Patents

Literature

35results about How to "Smooth grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Method for conducting grouting construction at back of pile bottom of cast-in-place pile

A method for conducting grouting construction at the back of the pile bottom of a cast-in-place pile sequentially includes the following steps: (1) manufacturing and arranging a grouting pipe which comprises a plurality of grouting steel pipe sections sequentially connected from top to bottom with the lower end of the lowest grouting steel pipe section connected with a grouting spraying nozzle; (2) assembling a grouting station and a slurry transportation pipeline; (3) grouting. The method is characterized in that the grouting spraying nozzle used in the step (1) comprises a slurry spraying pipe body, a slurry inlet is formed in the upper end of the slurry spraying pipe body, a plurality of slurry discharging holes are formed in the lateral wall of the slurry spraying pipe body, a grouting one-way valve is installed on the slurry discharging holes, a sand wrapping device is arranged on the outside of the slurry spraying pipe body, a sand isolation layer is arranged between the sand wrapping device and the outer side of the slurry spraying pipe body, and the sand isolation layer covers the grouting one-way valve. When the grouting spraying nozzle reaches the bottom of a pile hole, and the portion of the upper end of the grouting pipe higher than the ground reaches preset height, the upper end of the grouting pipe is fixedly connected with a protection barrel at the top of the pile hole. By means of the method, smooth grouting can be achieved, grouting quality is ensured, and success ratio is ensured.

Owner:广东省第二建筑工程有限公司

Water proofing and leak repairing construction method for sewage pipe network below underground water level

The invention discloses a water proofing and leak repairing construction method for a sewage pipe network below the underground water level. The method is performed through the following steps that 1, sewage removal is performed on a pipeline; 2, leak points are found and marked; 3, a precipitation well is drilled, and precipitation processing is performed on a construction well point; 4, leaking stoppage is performed on the interior of the pipeline; 5, a grouting hole is drilled, and cement paste is backfilled and grouted. According to the method, a lining pipe does not need to be used, the construction cost is saved by 50% compared with the method that water proofing and leak repairing are performed on the sewage pipe network in a lining pipe mode, and the high application and popularization value is achieved; the actual available pipe diameter of the sewage pipeline cannot be reduced, and the phenomenon that the drainage capacity of the sewage pipeline is reduced due to water proofing and leak repairing cannot occur; by grouting on the exterior of the pipeline to form a grouting layer at the periphery of the sewage pipeline, the strata at the periphery of the sewage pipeline is reinforced, and effective protection on the sewage pipeline is formed to prevent formation stress from destroying the sewage pipeline.

Owner:XUCHANG WATER CONSERVANCY CONSTR ENG CO LTD

Method for cultivating zinc-rich wheat

InactiveCN104823645AImprove fertilityImprove seedling rateFertilising methodsHorticultureSitodiplosis mosellanaOrganic fertilizer

The invention relates to a method for cultivating zinc-rich wheat. Before sowing, specially made organic fertilizer is mixed with planting soil, and the obtained mixture can kill take-all pathogens, and avoid take-all during cultivation. After the organic fertilizer is mixed with the planting soil, the fertility of the soil can be improved, and tillering of wheat can be more promoted before winter. Wheat seeds are soaked with specially made seed soaking liquid so that pathogens carried by the wheat seeds can be killed, and the wheat seeds soaked with the seed soaking liquid can quickly sprout. From the seedling stage to the tillering stage of wheat, leaf fertilizer is sprayed on the surfaces of leafbuds every other day, so that efficient tillering of wheat can be promoted. From the tillering stage to overwintering stage of wheat, the field is covered by straw, so that evaporation of water can be reduced, successful overwintering of wheat is ensured, effective tillering is ensured while ineffective tillering is controlled, and lodging is avoided. From blooming stage to filling stage of wheat, the leaf fertilizer is sprayed, so that the photosynthesis of wheat is promoted, and sitodiplosis mosellana and wheat aphids can be expelled and killed.

Owner:唐兴龙

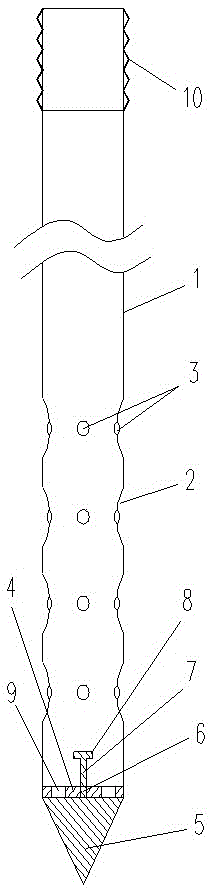

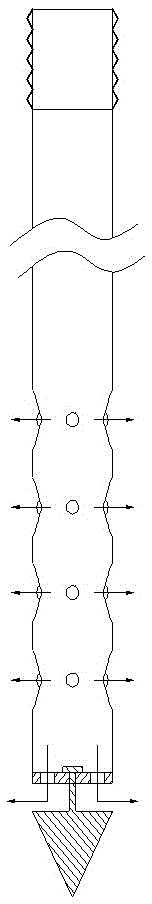

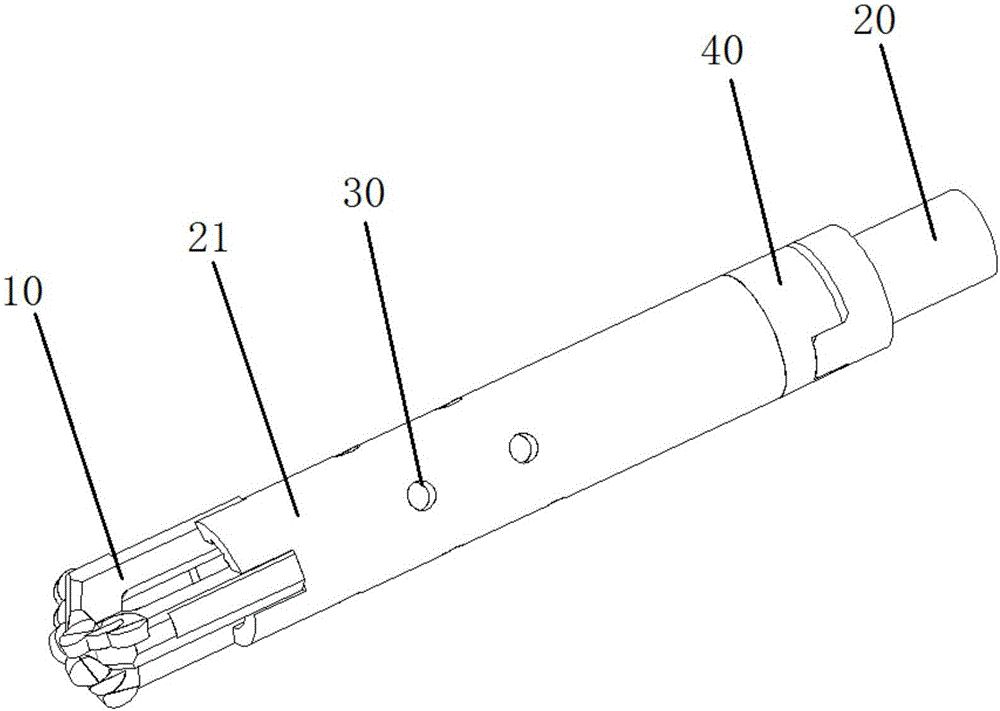

Grouting pipe

The invention discloses a grouting pipe which comprises a grouting pipe body. A plurality of inwards-concave parts are formed in the pipe wall of the front portion of the grouting pipe body, and at least one grout injecting hole is formed in each inwards-concave part. By means of the manner, the grouting pipe is simple and reasonable in structure and suitable for a pipe driving grouting method, the grouting holes are not liable to be blocked, grouting is smooth, and effects are good.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

Freezing pipe injected grout non-return device

InactiveCN103938613AGuarantee processing construction qualityPrevent mutual flowSoil preservationArchitectural engineeringWater treatment

The invention discloses a freezing pipe injected grout non-return device which is provided with an outer pipe and an inner pipe arranged in the outer pipe. A lower end sealing plate for simultaneously sealing the lower end of the outer pipe and the lower end of the inner pipe is arranged at the lower end of the outer pipe and the lower end of the inner pipe, a spring and a ball arranged on the spring are arranged in the inner pipe, an upper end sealing plate is arranged at the upper end of the outer pipe, a grout outlet matched with the ball is formed in the center of the upper end sealing plate, the outer pipe is provided with grout overflowing holes and a rubber sleeve for plugging the grout overflowing holes, and the upper end and the lower end of the rubber sleeve are provided with rubber sleeve fixing rings respectively. The freezing pipe injected grout non-return device is used for freezing hole pipe fixing water sealing processing, the construction technology of pipe fixing water sealing processing can be simplified, the requirements for construction devices and the construction technology can be reduced, the construction efficiency can be improved, the construction cost can be saved, and the construction quality can be guaranteed.

Owner:BEIFANG YANSHENG ENG TECH

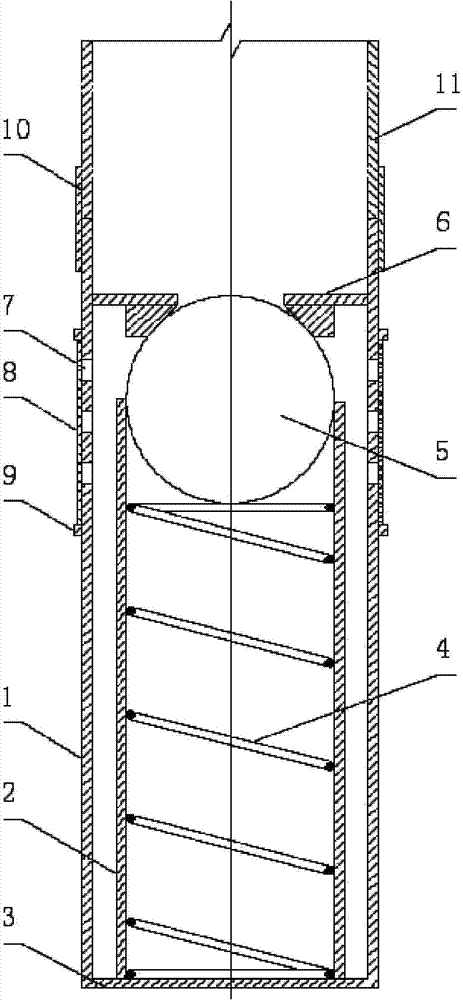

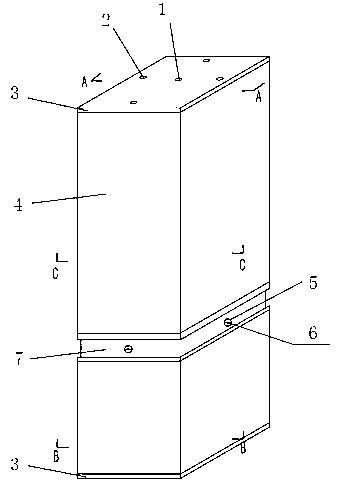

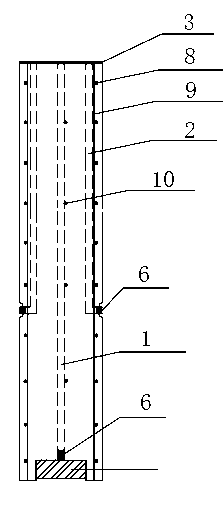

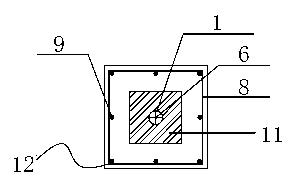

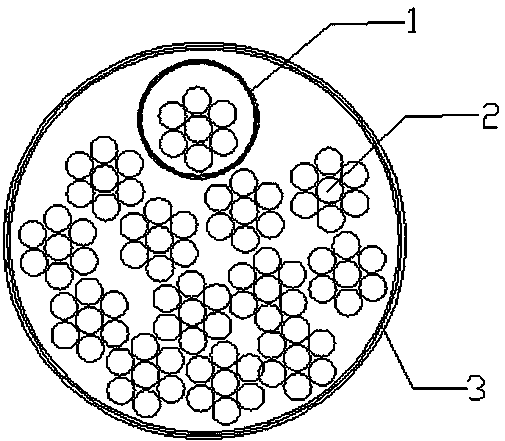

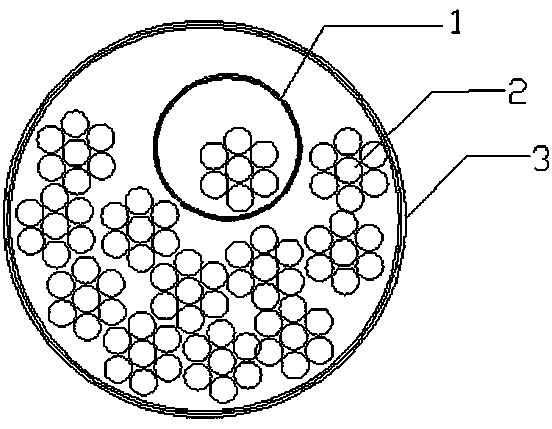

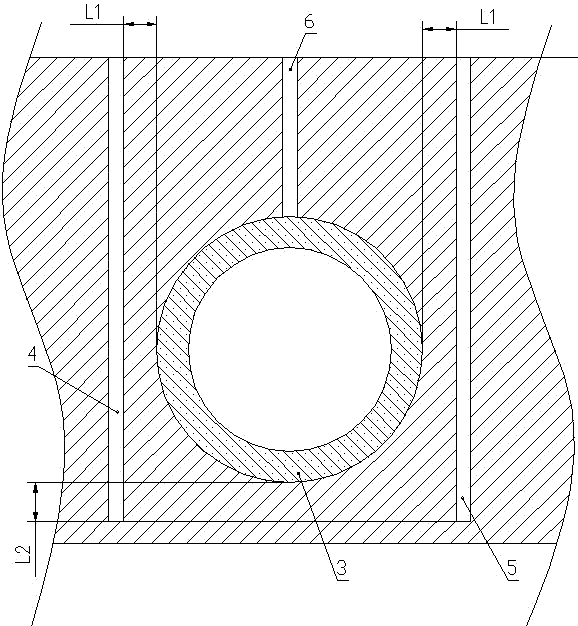

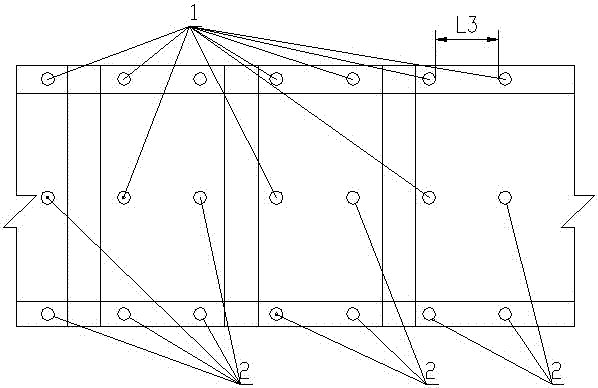

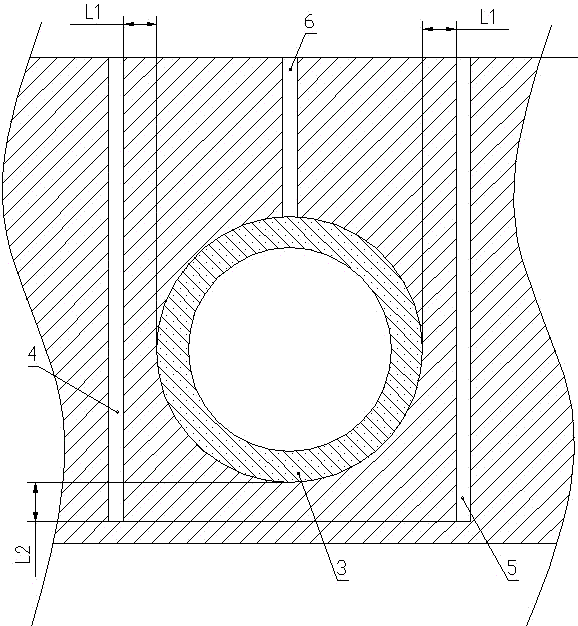

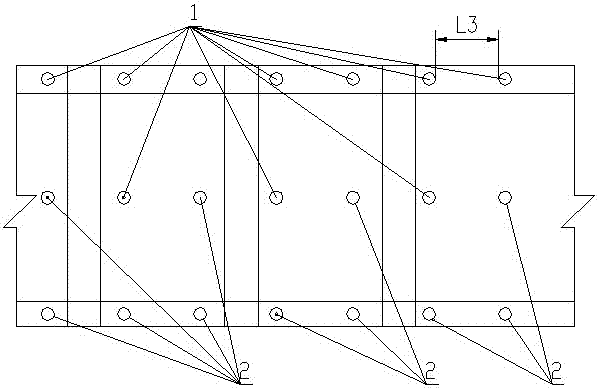

Precast concrete post grouting pile and grouting process

InactiveCN103015414ADimensions are easy to controlQuality controllableBulkheads/pilesCement pasteRebar

The invention discloses a precast concrete post grouting pile which comprises a post grouting pile body, a reinforcement cage framework, flanges, a post grouting tank, a post grouting pipe, a grouting hole and a pile bottom filler, wherein the reinforcement cage framework comprises longitudinal ribs and surrounding ribs; one end or two ends of the framework are welded with the flanges; at least one post grouting pipe runs through the center or the side edge position of the framework or the center and the side edge position of the framework; one end of the post grouting pipe is provided with the grouting hole; the grouting hole is positioned in the post grouting tank; and the post grouting tank is arranged on the post grouting pile body. In the constructing process, the post grouting pile is sunken and immediately, cement paste or powder paste with a specific surface area of 2,500 to 6,500kg / cm<2> is injected into the post grouting pile body by the grouting pipe, so that sufficient adhesion of the grouted paste and a soil layer around the pile is ensured. The precast concrete post grouting pile can realize improvement on rock and soil common resistance of soil and the pile so as to further play bearing capacity of the pile; and meanwhile, the number of the used piles can be reduced and engineering cost is reduced.

Owner:建华建材(四川)有限公司

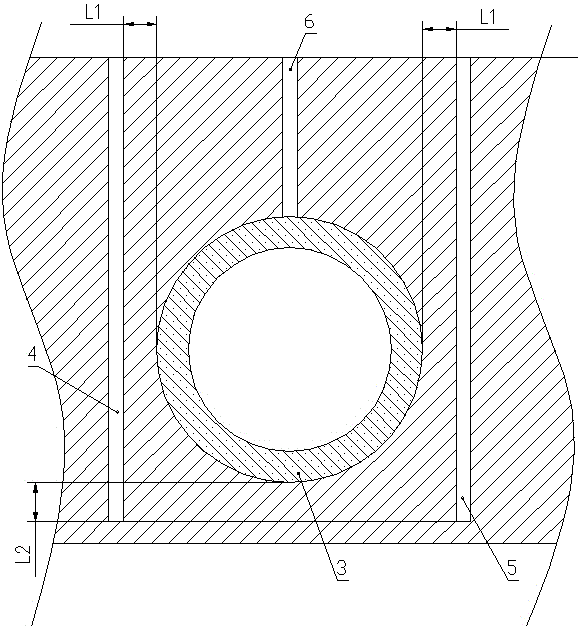

Sewage pipeline internal plugging and external grouting construction method

ActiveCN105604163ALow costEasy constructionFoundation engineeringSewer pipelinesEngineeringStructural engineering

The invention discloses a sewage pipeline internal plugging and external grouting construction method. The construction method sequentially includes the following steps that firstly, pipeline internal plugging is performed; secondly, grouting holes are drilled, and cement slurry backfill grouting is performed. In the first step, pipe body leakage points of a sewage pipeline and the peripheries of the leakage points are subjected to chiseling, cleaning and washing, chiseling reaches the concrete surface of the sewage pipeline in the aspect of depth, and then plugging materials are used for compact filling. In the second step, a drilling machine is used for drilling a row of drill holes in each of the soil layers of the left side and the right side of the sewage pipeline, and the drill holes serve as the grouting holes; a row of drill holes are drilled in a soil layer above the center line of the sewage pipeline and serve as the grouting holes; grouting materials are added into a high-speed stirrer to be evenly stirred, and a grouting pump is started to start grouting when the fluidity meets the grouting requirement. By means of the method, compared with a traditional mode that a lining pipe is used, cost is greatly saved, the practical available pipe diameter of the sewage pipeline is not shrunk, and stratum stress is prevented from damaging the sewage pipeline.

