Light beer as well as preparation method and preparation device thereof

A light color, beer technology, applied in the direction of beer brewing, etc., can solve the problems of heavy water, weak taste, unsuitable for pursuing high-quality drinks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

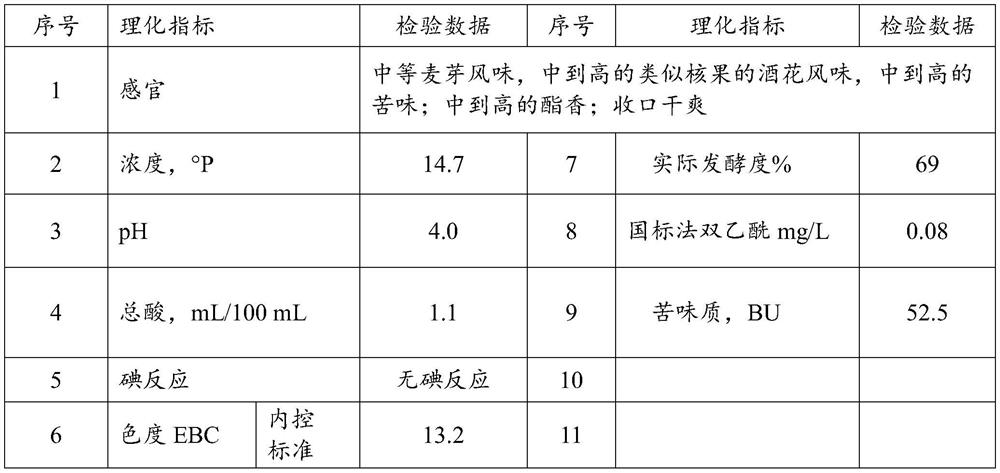

Embodiment 1

[0041] 170kg of light-colored Pilsner malt, 80kg of Munich malt, 12kg of red malt, and 10kg of dark-colored caramel malt were mixed and crushed to obtain ground malt; wherein, during the step of obtaining ground malt, the grinding included double-roll grinding, and the distance between the rolls The value range is 0.30mm, and the value range of the distance between the rollers can ensure that the state of the obtained pulverized product is: the wheat husk is broken but not broken, and the endosperm is very finely pulverized.

[0042] The crushed malt is slurried, saccharified, and wort filtered in sequence to obtain clear wort. Among them, the standard leaching method saccharification process, the ratio of material to water is 1:3.5, the material is cut at 50°C, and the temperature is kept for 20 minutes. Raise the temperature to 60°C and keep it warm for 30min. Raise the temperature to 70°C until the iodine test is qualified. The temperature is raised to 78°C and the wort i...

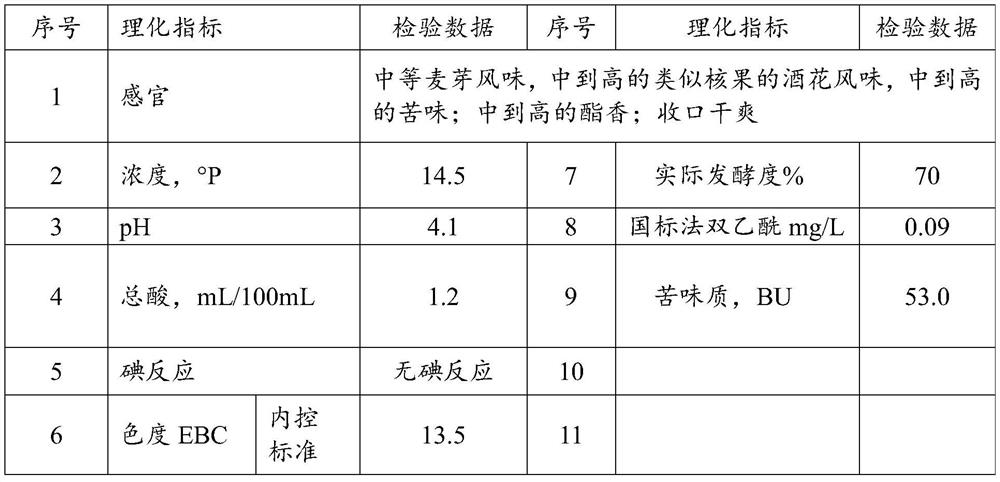

Embodiment 2

[0048] 160kg of light-colored Pilsner malt, 70kg of Munich malt, 8kg of red malt, and 5kg of dark-colored caramel malt were mixed and crushed to obtain a malt crushed product; wherein, during the step of obtaining the malt crushed product, the crushing included double-roll crushing, and the distance between the rollers The value range is 0.31mm, and the value range of the roller spacing can ensure that the state of the obtained pulverized product is: the wheat husk is broken but not broken, and the endosperm is very finely pulverized.

[0049] The crushed malt is slurried, saccharified, and wort filtered in sequence to obtain clear wort. Among them, the standard leaching method saccharification process, the ratio of material to water is 1:3, the material is cut at 45°C, and the temperature is kept for 15 minutes. Raise the temperature to 60°C and keep it warm for 30min. Raise the temperature to 72°C until the iodine test is qualified. The temperature is raised to 78°C and th...

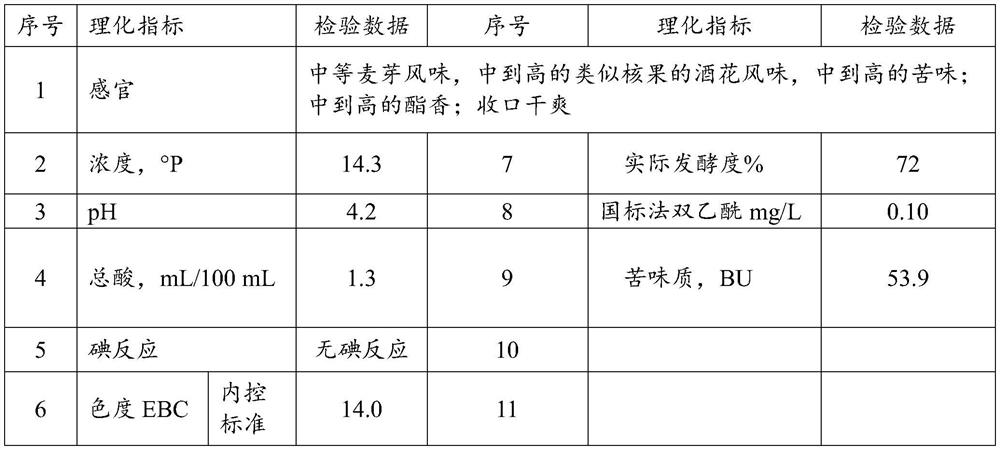

Embodiment 3

[0055] 180kg of light-colored Pilsner malt, 90kg of Munich malt, 16kg of red malt, and 15kg of dark-colored caramel malt were mixed and crushed to obtain a ground malt product; wherein, during the step of obtaining the ground malt product, the grinding included double-roll crushing, and the distance between the rolls The value range is 0.32mm, and the value range of the roller spacing can ensure that the state of the obtained pulverized product is: the wheat husk is broken but not broken, and the endosperm is very finely pulverized.

[0056] The crushed malt is slurried, saccharified, and wort filtered in sequence to obtain clear wort. Among them, the standard leaching method saccharification process, the ratio of material to water is 1:3.5, the material is cut at 45°C, and the temperature is kept for 30 minutes. Raise the temperature to 60°C and keep it warm for 35 minutes. Raise the temperature to 72°C until the iodine test is qualified. The temperature is raised to 78° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com