Electromagnetic press-type automatic putting and exiting press plate

A push-type, electromagnetic technology, applied in the field of electric power, can solve the problems that the electric pressure plate cannot be manually switched on and off, the threat to the personal safety of the operator, and the structure of the electric pressure plate is complicated, etc., and achieves the effect of wide applicability, simple structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

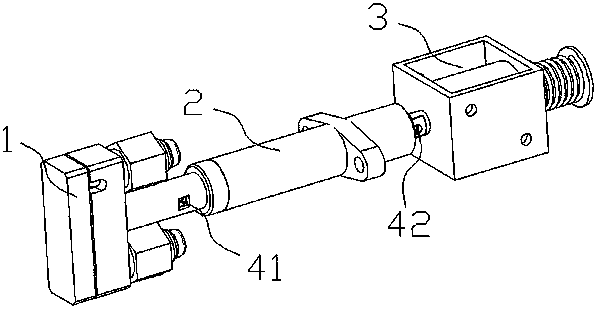

[0045] An electromagnetic pressing type automatic throwing and retreating pressure plate, such as figure 1 As shown, along the overall axial direction of the mechanism, it consists of a pressing plate mechanism 1, a pressing action mechanism 2 and an electromagnetic pressing mechanism (push-pull electromagnet 3). The rear end of the pressing plate mechanism 1 is fixedly connected with the front end of the pressing action mechanism 2 by bolt I41; the rear end of the pressing action mechanism 2 is fixedly connected with the front end of the push-pull electromagnet 3 by bolt II42. The central axes of the pressing plate mechanism 1, the pressing action mechanism 2 and the push-pull electromagnet 3 coincide.

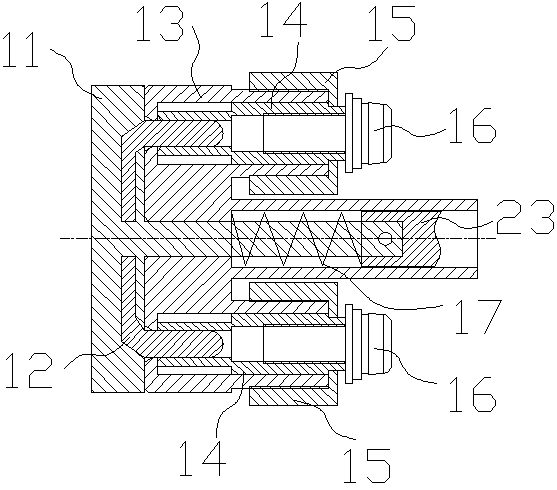

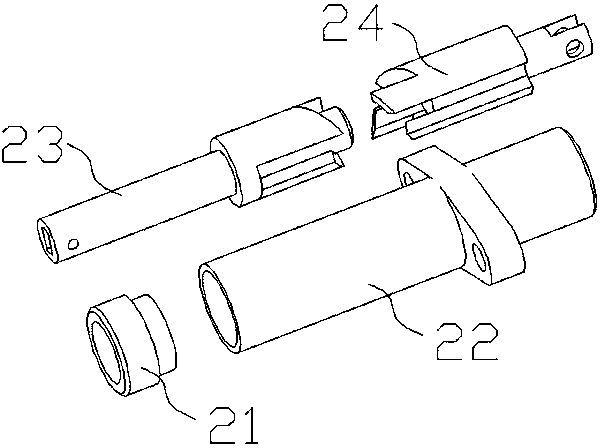

[0046] Such as figure 2 As shown, the pressing plate mechanism 1 is composed of a moving plate and a fixed plate; the moving plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com