Owner:XUCHANG WATER CONSERVANCY CONSTR ENG CO LTD

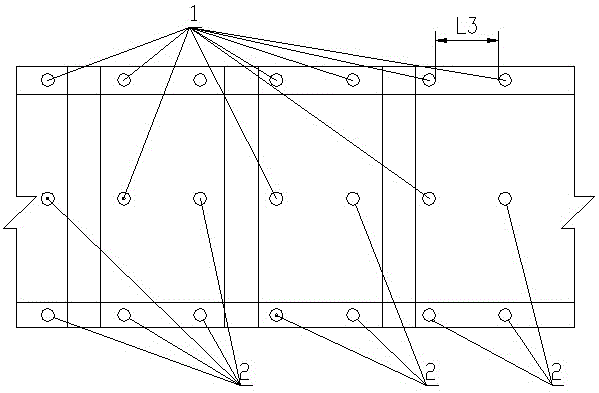

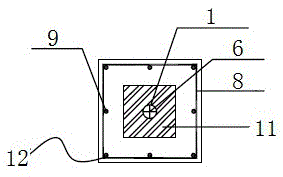

Protective device for prestressed duct hole-forming

PendingCN107740592AOvercome the defect of high cost and small scope of applicationLow costForms/shuttering/falseworksBuilding material handlingPre stressArchitectural engineering

The invention relates to a protective device for prestressed duct hole-forming. According to the corrugated pipe protection measures, steel stranded wires parallel to bundled steel wires and a plasticpipe above the steel stranded wires are in formed holes of a corrugated pipe and occupied a certain space, an effective channel is formed in formed holes of the steel stranded wires and the prestressed duct after concrete pouring is completed and the a plastic pipe is pulled out, the channel can be deformed and moved with tensioning of the steel stranded wires when prestress tensioning, while theformed channel area can further ensure smooth passing of cement paste during mud jacking in the later to the smallest extent. According to the scheme, the weakness of protecting a linear plate is solved exactly, the protective device is adapted to various ducts and various working conditions, is low in cost, and can be reused. The defects that during prestressed duct hole-forming, holes exist inthe hole wall of the corrugated pipe, local release slurry leakage happens, the steel stranded wires cannot threaded in after denting cause by impacting, and mud jacking cannot be achieved after the steel stranded wires are threaded firstly and tensioning is conducted are overcome; and the defects that the cost of linear pipe protecting is high and the adaptation range is small are further overcome, so that the effect that the duct is protected to be smooth can be achieved.

