Freezing pipe injected grout non-return device

A technology of non-return devices and freezing pipes, which is applied in infrastructure engineering, soil protection, construction, etc., and can solve problems such as high construction costs, loss of shallow water resources, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

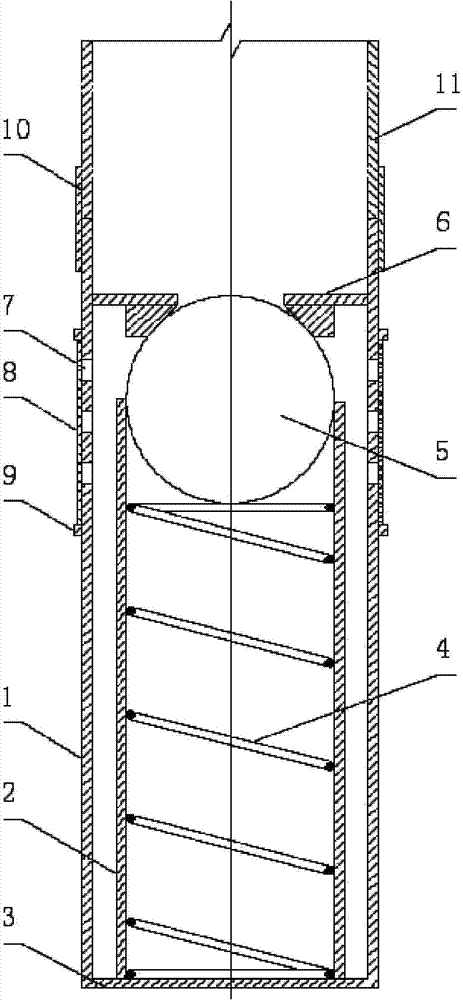

[0010] The present invention will be further described in conjunction with the accompanying drawings and implementation examples.

[0011] As shown in the accompanying drawings, this freezing pipe grouting check device has an outer pipe 1, and the outer pipe 1 adopts a pipe body with the same inner and outer diameters as the freezing pipe 11 used. An inner tube 2 is arranged inside the outer tube 1, and the inner tube 2 is placed at the center of the outer tube 1, and the length of the inner tube 2 is shorter than that of the outer tube 1. The lower ends of the outer tube 1 and the inner tube 2 are provided with a lower end sealing plate 3 that simultaneously forms the lower ends of the outer tube 1 and the inner tube 2 . During specific implementation, the lower end sealing plate 3 can also be set as a downwardly protruding conical plate, so as to facilitate the lowering of the tube. The inner tube 2 is provided with a spring 4 and a sphere 5 placed above the spring, the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com