Grouting pipe construction method for post grouting of cast-in-place pile

A construction method and grouting pipe technology, which are applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high grouting pressure, failure to open grouting holes, and failure to reach grouting volume, etc. Large grouting space and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

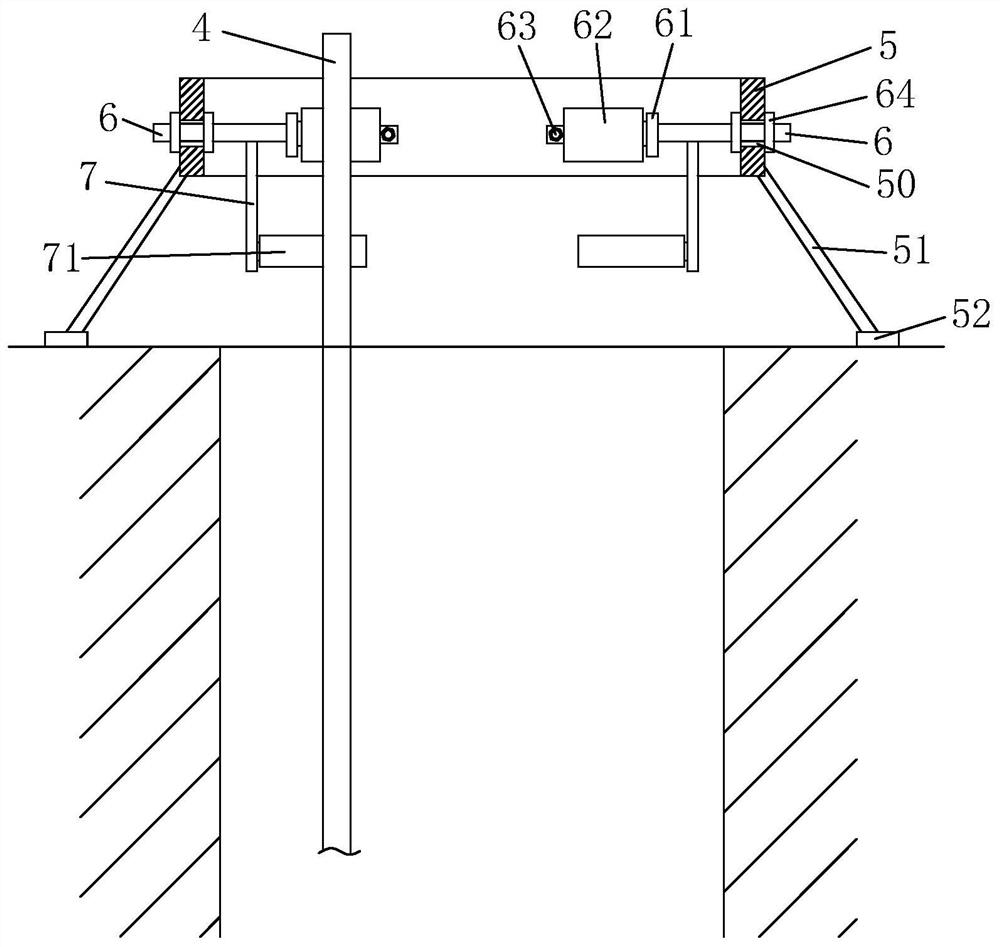

[0034] The application will be described in further detail below in conjunction with the accompanying drawings.