Owner:NO 2 ENG CO LTD OF CHINA RAILWAY CONSTR 11 BUREAU GRP +1

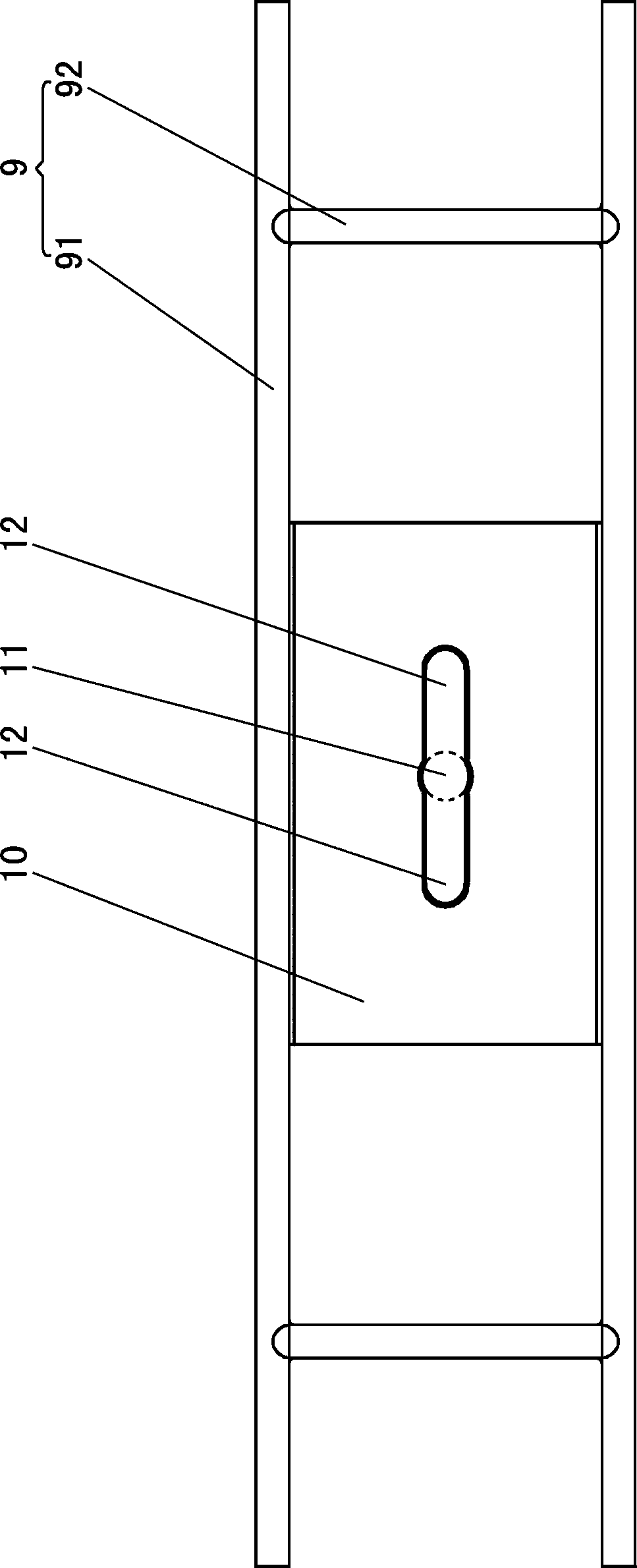

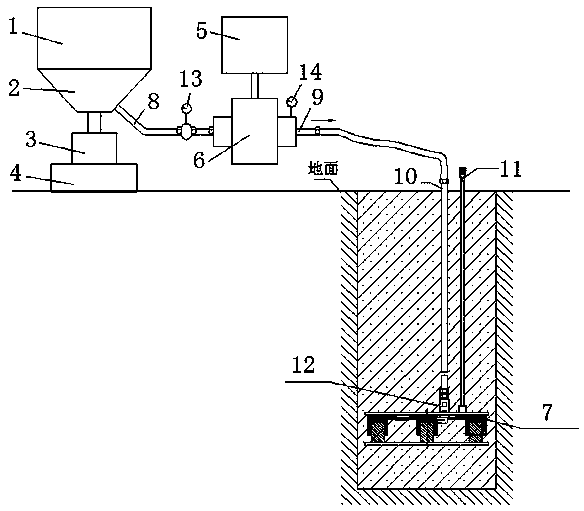

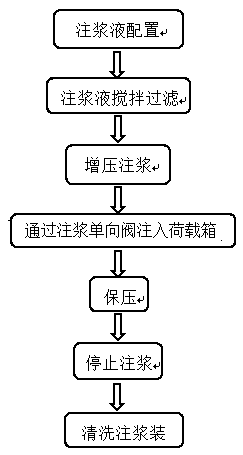

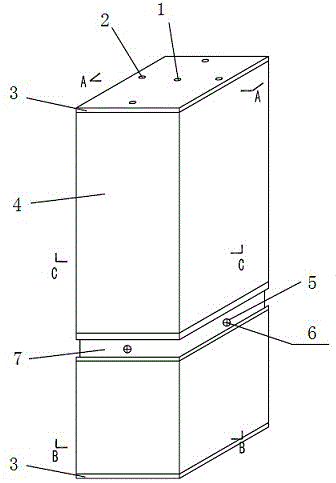

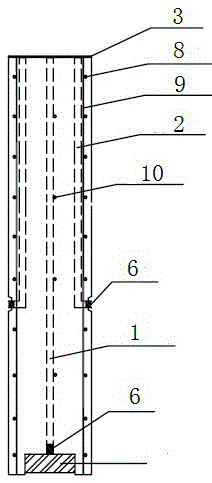

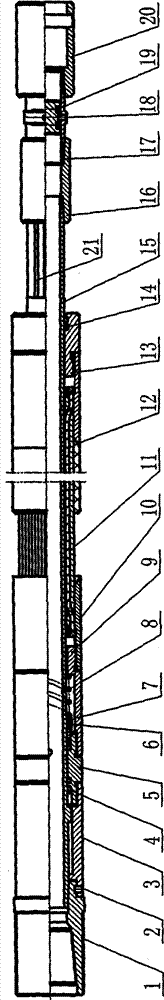

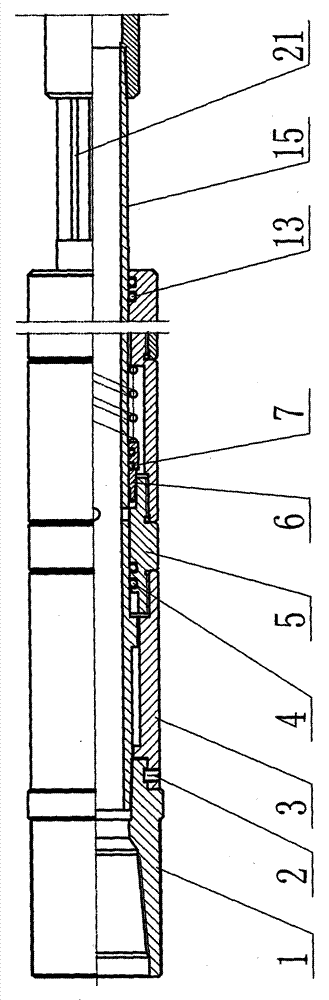

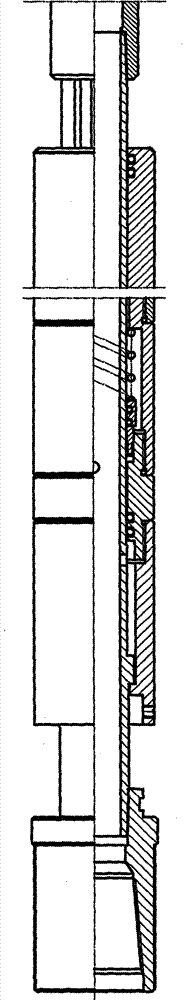

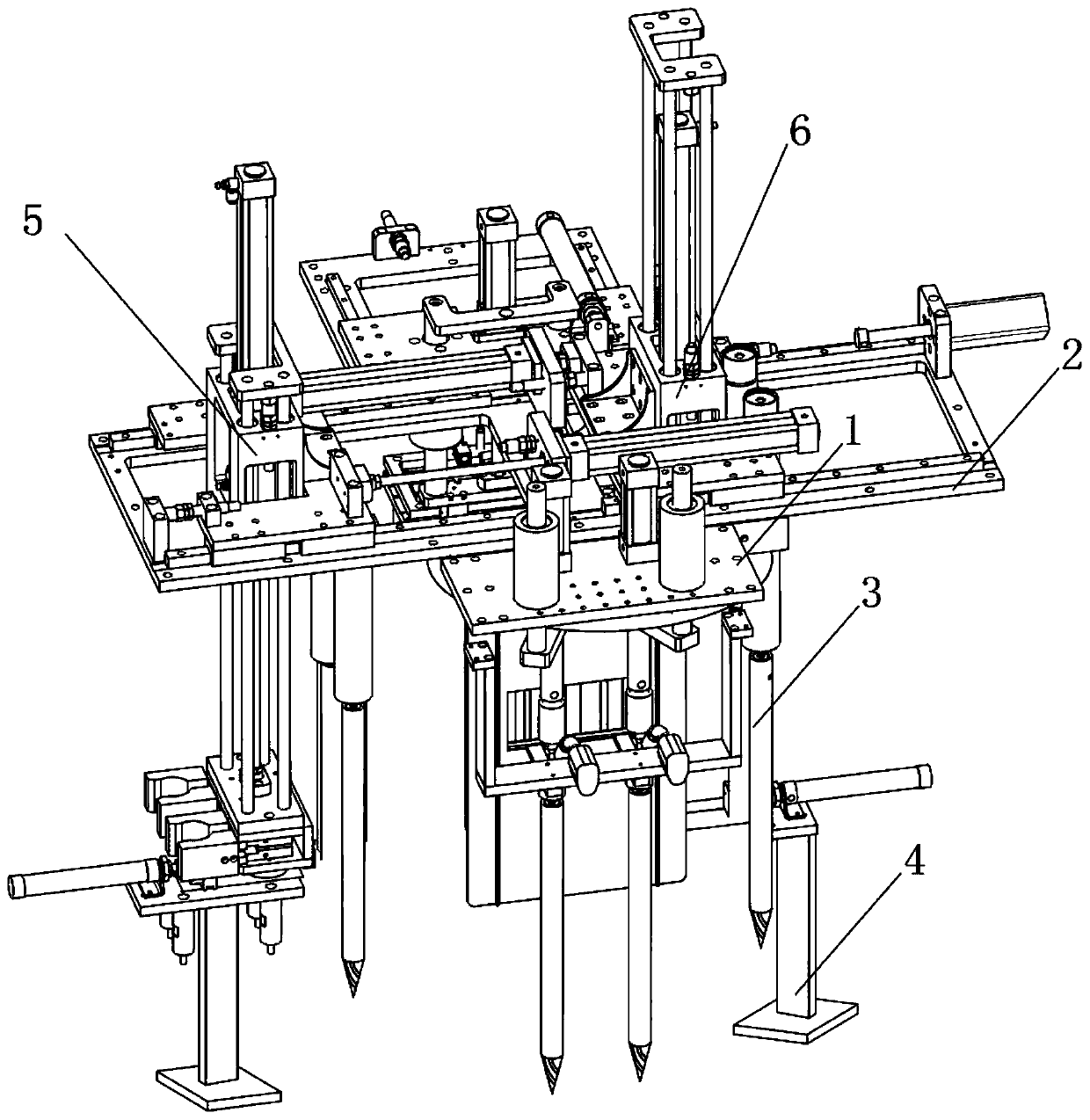

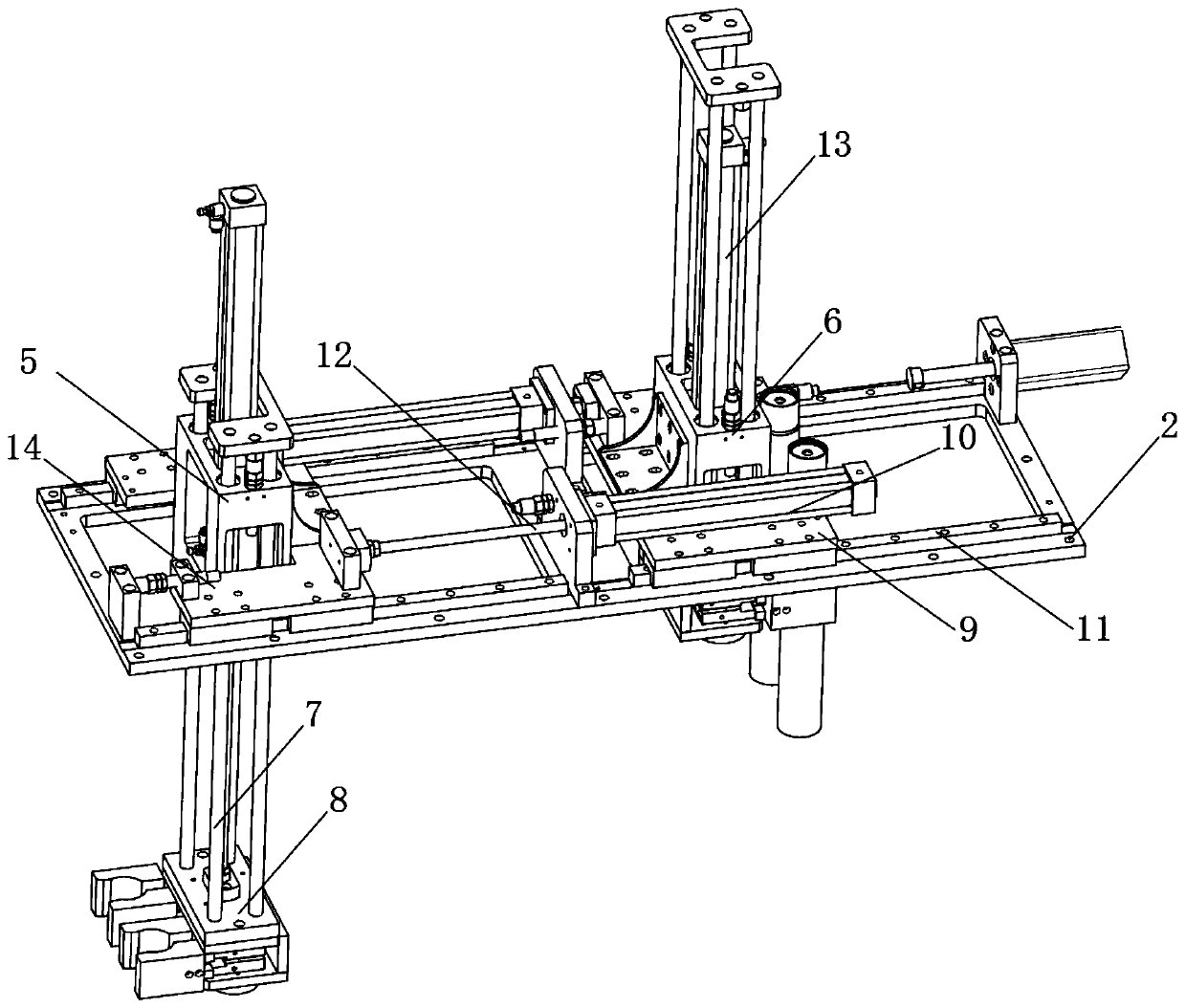

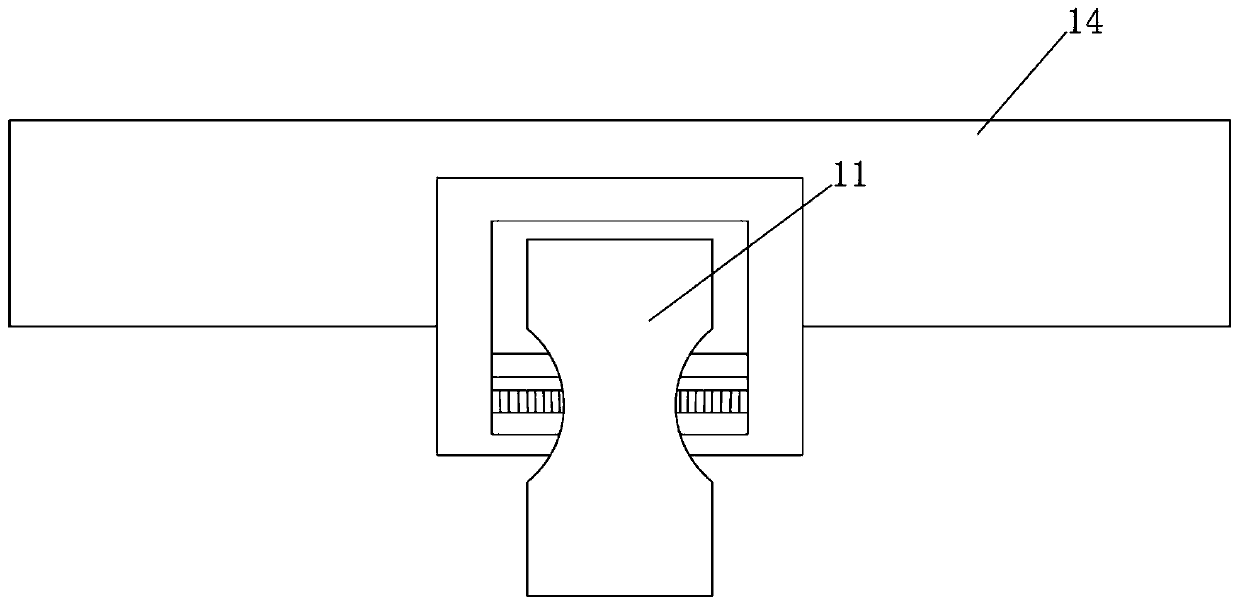

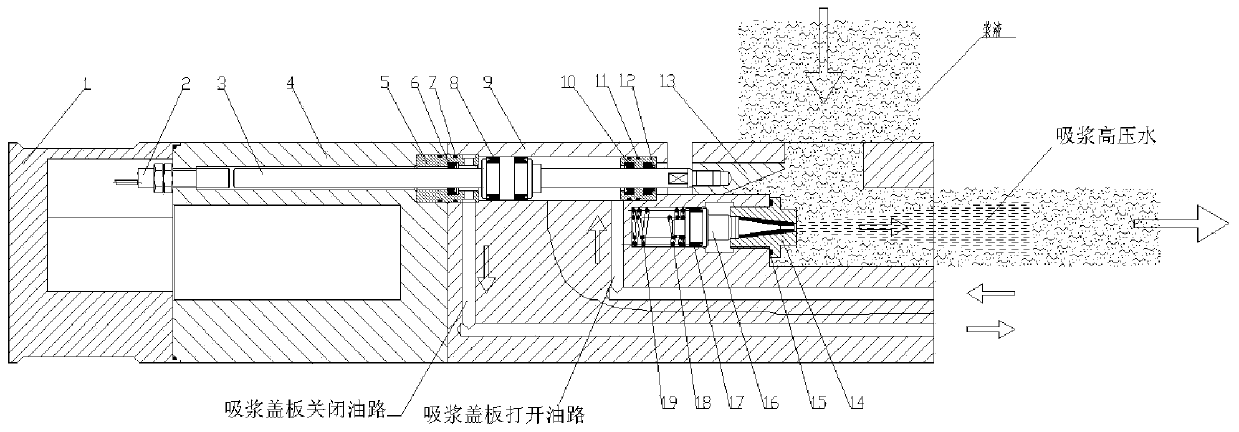

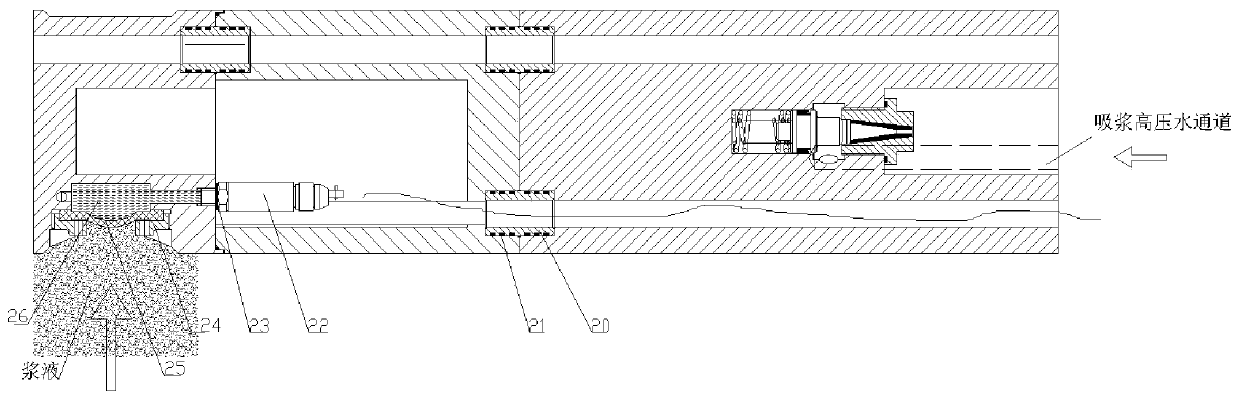

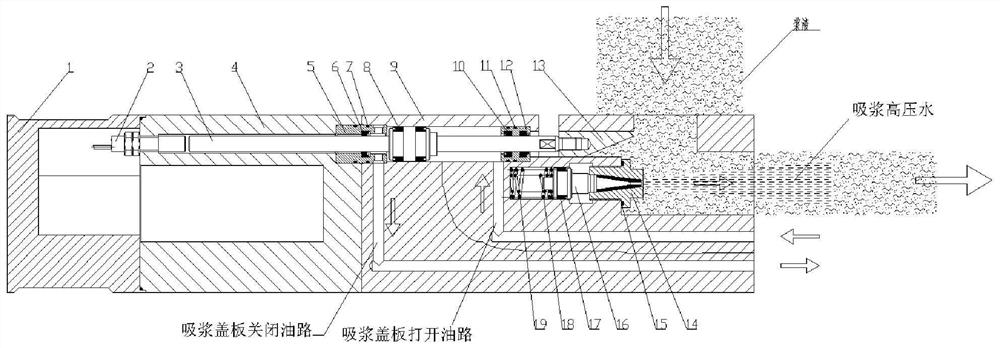

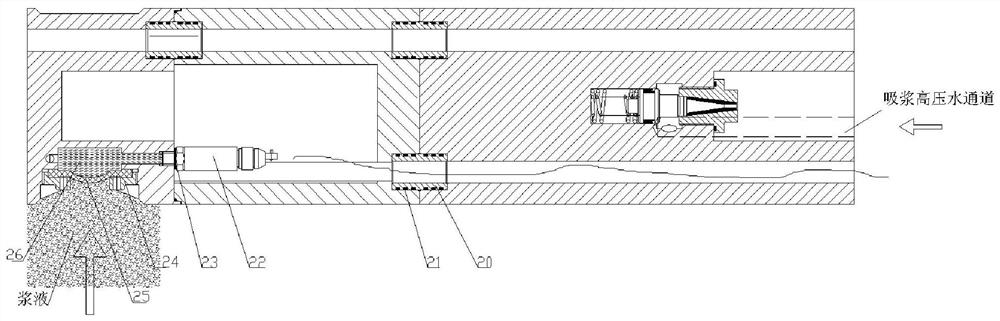

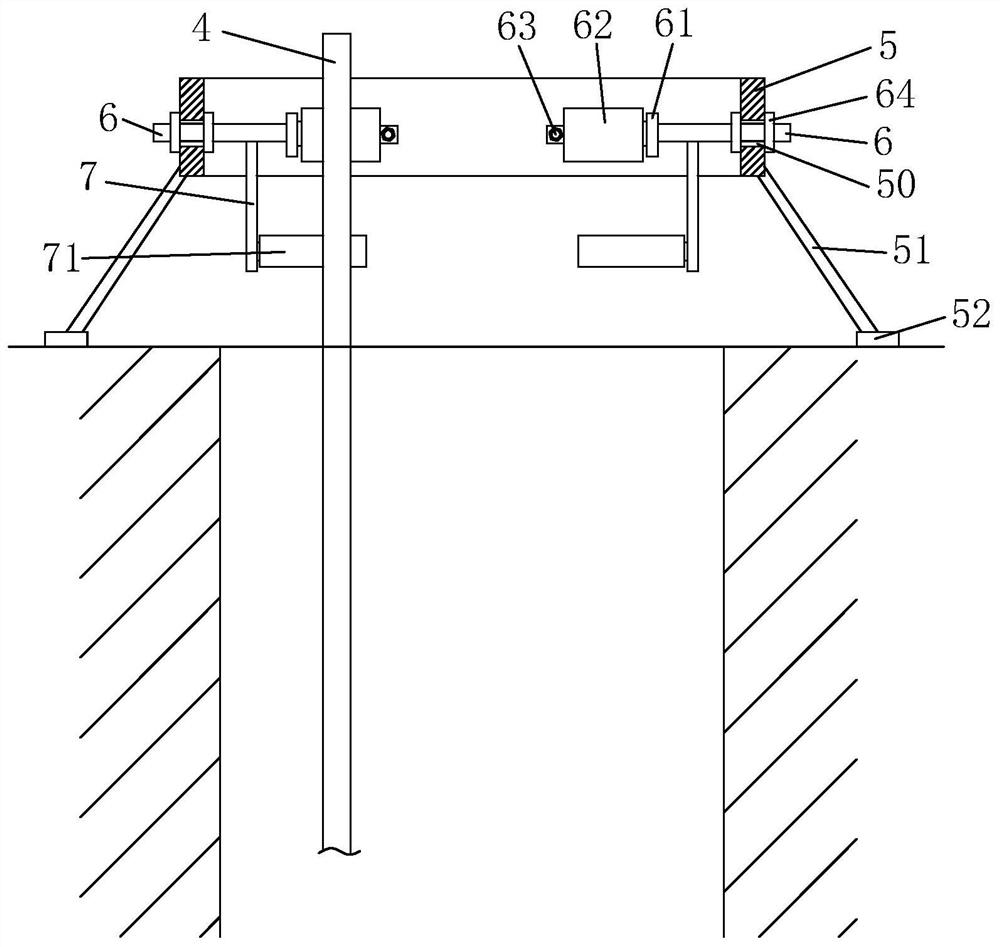

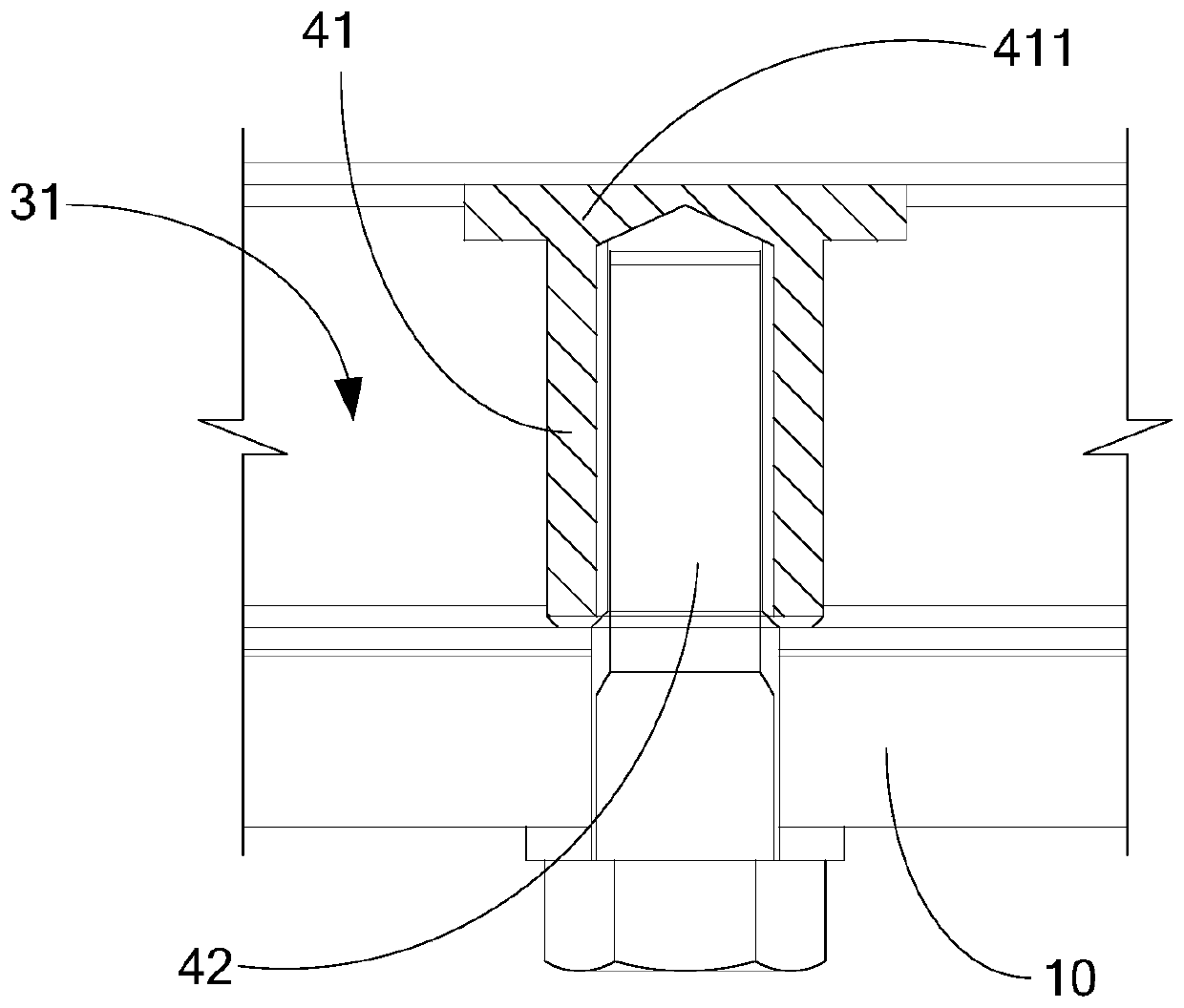

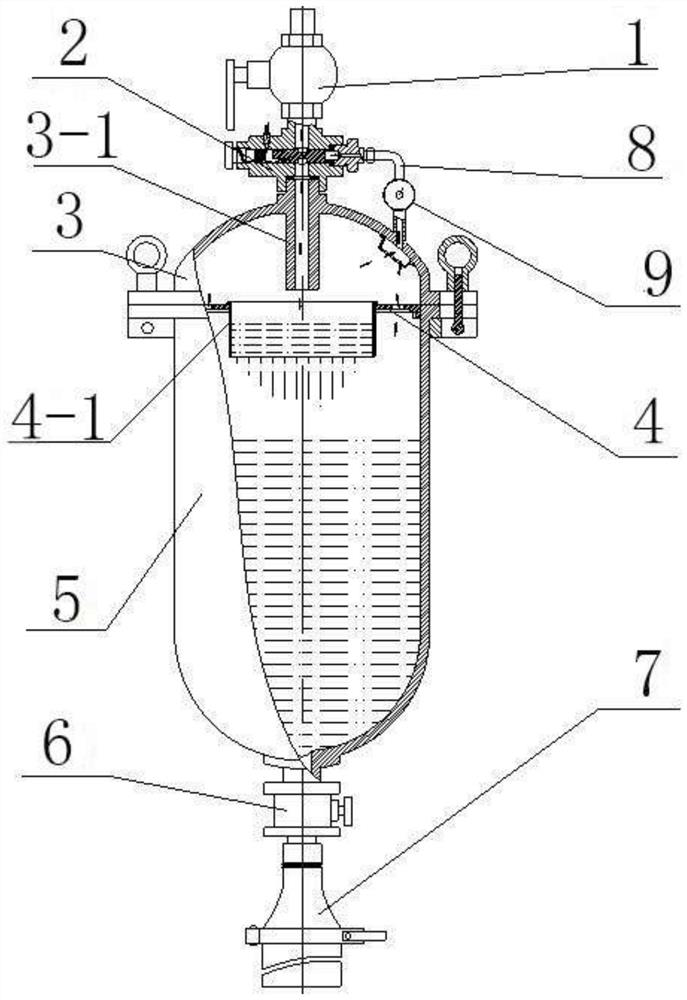

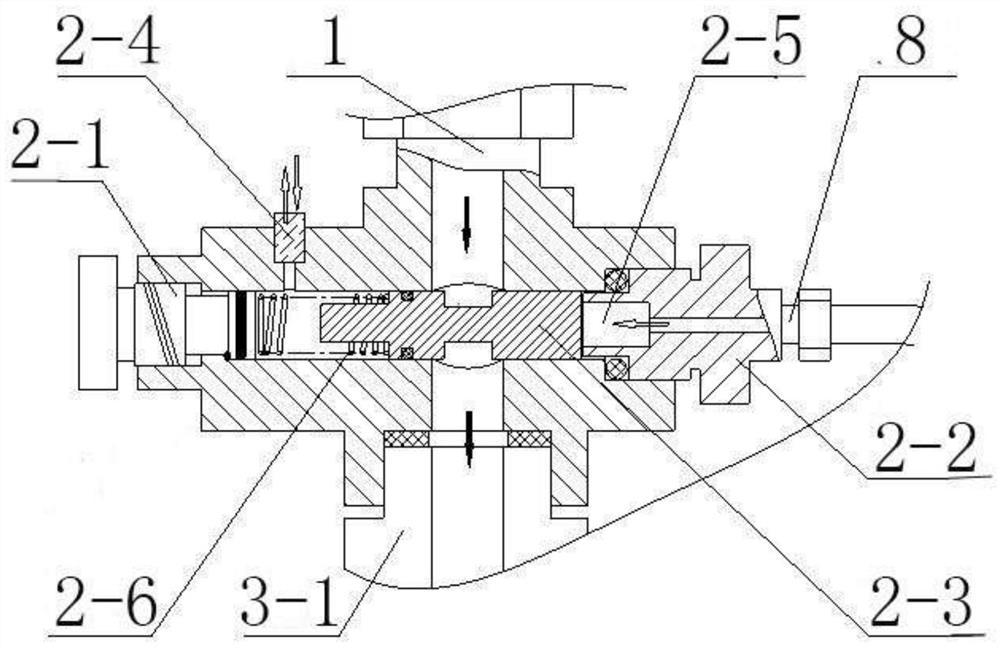

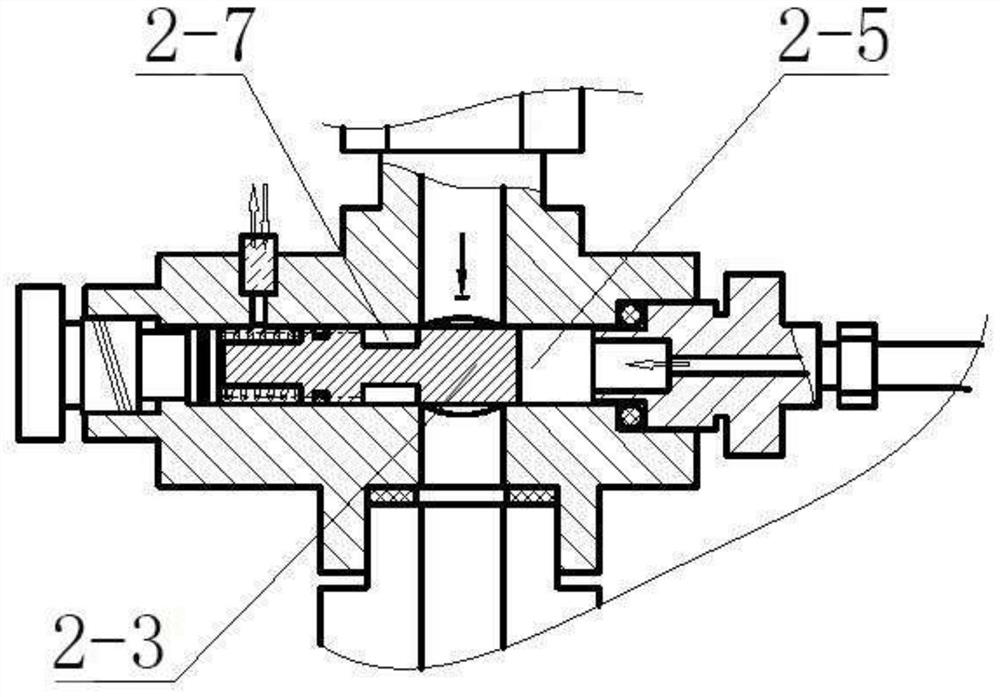

In-cylinder grouting device used after self-balancing load box static load detection test and grouting method thereof

The invention relates to an in-cylinder grouting device used after a self-balancing load box static load detection test and a grouting method thereof, and is applied to the technical field of in-cylinder grouting of a load box after the building foundation pile self-balancing bearing force static load test. The device comprises a stirring device, a filtering stirring device, a stirring driving device, a weighing device, a pressurizing driving device, a pressurizing grouting device and an in-cylinder grouting load box; the filtering stirring device is arranged below the stirring device, the lower end of the filtering stirring device is connected to the stirring driving device, and the weighing device is located below the stirring driving device; the filtering stirring device is connected tothe pressurizing grouting device through a suction port, and the pressurizing grouting device is connected with the pressurizing driving device; an output port of the pressurizing grouting device isconnected with the in-cylinder grouting load box through a grouting pipe; and the in-cylinder grouting load box is connected with the grouting pipe.

Owner:NANCHANG YONGQI TECH DEV

A prefabricated concrete post-grouting pile and its grouting process

InactiveCN103015414BDimensions are easy to controlQuality controllableBulkheads/pilesCement slurryRebar

The invention discloses a prefabricated concrete post-grouting pile, which comprises a post-grouting pile body, a steel cage skeleton, a flange, a post-grouting groove, a post-grouting pipe, a grouting hole and a pile bottom filler, wherein the steel cage The frame includes longitudinal ribs and surrounding ribs, flanges are welded at one or both ends of the frame, at least one post-grouting pipe runs through the center or side of the frame or both positions, and one end of the post-grouting pipe A grouting hole is provided, the grouting hole is located in the rear grouting groove, and the rear grouting groove is arranged on the rear grouting pile body. During construction, after the above-mentioned post-grouting pile sinks, immediately inject cement slurry or powder slurry with a specific surface area of 2500~6500kg / cm2 into the post-grouting pile body through the grouting pipe to ensure that the grouting slurry is compatible with the soil around the pile. The layers are fully bonded. The invention can improve the joint resistance of rock and soil between the soil and the pile, further exert the self-bearing capacity of the pile, reduce the number of piles used, and reduce the engineering cost.

