High-pressure grout stopping device for L-shaped drill hole ground pre-grouting

A pre-grouting, ground technology, used in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve problems such as inability to unplug, in-hole accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

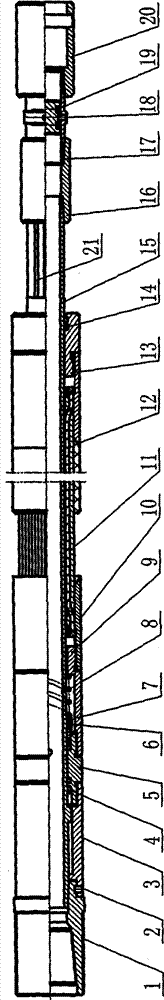

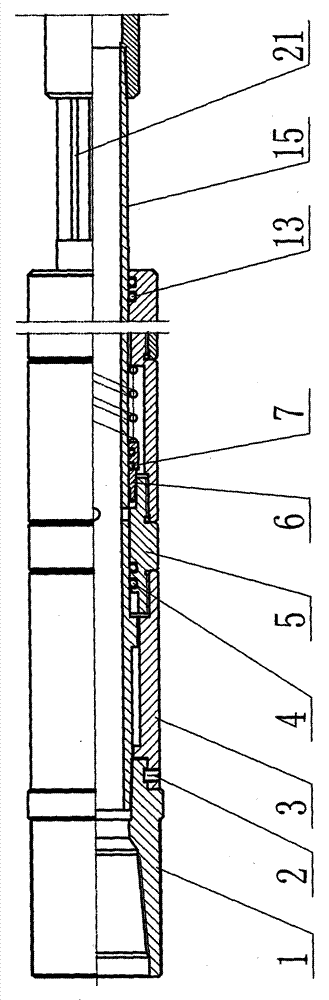

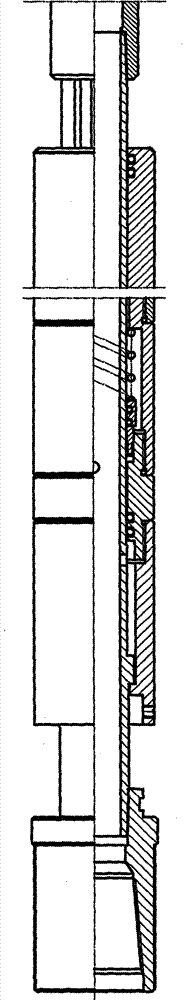

[0015] Such as figure 1 As shown, the L-shaped ground pre-grouting high-pressure grouting equipment for drilling in this embodiment includes a central pipe 15, a rubber cartridge assembly 11 and a blind plugging mechanism for blocking the lower end of the central pipe 15. The rubber cartridge The assembly 11 is set on the central tube 15, and a closed ring cavity is formed between the inner wall of the rubber cartridge assembly 11 and the outer surface of the central tube 15; There is a liquid inlet hole in fluid communication with the hollow tube hole of the central pipe 15, and the fluid communication between the closed ring chamber and the liquid inlet hole is through a one-way fluid conduction mechanism, and the one-way fluid conduction The passage mechanism is opened under the action of the fluid pressure in the hollow pipe hole, so that the fluid in the hollow pipe hole enters the closed ring cavity through the liquid inlet hole and the one-way fluid conduction mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com