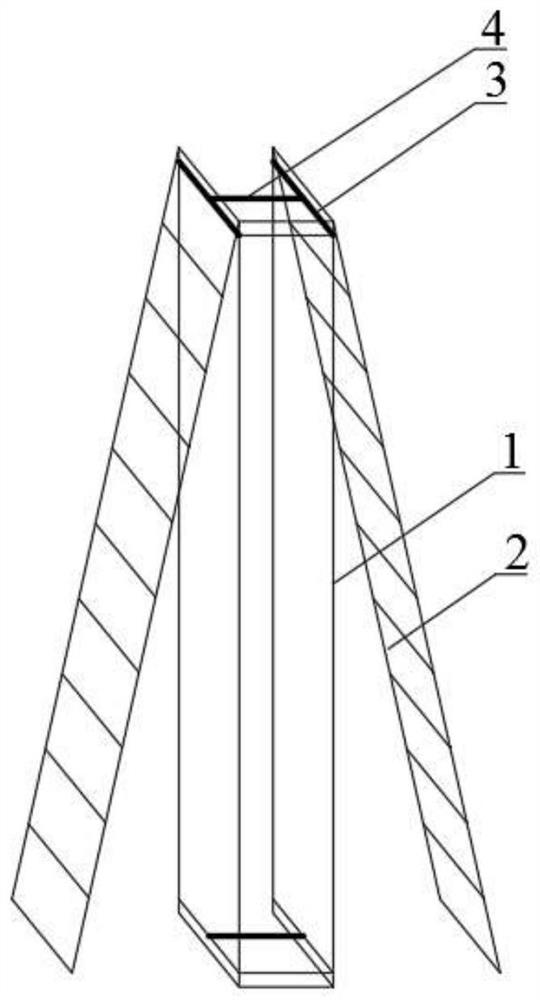

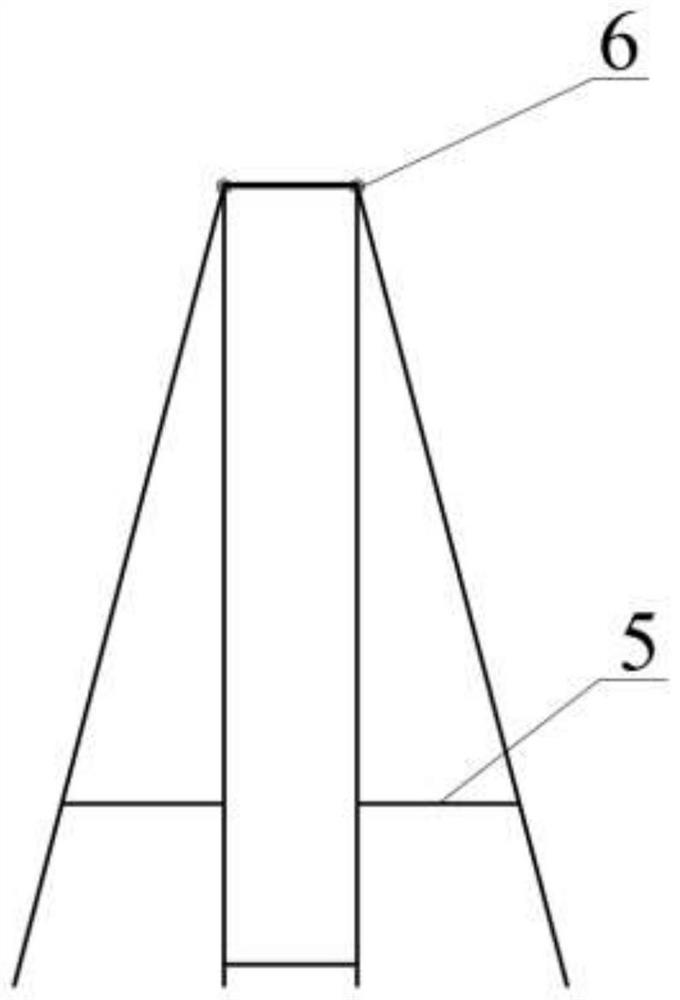

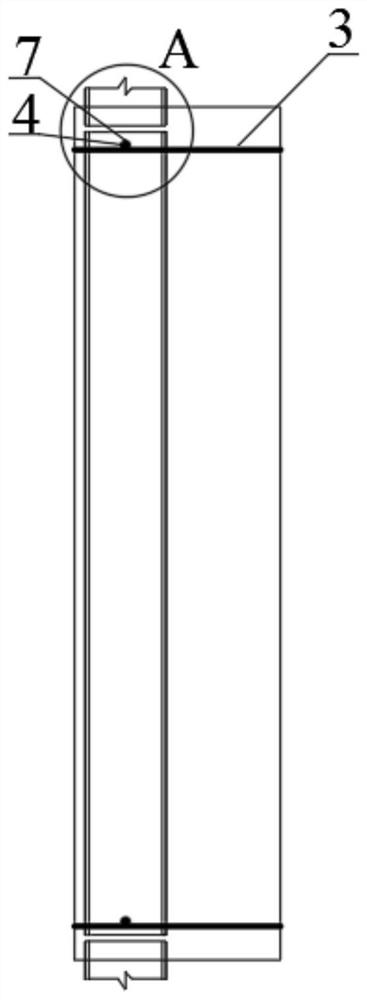

[0027] Such as Figure 1-Figure 3 As shown, a construction method for pipe jacking construction to break the SMW pile opening, the method depends on the mobile frame used for pipe jacking construction to break the SMW pile opening, the mobile frame includes a main frame body whose inner cavity can accommodate H-shaped steel 1. The ladder 2 is movably connected to both sides of the top of the main frame body 1. One end of the main frame body 1 is open, and the upper and lower ends of the two sides adjacent to the open end are fixedly connected with longitudinal ribs 3, and the two opposite longitudinal ribs 3 are flexibly connected. The bearing pin 4 that is arranged transversely.

[0028] Wherein, the length of the main frame body 1 is 2.5 to 3 times of the length of the H-shaped steel, which ensures that the H-shaped steel can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com