Owner:建华建材(四川)有限公司

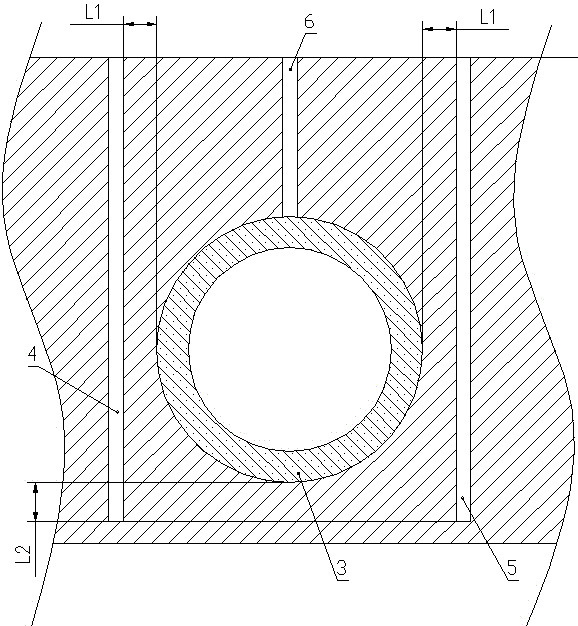

High-pressure grout stopping device for L-shaped drill hole ground pre-grouting

The invention relates to a high-pressure grout stopping device for L-shaped drill hole ground pre-grouting. The high-pressure grout stopping device comprises a center pipe, a rubber barrel assembly and a blind blocking mechanism used for blocking a pipe opening in the lower end of the center pipe. The center pipe is sleeved with the rubber barrel assembly. A sealed annular cavity is formed between the inner wall of the rubber barrel assembly and the outer surface of the pipe wall of the center pipe. The pipe wall of the center pipe is provided with a liquid inlet hole communicated with hollow pipe hole fluid of the center pipe, the sealed annular cavity and the liquid inlet hole are in fluid communication through a one-way fluid communication mechanism which is opened through the action of pressure of the fluid in a hollow pipe hole, the fluid in the hollow pipe hole enters the sealed annular cavity through the liquid inlet hole and the one-way fluid communication mechanism, and the rubber barrel assembly is expanded through the action of the pressure of the fluid in the sealed annular cavity. The blind blocking mechanism opens the pipe opening in the lower end of the center pipe through the action of pressure of the fluid in the hollow pipe hole. The outer surface of the lower end of the center pipe is provided with a pressure relief groove. The high-pressure grout stopping device overcomes the defects that an existing grout stopping device cannot meet the requirement for successful grout stopping in a large-vertex-angle drill hole or a horizontal drill hole (an L-shaped drill hole).

Owner:BEIJING CHINA COAL MINE ENG CO LTD

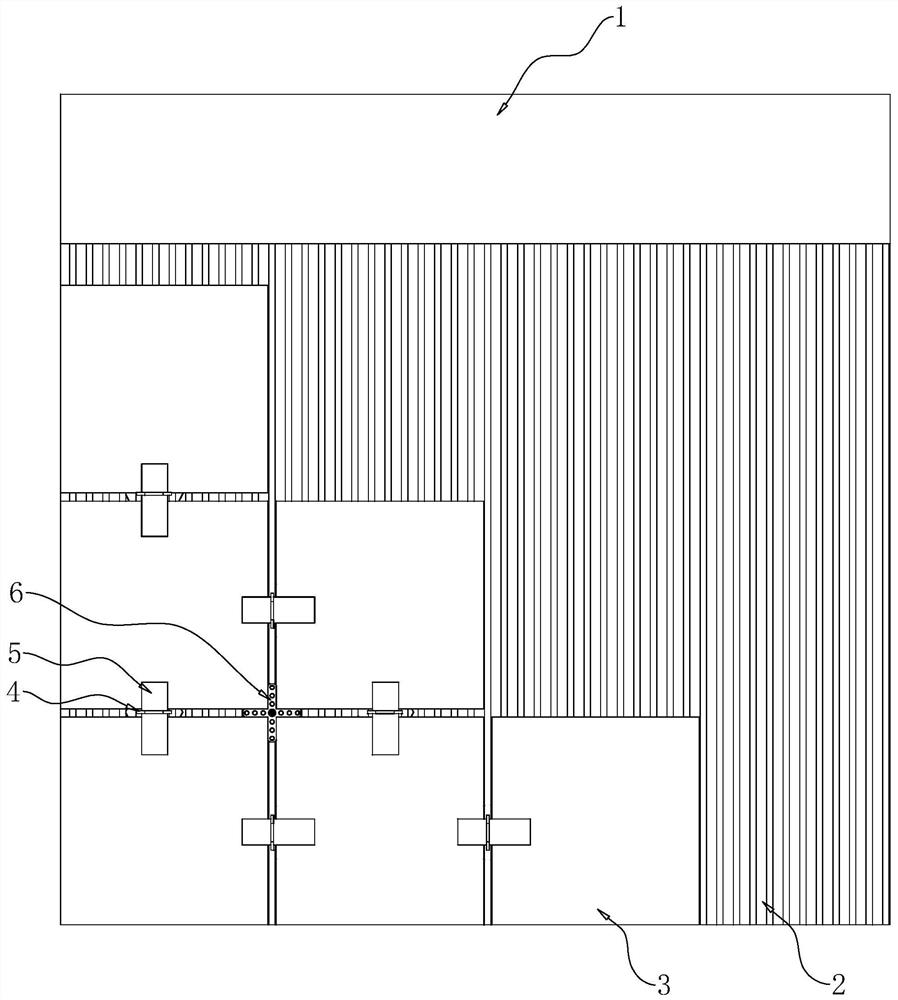

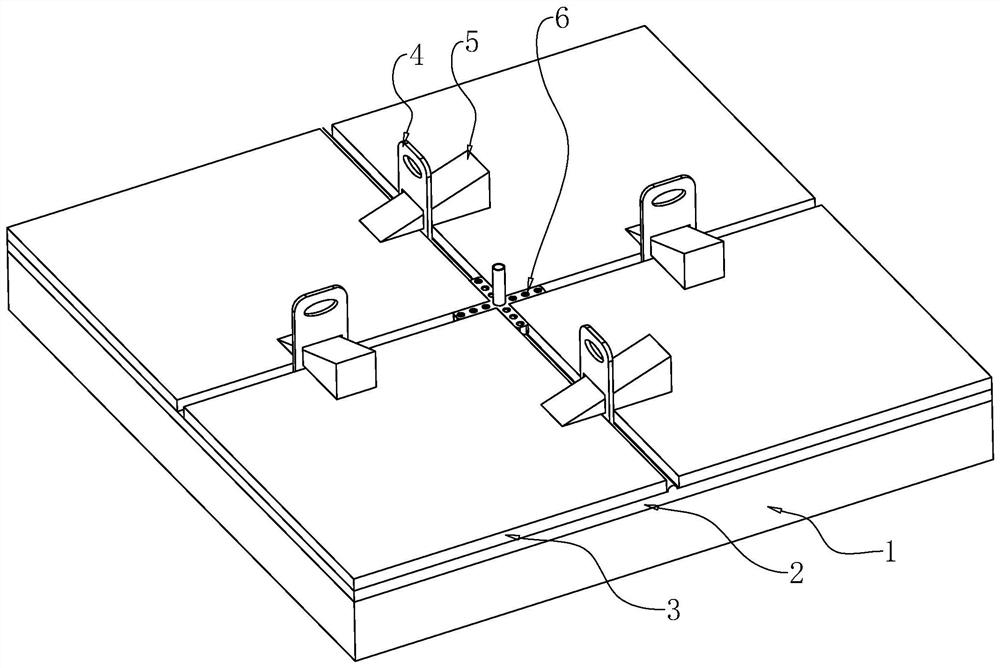

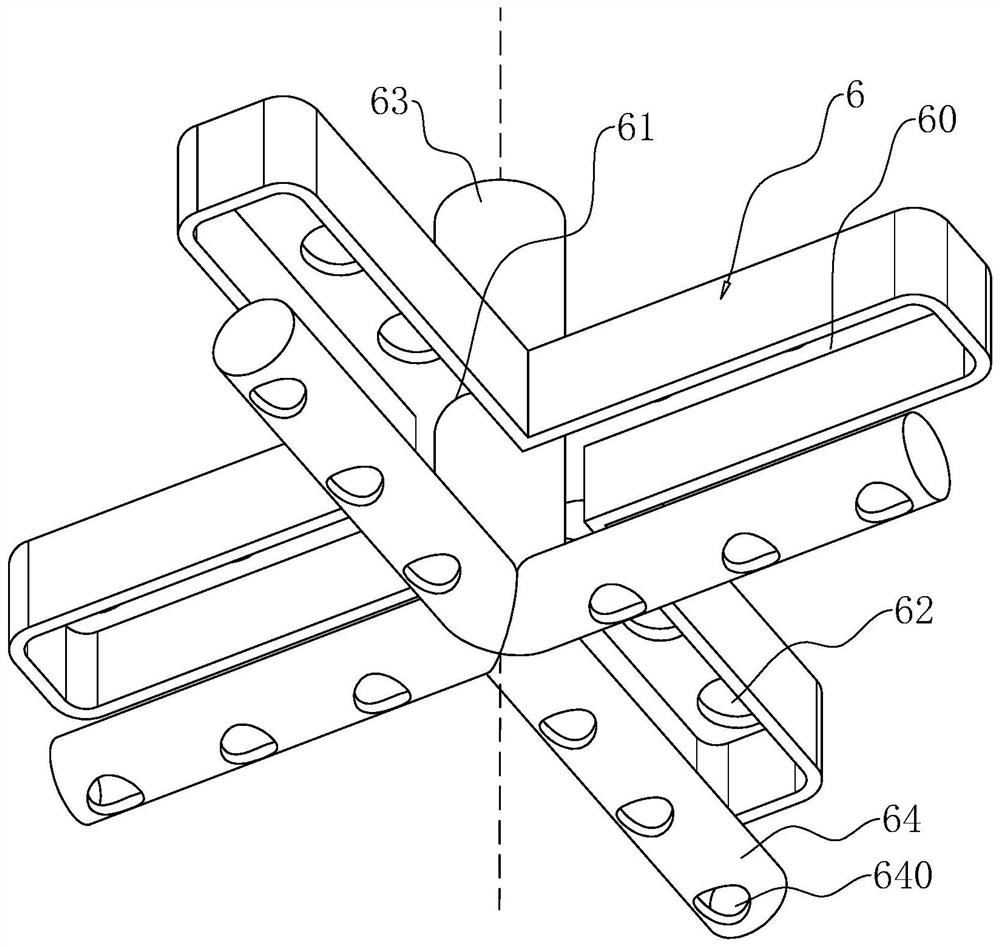

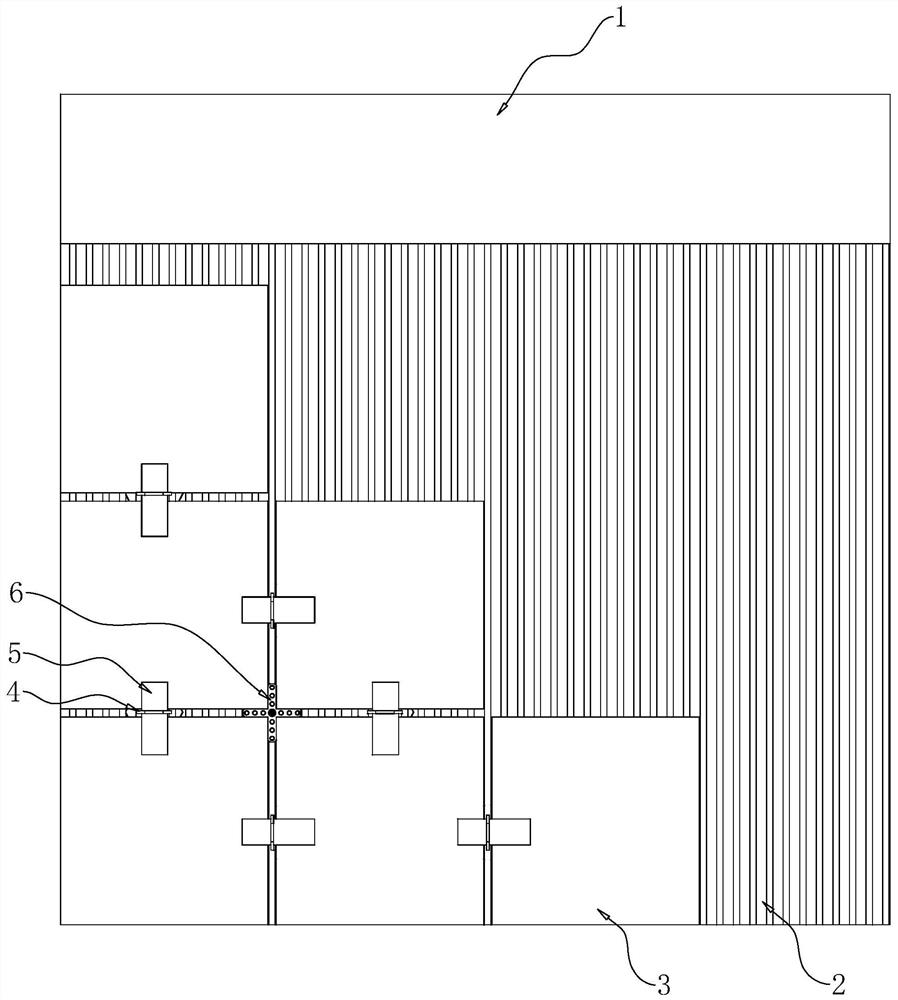

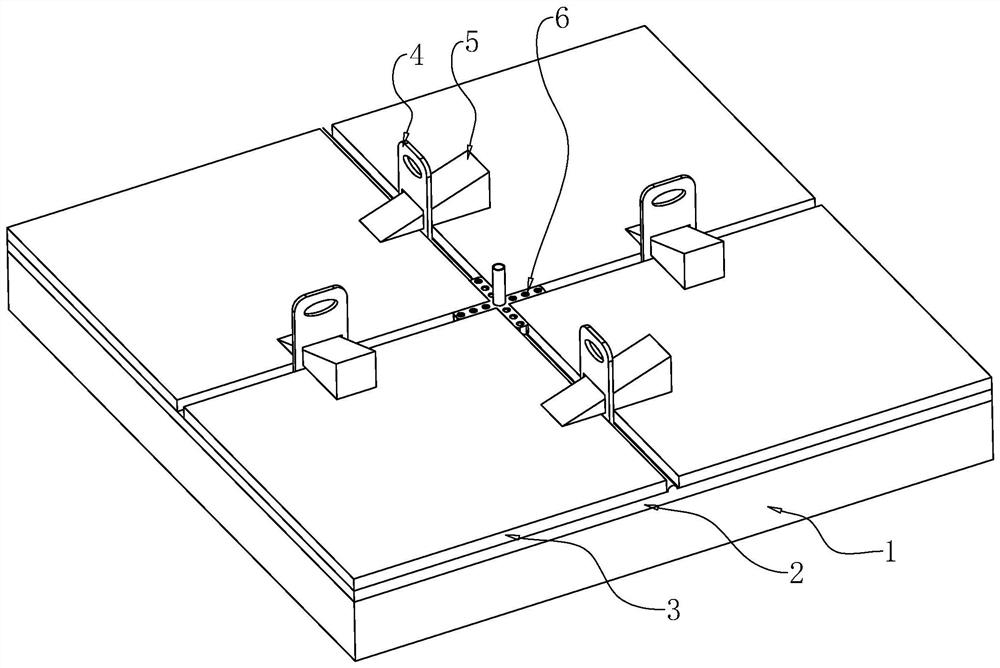

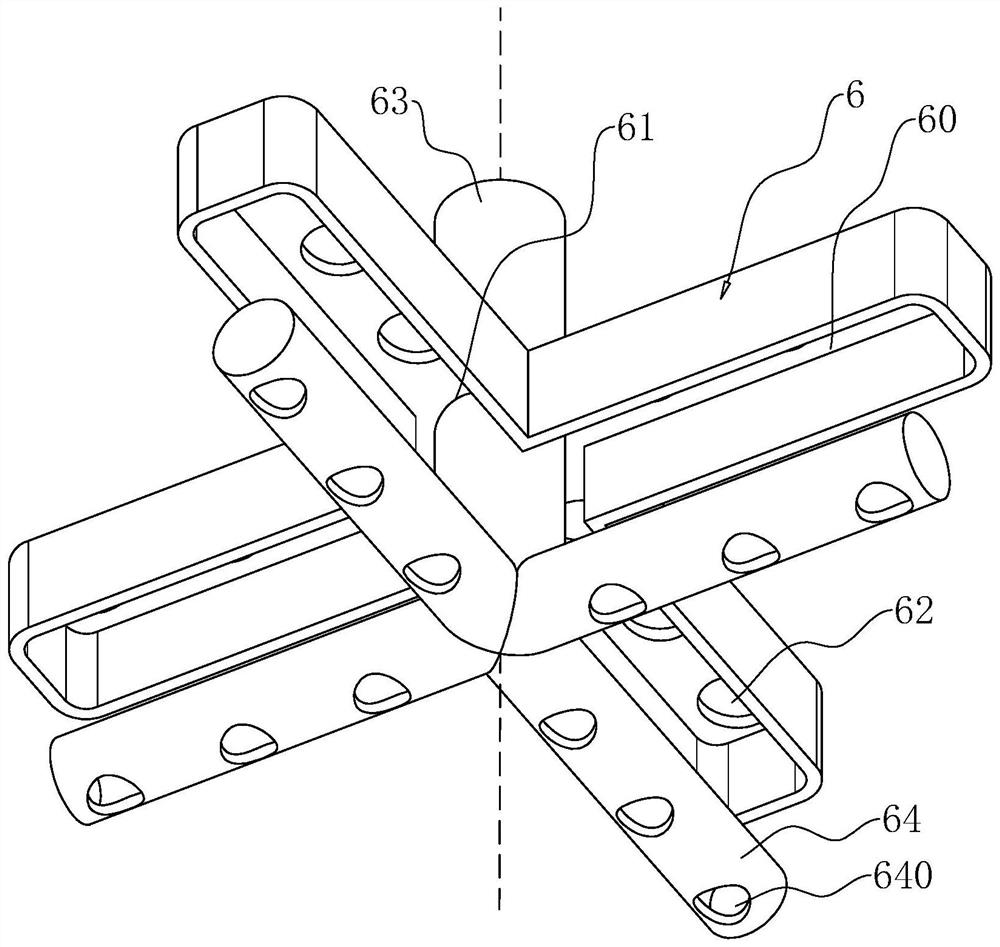

Ceramic tile thin pasting method layer structure and construction process thereof

ActiveCN112065000AEmpty position fillingExpand the scope of groutingBuilding constructionsComposite materialCeramic tiles

The invention relates to the field of decoration engineering, in particular to a ceramic tile thin pasting method layer structure and a construction process thereof. The ceramic tile thin pasting method layer structure comprises a base layer, a ceramic tile adhesive layer and ceramic tiles, all of which are sequentially arranged, a disposable base is placed between every two adjacent ceramic tiles, wedges are inserted onto the disposable bases, a cross-shaped positioning frame is mounted at a cross-shaped gap among the four adjacent ceramic tiles, and an avoiding hole is formed in the center position of the cross-shaped positioning frame. The ceramic tile thin pasting method layer structure has the effect of effectively solving the problem of hollowing below the end corners of the ceramictiles.

