Protective device for prestressed duct hole-forming

A protection device and prestressing technology, applied in the processing of building materials, on-site preparation of building components, formwork/template/work frame, etc. High cost, small scope of adaptation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

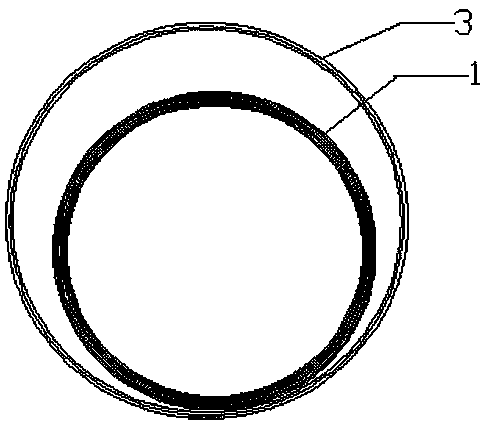

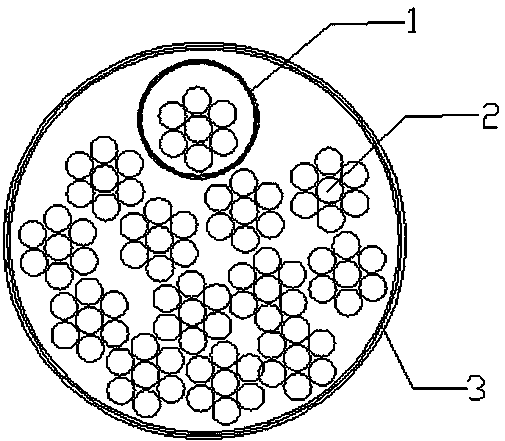

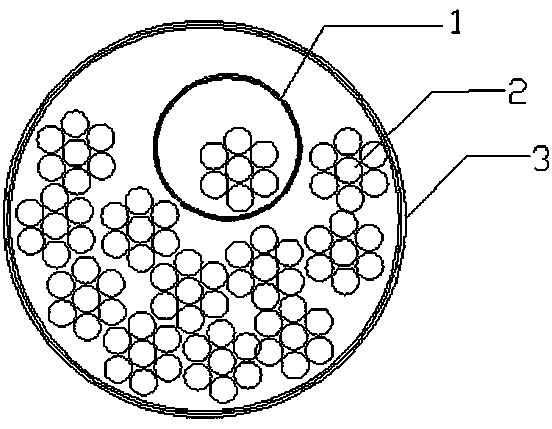

[0018] The present invention as figure 1 / 2 / 3 shown.

[0019] A protection device for forming a hole in a prestressed tunnel, including a bellows 3, the corrugated tube 3 forms a hole in the prestressed tunnel, the steel strand 3 first penetrates into the hole, and the steel strand 2 is inserted through the plastic pipe 1 until it passes through Holes are all formed. The protective measures for the bellows 3 are that the steel strands 2 of the parallel steel beams and the plastic pipe 1 on it occupy a certain space in the holes of the bellows 3. After the concrete pouring is completed, the plastic pipe 1 is pulled out The steel strand 2 and the prestressed tunnel form an effective channel in the hole. This channel will be stretched and displaced with the steel strand 2 when the prestress is stretched, but the formed channel area is the smallest and can ensure the rear The cement slurry passes through smoothly during grouting.

[0020] The diameter of the plastic pipe 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com