A disposable telescopic drilling tool used for fire prevention and grouting in coal mines

A fire-proof and one-off technology, applied in the field of one-time telescopic drilling tools and mining equipment, can solve the problems of affecting grouting efficiency, affecting construction efficiency, small pouring amount, etc., so as to improve grouting efficiency and eliminate cutting blind spots. , The effect of improving the hole forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

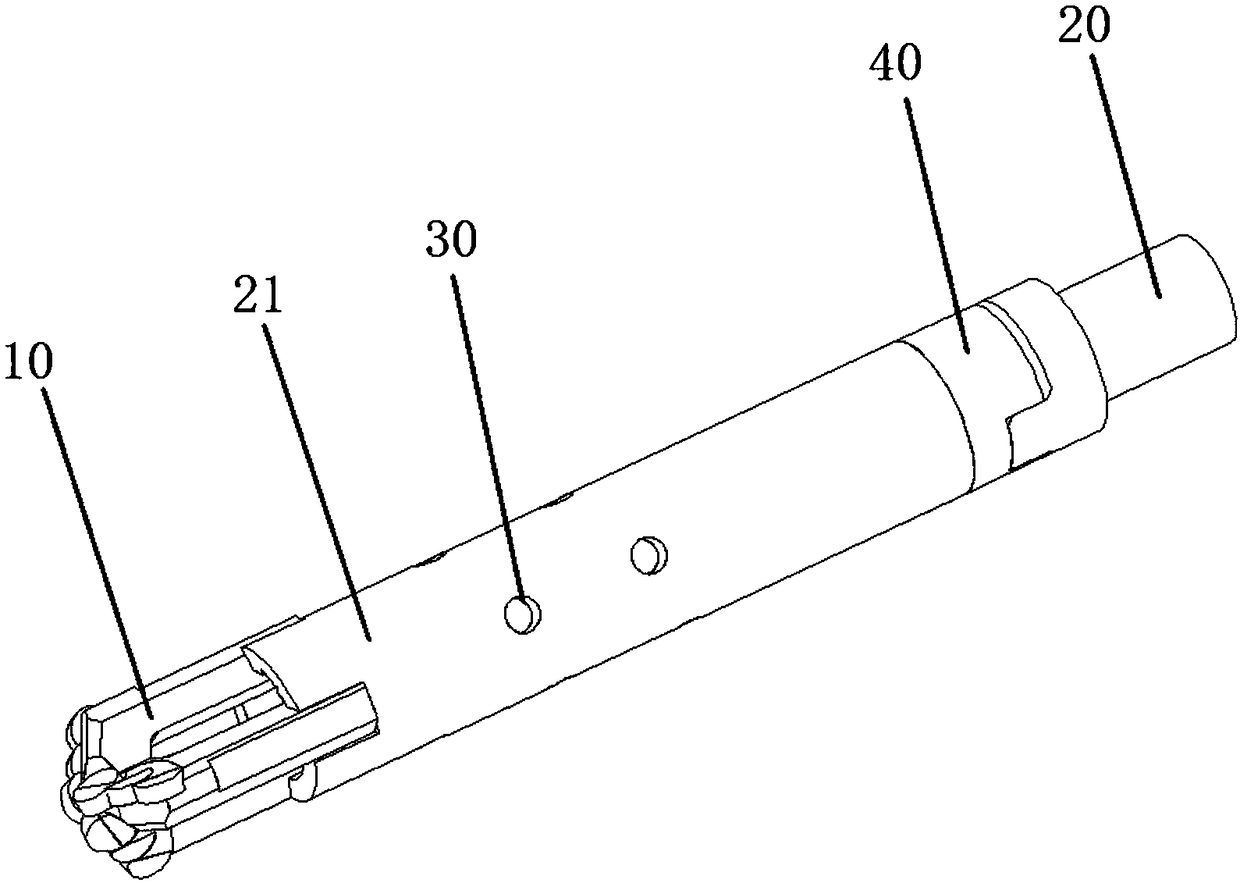

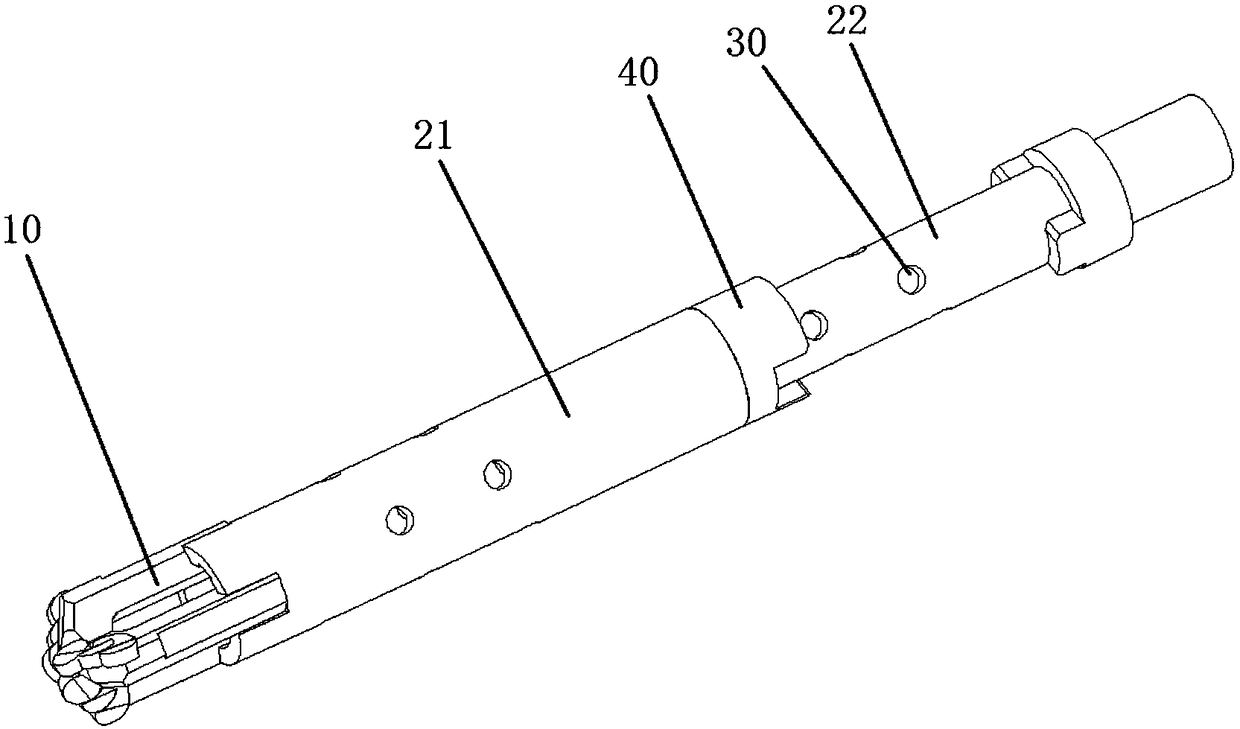

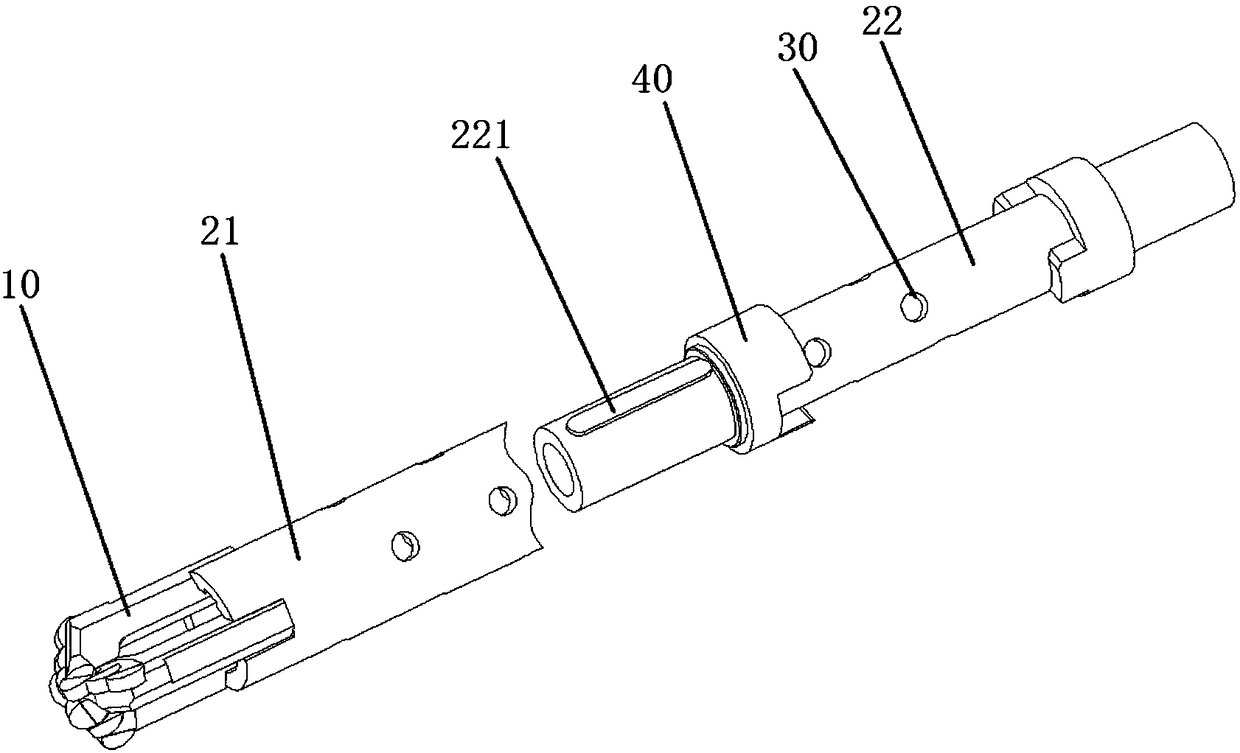

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] As shown in the figure, a disposable telescopic drilling tool for fire prevention and grouting in coal mines includes a leading drill bit 10 and a rod body 20, the leading drill bit 10 is arranged at the end of the rod body 20, and the leading leading drill bit 10 is arranged at the end of the rod body 20. The drill bit 10 includes three wing plates 11, the connection of the wing plates 11 is a hollow design, and each wing plate 11 is arranged with a top cutting piece 12, a middle cutting piece 13 and a bottom cutting piece along one side from top to bottom. Sheet 14; the three top cutting sheets 12 located at the top of the leading drill bit 10 are rotated 15 degrees in the same direction along the sidelines of the three wing plates 11, and the projections on the plane perpendicular to the axis of the rod body 20 are partially overlapped; the rod body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com