Owner:YENOVA NOVARTIS HOME DECORATION GRP CO LTD

Pile foundation reinforcing method

ActiveCN110016941ASo as not to damageExpand the movable rangeFoundation repairBulkheads/pilesHydraulic pumpStructural engineering

The invention discloses a pile foundation reinforcing method. The method comprises the steps of drilling, grouting, pressure grouting and plugging. The pile foundation reinforcing method has the beneficial effects as follows: the upper ends of a plurality of hollow positions are drilled through a drill rod, and during reinforcing of a pile foundation, the efficiency of drilling a hollow position of the pile foundation is improved, so that the overall work reinforcing efficiency of the pile foundation reinforcing method is improved, a plurality of drilling frames are driven to synchronously rotate and move through rotation of a rotary table, it is guaranteed that the drilling frames on a drilling device drill the hollow position of the pile foundation more precisely, and more time and laborare saved during pile foundation reinforcing work; a fourth hydraulic pump pushes a slurry box to turn over front and back through a third hydraulic rod, so that a slurry passing opening and a grouting pipe are turned over and adjusted, slurry in the grouting pipe is prevented from being blocked, it is guaranteed that a grouting device conducts grouting on the hollow position of the pile foundation more smoothly, it is guaranteed that the hollow position of the pile foundation is filled with the slurry more fully and comprehensively, and the pile foundation reinforcing quality is improved.

Owner:武汉科诚基础工程有限责任公司

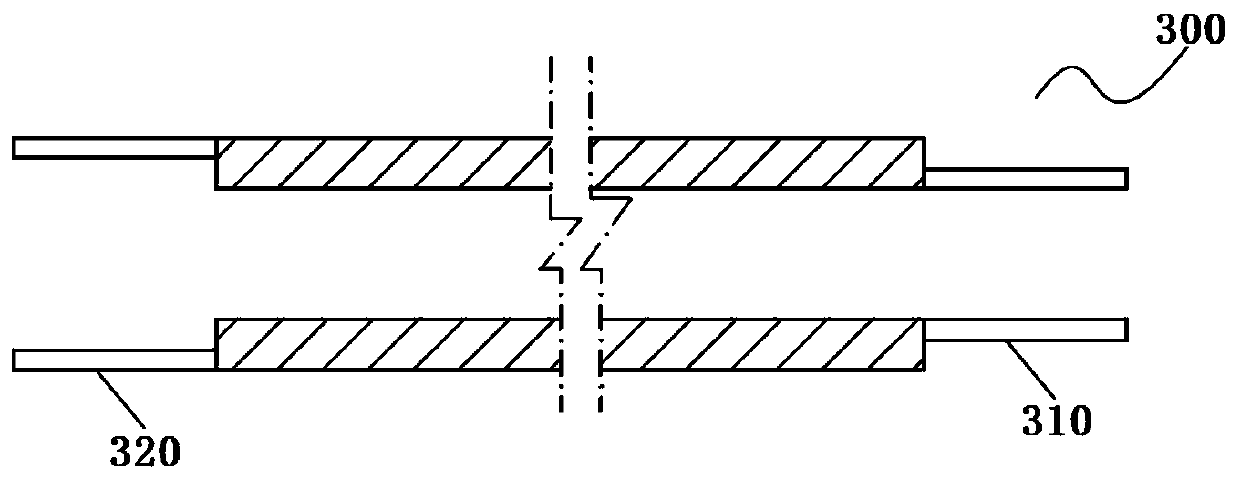

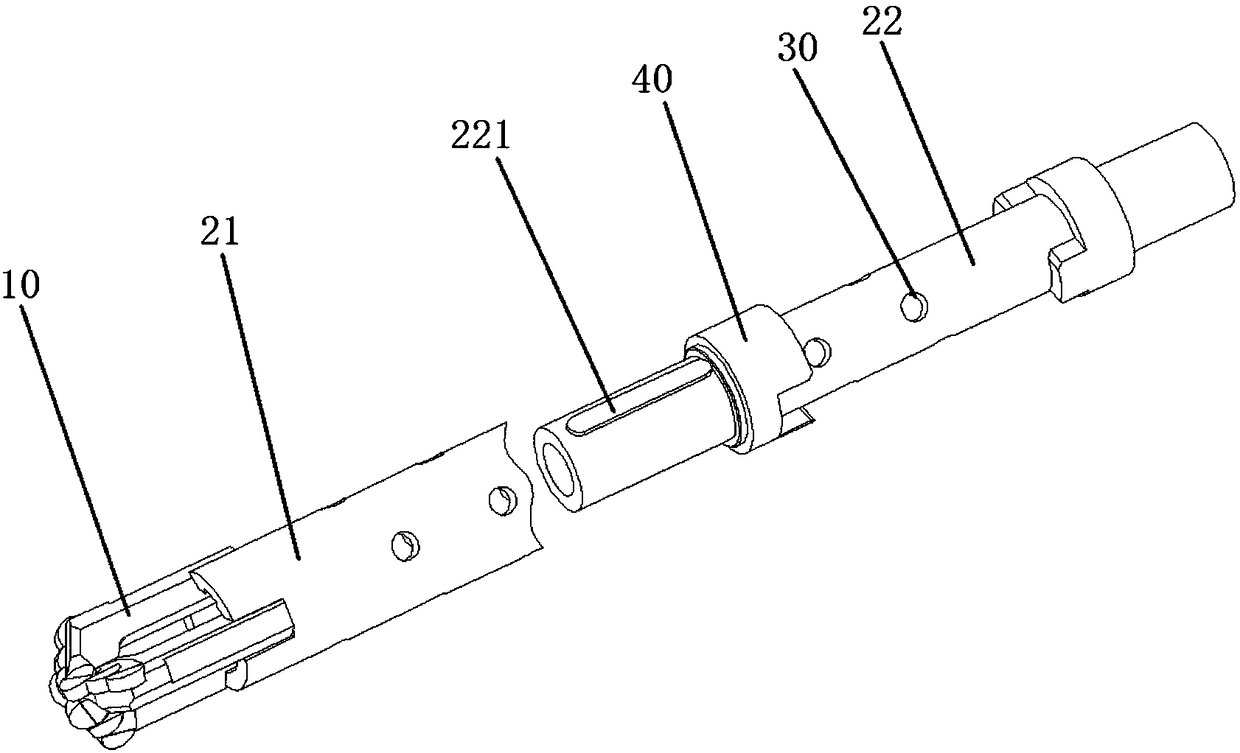

Rigid sleeve valve pipe assembly and using method thereof

PendingCN109882199AEasy to transport and constructSave groutUnderground chambersTunnel liningEngineeringGrout

The invention discloses a rigid sleeve valve pipe assembly and a using method thereof. The rigid sleeve valve pipe assembly comprises a first type sleeve valve pipe body, a second type sleeve valve pipe body and a third type sleeve valve pipe body which are connected in sequence, wherein the first type sleeve valve pipe body, the second type sleeve valve pipe body and the third type sleeve valve pipe body have the same pipe diameter size, a plurality of groups of plum blossom type grout vent holes are separately formed in the first type sleeve valve pipe body and the second type sleeve valve pipe body along the pipe walls of the first type sleeve valve pipe body and the second type sleeve valve pipe body, longitudinal intervals of the every two adjacent groups of grout vent holes are set as 20-40cm, and each group of grout vent holes comprises four grout vent hole bodies with the cross sections in a cross shape formed surrounding the pipe walls. The rigid sleeve valve pipe assembly adapts depth and high-pressure grouting, the grout vent holes are formed in a sleeve valve pipe in a plum blossom mode, grout can be diffused in multiple directions, the stratum is effectively filled, anelastic connecting piece can ensure that under the condition of without slip casting, a rubber blanket can firmly cover the grout vent holes, and the rubber blanket is prevented from falling in the transportation process or in the mounting process.

Owner:北京瑞威世纪铁道工程有限公司

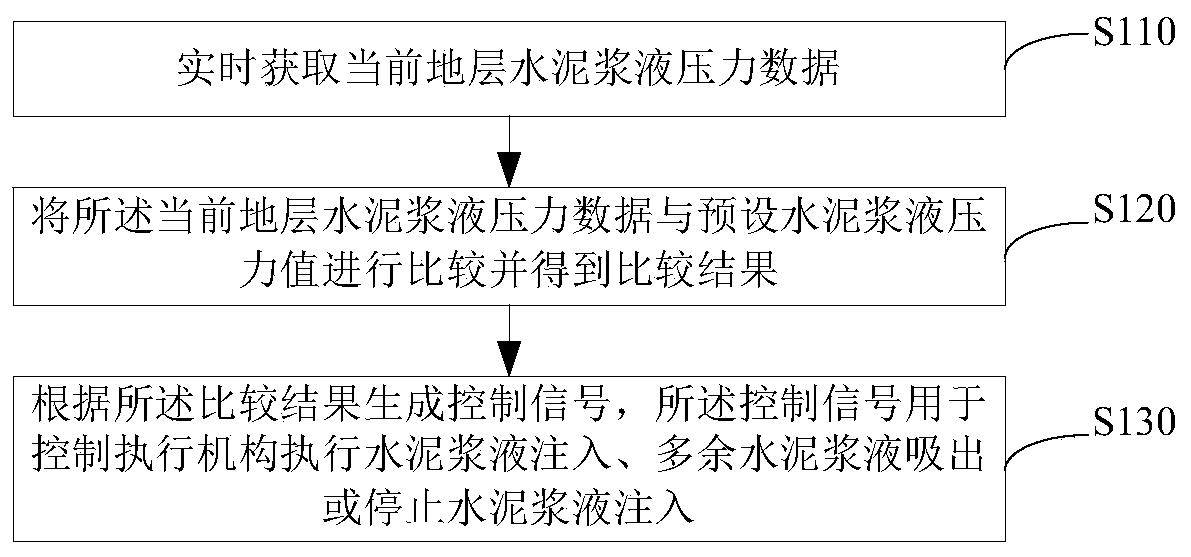

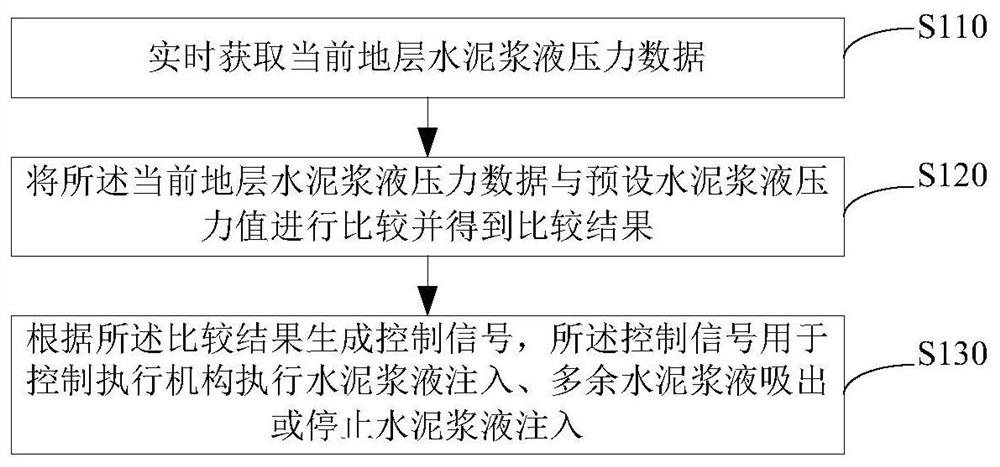

Grouting control method, device and system

ActiveCN111058450AEasy to controlRealize intelligent controlFoundation engineeringControl signalClassical mechanics

The invention relates to the technical field of drilling machine grouting, and particularly discloses a grouting control method. The grouting control method comprises the following steps of acquiringcement slurry pressure data of a current stratum in real time; comparing the cement grout pressure data of the current stratum with a preset cement grout pressure value to obtain a comparison result;and generating a control signal according to the comparison result, wherein the control signal is used for controlling an execution mechanism to execute cement slurry injection, redundant cement slurry suction or cement slurry injection stopping. The invention further discloses a grouting control device and system. According to the grouting control method, smooth grouting can be ensured, intelligent control is realized, and the problem of insufficient grouting or excessive overpressure grouting in the prior art is avoided.

