Method for conducting grouting construction at back of pile bottom of cast-in-place pile

A construction method and post-grouting technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as grouting failure, grouting one-way valve is not easy to open, grouting nozzle blockage, etc., to increase diffusion area, ensuring the quality and success rate of grouting, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The grouting construction method at the bottom of this cast-in-situ pile includes the following steps in turn:

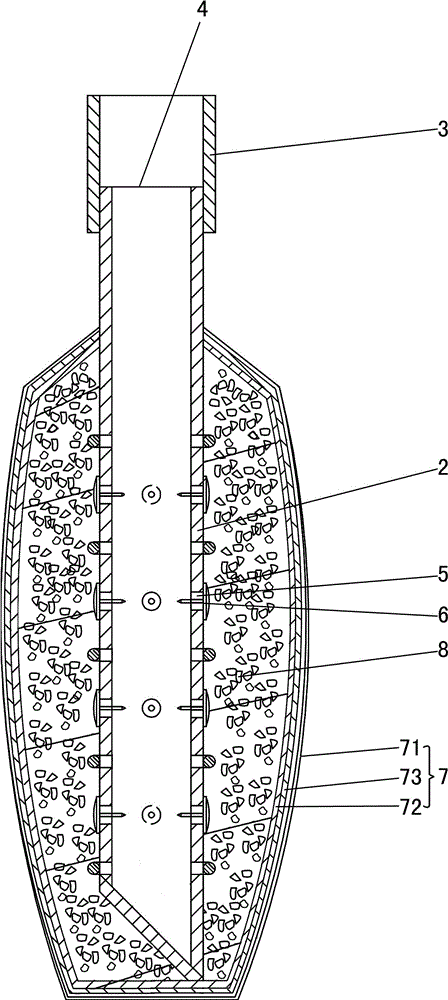

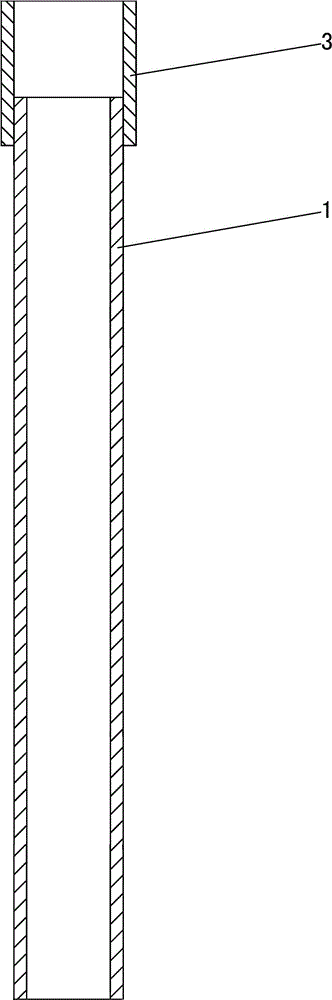

[0027] (1) Fabrication and placement of grouting pipes

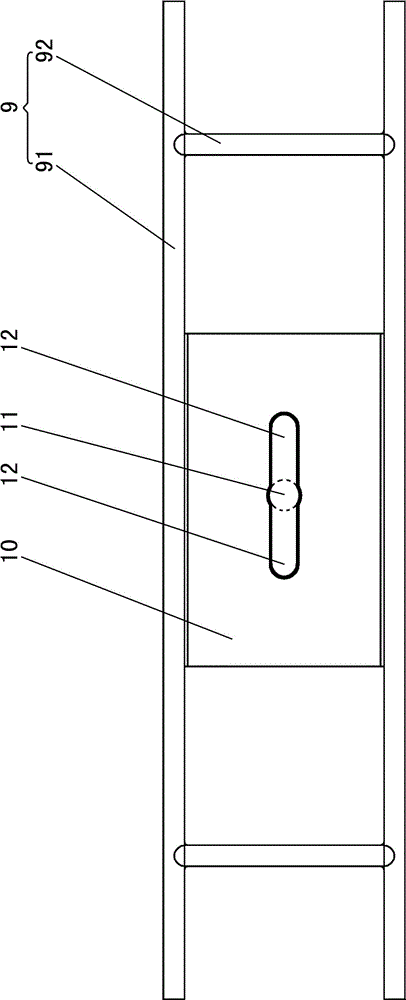

[0028] The grouting pipe includes multiple sections of grouting steel pipe sections connected sequentially from top to bottom, and the lower end of the lowest grouting steel pipe section is connected with a grouting injection head. refer to figure 1 and figure 2 , the grouting steel pipe section used includes a grouting pipe body 1, the grouting injection head used includes a grouting pipe body 2, the upper end of the grouting pipe body 1 is provided with a steel sleeve 3, and the upper end of the grouting pipe body 2 is also provided with a steel sleeve Sleeve 3, the inner edge of the cross section of the steel sleeve 3 matches the shape and size of the outer edge of the cross section of the grouting pipe body 1; A plurality of grouting holes 5 are arranged on the grouting hole 5, and a grouting ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com