Servo motor and robot

A servo motor and connector technology, applied in the field of robotics, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

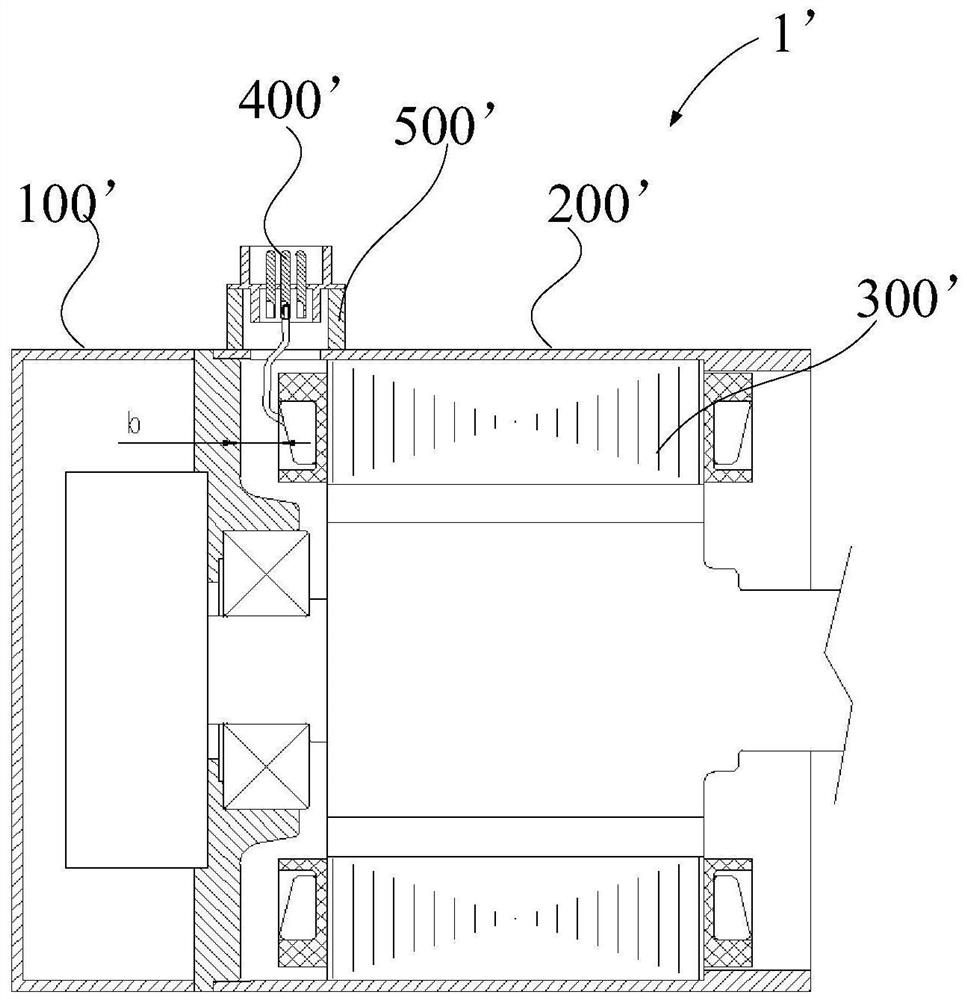

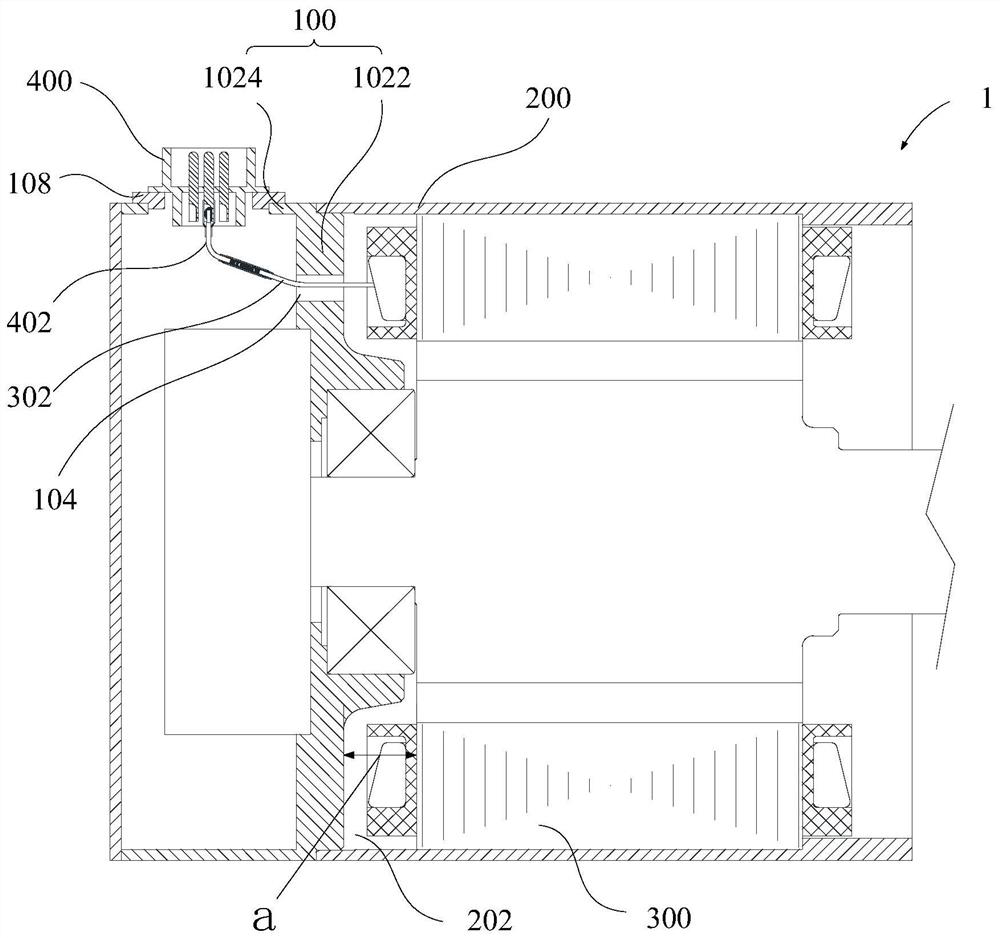

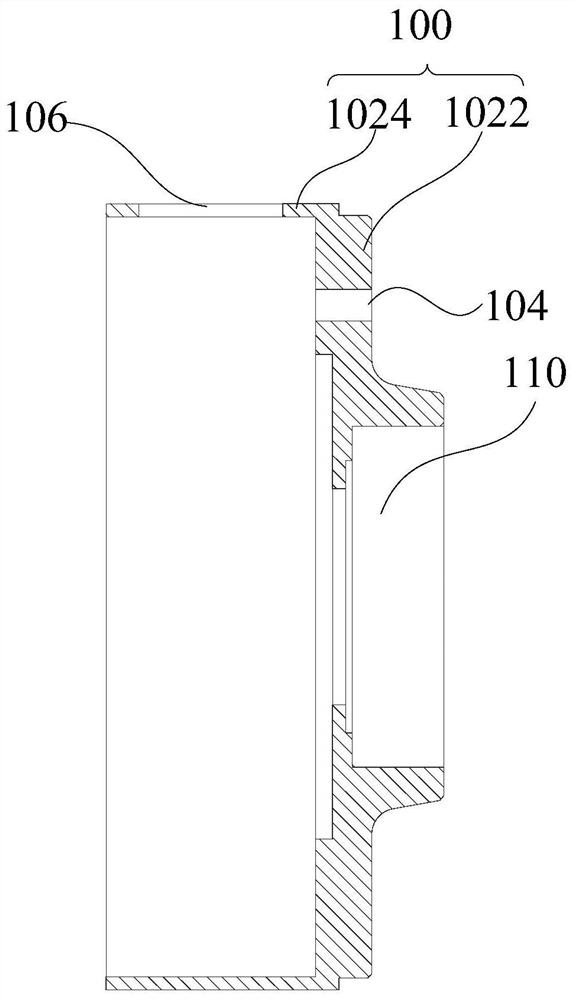

[0048] One embodiment of the present invention proposes a servo motor 1, such as Figure 2 to Figure 3 As shown, the servo motor 1 includes an end cover 100 , a through hole 104 and a mounting hole 106 opened on the end cover 100 , a connector 400 and a stator winding 300 .

[0049] Specifically, the through hole 104 is provided at the end of the end cover 100 to lead out the first cable 302 of the stator winding 300 . The installation hole 106 is provided on the end cover 100 and functions to install the connector 400 .

[0050] The servo motor 1 provided by the present invention, such as Figure 2 to Figure 3 As shown, by providing a through hole 104 communicating with the installation cavity 202 of the housing 200 on the end cover 100 , the first cable 302 of the stator winding 300 can be led out to the outside of the housing 200 . Further, the connector 400 is installed in the installation hole 106 through the installation hole 106 provided on the end cover 100, so that ...

specific Embodiment

[0072] The application provides a servo motor 1, such as Figure 2 to Figure 6 As shown, the servo motor 1 includes an end cover 100 and a housing 200 , as well as a stator winding and a connector 400 . Specifically, it includes a through hole 104 provided at the end of the end cover 100 and a mounting hole 106 on a side wall of the end cover 100 . The end cover 100 and the housing 200 enclose the installation cavity 202, the stator winding 300 is installed in the installation cavity 202, the through hole 104 communicates with the installation cavity 202, and the first cable 302 of the stator winding 300 is led out to the housing through the through hole 104 200, the connector 400 is installed on the mounting hole 106 of the end cover 100 through the connecting flange 108, and the second cable 402 of the connector 400 is connected with the first cable 302 of the stator winding 300 on the outside of the housing 200. .

[0073] Specifically, such as figure 2 , Figure 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com