Owner:JIANGSU WUXI MINERAL EXPLORATION MASCH GENERAL FAB CO LTD

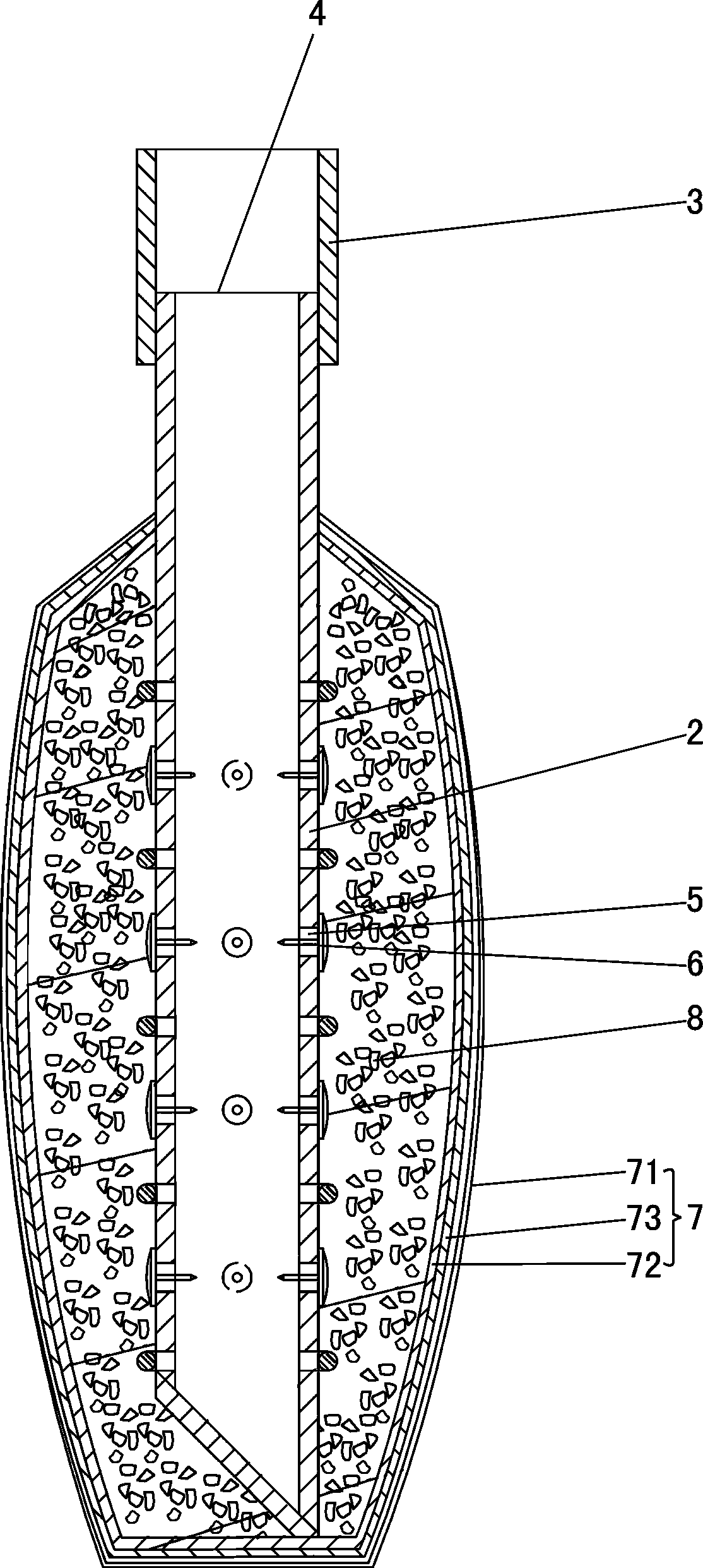

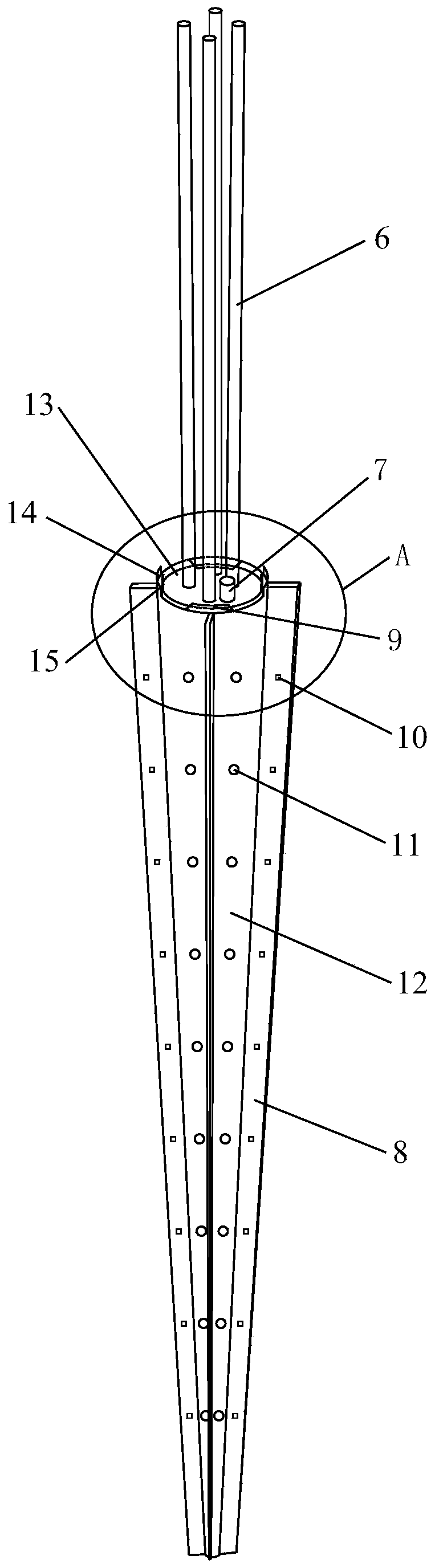

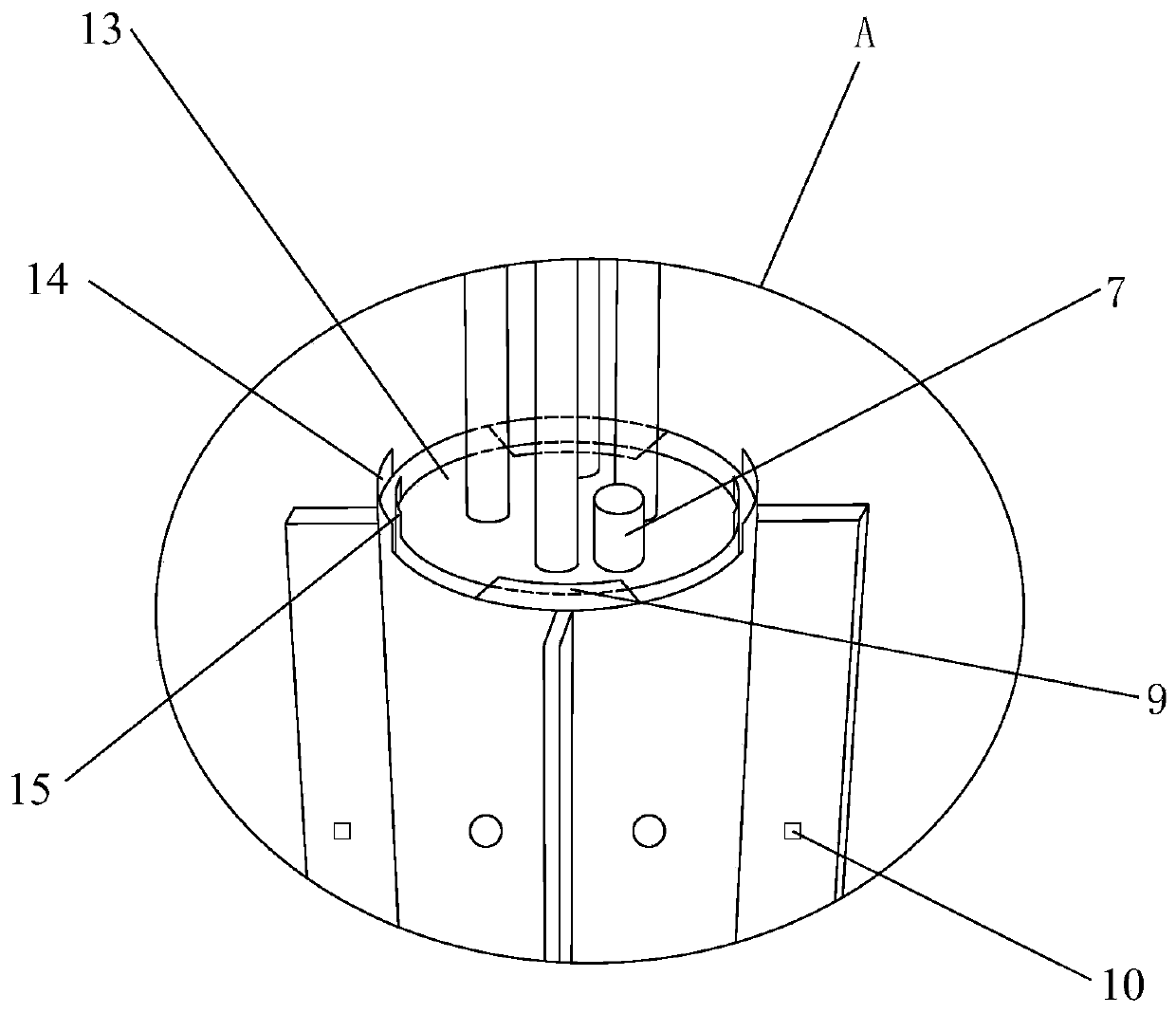

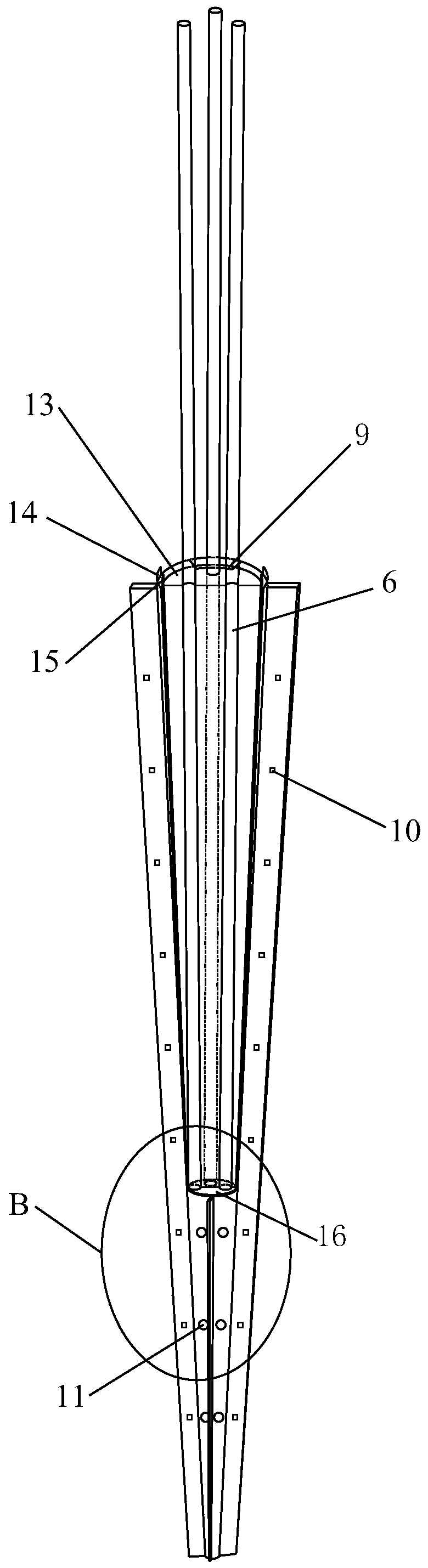

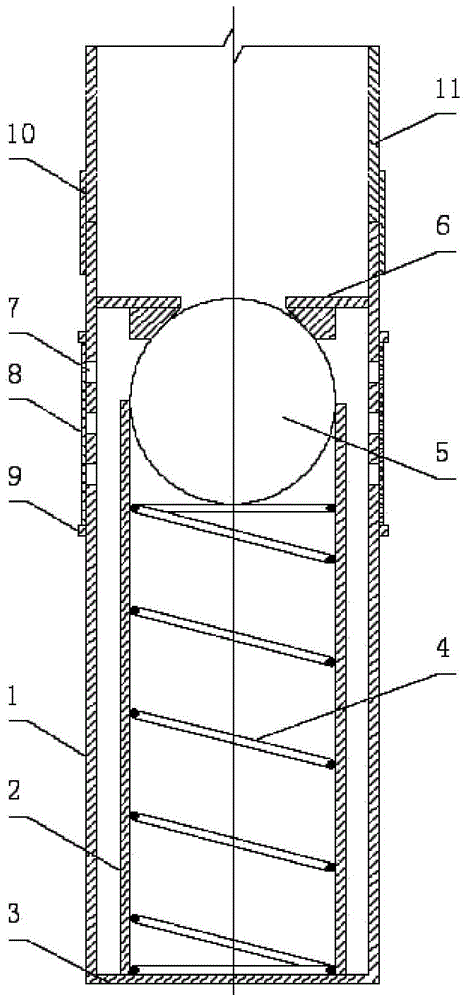

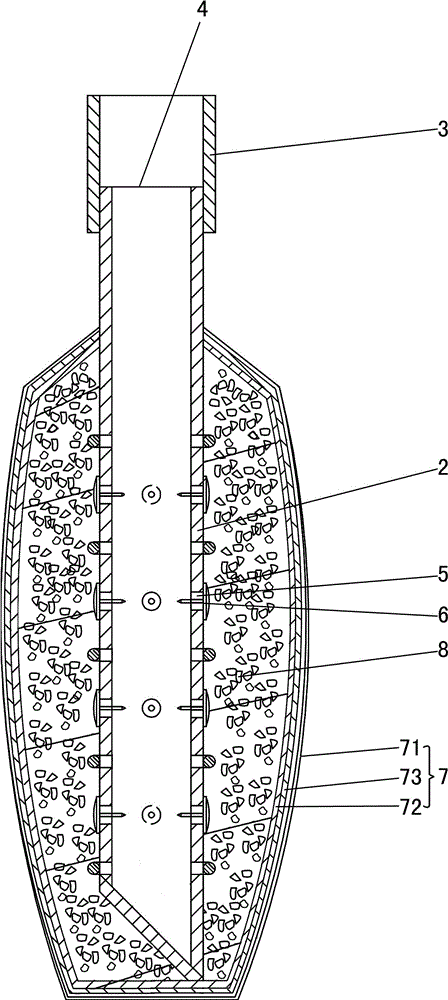

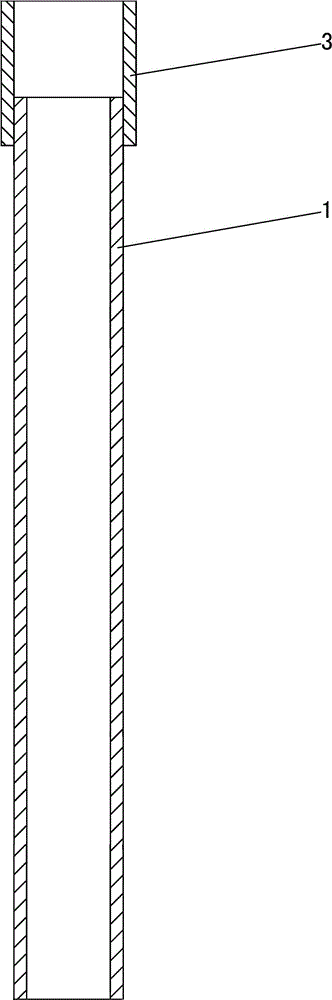

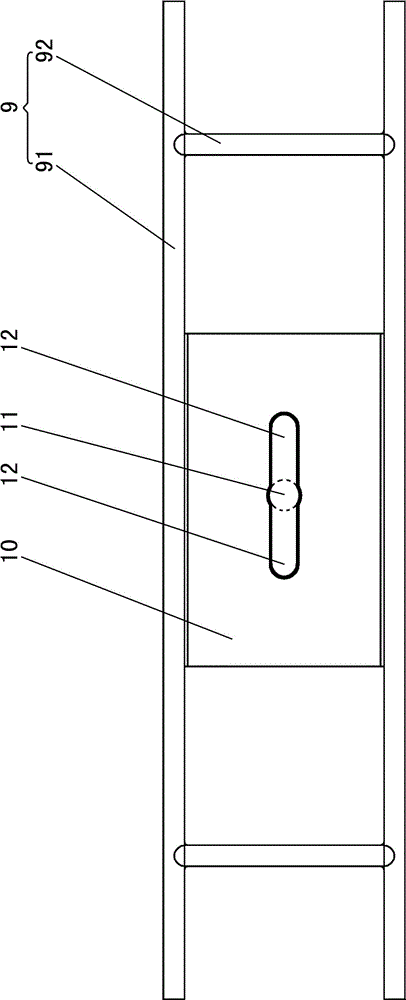

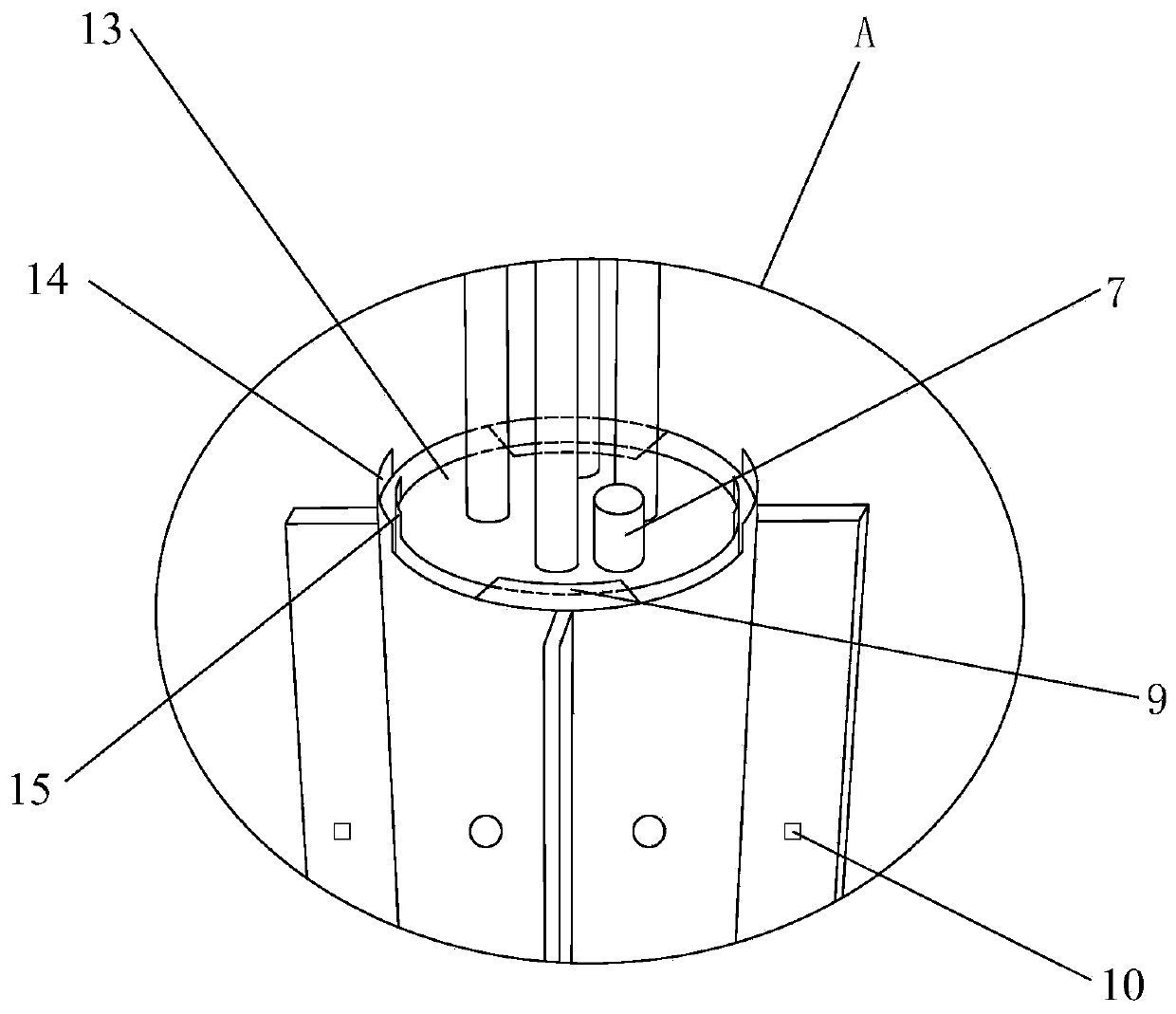

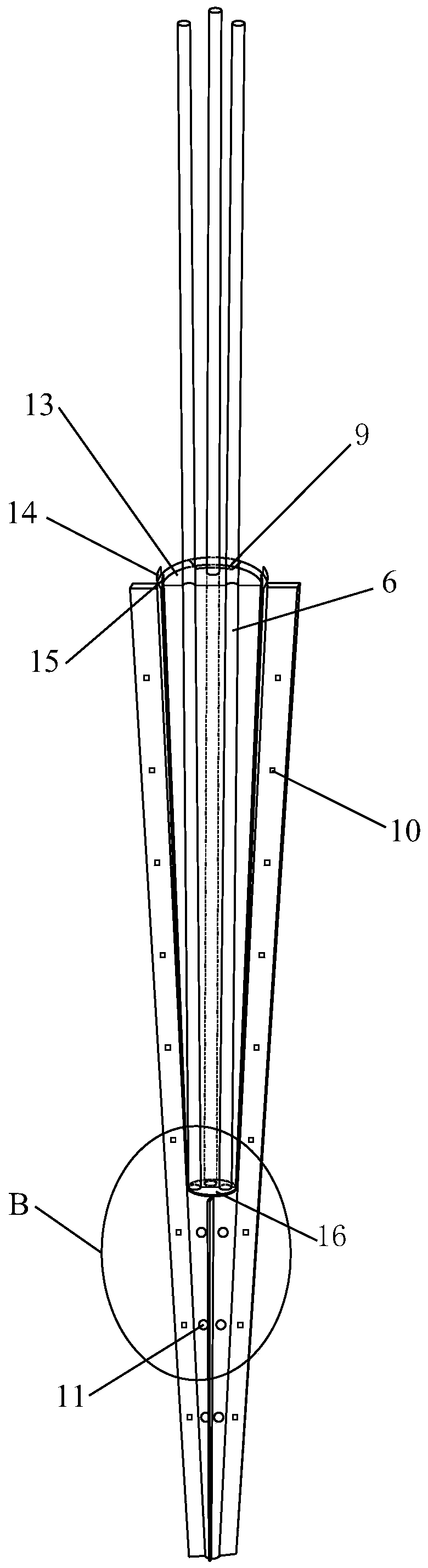

A coal pile temperature measurement and cooling grouting device and system

InactiveCN110108377BPrevent oxidationSuppress spontaneous combustionThermometers using electric/magnetic elementsUsing electrical meansThermodynamicsCooling effect

Owner:XIAN UNIV OF SCI & TECH

Freezing pipe grouting non-return device

InactiveCN103938613BGuarantee processing construction qualityPrevent mutual flowSoil preservationArchitectural engineeringWater treatment

The invention discloses a freezing pipe injected grout non-return device which is provided with an outer pipe and an inner pipe arranged in the outer pipe. A lower end sealing plate for simultaneously sealing the lower end of the outer pipe and the lower end of the inner pipe is arranged at the lower end of the outer pipe and the lower end of the inner pipe, a spring and a ball arranged on the spring are arranged in the inner pipe, an upper end sealing plate is arranged at the upper end of the outer pipe, a grout outlet matched with the ball is formed in the center of the upper end sealing plate, the outer pipe is provided with grout overflowing holes and a rubber sleeve for plugging the grout overflowing holes, and the upper end and the lower end of the rubber sleeve are provided with rubber sleeve fixing rings respectively. The freezing pipe injected grout non-return device is used for freezing hole pipe fixing water sealing processing, the construction technology of pipe fixing water sealing processing can be simplified, the requirements for construction devices and the construction technology can be reduced, the construction efficiency can be improved, the construction cost can be saved, and the construction quality can be guaranteed.

Owner:BEIFANG YANSHENG ENG TECH

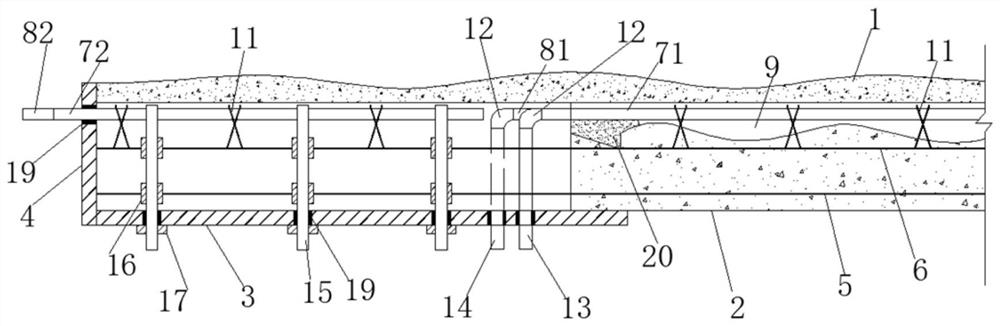

Secondary lining vault anti-disengaging device and construction method

ActiveCN112593978AAvoid voidsUniform and reasonable forceUnderground chambersHydro energy generationArchitectural engineeringLap joint

The invention discloses a secondary lining vault anti-disengaging device and a construction method. According to the anti-disengaging device, a secondary lining is arranged below a primary lining of the device, a lower-layer reinforcing mesh and an upper-layer reinforcing mesh are arranged in the secondary lining, a bottom formwork is arranged below a next-section secondary lining and is in lap joint with a previous-section secondary lining, an end formwork is arranged in front of the next-section secondary lining, a horizontal grouting pipe I and a horizontal exhaust pipe I are arranged belowthe primary lining, small holes are punched in the peripheries of the horizontal grouting pipe I and the horizontal exhaust pipe I and are wrapped with filter cloth, 3-6 detection pipes are arrangedalong the central axis of the secondary lining of each section, the tops of the detection pipes are 12 cm lower than the surface of the primary lining, and the detection pipes penetrate into positioning sleeves fixed on the upper-layer reinforcing mesh and the lower-layer reinforcing mesh. According to the anti-disengaging device, tunnel secondary lining vault concrete disengagement can be prevented, and the secondary lining construction quality is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

A grouting control method, device and system

ActiveCN111058450BEasy to controlRealize intelligent controlFoundation engineeringControl signalCement slurry

The present invention relates to the technical field of drilling rig grouting, and specifically discloses a grouting control method, which includes: obtaining the current formation cement slurry pressure data in real time; comparing the current formation cement slurry pressure data with a preset cement slurry pressure value And obtain the comparison result; generate a control signal according to the comparison result, and the control signal is used to control the actuator to perform cement slurry injection, suck out excess cement slurry or stop cement slurry injection. The invention also discloses a grouting control device and system. The grouting control method provided by the invention can ensure the smooth progress of grouting, realize intelligent control, and avoid the problems of insufficient grouting or excessive pressure grouting in the prior art.

Owner:JIANGSU WUXI MINERAL EXPLORATION MASCH GENERAL FAB CO LTD

Construction Method of Internal Leakage Plugging and External Grouting of Sewage Pipeline

The invention discloses a sewage pipeline internal plugging and external grouting construction method. The construction method sequentially includes the following steps that firstly, pipeline internal plugging is performed; secondly, grouting holes are drilled, and cement slurry backfill grouting is performed. In the first step, pipe body leakage points of a sewage pipeline and the peripheries of the leakage points are subjected to chiseling, cleaning and washing, chiseling reaches the concrete surface of the sewage pipeline in the aspect of depth, and then plugging materials are used for compact filling. In the second step, a drilling machine is used for drilling a row of drill holes in each of the soil layers of the left side and the right side of the sewage pipeline, and the drill holes serve as the grouting holes; a row of drill holes are drilled in a soil layer above the center line of the sewage pipeline and serve as the grouting holes; grouting materials are added into a high-speed stirrer to be evenly stirred, and a grouting pump is started to start grouting when the fluidity meets the grouting requirement. By means of the method, compared with a traditional mode that a lining pipe is used, cost is greatly saved, the practical available pipe diameter of the sewage pipeline is not shrunk, and stratum stress is prevented from damaging the sewage pipeline.

