High-strength joint construction device suitable for composite cavity components

A high-strength, cavity technology, applied in the direction of connecting components, shaft equipment, pins, etc., can solve problems such as lack of equipment, and achieve high tensile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

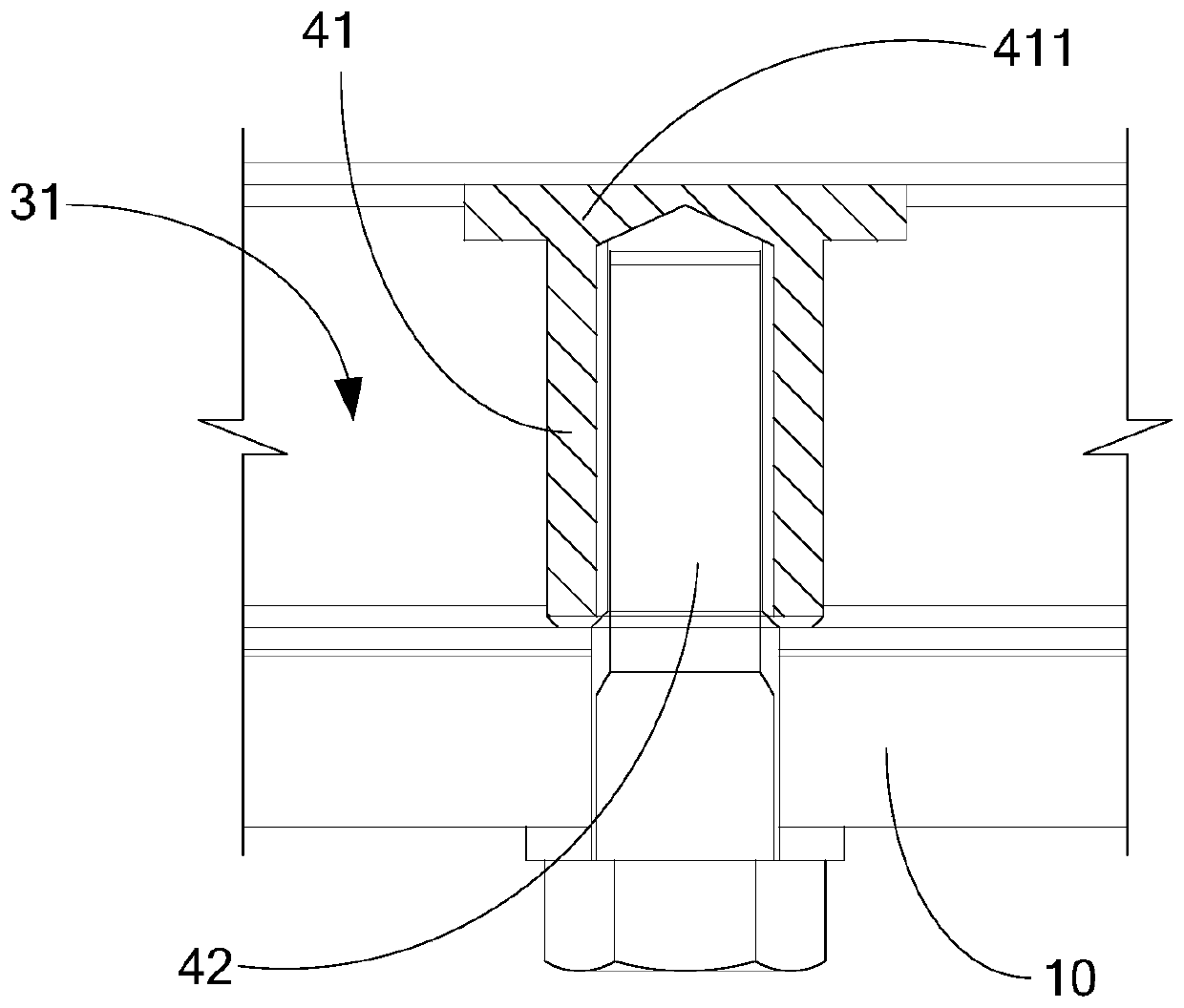

[0022] In order to solve the problem that the joint of the existing composite lining (composite cavity) structure only considers easy installation and smooth grouting and does not have high tensile and flexural strength, the present invention provides a suitable High-strength joint construction device for composite cavity members.

[0023] The high-strength joint construction device of the present invention suitable for composite cavity components will be further described below with reference to the accompanying drawings and specific embodiments. Those skilled in the art can easily understand other advantages and functions of the present invention from the content disclosed in this specification.