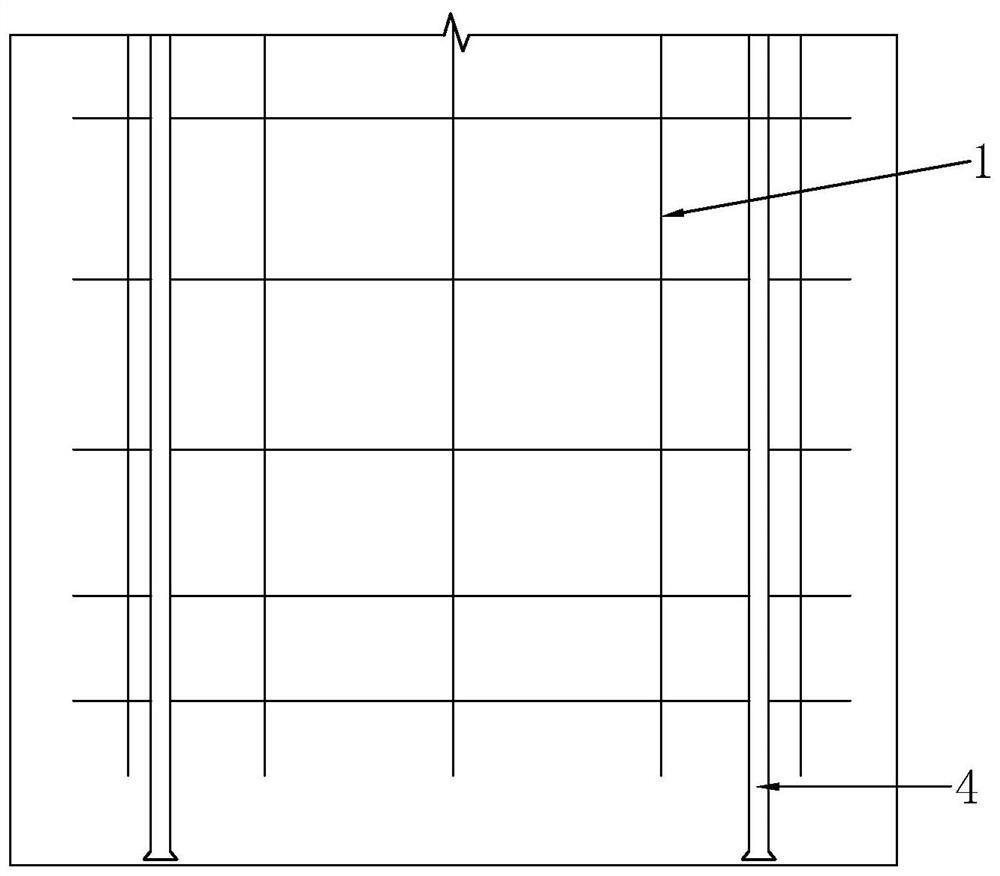

[0035] The embodiment of the present application discloses a grouting pipe construction method for grouting after pouring piles, such as figure 1 with figure 2 shown, including the following steps:

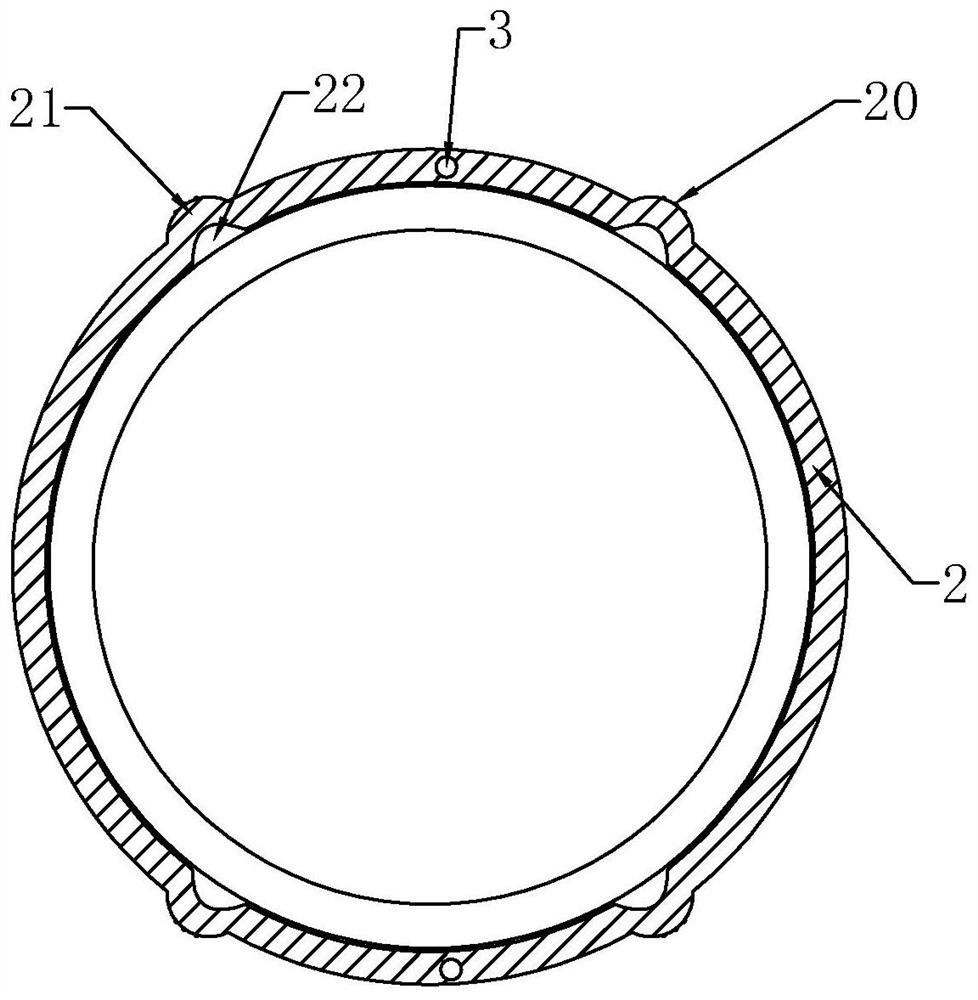

[0036] Step 1: making the pile side grouting hose 2, and selecting a number of predetermined positions on the completed pile side grouting hose 2 body, and then opening a number of side grouting holes 20 at the predetermined positions;

[0037] Step 2: install several pile side grouting hoses 2 around the outer circumference of the reinforcement cage 1 on the pile side. The side of the grout hose 2 with the side grout hole 20 should protrude away from the reinforcement cage 1, so that the outer side of the pile side grouting hose 2 forms an outer convex part 21, and the inner side forms an inner concave part 22;

[0038] Step 3: install a plurality of pile side gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com