Owner:XUCHANG WATER CONSERVANCY CONSTR ENG CO LTD

Waterproof and Leakage Repairing Construction Method for Sewage Pipe Network Below Groundwater Level

The invention discloses a water proofing and leak repairing construction method for a sewage pipe network below the underground water level. The method is performed through the following steps that 1, sewage removal is performed on a pipeline; 2, leak points are found and marked; 3, a precipitation well is drilled, and precipitation processing is performed on a construction well point; 4, leaking stoppage is performed on the interior of the pipeline; 5, a grouting hole is drilled, and cement paste is backfilled and grouted. According to the method, a lining pipe does not need to be used, the construction cost is saved by 50% compared with the method that water proofing and leak repairing are performed on the sewage pipe network in a lining pipe mode, and the high application and popularization value is achieved; the actual available pipe diameter of the sewage pipeline cannot be reduced, and the phenomenon that the drainage capacity of the sewage pipeline is reduced due to water proofing and leak repairing cannot occur; by grouting on the exterior of the pipeline to form a grouting layer at the periphery of the sewage pipeline, the strata at the periphery of the sewage pipeline is reinforced, and effective protection on the sewage pipeline is formed to prevent formation stress from destroying the sewage pipeline.

Owner:XUCHANG WATER CONSERVANCY CONSTR ENG CO LTD

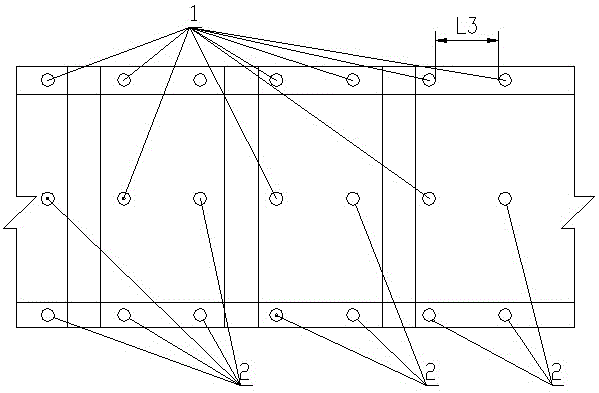

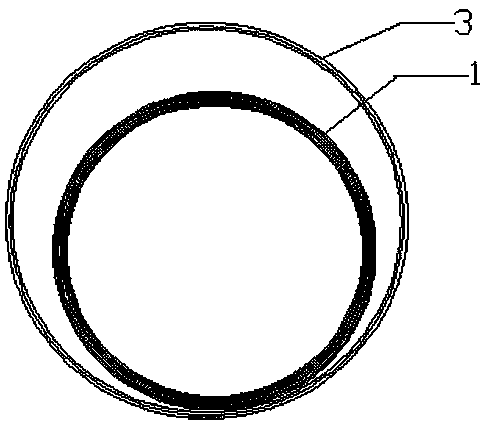

Grouting pipe construction method for post grouting of cast-in-place pile

The invention discloses a grouting pipe construction method for post grouting of a cast-in-place pile. The grouting pipe construction method comprises the steps of manufacturing pile side grouting hoses, and forming side grout outlet holes in the preset positions of the manufactured pile side grouting hoses; installing a plurality of pile side grouting hoses on the pile side along the peripheral side of a reinforcement cage in a surrounding mode, so that the sides, with the side grout outlet holes, of the pile side grouting hoses are arranged in a protruding mode away from the reinforcement cage, outer protruding parts are formed on the outer sides of the pile side grouting hoses, and inner concave parts are formed on the inner sides of the pile side grouting hoses; installing a plurality of pile side grouting pipes in the preset position of the reinforcement cage, and communicating grout outlet holes in the bottoms of the pile side grouting pipes with pipe bodies of the pile side grouting hoses; installing a pile bottom grouting pipe at the bottom of the reinforcement cage, so that the bottom of the pile bottom grouting pipe extends out of the bottom of the reinforcement cage by a preset length; and connecting the pile side grouting pipes and the pile bottom grouting pipe with a grouting device. According to the grouting pipe construction method, the situation that the grout outlet holes of the grouting pipes are completely wrapped by concrete can be avoided, follow-up grouting is in a smooth state, and the construction quality of a pile foundation is improved.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

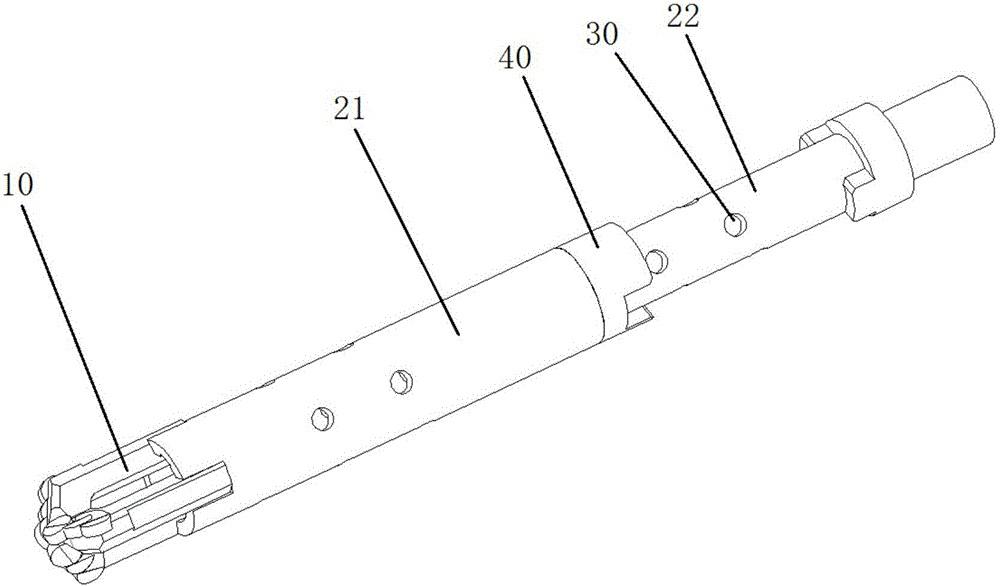

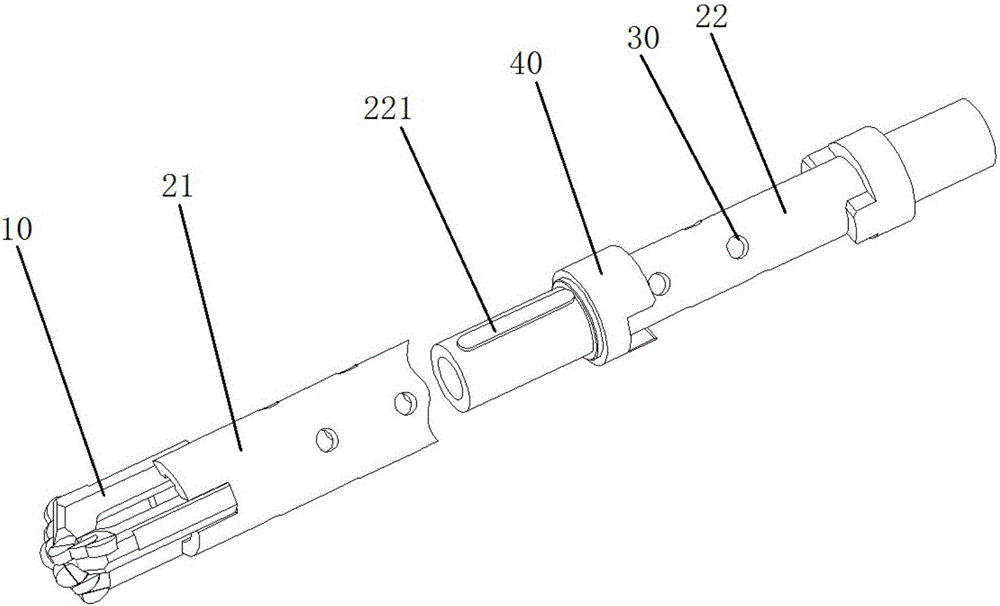

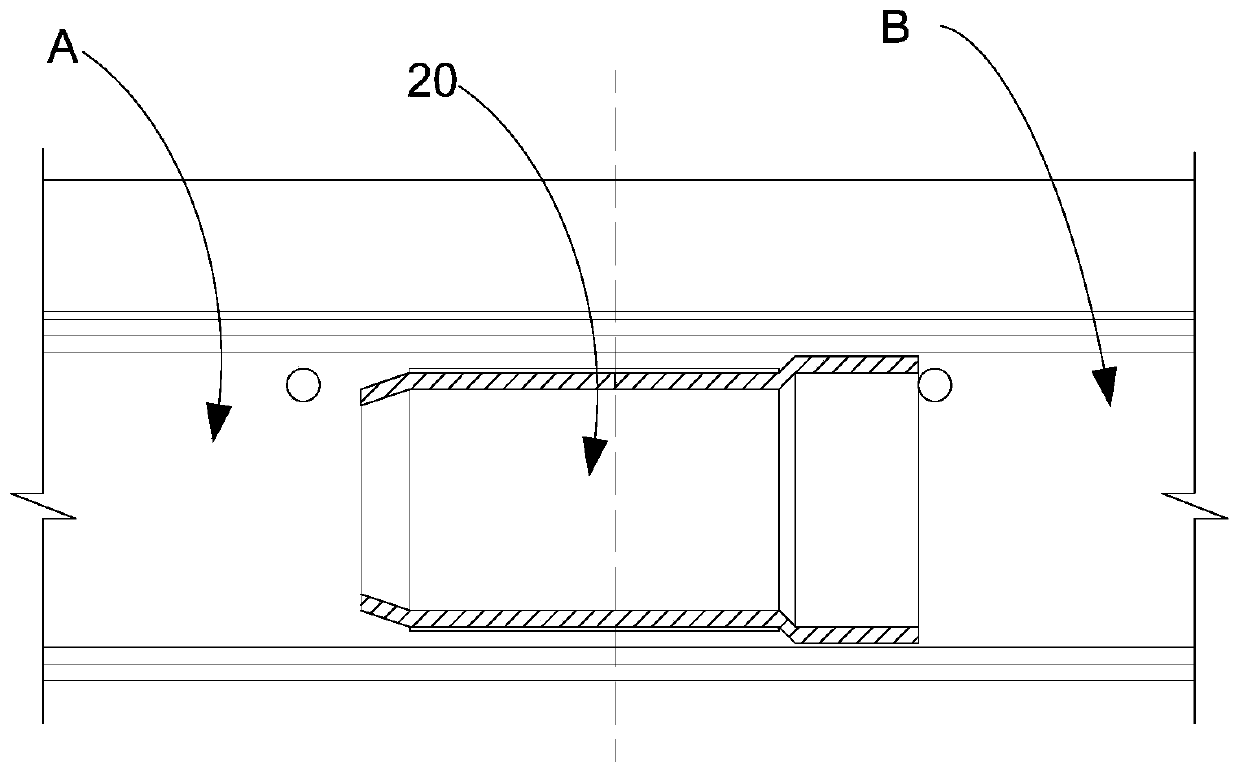

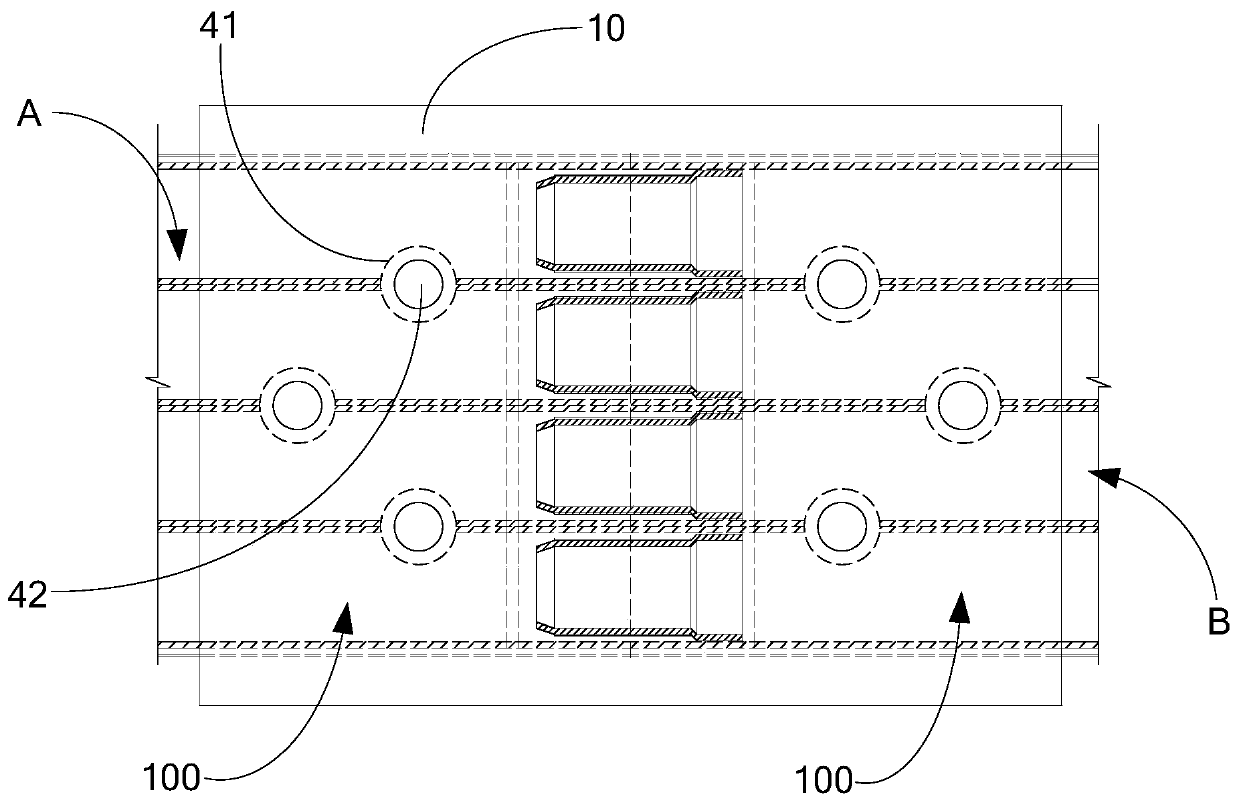

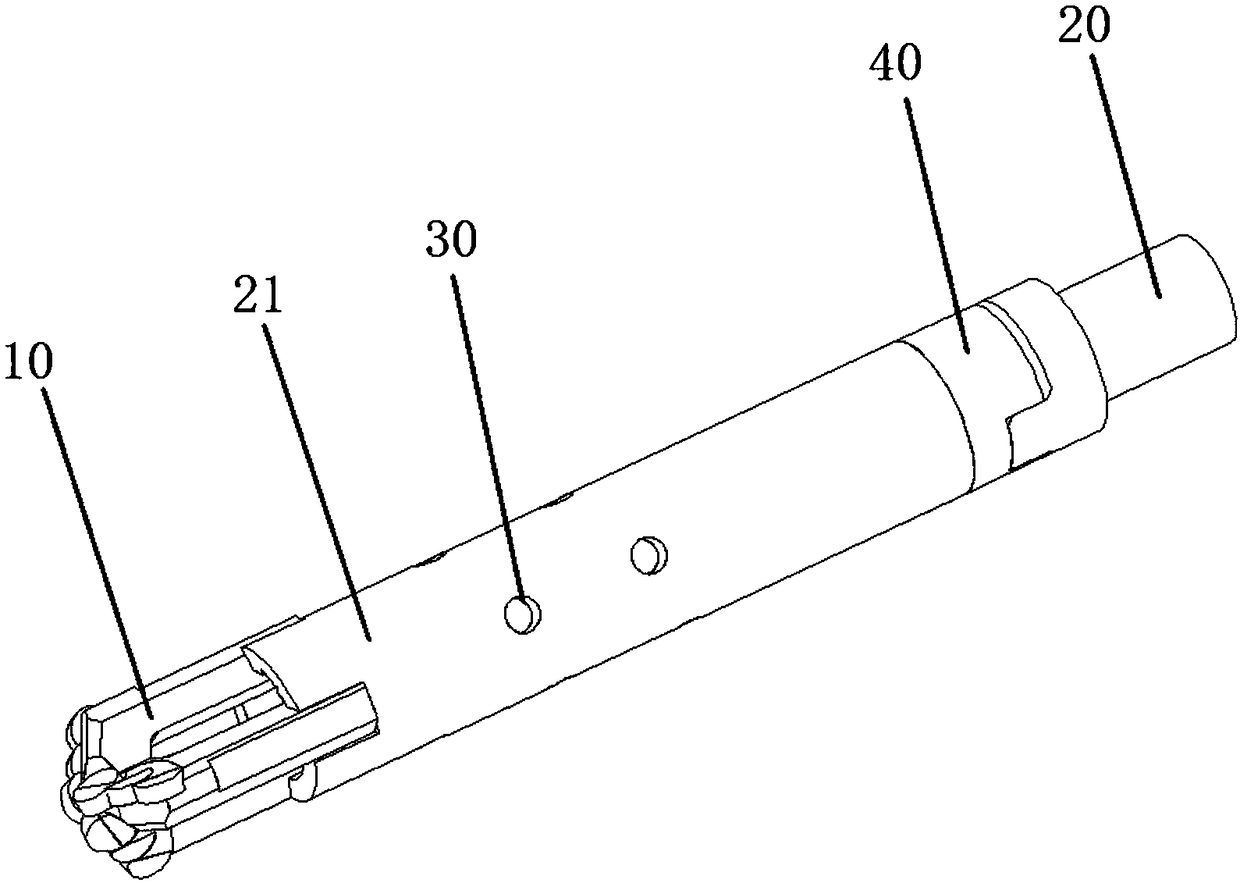

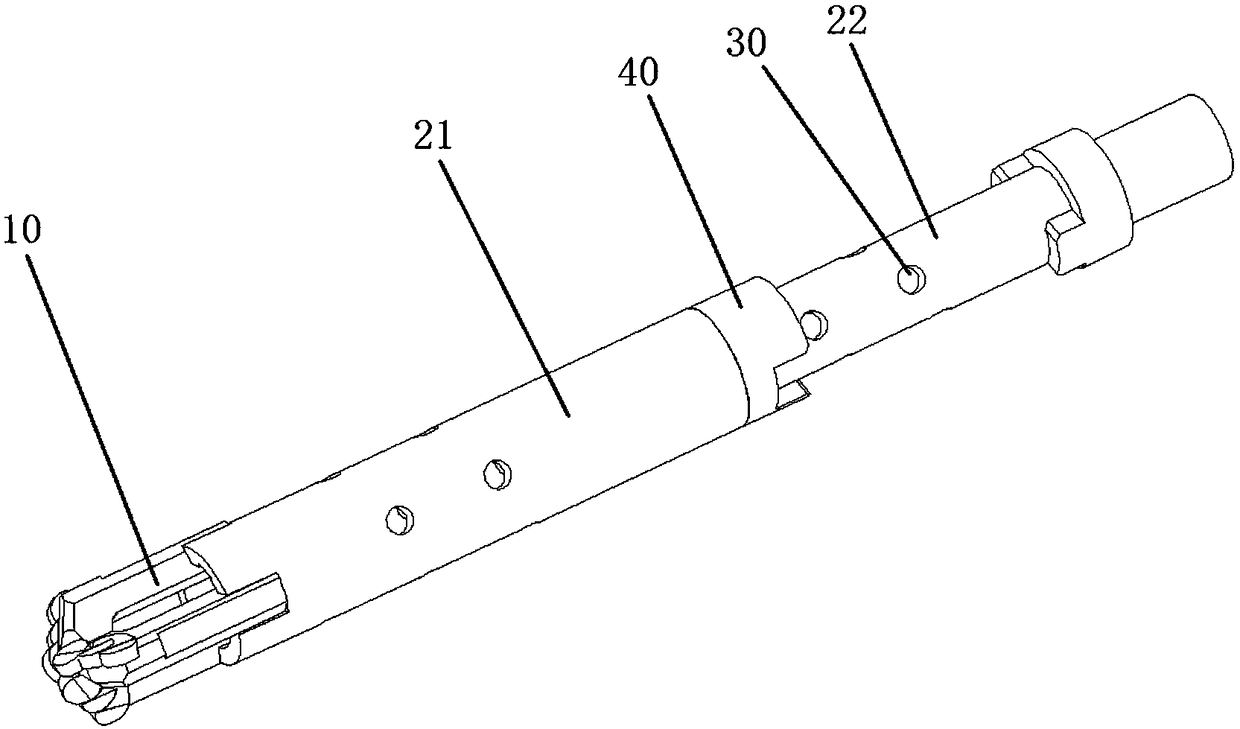

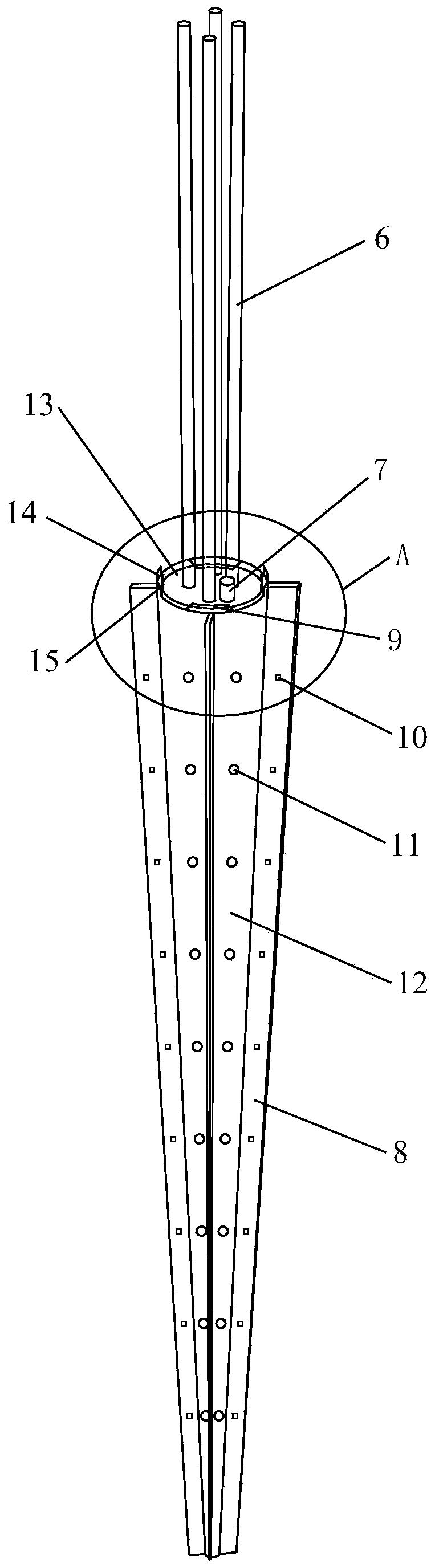

Disposable telescopic drilling tool used for fire preventing and extinguishing grouting in underground coal mine

