Pressing plate throwing and withdrawing device, pressing plate throwing and withdrawing mechanism, and pressing plate throwing and withdrawing control system

A pressing plate and driving motor technology, which is applied in the field of substation operation and maintenance, can solve problems such as violation of maintenance circuit safety regulations, device damage, misoperation or failure, and achieve the effect of lower workload and operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

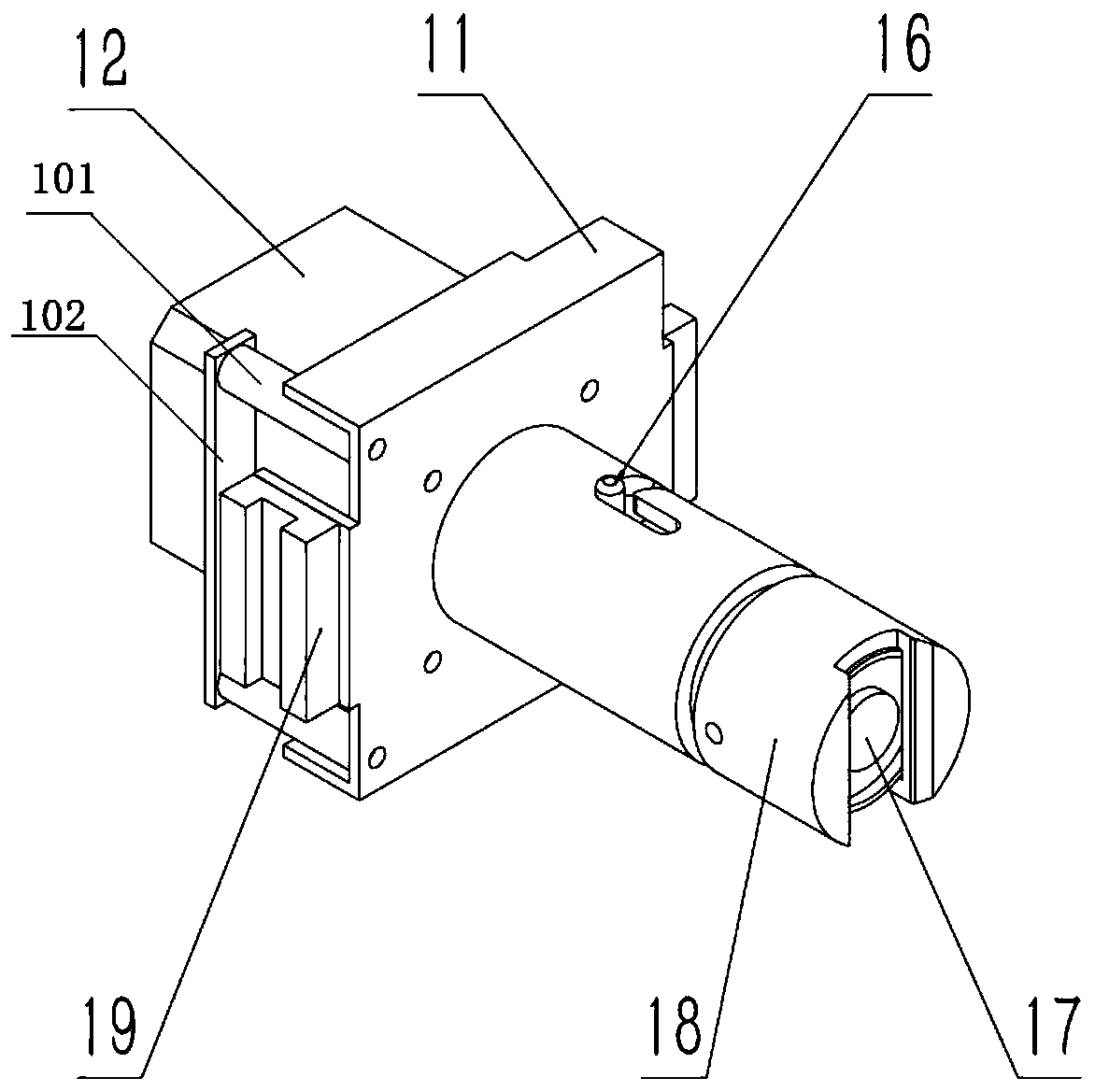

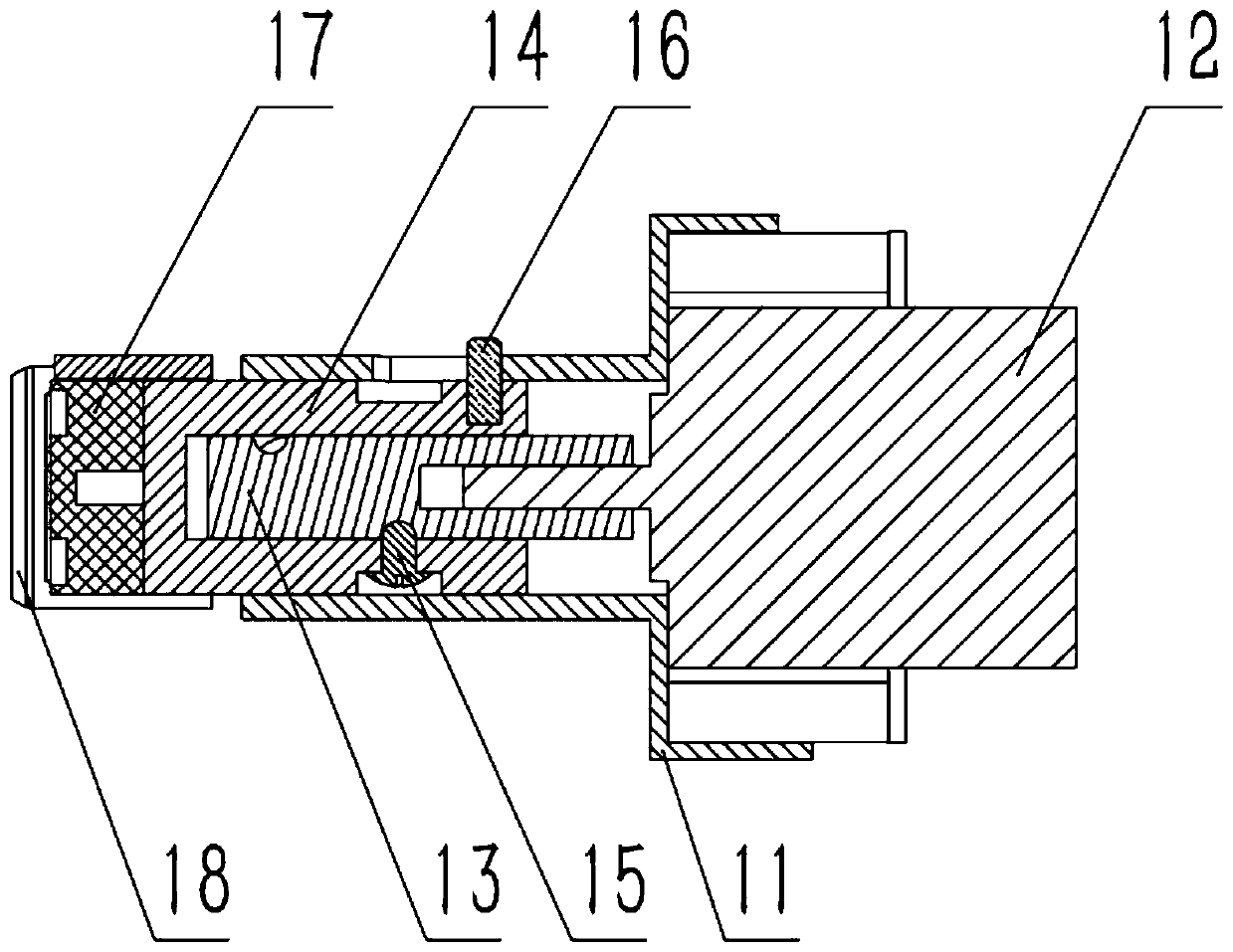

[0053] refer to Figure 1 to Figure 3 As shown, this embodiment is a pressure plate ejector 1, which includes a base 11, an ejection and retraction drive motor 12, an electromagnet 17 and a transmission assembly, the ejection and retraction drive motor is installed on the base 11, and the electromagnet 17 passes through the transmission assembly. The output shaft of the drive motor 12 is driven and connected by transmission; the base 11 includes a casing extending to the outer periphery of the motor output shaft, and the casing is provided with a guide rail groove;

[0054] The transmission assembly includes a piston 14. One end of the piston 14 is rotatably connected to the output shaft of the throwing and retracting drive motor, and the other end is fixedly connected to the electromagnet 17. The piston 14 is fixed with a guide pin 16 that can move along the guide rail groove, and the piston 14 passes through the guide pin 16. Slide to connect the housing.

[0055] When the ...

Embodiment 1-1

[0057] Based on Embodiment 1, in this embodiment:

[0058] The transmission assembly also includes a threaded rod 13 with an external thread, and one end of the threaded rod 13 is fixedly connected to the output shaft of the driving motor 12 for throwing and retracting; the piston 14 is hollow and has an open end, and the inner part of the piston 14 is provided with an external thread to match the external thread of the threaded rod. The threaded pin 15 is provided, so that the rotation of the threaded rod 13 can drive the piston 14 to rotate or move in the axial direction in a state where the circumferential movement is restricted. The output shaft of the throwing and retracting drive motor forms a worm drive structure between the threaded rod and the piston, so that the rotation of the motor output shaft can be converted into the axial linear movement of the piston or follow the rotation in the state of unrestricted outer circumference.

