Sewage pipeline internal plugging and external grouting construction method

A technology for sewage pipelines and construction methods, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of high construction cost, no sewage pipeline protection, waste of resources, etc. Value, the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

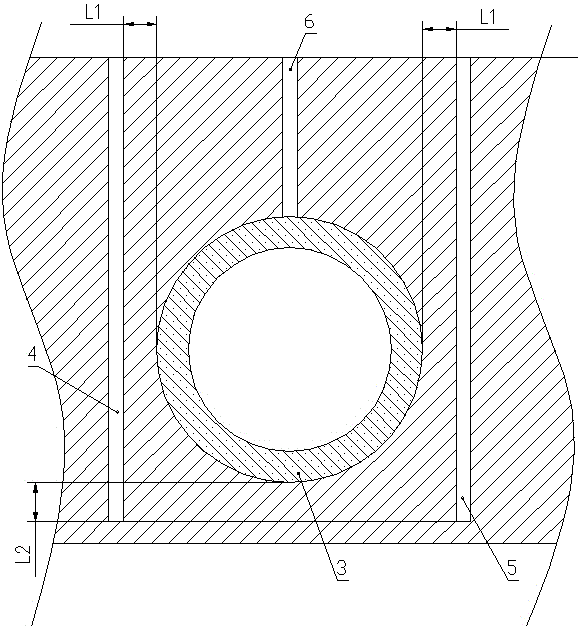

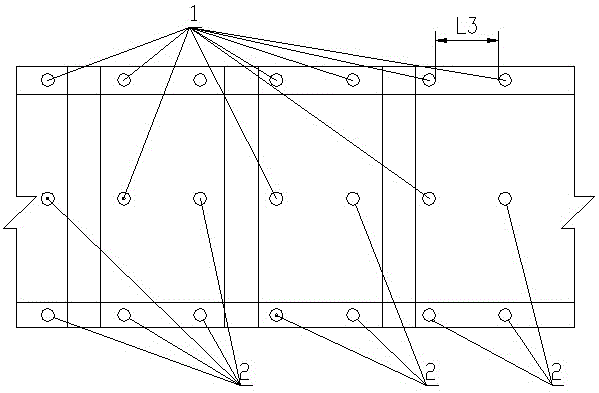

[0037] Such as figure 1 and figure 2 Shown, the construction method of external grouting for plugging inside the sewage pipeline of the present invention is carried out according to the following steps:

[0038] The first step is to plug the leak in the pipeline;

[0039] The second step is to drill the grout holes and backfill the grout with grout.

[0040] The first step, namely the step of plugging in the pipeline, is specifically:

[0041]For the leakage point of the sewage pipe 3 pipe body, chisel, clean and rinse the parts around the leakage point. The depth of the chiseling is to reach the concrete surface of the sewage pipe 3, and then fill it with a plugging material. Specifically, use a flat Drill into oilseed at the leakage point, then plug the hole with quick-setting waterproof material, level it, and fill the gap around the leakage point with composite waterproof material (such as epoxy resin material) after solidification;

[0042] The concrete plugging oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com