ActiveCN106437531AIncrease the amount of groutExtended perfusion rangeEarth drilling toolsCoalDrill bit

The invention discloses a disposable telescopic drilling tool used for fire preventing and extinguishing grouting in an underground coal mine. A front leading drill bit comprises three wing panels, joints of the three wing panels are in hollowed-out design, three top cutting disks located at the topmost end of the front leading drill bit rotate by 15 degrees towards the same direction along the side boundaries of the three wing panels correspondingly, and the projection portions of the three top cutting disks on a plane perpendicular to the axis of a rod body are overlapped; a flat key is arranged on the surface of the front portion of an inner core in the length direction, and a key groove matched with the flat key is formed in the inner wall of a sleeve in the length direction; and the rear end of the key groove makes contact with a clamping component, and a plurality of grouting holes are formed in the sleeve and the inner core. According to the disposable telescopic drilling tool used for the fire preventing and extinguishing grouting in the underground coal mine, under the precondition that hole-drilling construction is not influenced, a grouting way is extended from dot grouting to line grouting, and thick liquid is grouted from the multiple distributed grouting holes to a drilling rod, so that the grouting quantity is increased, the hole blocking probability is lowered, and grouting efficiency is improved; and full cutting is achieved, thus, the hole forming speed is greatly increased, and the three top cutting disks share the destructive power of a rock body to a single top cutting disk, so that the situation that hole drilling is successfully conducted is guaranteed.

Owner:CHINA UNIV OF MINING & TECH +1

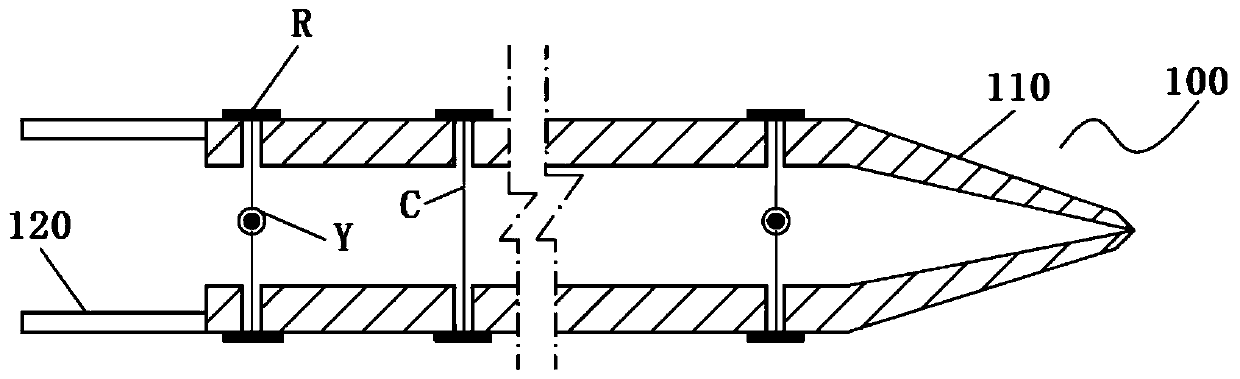

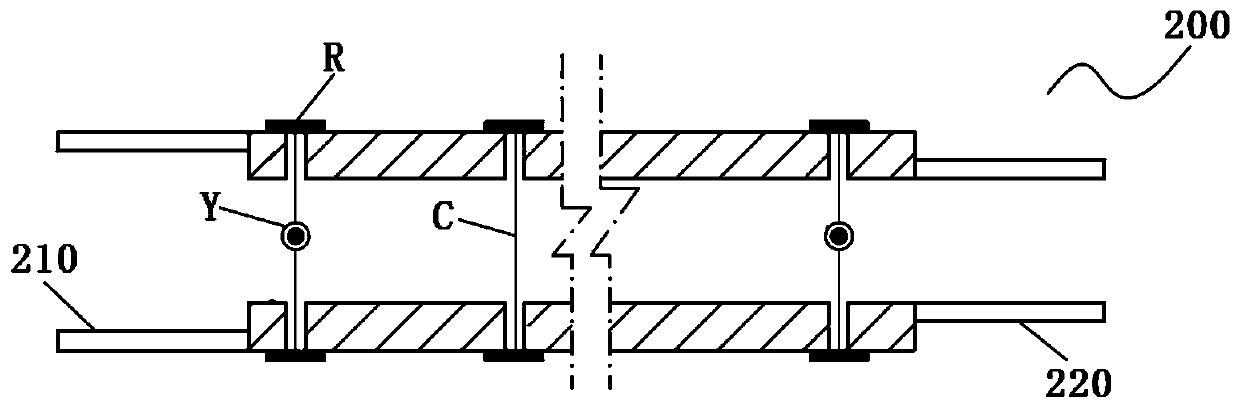

High-strength joint construction device suitable for composite cavity components

ActiveCN110630287AEasy to installSmooth groutingUnderground chambersTunnel liningHigh intensityEngineering

The invention discloses a high-strength joint construction device suitable for composite cavity components. The high-strength joint construction device is applied to the composite cavity components where a plurality of cavities are formed. Cavity walls are arranged between adjacent cavities. The high-strength joint construction device comprises a high-strength connection plate arranged at the joint of the adjacent composite cavity components, a nut and a bolt. A connector assembly face located on the first side is formed on the two composite cavity components. The high-strength connection plates is attached and connected to the connector assembly face. Two connection parts are formed on the high-strength connection plate and are connected to the two composite cavity components correspondingly. The nut penetrates through the cavity walls from the second side of the composite cavity components to the first side. Connection holes are formed in the connection parts. The bolt penetrates through the connection holes and is in threaded connection with the nut. Specifically, the high-strength connection plate covers the joint between the adjacent composite cavity components, high-strengthconnection between the composite cavity components is achieved, the high-strength joint construction device has high tensile resistance and bending resistance, and a high-strength continuum is formedto effectively reinforce a stagger-jointed assembling tunnel.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Method for conducting grouting construction at back of pile bottom of cast-in-place pile

A method for conducting grouting construction at the back of the pile bottom of a cast-in-place pile sequentially includes the following steps: (1) manufacturing and arranging a grouting pipe which comprises a plurality of grouting steel pipe sections sequentially connected from top to bottom with the lower end of the lowest grouting steel pipe section connected with a grouting spraying nozzle; (2) assembling a grouting station and a slurry transportation pipeline; (3) grouting. The method is characterized in that the grouting spraying nozzle used in the step (1) comprises a slurry spraying pipe body, a slurry inlet is formed in the upper end of the slurry spraying pipe body, a plurality of slurry discharging holes are formed in the lateral wall of the slurry spraying pipe body, a grouting one-way valve is installed on the slurry discharging holes, a sand wrapping device is arranged on the outside of the slurry spraying pipe body, a sand isolation layer is arranged between the sand wrapping device and the outer side of the slurry spraying pipe body, and the sand isolation layer covers the grouting one-way valve. When the grouting spraying nozzle reaches the bottom of a pile hole, and the portion of the upper end of the grouting pipe higher than the ground reaches preset height, the upper end of the grouting pipe is fixedly connected with a protection barrel at the top of the pile hole. By means of the method, smooth grouting can be achieved, grouting quality is ensured, and success ratio is ensured.

Owner:广东省第二建筑工程有限公司

A filtering and stabilizing acrylic grouting tank device

The invention discloses a device for filtering and stabilizing an acrylic grouting tank, which comprises a tank body and an upper cover. A circular shelf is arranged at the joint between the tank body and the upper cover, and a detachable and large-capacity filter screen is arranged in the middle of the shelf. , the top of the upper cover is connected with an automatic valve, the left and right sides of the automatic valve are respectively provided with an adjusting bolt and a sealing bolt, the adjusting bolt is connected to the valve plug through a spring, one end of the air pipe is connected to the sealing bolt, and the other end of the air pipe is connected to the upper cover , the space between the sealing bolt and the valve plug forms an air intake chamber, and the upper and lower ends of the automatic valve are respectively connected with a feed valve and a guide tube. Easy to implement, good effect, improve production efficiency, greatly improve product quality and process level, product light transmittance generally increased from below 92% to about 96‑97%, greatly expand the application field of products and the high standard requirements of special industries .

Owner:瑞昌荣联环保科技有限公司

A ceramic tile thin paste method layer structure and its construction technology

ActiveCN112065000BEmpty position fillingExpand the scope of groutingBuilding constructionsStructural engineeringMechanical engineering

The present application relates to the field of decoration engineering, in particular to a ceramic tile thin paste layer structure and its construction technology, which includes a base layer, a tile adhesive layer and ceramic tiles arranged in sequence, and a disposable The base has a wedge inserted on the disposable base, a cross positioning frame is installed at the cross gap between four adjacent ceramic tiles, and a relief hole is provided at the center of the cross positioning frame. The application has the effect of effectively solving the problem of hollowing under the corners of tiles.

Owner:YENOVA NOVARTIS HOME DECORATION GRP CO LTD

A disposable telescopic drilling tool used for fire prevention and grouting in coal mines

ActiveCN106437531BIncrease the amount of groutExtended perfusion rangeEarth drilling toolsStructural engineeringFire prevention

The invention discloses a disposable telescopic drilling tool used for fire preventing and extinguishing grouting in an underground coal mine. A front leading drill bit comprises three wing panels, joints of the three wing panels are in hollowed-out design, three top cutting disks located at the topmost end of the front leading drill bit rotate by 15 degrees towards the same direction along the side boundaries of the three wing panels correspondingly, and the projection portions of the three top cutting disks on a plane perpendicular to the axis of a rod body are overlapped; a flat key is arranged on the surface of the front portion of an inner core in the length direction, and a key groove matched with the flat key is formed in the inner wall of a sleeve in the length direction; and the rear end of the key groove makes contact with a clamping component, and a plurality of grouting holes are formed in the sleeve and the inner core. According to the disposable telescopic drilling tool used for the fire preventing and extinguishing grouting in the underground coal mine, under the precondition that hole-drilling construction is not influenced, a grouting way is extended from dot grouting to line grouting, and thick liquid is grouted from the multiple distributed grouting holes to a drilling rod, so that the grouting quantity is increased, the hole blocking probability is lowered, and grouting efficiency is improved; and full cutting is achieved, thus, the hole forming speed is greatly increased, and the three top cutting disks share the destructive power of a rock body to a single top cutting disk, so that the situation that hole drilling is successfully conducted is guaranteed.

Owner:CHINA UNIV OF MINING & TECH +1

Coal pile temperature measuring and cooling grouting device and system

InactiveCN110108377APrevent oxidationSuppress spontaneous combustionThermometers using electric/magnetic elementsUsing electrical meansCooling effectEngineering

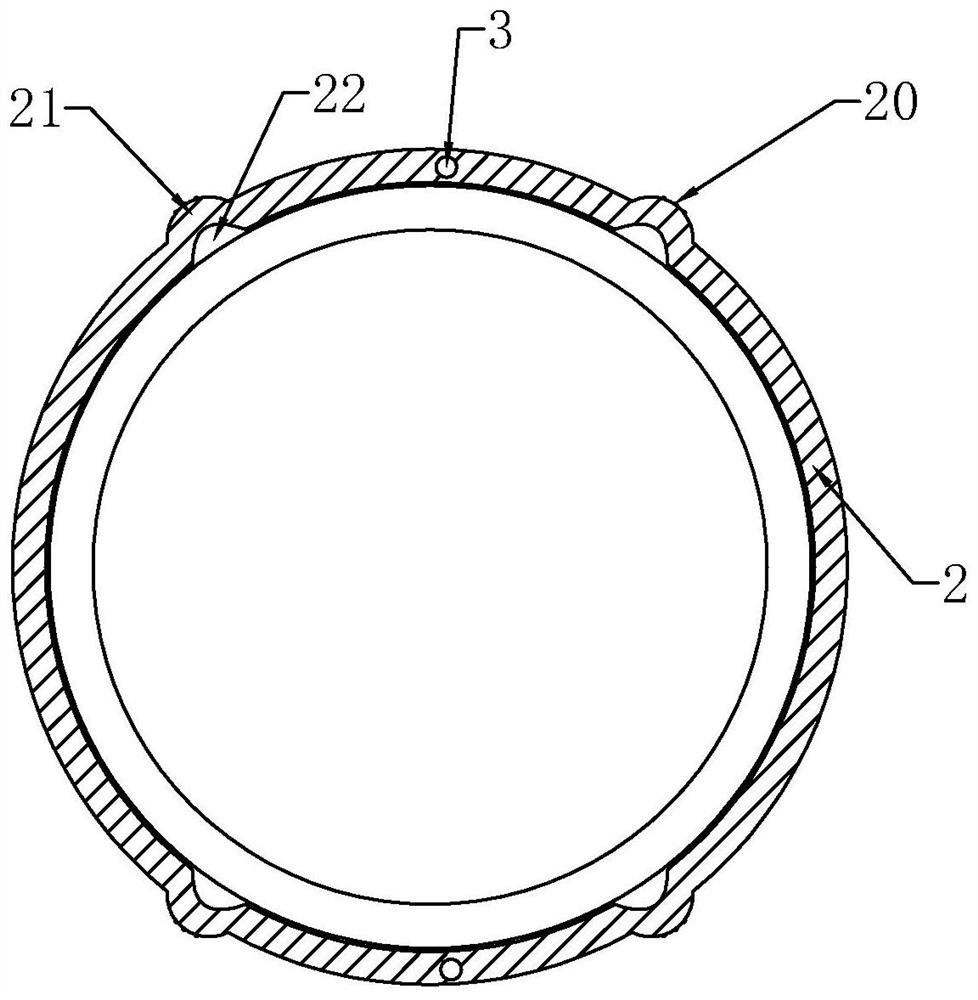

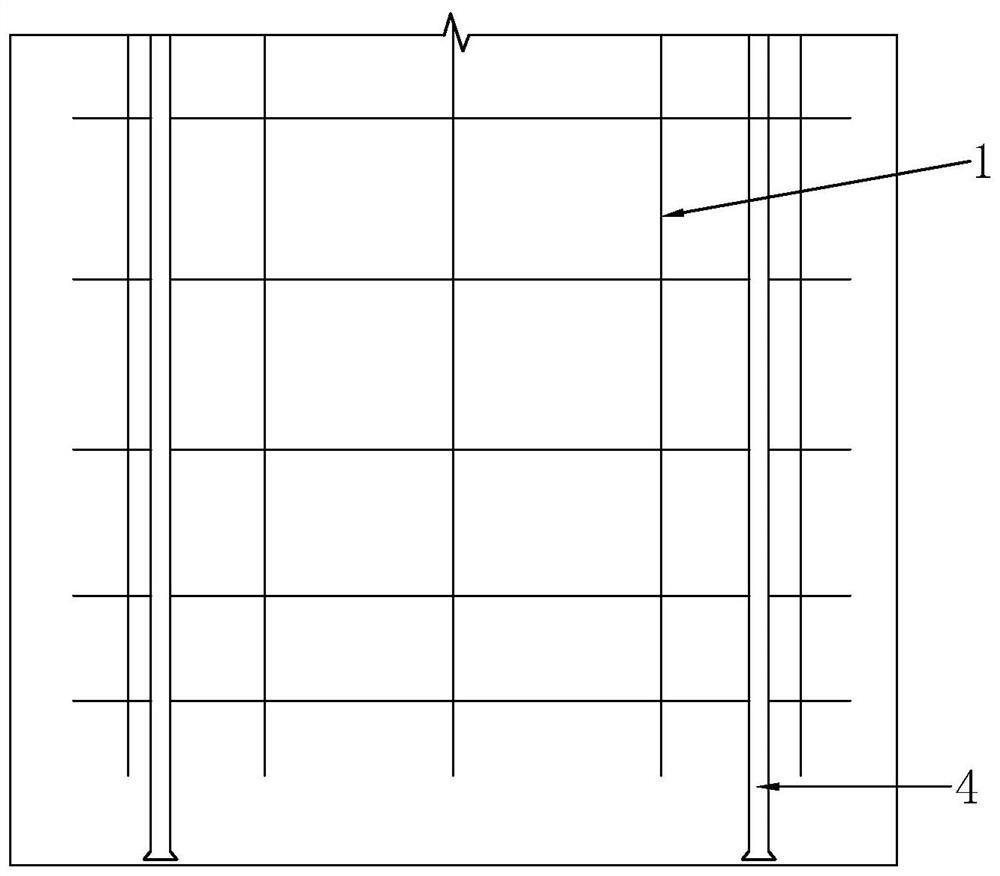

The invention discloses a coal pile temperature measuring and cooling grouting device. The coal pile temperature measuring and cooling grouting device comprises an outer-layer inverted circular truncated cone body, an inner-layer inverted circular truncated cone body and self-heat-transfer heat pipes; the inner-layer inverted circular truncated cone body is connected with the outer-layer invertedcircular truncated cone body through bayonets; the top of the outer-layer inverted circular truncated cone body is of an open structure; the bottom of the outer-layer inverted circular truncated conebody is provided with an outer-layer circular truncated cone body bottom plate; the top of the inner-layer inverted circular truncated cone body is provided with an inner-layer inverted circular truncated cone body top plate; the bottom of the inner-layer inverted circular truncated cone body is provided with an inner-layer inverted circular truncated cone body bottom plate; the lower ends of theself-heat-transfer heat pipes penetrate through the inner-layer inverted circular truncated cone body top plate and extend into the middle-lower part of the inner-layer inverted circular truncated cone body; fins are arranged on the outer side wall of the outer-layer inverted circular truncated cone body; the fins are provided with a plurality of thermocouples; a plurality of outer-layer invertedcircular truncated cone body grout outlets are formed in the outer-layer inverted circular truncated cone body; a plurality of inner-layer inverted circular truncated cone body grout outlets are formed in the inner-layer inverted circular truncated cone body; and the inner-layer inverted circular truncated cone body is provided with a grouting system. The invention further discloses a coal pile temperature measuring and cooling grouting system. With the coal pile temperature measuring and cooling grouting device and system of the invention adopted, the temperature of a coal pile can be monitored in real time, the coal pile can be cooled through the self-heat-transfer heat pipes; the coal pile can be accurately cooled through grouting; and a cooling effect is good.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com