[0059] The threaded rod 13 , the pis...

Embodiment 2

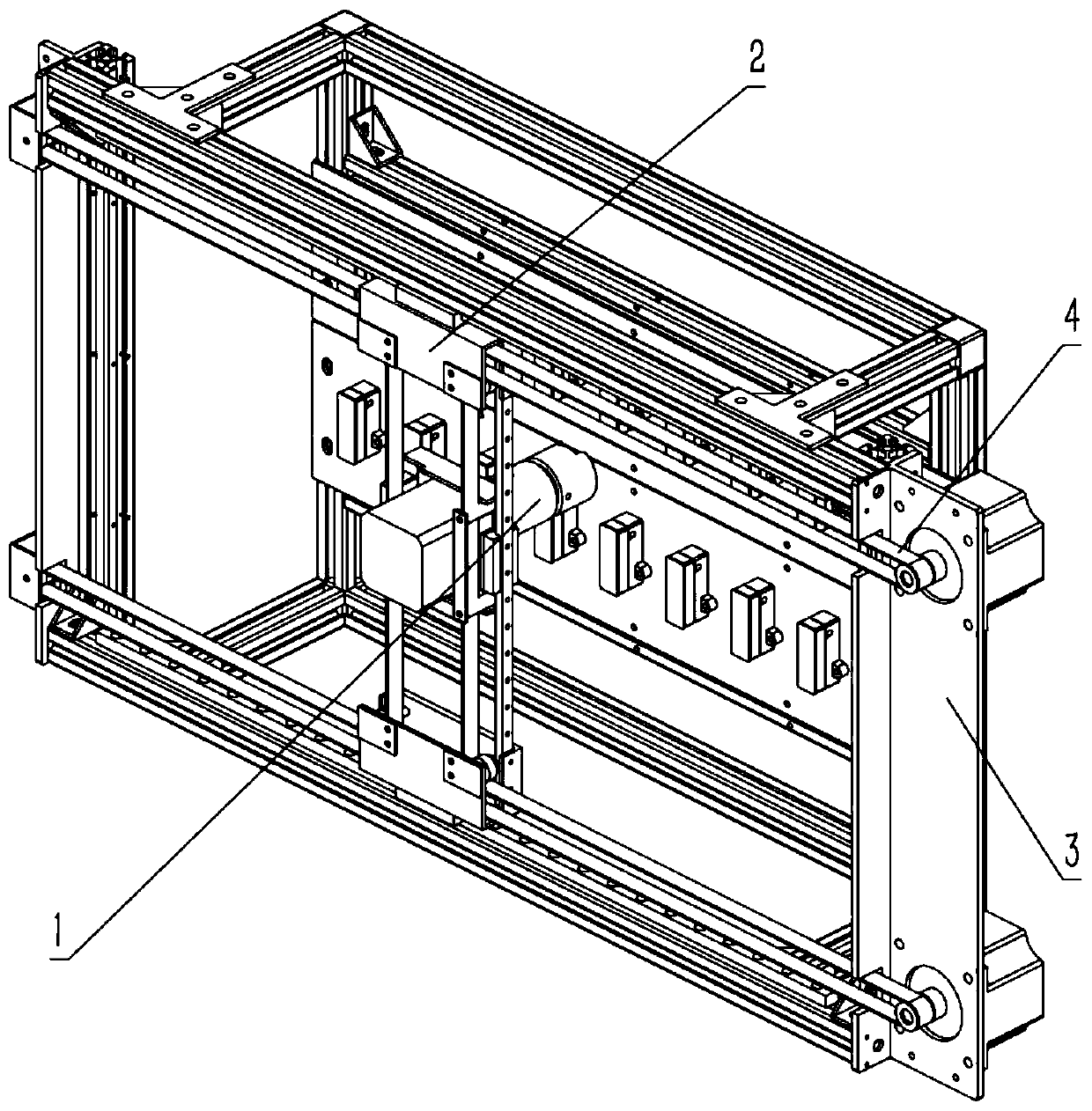

[0066] Based on Example 1, combined with Figure 1 to Figure 5 ,in particular figure 1 , this embodiment is a pressure plate throwing and retracting mechanism based on the pressure plate throwing and retracting device in the first embodiment, including a frame 3, a pressure plate throwing and withdrawing device 1 and a mobile driving unit for the throwing and withdrawing device; any one of the embodiments; the ejector mobile drive unit includes a mobile drive motor, a transmission timing belt 4 and a mobile pair 2;

[0067] refer to Figure 5 As shown, there are at least two mobile drive motors, which are respectively installed on both sides of the frame 3 or both ends on the same side, and an output synchronizing wheel 36 is installed on the output shaft. The four corners of the frame are not installed to move The corners of the driving motor are respectively installed with frame synchronizing wheels 37;

[0068] The frame is provided with at least one linear transverse gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com