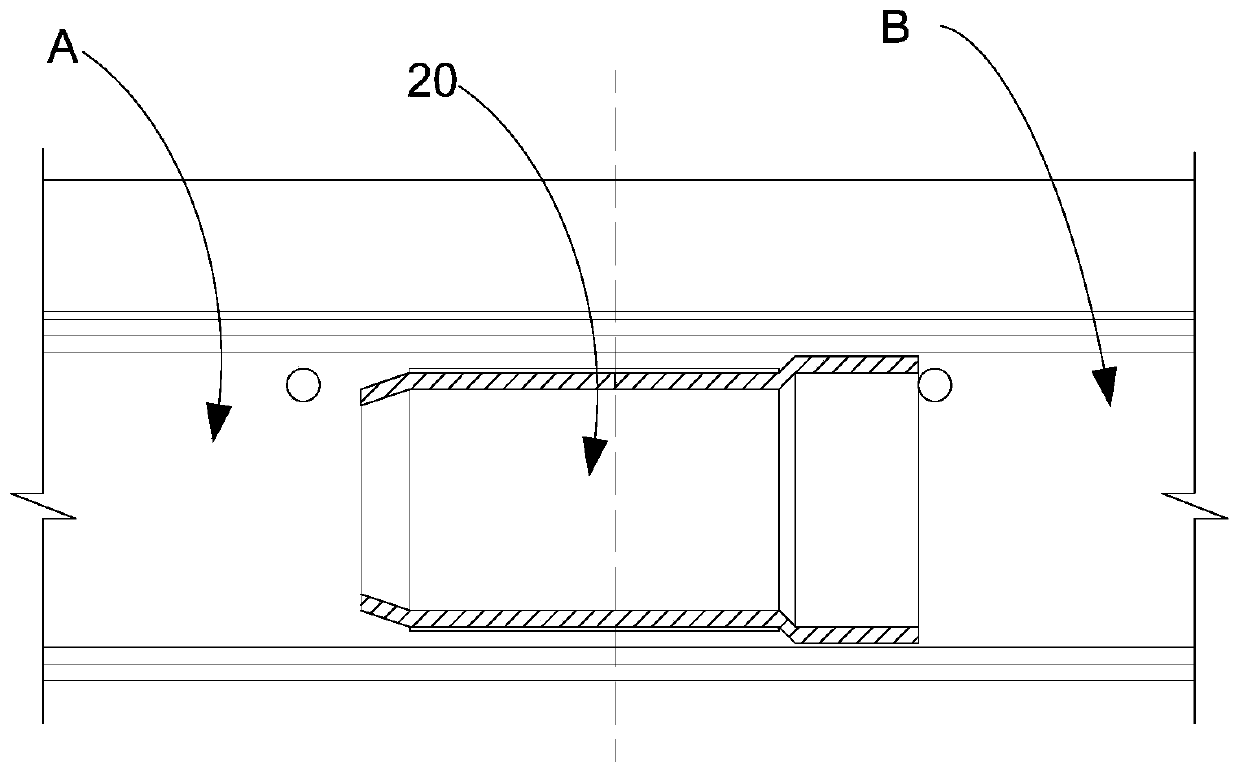

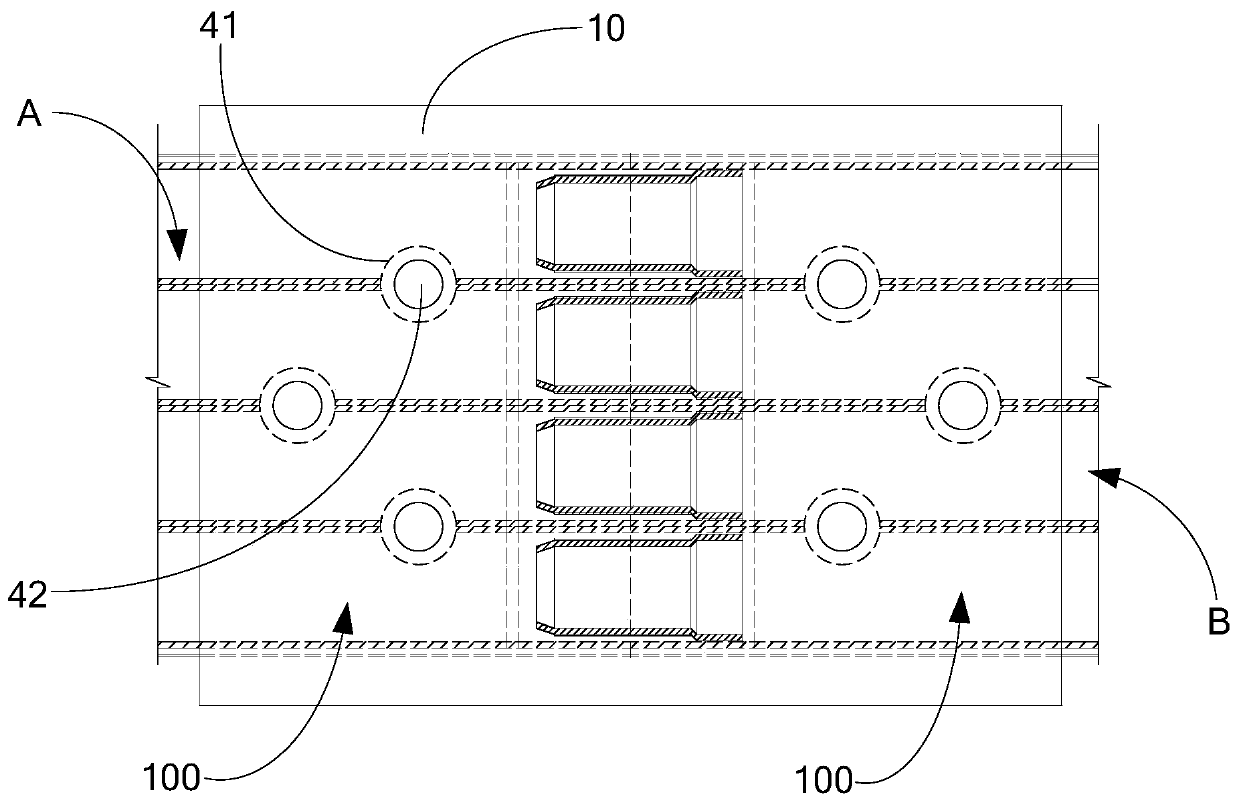

[0024] combine figure 2 and image 3 As shown, the present invention is suitable for a high-strength joint construction device of a composite cavity member, and is applied to a composite cavity member formed with a plurality of cavities 31, and a cavity wall 32 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com