Through shaft type remote control pressing plate and remote control method thereof

A technology of penetrating shaft and pressing plate, applied in general control system, program control, computer control, etc., can solve the problems of motor stall, low control precision, wear and so on, and achieve the effect of high reliability and simple transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

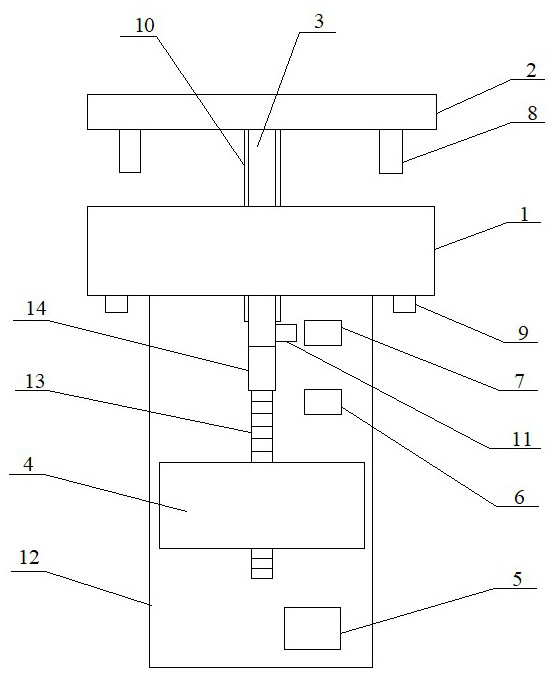

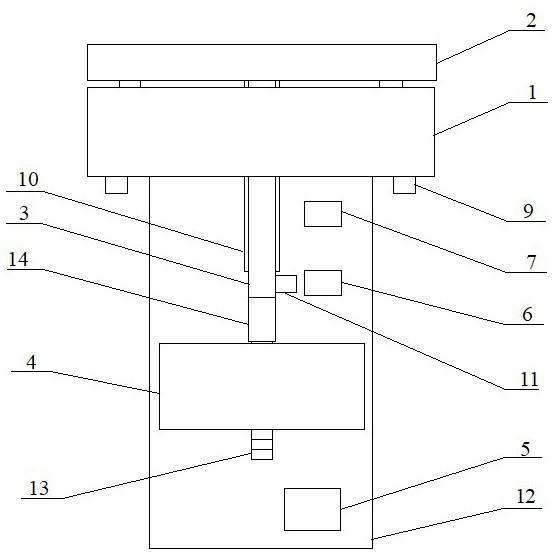

[0028] Such as Figure 1~2 As shown, a through-axis remote control platen includes a platen body and an intelligent control component. The platen body includes a platen base 1, a platen handle 2 and a platen connecting rod 3. The intelligent control component includes a through-axis stepper motor 4. Control circuit 5, cast state detection circuit 6 and retreat state detection circuit 7; a through hole is set in the center of the platen base 1, and the lower end of the platen connecting rod 3 passes through the through hole, and is connected with the platen through the screw structure. The through-shaft stepping motor 4 is connected, and the pressure plate handle 2 is arranged on the upper end of the pressure plate connecting rod 3; the control circuit 5 controls the rotation of the through-shaft stepping motor 4 according to the remote control signal to drive the pressure plate connecting rod 3. Move up and down to carry out the back and forth operation of the pressing plate. ...

Embodiment 2

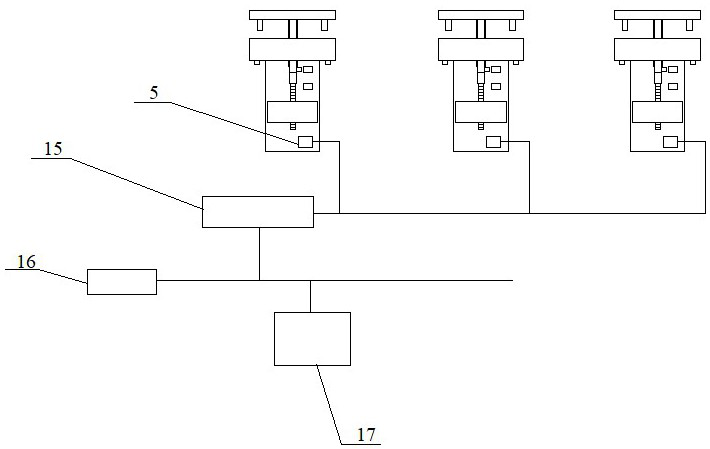

[0035] A remote control method for the through-shaft remote control platen, comprising the following steps:

[0036] The host computer in the monitoring center or operation and maintenance center station sends control commands to the control circuit;

[0037] The control circuit outputs control signals to the through-axis stepping motor, and the through-axis stepping motor rotates forward or reverse according to the control signal, driving the connecting rod of the pressure plate to move upward or downward, and the through-axis stepping motor rotates according to the signal After stopping at a specific angle, the connecting rod of the pressure plate moves up or down to the exit or input position of the pressure plate;

[0038] The bumps on the connecting rod of the pressure plate correspond to the detection circuit of the throwing state or the detection circuit of the retreating state to realize the detection of the state of the pressure plate, and the state signal of the pres...

Embodiment 3

[0040] Such as Figure 1~3 As shown, a through-axis remote control platen includes a platen body and an intelligent control component. The platen body includes a platen base 1, a platen handle 2 and a platen connecting rod 3. The intelligent control component includes a through-axis stepper motor 4. Control circuit 5, cast state detection circuit 6 and retreat state detection circuit 7; a through hole is set in the center of the platen base 1, and the lower end of the platen connecting rod 3 passes through the through hole, and is connected with the platen through the screw structure. The through-shaft stepping motor 4 is connected, and the pressure plate handle 2 is arranged on the upper end of the pressure plate connecting rod 3; the control circuit 5 controls the rotation of the through-shaft stepping motor 4 according to the remote control signal to drive the pressure plate connecting rod 3. Move up and down to carry out the back and forth operation of the pressing plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com